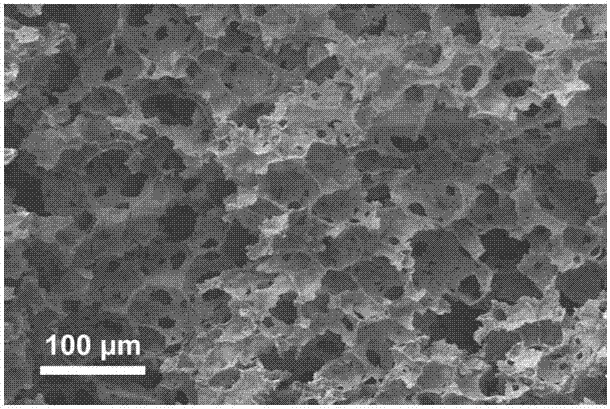

Nano-composite biological scaffold with multi-stage controllable through hole structure, and preparation method and application thereof

A nano-composite, bio-scaffold technology, applied in tissue regeneration, medical science, prostheses, etc., can solve the problems of insufficient space for cell adhesion, insufficient viscosity, and increased cost to achieve good biological activity and mechanical strength , low production cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing a nano composite biological scaffold with a multi-level controllable through-hole structure includes the following steps:

[0037] (1) Add 240 mg of polylactic acid and 240 mg of polycaprolactone to 8 mL of dichloromethane, and sonicate for 10 minutes in an ice water bath to completely dissolve the polylactic acid and polycaprolactone;

[0038] (2) Add 16 mg of hydrophobically modified silica nanoparticles (with a particle size of 20-30 nm) to the solution obtained in step (1), sonicate it in an ice water bath for 5 minutes, disperse uniformly, and prepare an oil phase;

[0039] (3) Add 24 ml of distilled water to the oil phase in 6 batches, and the oil-water mixed system is obtained by vortex mixing and emulsification for 30 min with a vortex mixer at 2800r / min;

[0040] (4) Put the emulsion obtained in step (3) into a 300 CC American syringe, and assemble the matching American piston and a flat tip needle with an inner diameter of 0.9 mm, edit the progra...

Embodiment 2

[0044] A method for preparing a nano-composite biological scaffold with a multi-level controllable through-hole structure includes the following steps:

[0045] (1) Add 320 mg of polylactic acid and 320 mg of polycaprolactone to 8 mL of dichloromethane, and sonicate in an ice water bath for 10 minutes to completely dissolve the polylactic acid and polycaprolactone;

[0046] (2) Add 20 mg of hydrophobically modified silica nanoparticles (with a particle size of 20-30 nm) to the solution obtained in step (1), sonicate it in an ice water bath for 5 minutes, disperse uniformly, and prepare an oil phase;

[0047] (3) Add 24 ml of distilled water to the oil phase in 6 batches, and the oil-water mixed system is obtained by vortex mixing and emulsification for 30 min with a vortex mixer at 2800r / min;

[0048] (4) Put the emulsion obtained in step (3) into a 300 CC American syringe, and assemble the matching American piston and a flat tip needle with an inner diameter of 0.9 mm, edit the progra...

Embodiment 3

[0052] A method for preparing a nano-composite biological scaffold with a multi-level controllable through-hole structure includes the following steps:

[0053] (1) Add 40 mg of polylactic acid and 40 mg of polycaprolactone to 8 mL of dichloromethane, and sonicate for 10 minutes in an ice water bath to completely dissolve the polylactic acid and polycaprolactone;

[0054] (2) Add 3 mg of hydrophobically modified silica nanoparticles (with a particle size of 20-30 nm) to the solution obtained in step (1), sonicate it in an ice water bath for 5 minutes, disperse uniformly, and prepare an oil phase;

[0055] (3) Add 5 batches of 32 ml distilled water to the oil phase, and the oil-water mixed system is obtained by vortex mixing and emulsification with a vortex mixer at 1000r / min for 15 minutes;

[0056] (4) Put the emulsion obtained in step (3) into a 300 CC American syringe, and assemble the matching American piston and a flat tip needle with an inner diameter of 0.9 mm, edit the program ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com