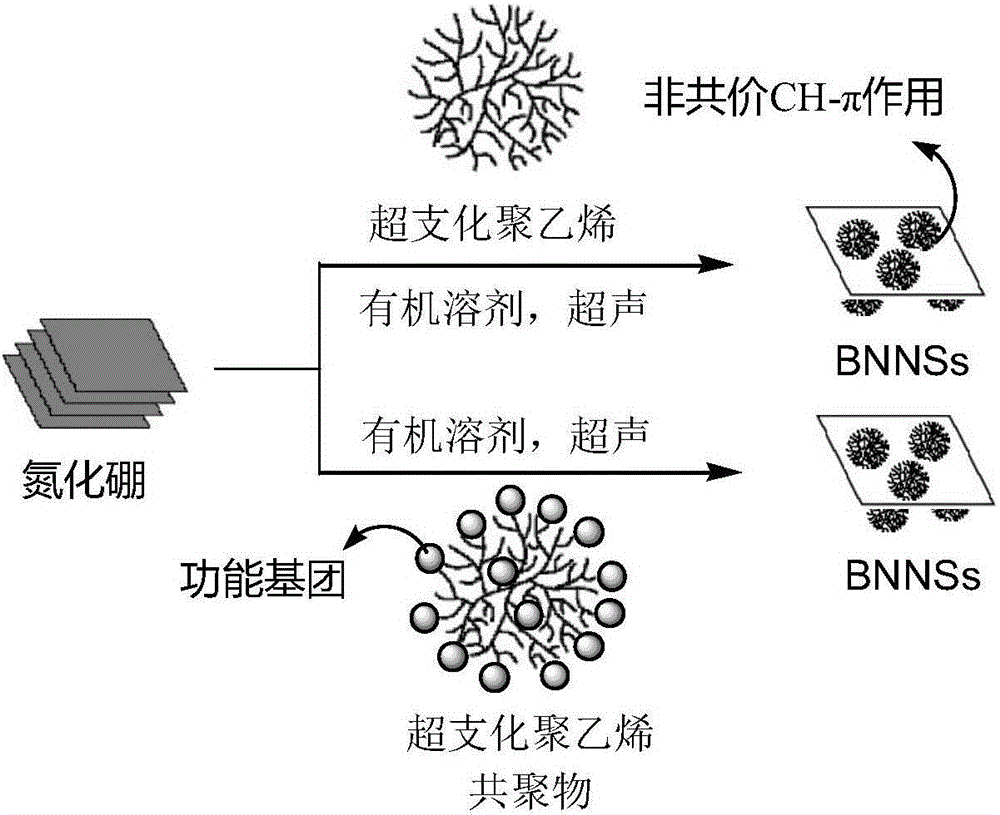

Efficient preparation method of boron nitride nanosheet and organic dispersion liquid thereof

A technology of boron nitride and nanosheets, which is applied in the fields of chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve complex transfer technology, poor product structure control level, functional small molecule compounds or polymer structure and composition requirements. advanced questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

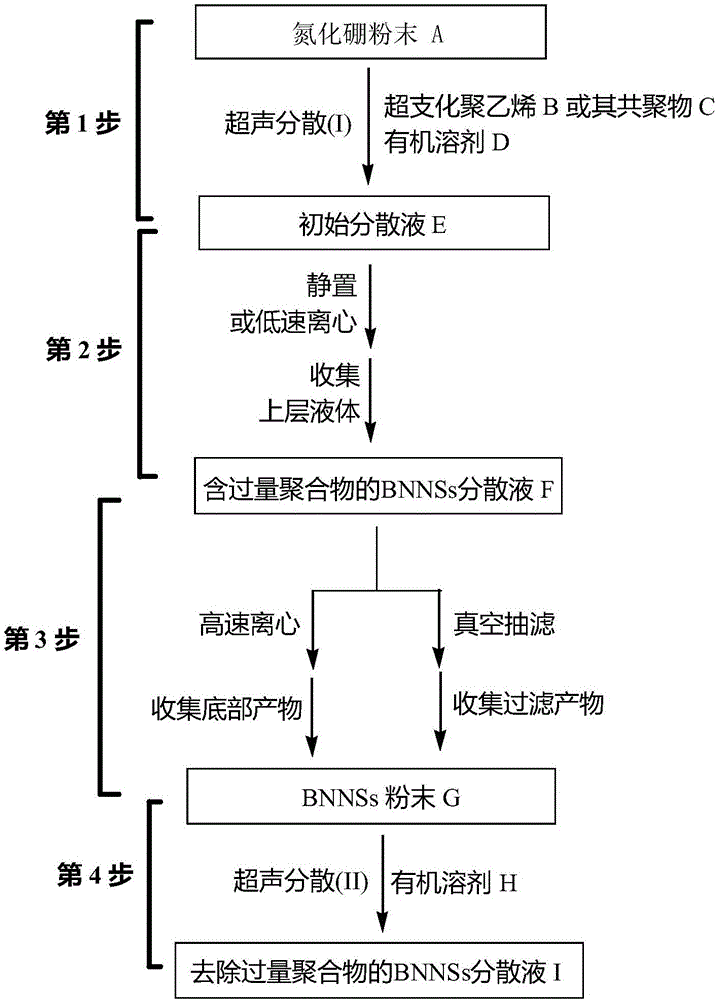

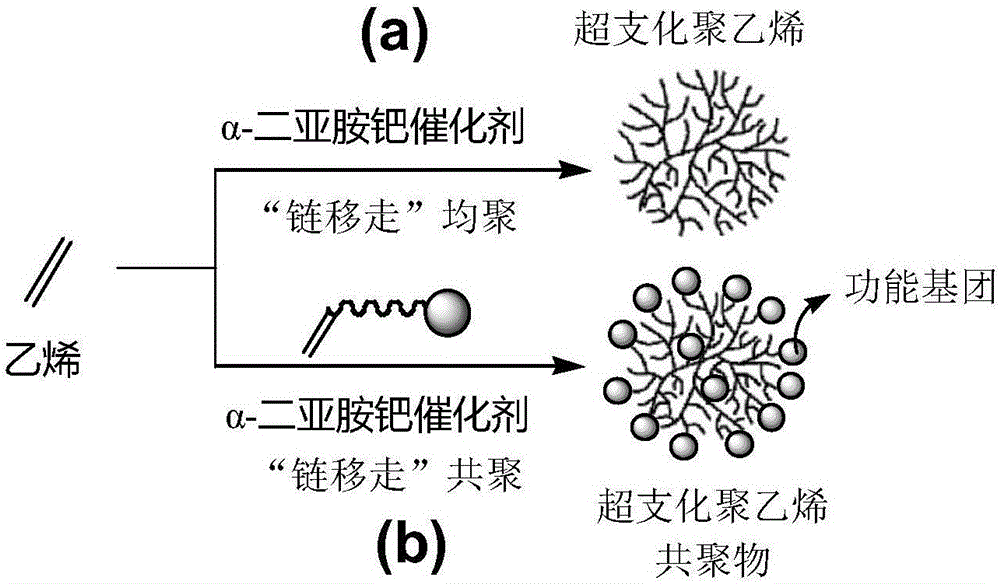

Method used

Image

Examples

Embodiment 1、2

[0080] Embodiment 1, 2, comparative example 1, 2

[0081] 1. Sample preparation

[0082] (1) The preparation of embodiment 1 sample is carried out as follows:

[0083] Step 1: Under the protection of ethylene, add 50.0 mL of anhydrous dichloromethane to a Schlenk double-layer reaction flask with a capacity of 250 mL, keep the temperature of the system at 35 ° C by stirring, and then add 0.10 g of acetonitrile α-diethylene oxide Amine palladium catalyst (1, concentration 2.0 g / L), at a constant temperature of 35° C. and ethylene pressure of 0.1 MPa, the polymerization was continued for 24 h by stirring. After the reaction, the obtained product was poured into 50 mL of methanol containing 1 wt% hydrochloric acid, and stirred to terminate the polymerization. After further drying the solvent, the obtained product was dissolved with an appropriate amount of THF, and a small amount of hydrogen peroxide and hydrochloric acid were added, stirred at room temperature for 1 h to dissol...

Embodiment 3, comparative example 3、4、5

[0098] 1. Sample preparation

[0099] (1) The preparation of embodiment 3 sample is carried out as follows:

[0100] Step 1: Under the protection of ethylene, add 50.0 mL of anhydrous dichloromethane to a Schlenk double-layer reaction flask with a capacity of 250 mL, keep the system temperature at 15 ° C by stirring, and then add 0.10 g of acetonitrile α-diethylene oxide Amine palladium catalyst (1, concentration 2.0g / L) and 2.50g methyl acrylate (MA, 0.58mol / L) were injected into the reaction flask, and the polymerization was continued for 24h by stirring at a constant temperature of 15°C and ethylene pressure of 0.1MPa . After the reaction, the resulting product was poured into 50 mL of acidified methanol with a concentration of 1 wt%, and stirred to terminate the polymerization. After further drying the solvent, the obtained product was dissolved with an appropriate amount of THF, and a small amount of hydrogen peroxide and hydrochloric acid were added, stirred at room te...

Embodiment 4

[0125] Embodiment 4, comparative example 6

[0126] 1. Sample preparation

[0127] (1) The preparation of embodiment 4 sample is carried out as follows:

[0128] Step 1: Under the protection of ethylene, add 50.0 mL of anhydrous dichloromethane to a Schlenk double-layer reaction flask with a capacity of 250 mL, keep the system temperature at 15 ° C by stirring, and then add 0.10 g of acetonitrile α-diethylene oxide Amine palladium catalyst (1, concentration 2.0g / L) and 4.50g butyl acrylate (BA, 0.70mol / L) were injected into the reaction flask, and the polymerization was continued for 24h by stirring at a constant temperature of 15°C and ethylene pressure of 0.1MPa . After the reaction, the resulting product was poured into 50 mL of acidified methanol with a concentration of 1 wt%, and stirred to terminate the polymerization. After further drying the solvent, the obtained product was dissolved with an appropriate amount of THF, and a small amount of hydrogen peroxide and hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com