Yttrium-stabilized zirconia ceramic nano-powder as well as preparation method and application thereof

A technology of yttrium-stabilized zirconia and nano-powder, which is applied in the fields of zirconia, chemical instruments and methods, preparation/processing of rare earth metal compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0082] Preparation of Precipitant Solution. Wherein, the precipitating agent can be at least one of ammonia water, ammonium carbonate and urea. Add a certain amount of dispersant to the precipitant mother liquor before titration to obtain a precipitant solution containing dispersant. Among them, polyethylene glycol, polyethyleneimine, ammonium polyacrylate and ammonium citrate can be selected as the dispersant. The content of the dispersant may be 0.1wt%-5wt%. The concentration of the precipitant in the precipitant solution containing the dispersant is controlled between 0.01 and 4.0 mol / L.

[0083] Adding the mixed solution of metal ions into the precipitating agent solution containing the dispersant, and fully stirring to obtain the precipitating liquid, wherein the terminal pH of the precipitating liquid is 7-12. Wherein, the metal ion mixed solution is added in dropwise addition or spray addition. Wherein the speed of adding dropwise can be 1~40ml / min. Normal situatio...

Embodiment 1

[0101] press Y 0.16 Zr 0.84 o 1.92 Chemical composition, respectively measure 120ml of ZrOCl with a concentration of 1.5mol / L 2 solution and 14.20ml concentration is 2.414mol / L Y(NO 3 ) 3 Pour the solution into a beaker, first add a small amount of deionized water to mix evenly, and finally add deionized water to set the volume to 600ml. At this time, the Zr in the mixed solution 4+ The concentration is 0.3mol / L. Then prepare 500ml concentration of 0.7mol / L ammonia precipitant solution, and add 0.4270g of PEG4000 as a dispersant. Add the mixed solution of metal ions dropwise (dropwise added) into the ammonia precipitant at a rate of 20ml / min and stir thoroughly, stop the titration when the pH of the precipitant solution = 8.75, continue to stir for 10min, and age at 25°C 1h. The aged slurry was washed 4 times with deionized water and 2 times with absolute ethanol. The washed precipitate was dried in an oven at 70°C for 20 hours, and the dried powder was passed through a...

Embodiment 2

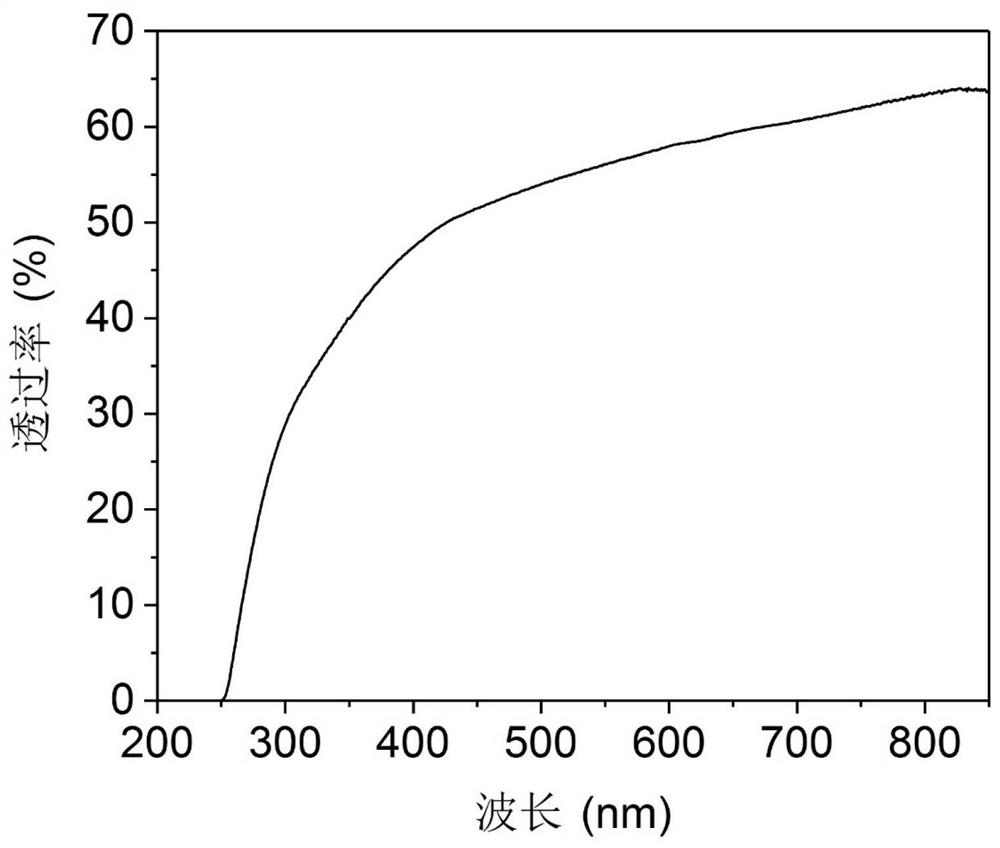

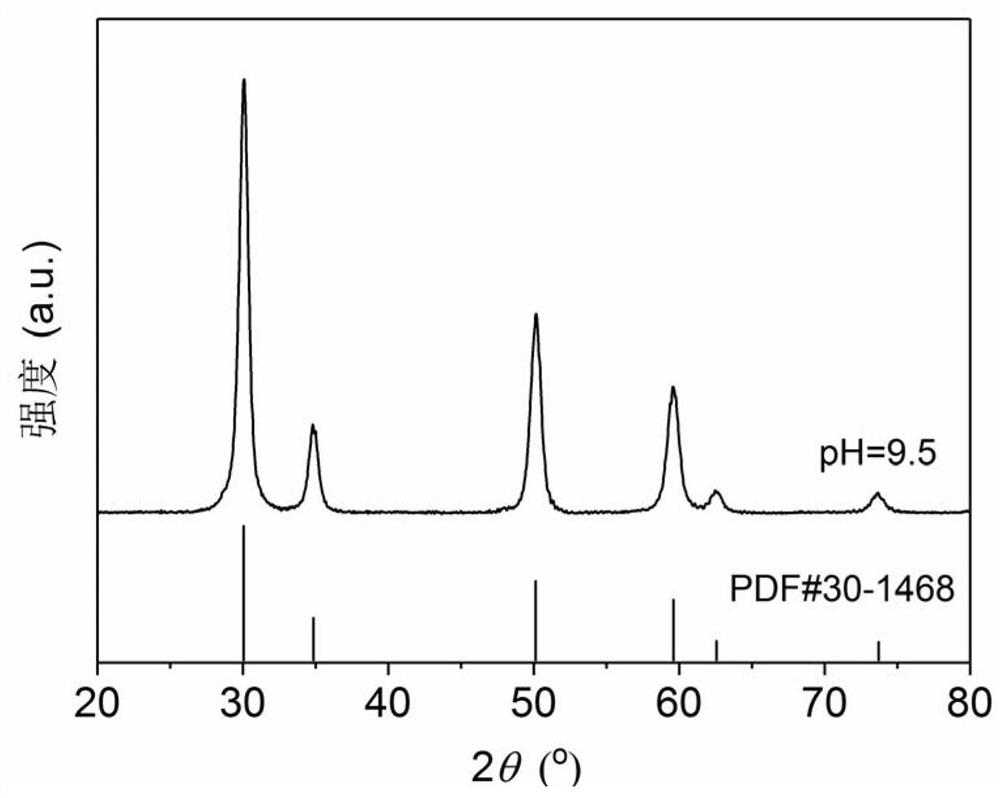

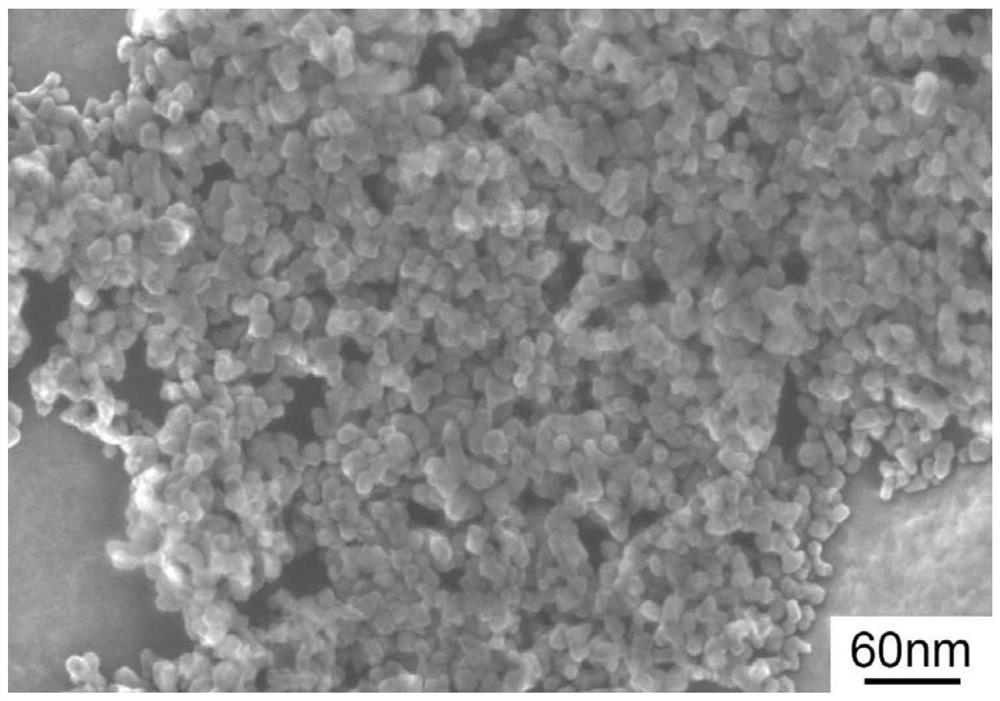

[0104] press Y 0.16 Zr 0.84 o 1.92 Chemical composition, respectively measure 120ml of ZrOCl with a concentration of 1.5mol / L 2 solution and 14.20ml concentration is 2.414mol / L Y(NO 3 ) 3 Pour the solution into a beaker, first add a small amount of deionized water to mix evenly, and finally add deionized water to set the volume to 600ml. At this time, the Zr in the mixed solution 4+ The concentration is 0.3mol / L. Then prepare 500ml concentration of 0.7mol / L ammonia precipitant solution, and add 0.3251g of PEG4000 as a dispersant. Add the mixed solution of metal ions dropwise into the ammonia precipitation agent at a rate of 20ml / min and stir thoroughly. Stop the titration when the pH of the solution of the precipitation agent is 9.5, continue to stir for 10min, and age at 25°C for 1h. The aged slurry was washed 4 times with deionized water and 2 times with absolute ethanol. The washed precipitate was dried in an oven at 70°C for 20 hours, and the dried powder was passed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com