Wide-color-gamut glass for LED display and preparation method thereof

A wide color gamut, glass technology, applied in glass manufacturing equipment, glass molding, chemical instruments and methods, etc., to achieve the effects of high output and yield, increased output, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

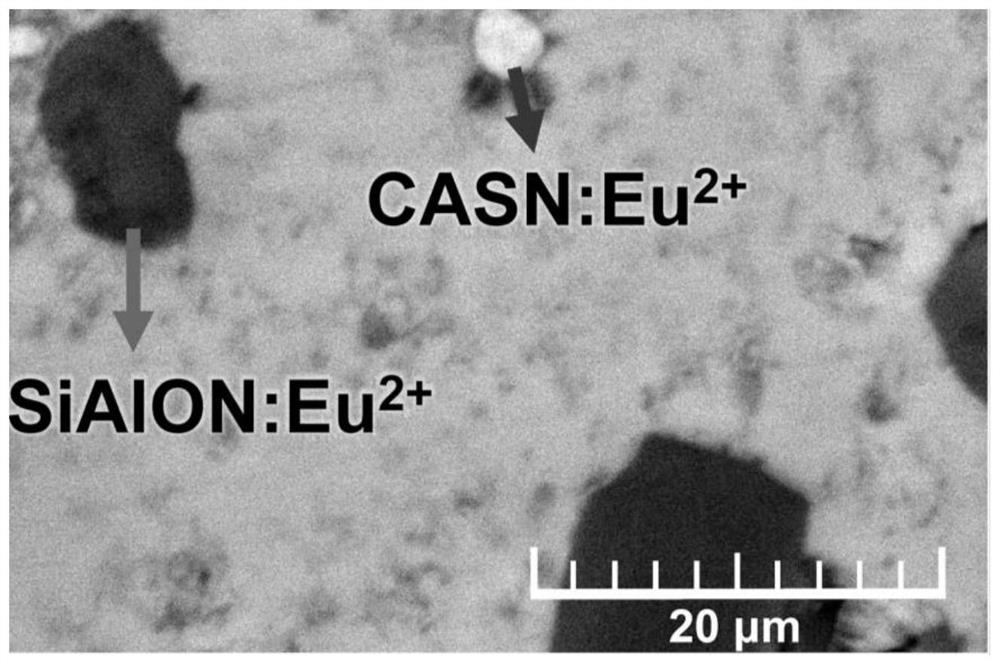

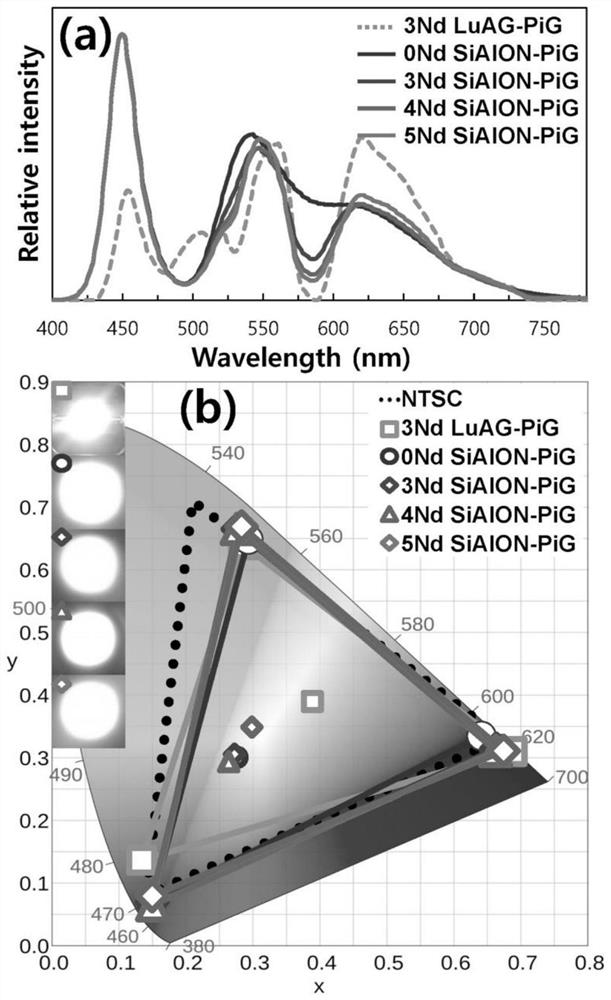

[0017] Example 1: 65SiO 2 -25Na 2 O-5BaO-5ZnO-3mol%Nd 2 o 3 , doped with 0.3.wt%β-SiAlON:Eu 2+ phosphor, and 1 wt.%CaAlSiN 3 :Eu 2+ Phosphor powder;

[0018] Weigh SiO with a purity greater than 99.9% according to the stoichiometric ratio 2 、Na 2 O, BaO, ZnO, Nd 2 o 3 Place in an alumina crucible, melt at 1450°C for 30 minutes, then water quench and dry to obtain glass without phosphor powder. After pulverizing the glass and commercially available β-SiAlON:Eu with a purity greater than 99.99% 2+ Phosphor and CaAlSiN 3 :Eu 2+ Phosphor powder is evenly mixed according to the mass ratio. The mixture was pressed, then sintered in air at 600° C. for 1 h, and then cooled naturally to obtain the glass.

Embodiment 2

[0019] Example 2: 65SiO 2 -25Na 2 O-5BaO-5ZnO-4mol%Nd 2 o 3 , doped with 0.3.wt%β-SiAlON:Eu 2+ phosphor, and 2 wt.%CaAlSiN 3 :Eu 2+ Phosphor powder;

[0020] Weigh SiO with a purity greater than 99.9% according to the stoichiometric ratio 2 、Na 2 O, BaO, ZnO, Nd 2 o 3 Put it in an alumina crucible, melt it at 1300°C for 60 minutes, then water quench and dry to obtain glass without phosphor doped. After pulverizing the glass and commercially available β-SiAlON:Eu with a purity greater than 99.99% 2+ Phosphor and CaAlSiN 3 :Eu 2+ Phosphor powder is evenly mixed according to the mass ratio. The mixture was pressed, then sintered in air at 500° C. for 2 h, and then cooled naturally to obtain the glass.

Embodiment 3

[0021] Example 3: 65SiO 2 -25Na 2 O-5BaO-5ZnO-5mol%Nd 2 o 3 , doped with 0.3.wt%β-SiAlON:Eu 2+ phosphor, and 3wt.%CaAlSiN 3 :Eu 2+ Phosphor powder;

[0022] Weigh SiO with a purity greater than 99.9% according to the stoichiometric ratio 2 、Na 2 O, BaO, ZnO, Nd 2 o 3 Place it in an alumina crucible, melt it at 1400°C for 40 minutes, then water quench and dry to obtain glass without phosphor powder. After pulverizing the glass and commercially available β-SiAlON:Eu with a purity greater than 99.99% 2+ Phosphor and CaAlSiN 3 :Eu 2+Phosphor powder is evenly mixed according to the mass ratio. The mixture was pressed, then sintered in air at 550° C. for 1.5 h, and then cooled naturally to obtain the glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com