Freeze drying preparation method for nano-rare earth oxide powder

An oxide powder, nano-rare earth technology, applied in rare earth metal compounds, chemical instruments and methods, nanotechnology and other directions, can solve the problems of cumbersome and complicated reaction process, high cost, power consumption and other problems, and achieve simple and convenient process, loose powder, Good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Dissolve 0.1 g of polyethylene glycol PEG in 100 mL of deionized water, then dissolve 2 g of yttrium nitrate in it, and finally add the solution to 200 ml with deionized water (the concentration of yttrium nitrate is 0.01 g / mL), Ultrasonic treatment (ultrasonic treatment power 100W, ultrasonic time 1h) to fully dissolve and disperse.

[0028] (2) Spray the solution into liquid nitrogen to prefreeze.

[0029] (3) After the temperature of the lyophilizer reaches the freezing temperature of -60°C and stabilizes, put the pre-frozen solution into the lyophilizer, turn on the vacuum pump and keep the vacuum below 20 Pa, and freeze-dry for 36 hours.

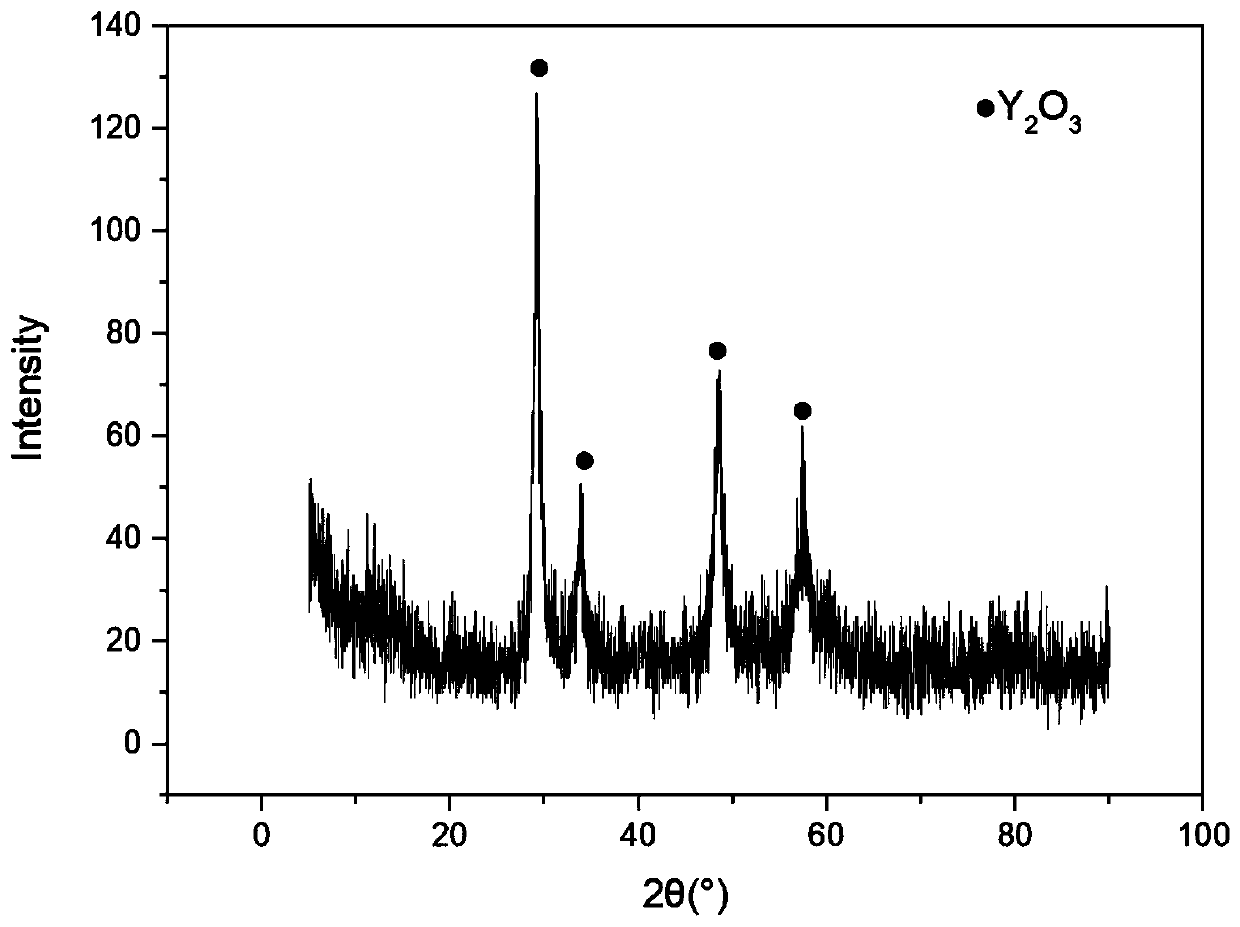

[0030] (4) Grinding the freeze-dried powder and calcining it in air at 500° C. for 1 h to remove the dispersant, and finally obtain ultrafine nanometer yttrium oxide powder. XRD such as figure 1 As shown, the phase is pure yttrium oxide. At the same time, the average grain size of the ultrafine nanometer yttrium oxide powd...

Embodiment 2

[0033] (1) Dissolve 2 g of polyethylene glycol PEG in 100 mL of deionized water, then dissolve 20 g of yttrium nitrate in it, and finally add the solution to 200 ml with deionized water (the concentration of yttrium nitrate is 0.1 g / mL). Ultrasonic treatment (ultrasonic treatment power 300W, ultrasonic time 0.3h) to fully dissolve and disperse.

[0034] (2) Spray the solution into liquid nitrogen to prefreeze.

[0035] (3) After the temperature of the lyophilizer reaches the freezing temperature of -50°C and stabilizes, put the pre-frozen solution into the lyophilizer, turn on the vacuum pump and keep the vacuum below 20 Pa, and freeze-dry for 24 hours.

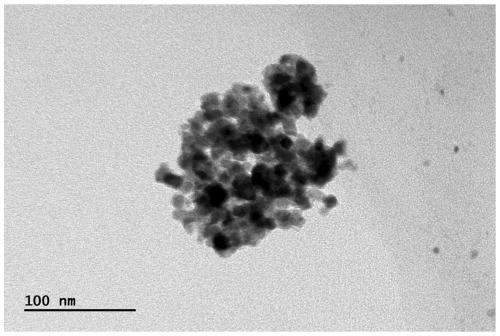

[0036] (4) Grinding the freeze-dried powder and calcining it in air at 500° C. for 1 h to remove the dispersant, and finally obtain ultrafine nanometer yttrium oxide powder. The average grain size of ultra-fine nanometer yttrium oxide powder is 35.4nm, and the surface morphology is as follows: Figure 4 shown. The powder o...

Embodiment 3

[0038] (1) First dissolve 0.02g fatty alcohol polyoxyethylene ether AE in 100mL deionized water, then dissolve 10g scandium nitrate in it, and finally add the solution to 200ml with deionized water (the concentration of scandium nitrate is 0.05g / mL ), using ultrasonic treatment (ultrasonic treatment power 200W, ultrasonic time 0.5h) to make it fully dissolved and dispersed.

[0039] (2) Spray the solution into liquid nitrogen to prefreeze.

[0040] (3) After the temperature of the lyophilizer reaches the freezing temperature of -50°C and stabilizes, put the pre-frozen solution into the lyophilizer, turn on the vacuum pump and keep the vacuum below 20 Pa, and freeze-dry for 24 hours.

[0041] (4) Grinding the freeze-dried powder and calcining it in air at 800° C. for 0.5 h to remove the dispersant, and finally obtain ultrafine nano scandium oxide powder. The average grain size of ultra-fine nano scandium oxide powder is 75.4nm. The powder obtained by the freeze-drying method ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com