Amorphous soft magnetic alloy coatings and preparation method thereof

A technology of soft magnetic alloy and amorphous alloy, which is applied in metal material coating process, coating, magnetic material, etc., can solve the difficulty of preparing amorphous shielding layer, without considering the high magnetic permeability and high saturation of amorphous alloy materials Comprehensive performance of magnetic induction, inconvenient use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In a preferred embodiment of the preparation method of the present invention, the alloy material smelted in the first step can be pulverized by atomization in a molten state to prepare alloy powder;

[0035] In another preferred embodiment of the preparation method of the present invention, the alloy material smelted in the first step can also be sprayed with alloy strips or scales in a molten state, and then the strips or scales are crushed to prepare alloy powder;

[0036] In a preferred embodiment of the preparation method of the present invention, the coating of the present invention is obtained by plasma spraying;

[0037] In another preferred embodiment of the preparation method of the present invention, the coating of the present invention is obtained by high velocity flame spraying.

[0038] Compared with prior art, the present invention has following advantage:

[0039] 1. Fe-Co based amorphous soft magnetic alloy material is used to prepare the coating, which...

Embodiment

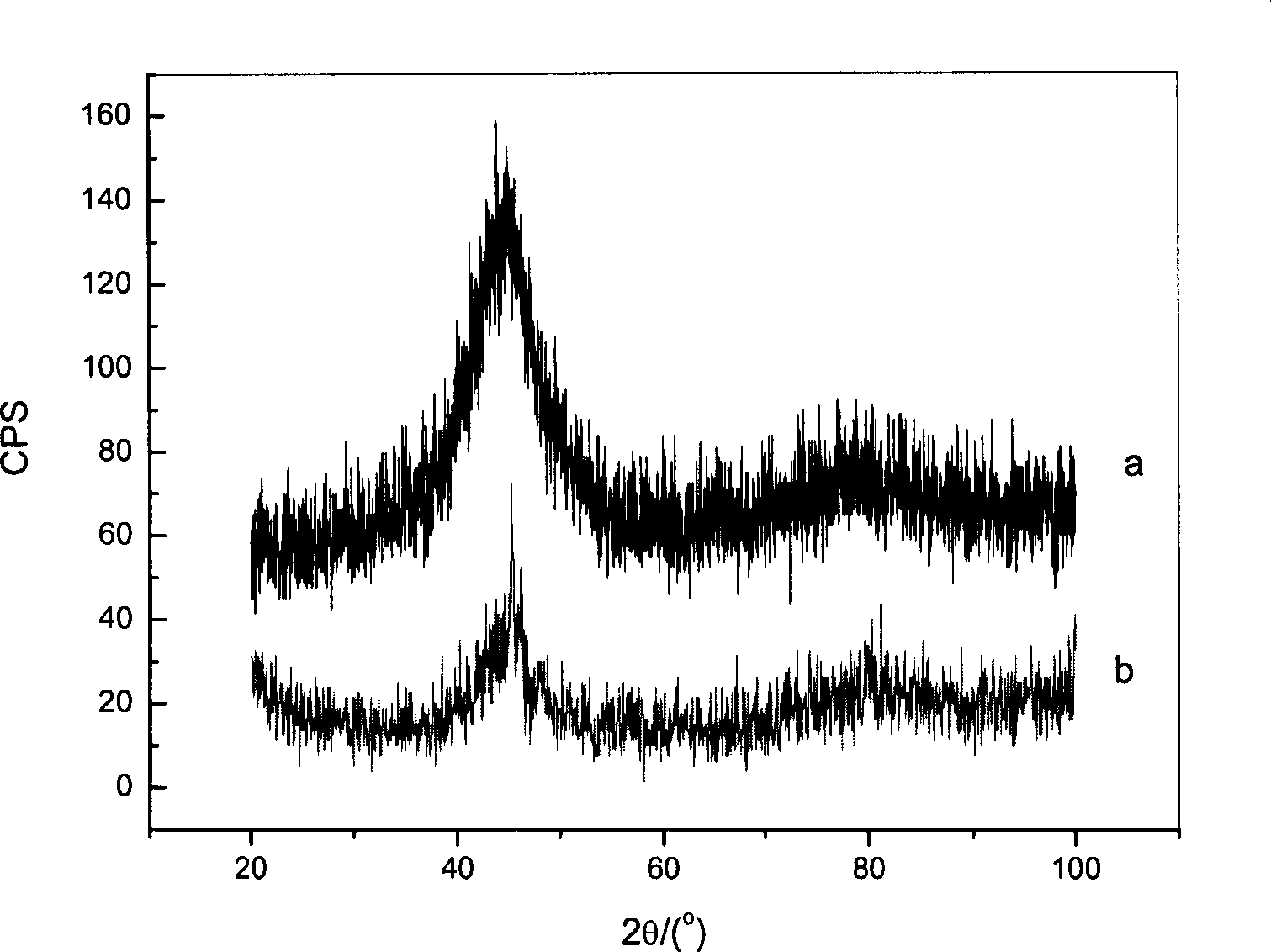

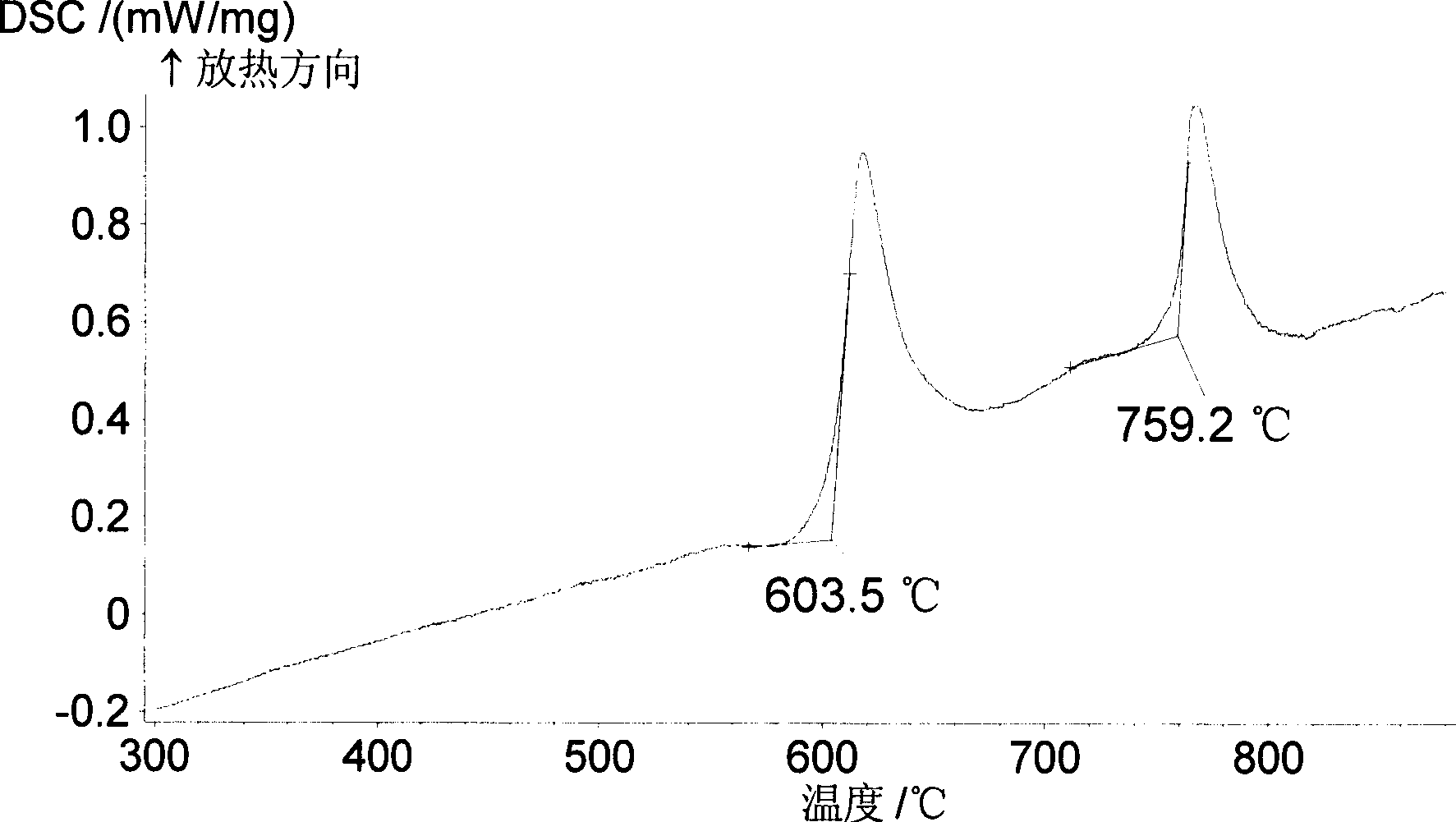

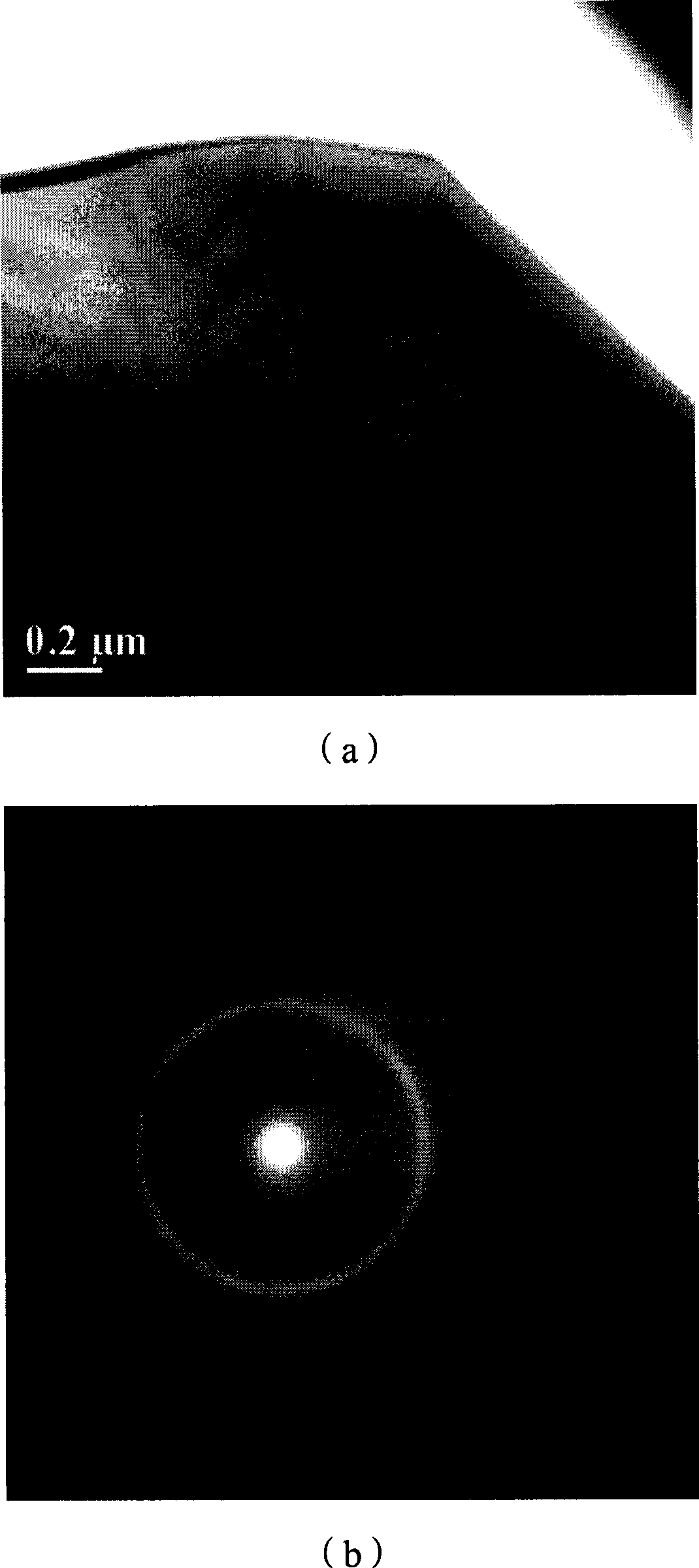

[0043] According to No. 1 ingredient Fe 36 co 36 Si 4 B 20 Nb 4 and No. 2 component [(Fe 0.6 co 0.4 ) 0.75 Si 0.05 B 0.2 〕 96 Nb 4 After batching, the alloy is smelted, and powders are prepared by gas atomization and water atomization processes respectively, and 300-60 mesh powders are obtained after sieving. The coating is prepared by plasma spraying, the substrate is copper, and sandblasting is carried out before spraying. The plasma spraying process parameters are: arc voltage 60V, arc current 500A, main gas (Ar gas) flow: 70-80L / min, hydrogen flow: 15 ~20L / min, spray distance 100~120mm, powder feeding speed 50~70g / min. Table 1 is the implementation process and performance.

[0044] Table 1 Example process and performance

[0045] Preface

No

prepare

Powder size

(mesh)

Spray side

Law

high frequency shielding

efficiency

(dB) DC magnetic screen

Masking efficiency

(dB) Micro Vickers Hardness

De...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shielding effectiveness | aaaaa | aaaaa |

| Self-corrosion potential | aaaaa | aaaaa |

| Self-corrosion current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com