An aqueous emulsion type terminator for PVC resin and vinyl chloride-vinyl acetate copolymer and a preparation method thereof

A technology of PVC resin and chloroacetate resin, applied in the field of terminator and its preparation, can solve problems such as inconvenience in use, and achieve the effects of wide application range, high resin aging whiteness, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

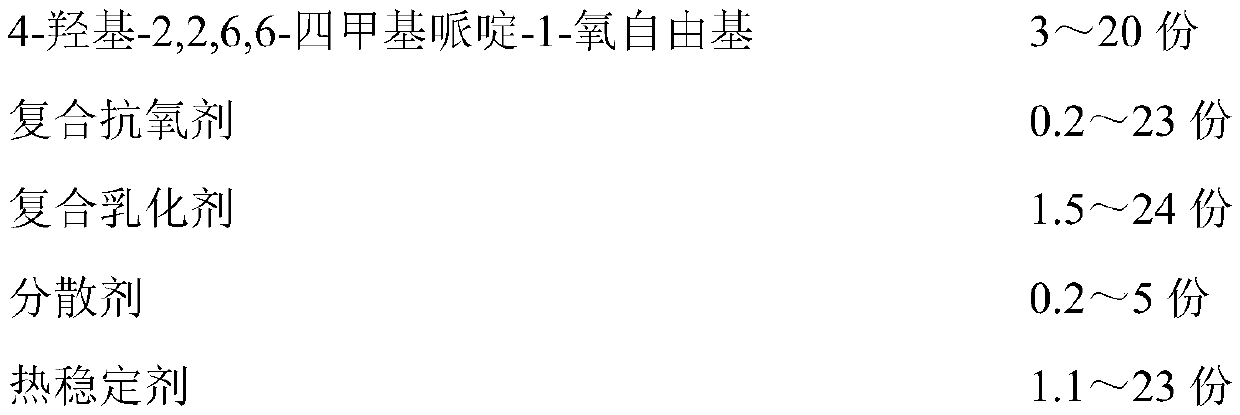

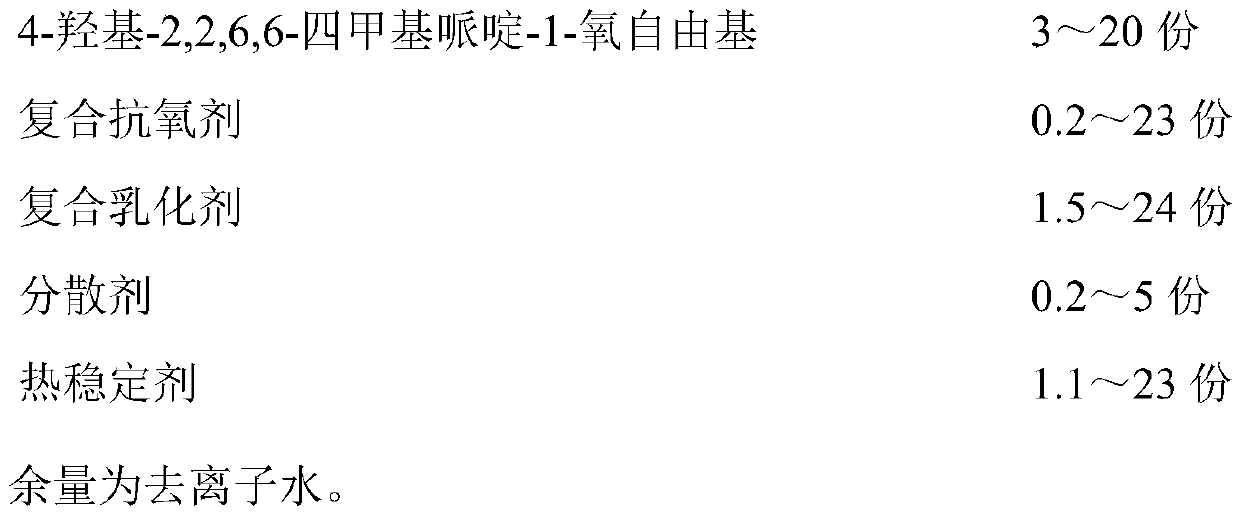

Method used

Image

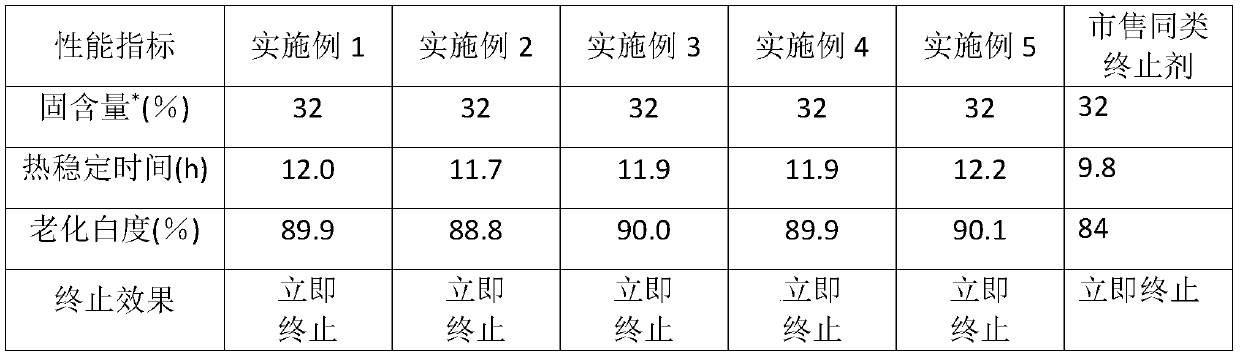

Examples

Embodiment 1

[0022] 12 parts of antioxidant 1010, 4 parts of antioxidant 168, 12 parts of zinc stearate, 8 parts of polyether-modified silicone oil with a hydroxyl value of 20-80 mgKOH / g, diisooctyl phthalate or monophosphite Add 3 parts of benzenediisooctyl ester into the reaction kettle, slowly raise the temperature to 50°C, keep stirring to dissolve all the solid components, and then add 4-hydroxy-2,2,6,6-tetramethylpiperidine-1- 15 parts of oxygen free radicals, continue to stir to form a uniform solution, then add 1.5 parts of methyl tin, 5 parts of sorbitan stearate, 4 parts of fatty alcohol polyoxyethylene ether, and 5 parts of polyoxyethylene sorbitan fatty acid ester Continue to stir for 10 min, add the remaining amount of deionized water, and then stir rapidly for 1 h. Finally, it is emulsified by an emulsification pump to obtain product 1#.

Embodiment 2

[0024] 12 parts of antioxidant 1010, 4 parts of antioxidant 264, 8 parts of zinc stearate, 5 parts of barium stearate, 10 parts of polyether modified silicone oil with a hydroxyl value of 20-80 mgKOH / g, phthalic acid di Add 4 parts of isooctyl or phenylenedi-isooctyl phosphite into the reaction kettle, slowly raise the temperature to 80°C, keep warm and stir to dissolve all the solid components, and then add 4-hydroxy-2,2,6,6-tetra 12 parts of methylpiperidine-1-oxyl radicals, continue to stir to form a uniform solution, then add 2 parts of methyl tin, 3 parts of sorbitan stearate, 5 parts of fatty alcohol polyoxyethylene ether and polyoxyethylene sorbitol 3 parts of alcoholic anhydride fatty acid ester continued to stir for 5 minutes, added the remaining amount of deionized water, and then stirred rapidly for 0.5 hours. Finally, it is emulsified by an emulsification pump to obtain product 2#.

Embodiment 3

[0026] 15 parts of antioxidant 1010, 2 parts of antioxidant 168, 16 parts of calcium stearate, 4 parts of polyether-modified silicone oil with a hydroxyl value of 20-80 mgKOH / g, diisooctyl phthalate or monophosphite Add 5 parts of benzenediisooctyl ester into the reaction kettle, slowly raise the temperature to 80°C, keep stirring to dissolve all the solid components, and then add 4-hydroxy-2,2,6,6-tetramethylpiperidine-1- 18 parts of oxygen free radicals, continue to stir to form a uniform solution, then add 0.5 parts of methyl tin, 1 part of sorbitan stearate, 7 parts of fatty alcohol polyoxyethylene ether, and 1 part of polyoxyethylene sorbitan fatty acid ester Continue to stir for 10 min, add the remaining amount of deionized water, and then stir rapidly for 1 h. Finally, it is emulsified by an emulsification pump to obtain product 3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com