Patents

Literature

43results about How to "Wear-resistant and corrosion-resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recycling zirconium oxide and yttrium oxide from yttrium oxide steady zirconium oxide solid fused mass waste matter

ActiveCN101244843ASignificant progressTo achieve the effect of resource utilizationRare earth metal compoundsZirconium oxidesZirconium hydrideYttria-stabilized zirconia

The invention relates to a method for recovering zirconia and yttria from the yttria-stabilized zirconia solid solution waste, which comprises the following steps: mixing the solid solution waste powder, sulfate and salt; acidizing and calcining at 200 to 320 DEG C; leaching the acidizing water and / or mother liquor under self-heating conditions; concentrating the leaching solution to leach zirconium sulfate; dissolving the zirconium sulfate in the water and purifying; neutralizing the zirconium hydroxide with alkali and precipitating; calcining the zirconium hydroxide to obtain zirconia; precipitating zirconium mother liquor to produce by-product of ammonium sulfate; neutralizing yttrium rich mother liquor and precipitating to obtain yttrium; dissolving yttrium rich residue with acid and purifying; precipitating oxalate to obtain yttrium oxalate; calcining to obtain the yttria. The method has the advantages of effectively separating the yttria from the zirconia in stable zirconia solid solution waste with optional yttrium ion under low temperature condition, changing the zirconia solid solution waste into valuables and utilizing the resources.

Owner:SHANDONG LEIBAO ZIRCONIUM SCI&TECH

Nanometer graphene reflection thermal insulation composite multifunctional ceramic coating layer and preparation method thereof

ActiveCN105951151AOutstanding heat insulationOutstanding FeaturesAnodisationCombustion chamberPlasma electrolytic oxidation

The invention discloses a reinforced alloy material; and a surface layer of the alloy material contains such elements as aluminum oxide, silicon dioxide and nanometer graphene. The alloy material is deeply extended on the basis of anodic oxidation, microarc oxidation and multi-component composite oxidation, and is a result under a complex effect of instant high temperature, multi-component composite oxidation liquid and nanometer penetrant through applying positive and negative high voltage, high current and positive and negative pulses by using unique structures, physical and chemical characteristics as ultrahigh hardness and high-temperature resistance, small size effects and surface and interface effects of such nanometer materials as nanometer graphene and nanometer silicon dioxide. The method comprises the steps of: (1) surface cleaning; (2) oxidation; and (3) penetration. The light alloy material after surface reinforcement by the method, in particular a combustion chamber of an internal combustion engine with fuel combustion consumption and generating a pollution source is prominent in reflection thermal insulation anti-carbon self catalysis function, and is higher in high-temperature erosion resistance and wear resistance.

Owner:四川鸿森达铝业科技有限公司

Hot spraying process of metal ceramic coating on surface of valve rod

The invention discloses a hot spraying process of a metal ceramic coating on surface of a valve rod, and relates to the field of manufacture of a valve. The hot spraying process comprises the technical procedures of mechanical pre-processing, surface purifying, surface coarsening, pre-heating treatment, hot spraying, accurately grinding and polishing and the like; a vacuum electric furnace is adopted in the heat treatment; the valve rod is pre-heated to 80-150 DEG C; hypersonic flame hot-spraying is adopted; and a valve rod base body is cooled by a forcible air cooling device when being subjected to hot spraying, and a smooth and compact high-performance metal ceramic coating with wear resistance, corrosion resistance, high binding strength and low porosity is formed on the surface of the valve rod after being polished. The process is high in coating efficiency, free from pollution, high in binding strength of the coating and low in porosity; wear-resisting and corrosion-resisting performances and high-temperature and heat vibration resistance of the surface of the valve rod are greatly improved without changing the precision of the overall size of the valve rod; the usability of the valve rod is greatly improved; the service life of the valve rod can be improved by 2-5 times; and the hot spraying process can be applied to a steam valve of a steam turbine unit, a special valve for a power station and other valves.

Owner:黄红霞

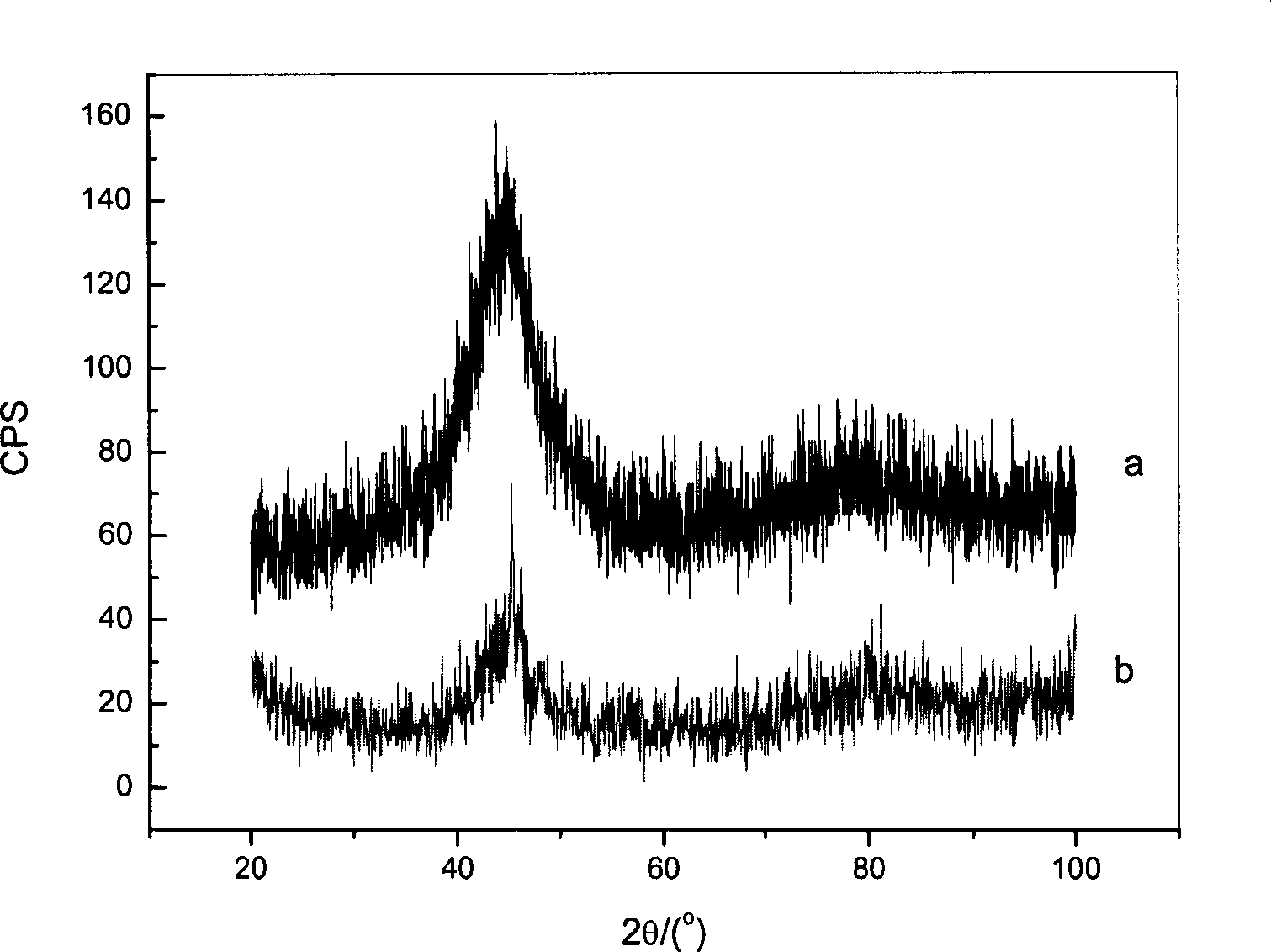

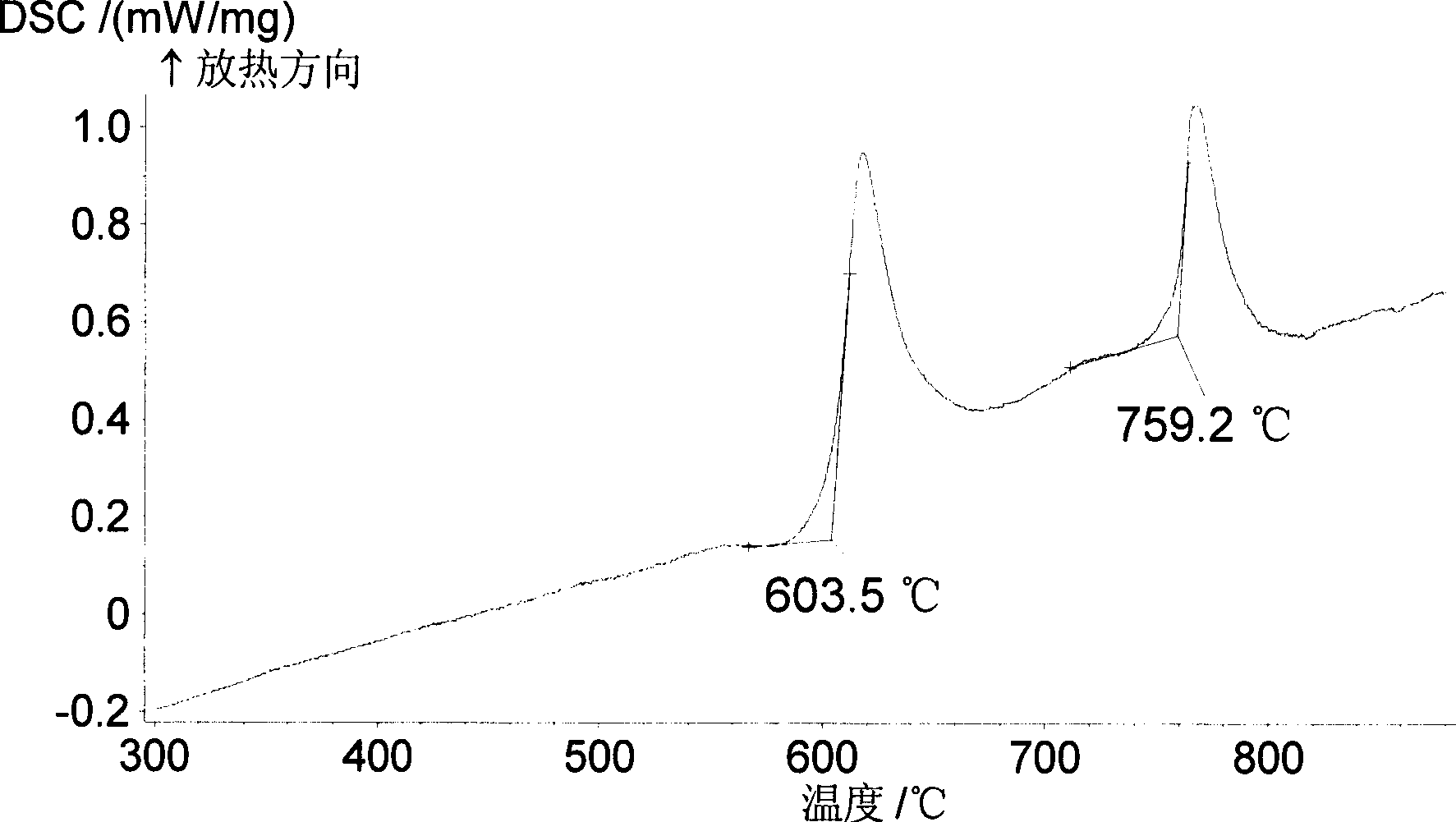

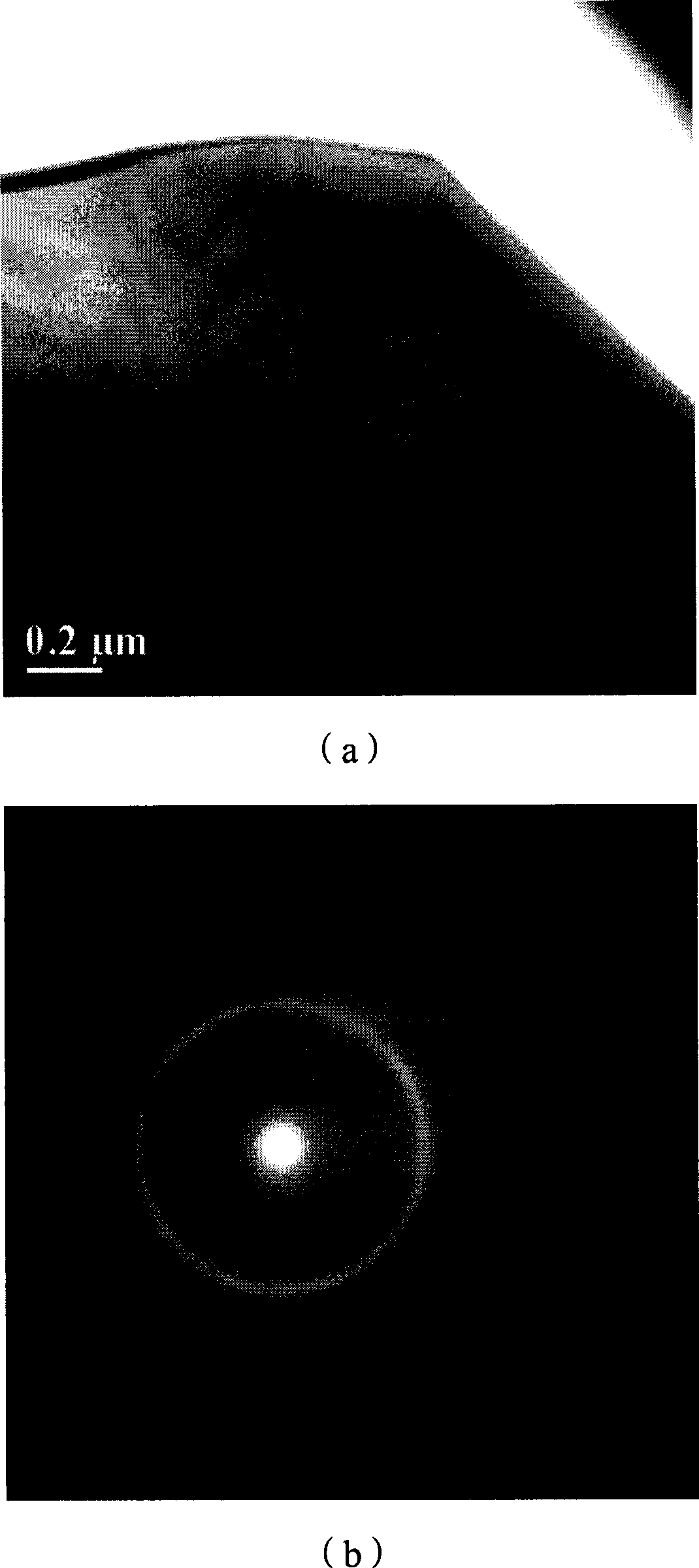

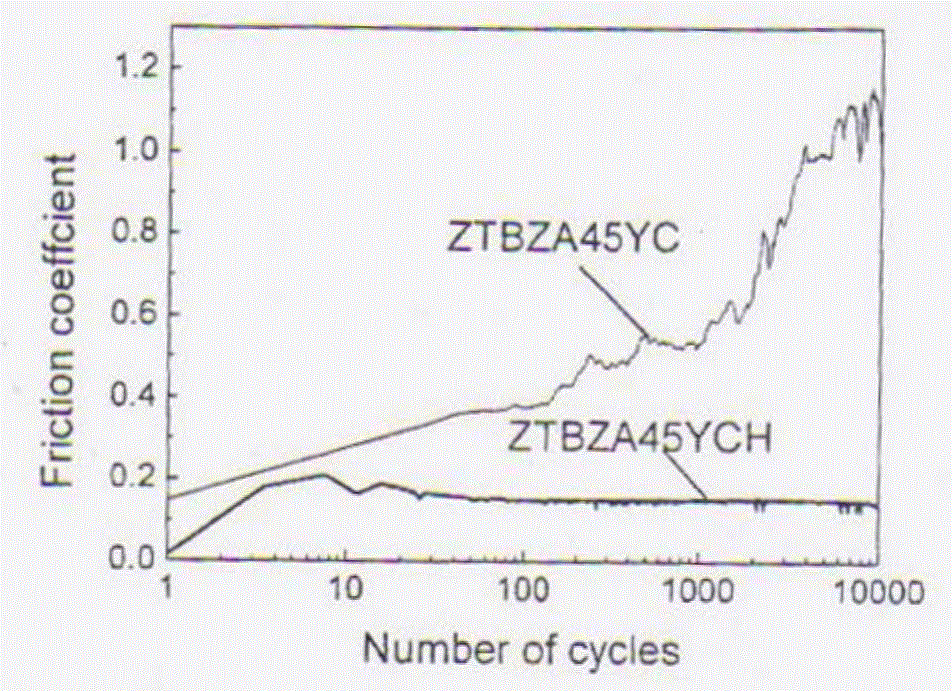

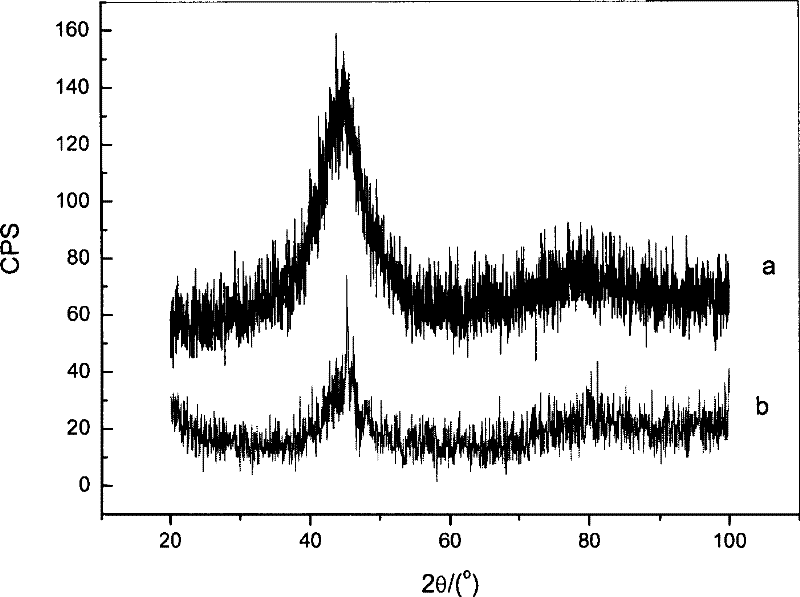

Amorphous soft magnetic alloy coatings and preparation method thereof

ActiveCN101441915ASimple processLess stress sensitiveMolten spray coatingMagnetic/electric field screeningMetallurgyMaterials science

The present invention relates to an amorphous soft magnetic alloy coating and the preparation method thereof, particularly relates to Fe-Co base amorphous soft magnetic alloy coating, characterized in that: (1) the sum of atom percentage content of Fe and Co is no less than 70&; (2) basically the coating is in amorphous structure. The invention also relates to the usage of the coating and the preparation method thereof.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Nickel-titanium system shape memory alloy

The invention discloses nickel-titanium system shape memory alloy. The nickel-titanium system shape memory alloy is formed by compounding six metal elements of nickel, titanium, copper, chromium, manganese and cadmium. The nickel-titanium system shape memory alloy comprises, by weight, 60.3%-64.9% of nickel, 21.4%-22.5% of titanium, 7.4%-8.3% of copper, 2.8%-3.7% of chromium, 1.9%-2.7% of manganese and 1.6%-2.5% of cadmium. The nickel-titanium system shape memory alloy is composed of the six metal elements of nickel, titanium, copper, chromium, manganese and cadmium and has the advantages that the memory resilence function is achieved, magnetism does not exist, abrasion, corrosion and high temperature are resisted, and toxicity does not exist.

Owner:ZHANGJIAGANG JIASHENG MACHINERY

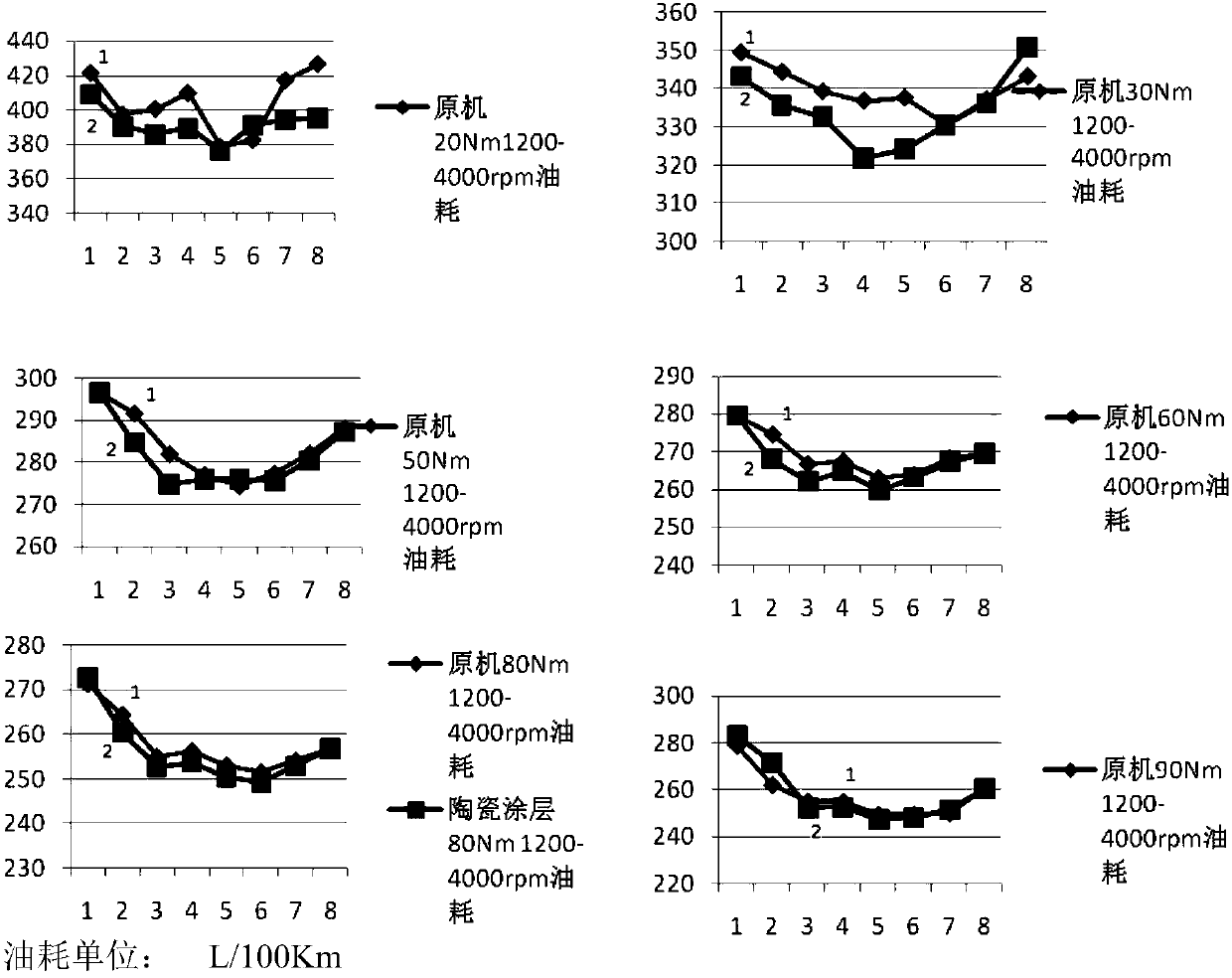

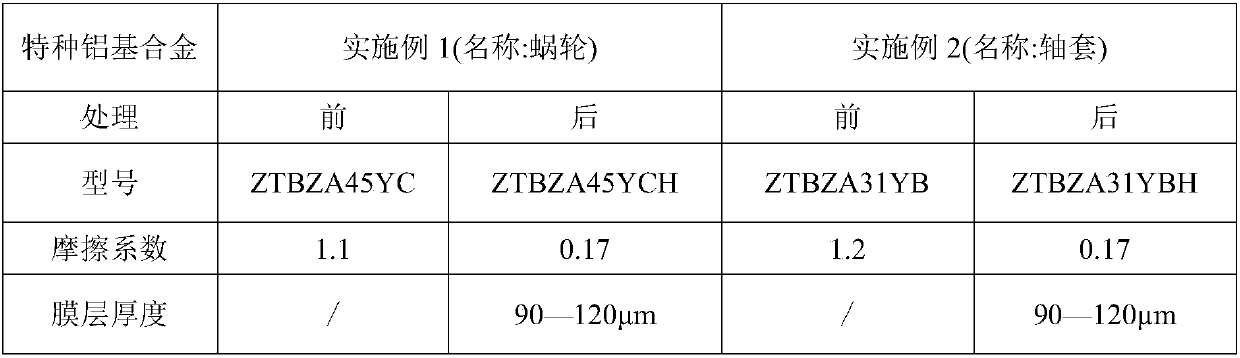

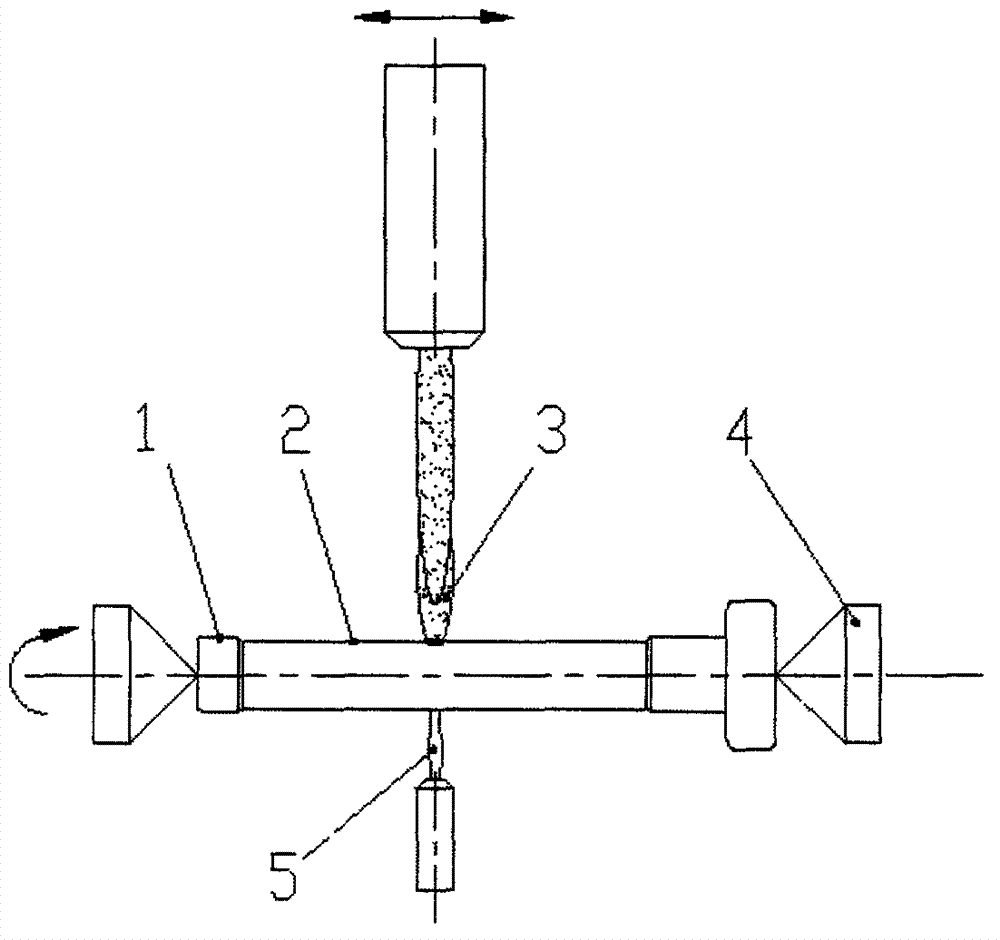

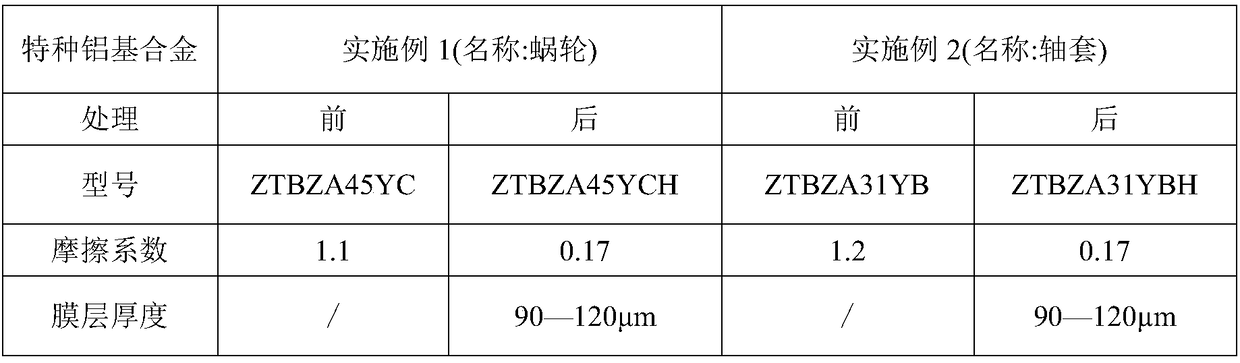

Method of processing surfaces of aluminium alloy pistons and precision friction pairs

ActiveCN103484849AHigh densityLow friction factorMaterial nanotechnologyMetallic material coating processesVolumetric Mass DensityMachining

The invention relates to a method of processing the surfaces of light alloy, in particular to a method of processing the surfaces of aluminium alloy pistons and precision friction pairs. The method comprises the steps that (1) washing is performed; (2) oxidization is performed; (3) hole plugging is performed. Nanoscale metal matrix ceramic oxidation film layers with the density up to the standard are respectively grown on the aluminium alloy pistons and precision friction pairs processed in the method, the density is increased, the diameters of blind holes are decreased obviously, nanometer penetrant blind holes are sealed, roughness is reduced, the friction coefficient is reduced, and the geometric dimensions are unchanged basically. The aluminium alloy pistons and precision friction pairs processed in the method can be installed for use in a matched mode without finish machining, industrial mass production can be achieved, and the method reduces production cost greatly compared with original technical methods.

Owner:邓才松 +1

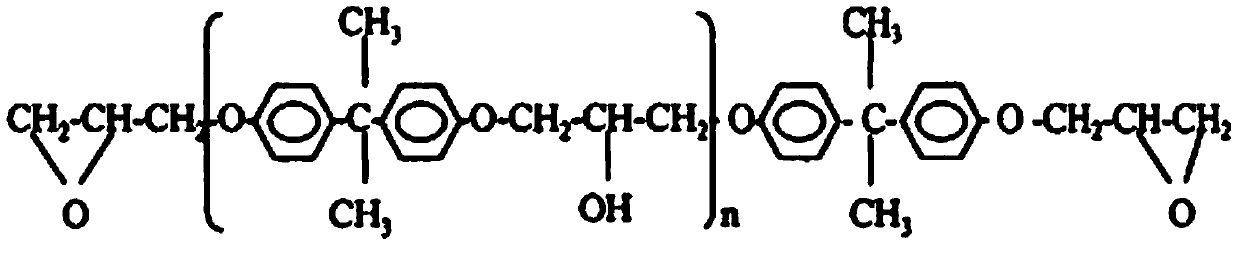

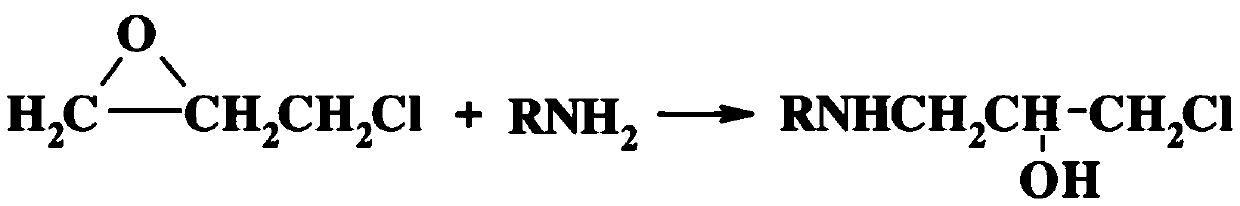

Metal-based polymer material preparation method, composite material preparation method and prepared mold

The invention belongs to the technical field of composite materials, and particularly relates to a metal-based polymer material preparation method. The method comprises the following steps of adding epoxy resin into a reaction kettle, heating and uniformly dispersing, adding 5-10 parts of modified epoxy resin, adding an epoxy diluent and a dispersing agent, adding an anti-settling aid, adding a polymerization aid, adding a defoaming agent, mixing Ti, iron oxide powder, electrolytic iron powder, reduced iron powder, carbon black, Cr, Mn, Mg, Zn, Wc, Al and ceramic micro powder to form metal mixed powder, and adding the metal mixed powder into a resin mixed solution, stirring, and defoaming. The preparation method of the composite material comprises the following steps of uniformly stirringthe curing agent and the high polymer material, controlling the temperature to be 20-35 DEG C for preliminary curing, and curing after the temperature is 80-160 DEG C to obtain the finished product. And the mold is made of a polymer composite material. And the prepared mold is high in strength and hardness, small in contractibility and good in sedimentation resistance.

Owner:江苏九铸合金新材料有限公司

Aluminum magnesium alloy material with wear resistance and corrosion resistance, and preparation method thereof

InactiveCN101974711AWear-resistant and corrosion-resistantReduce manufacturing costAnodisationMicro arc oxidationSolid phases

The invention relates to the metal manufacturing, in particular to an aluminum magnesium alloy material with wear resistance and corrosion resistance, and a preparation method thereof. The method comprises the following steps: firstly pouring the aluminum alloy slurry with 10% of solid phase by volume into a preheated die for molding to form an initial rigidification layer, wherein the high-frequency heating and quenching temperature is from 452 to 510 DEG C during the molding; then performing the grain refining process on the initial rigidification layer at the temperature of 500 to 530 DEG C for 4 to 4.5 hours to obtain the final rigidification layer; finally carrying out micro arc oxidation electrolysis water treatment on the rigidification layer to obtain the aluminum magnesium alloy material. The aluminum magnesium alloy material has the properties of wear resistance and corrosion resistance, low preparation cost, and convenient and simple operation for preparation, and can be widely used in the manufacture of parts for high-performing cars.

Owner:蔡乐勤

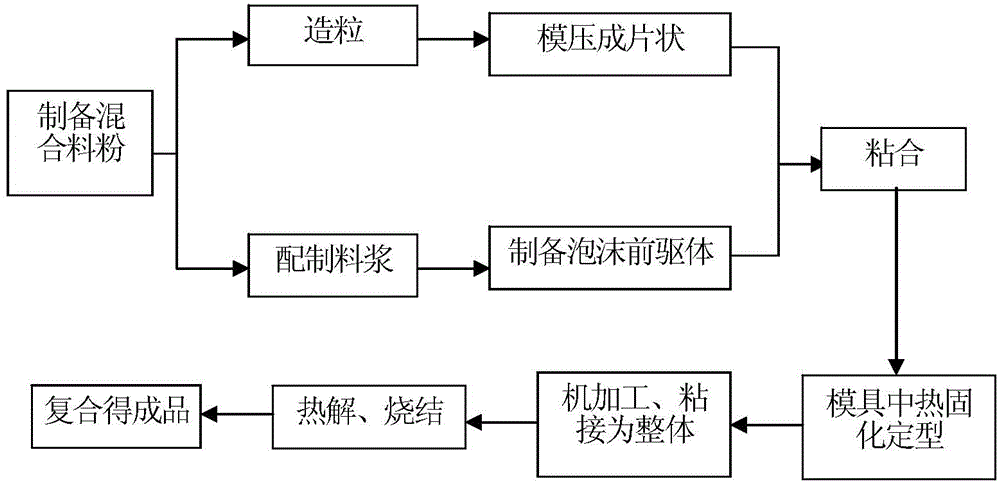

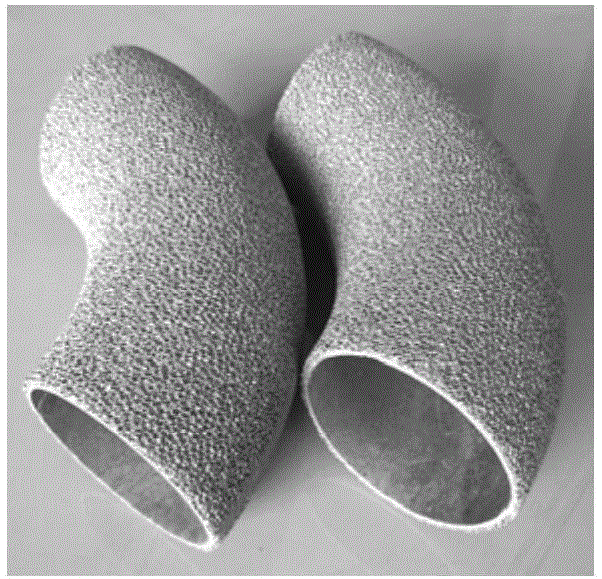

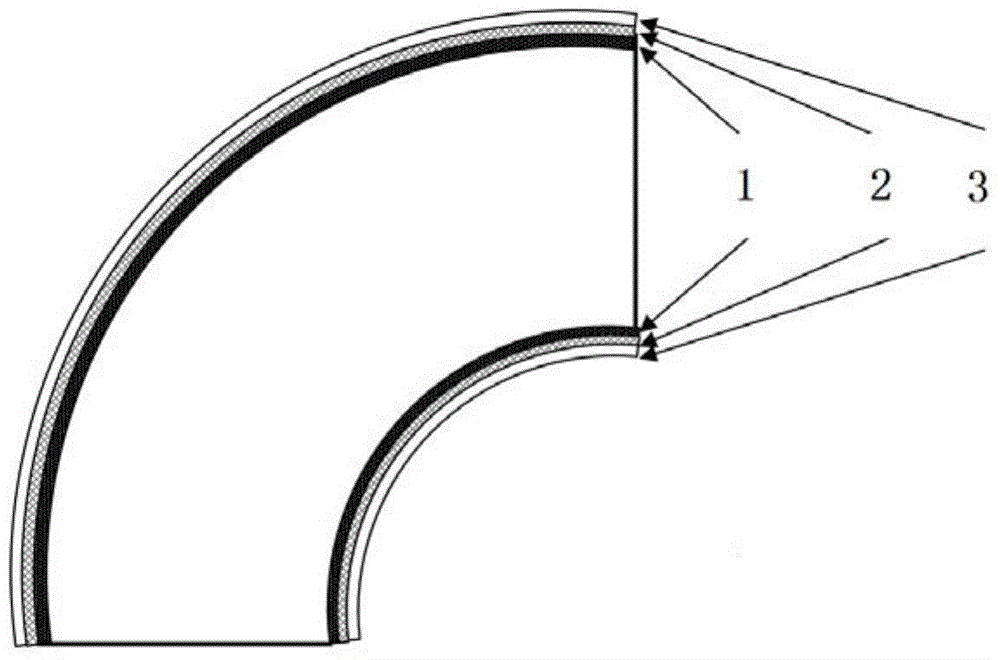

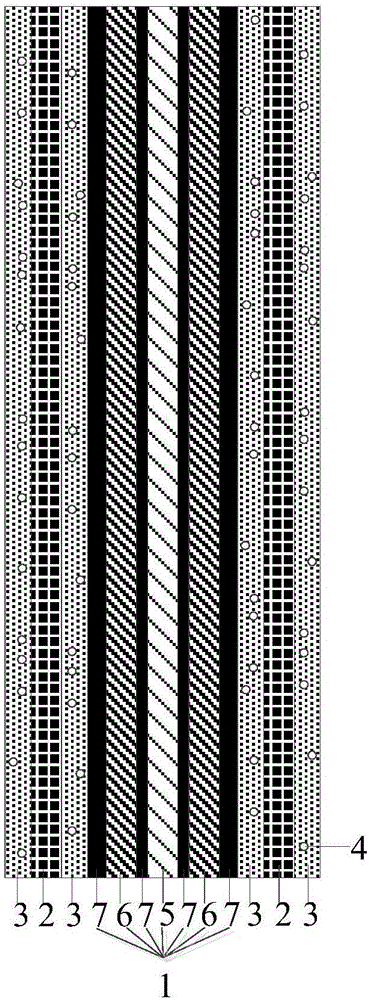

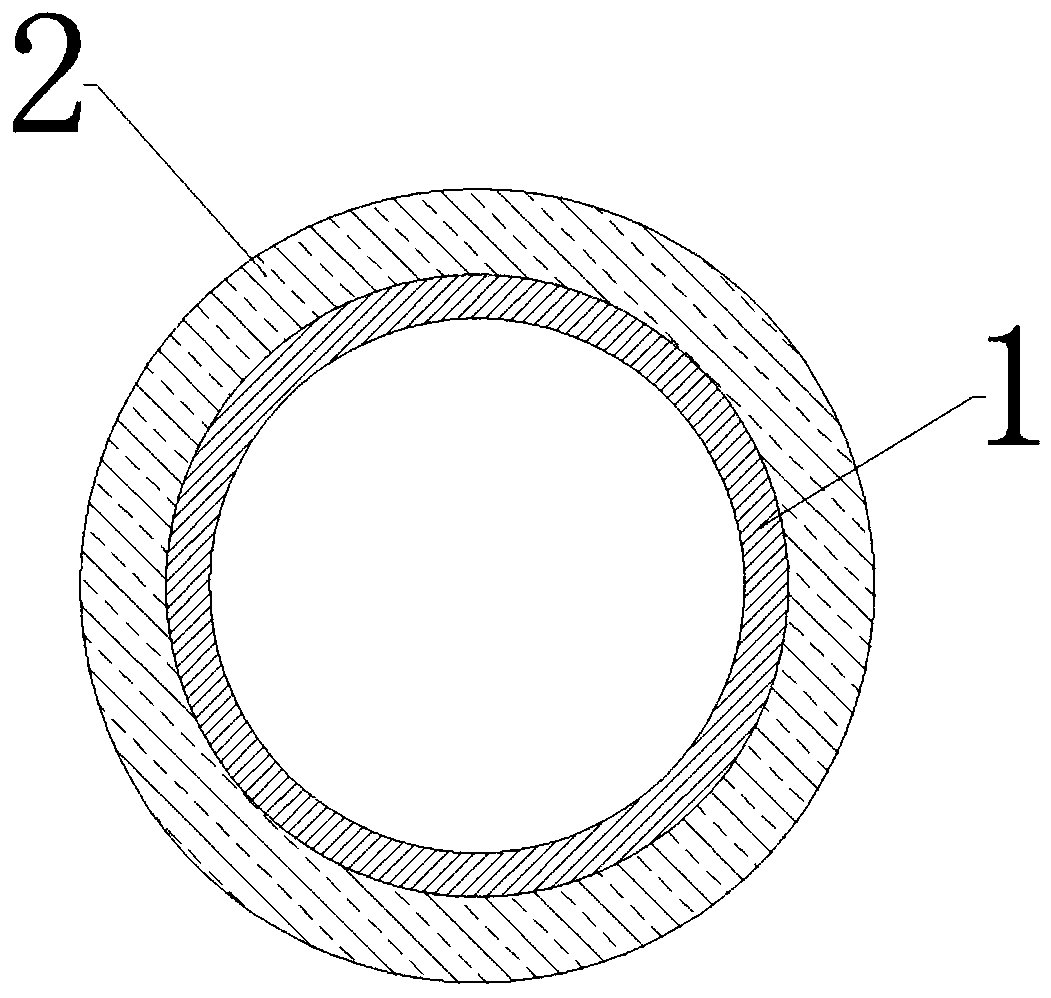

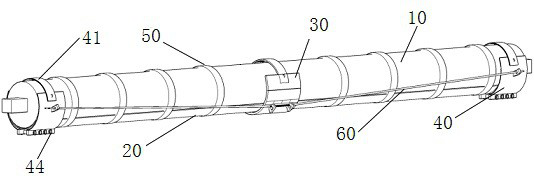

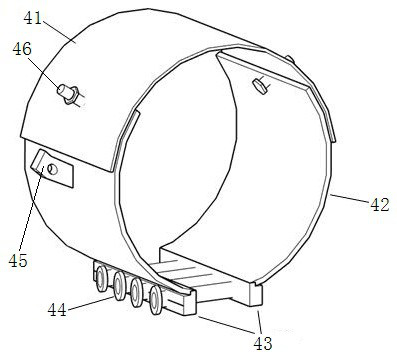

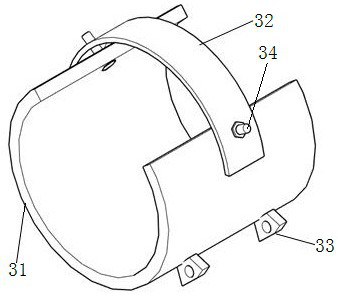

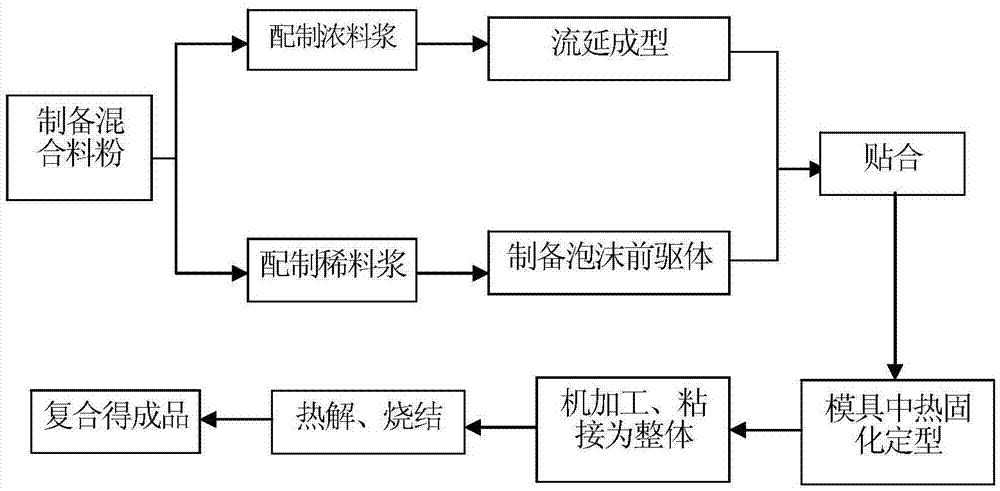

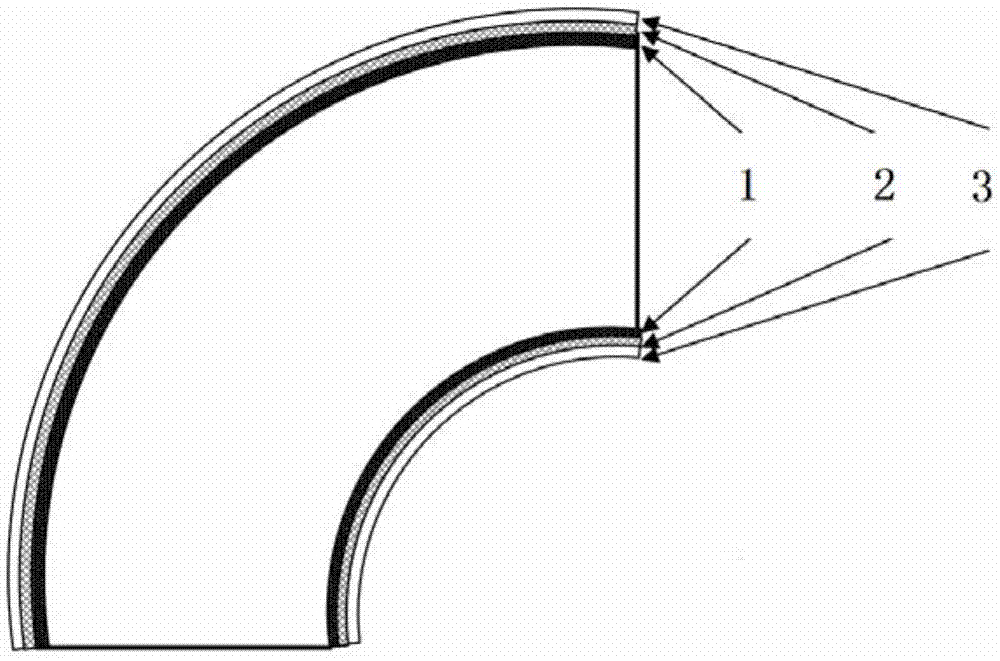

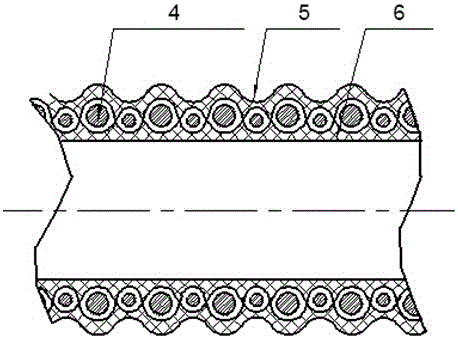

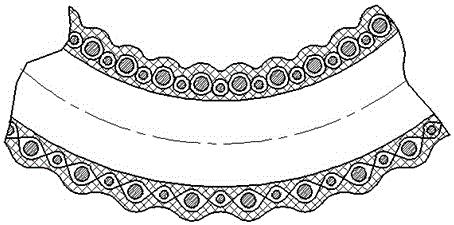

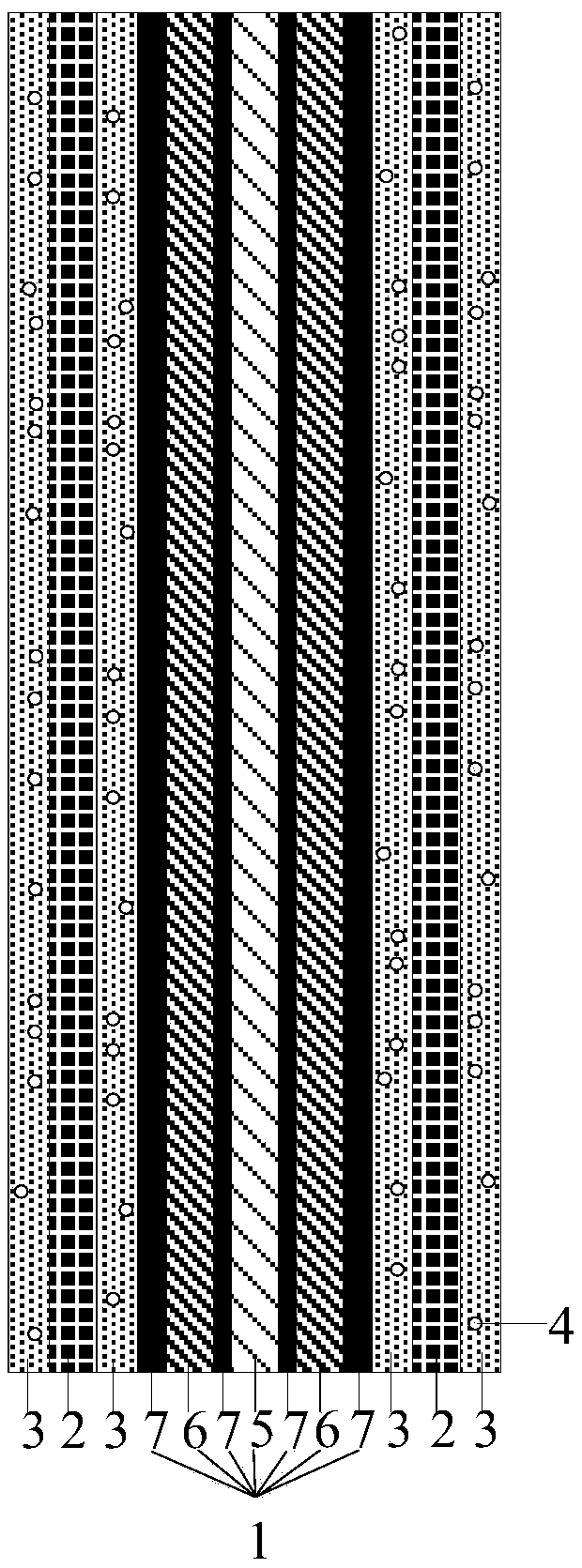

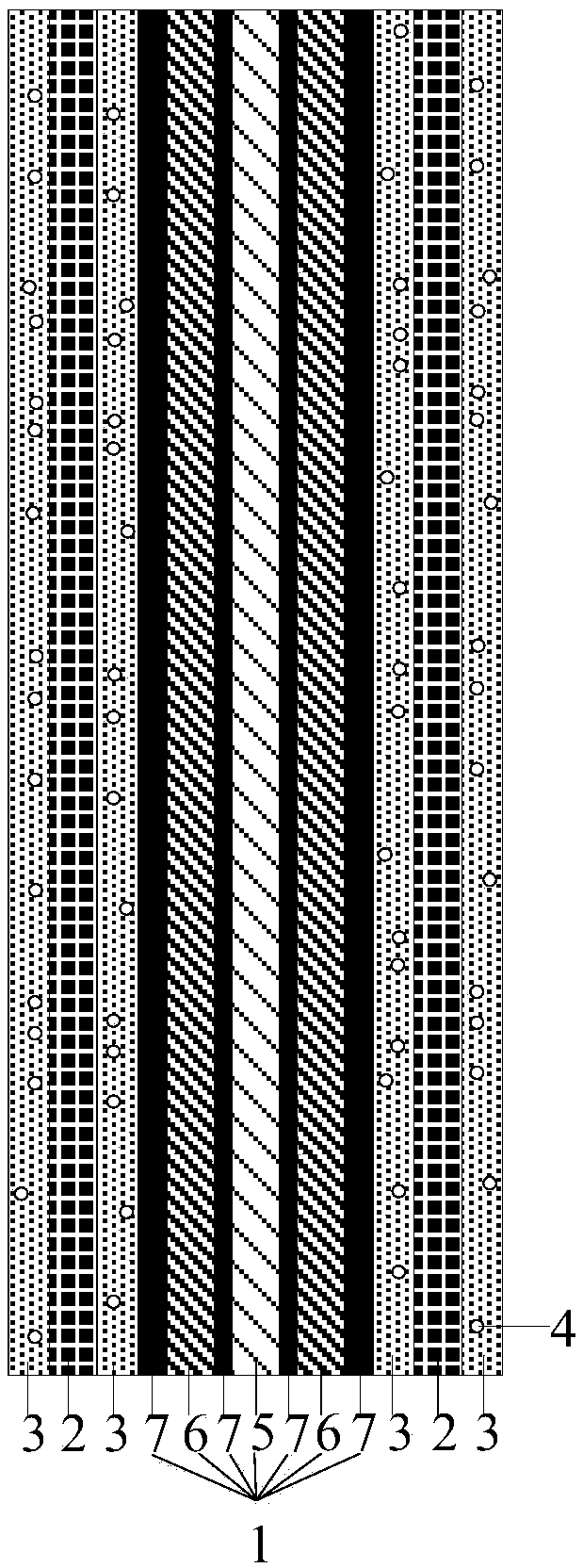

Abrasion-resistant and anticorrosion pipe or pipe fitting with double ceramic lining layers and preparation method of abrasion-resistant and anticorrosion pipe or pipe fitting

ActiveCN106321991AImprove wear resistanceImprove corrosion resistanceCorrosion preventionPipe protection against corrosion/incrustationParticulatesSurface layer

The invention relates to metal pipe or pipe fitting surface abrasion-resistant and anticorrosion protection technologies, in particular to an abrasion-resistant and anticorrosion pipe or pipe fitting with double ceramic lining layers and a preparation method of the abrasion-resistant and anticorrosion pipe or pipe fitting. The pipe or pipe fitting is composed of an abrasion-resistant and anticorrosion lining layer and a metal layer from inside to outside. The abrasion-resistant and anticorrosion lining layer is composed of a surface layer and a composite layer. The surface layer is a compact ceramic layer. The composite layer is a foamed ceramic layer. The composite layer is directly grown on the back face of the compact ceramic layer. The preparation process comprises the following steps of preparation of mixed powder, prilling and slurry preparing, sheet forming through mold pressing and preparation of a foam precursor, bonding, thermosetting forming in a mold, machining and bonding forming, pyrolyzing and sintering, and finished product obtaining through compositing. According to the ceramic lining layer abrasion-resistant and anticorrosion pipe or pipe fitting prepared through the method, the abrasion-resistant service life can be 5-10 times that of rubber lining abrasion-resistant layers, the pipe or pipe fitting has good tolerability to acid and alkali corrosion and high-temperature impact, and the replacement cycle of pipe or pipe fitting equipment can be effectively prolonged, so that the operating cost of enterprises is reduced, and emission of particulate pollutants is reduced.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

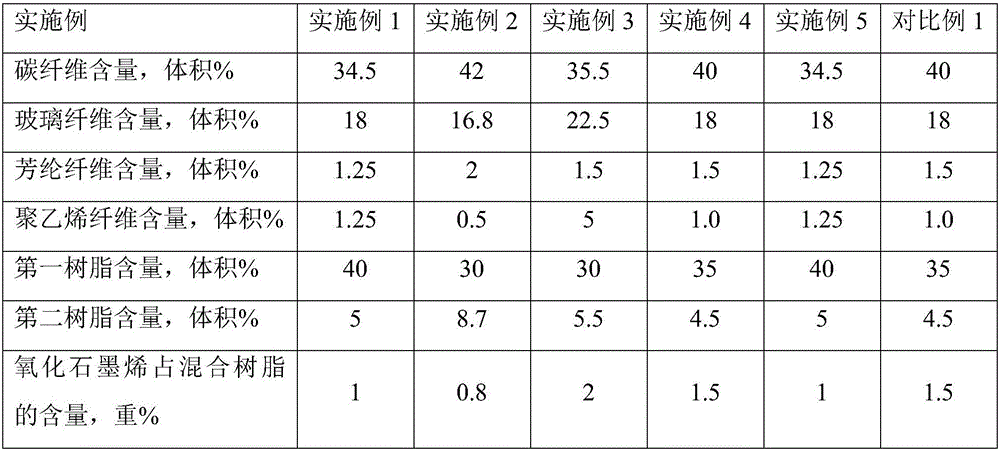

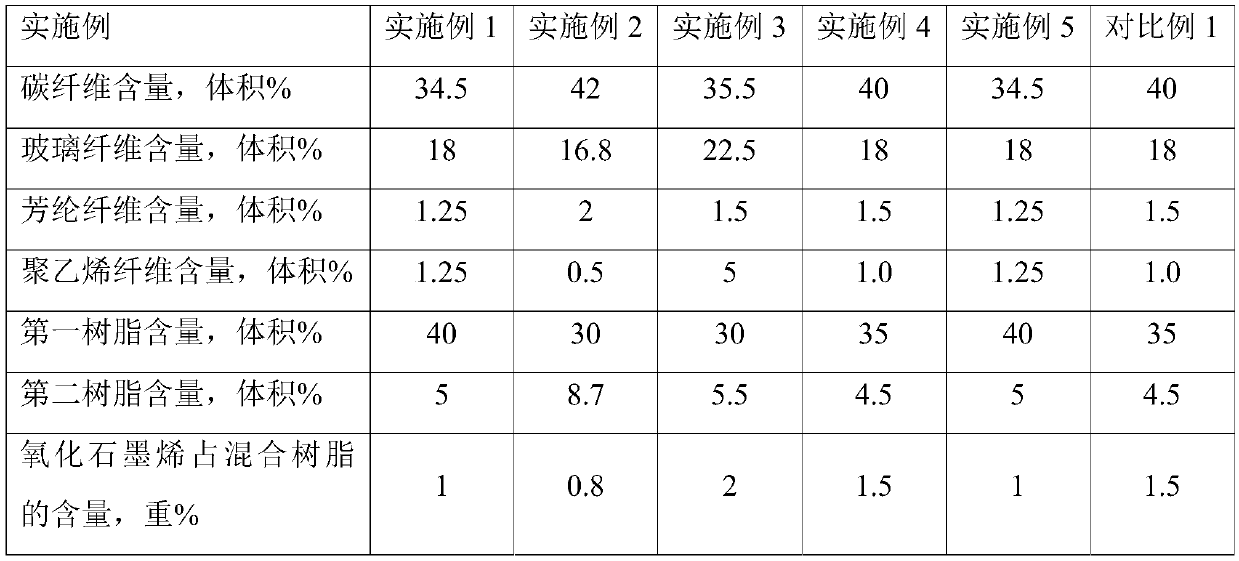

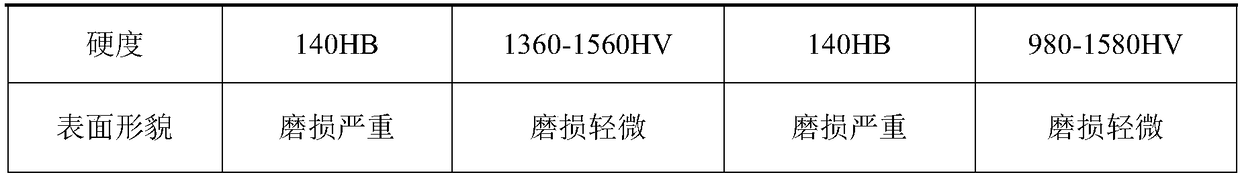

Preparation method for carbon fiber composite reinforced board used for vehicle, and composite reinforced board

ActiveCN106494061AHigh bonding strengthImprove impact resistanceSynthetic resin layered productsLaminationFiberboardAramid

The invention discloses a preparation method for a carbon fiber composite reinforced board used for a vehicle, and the composite reinforced board. The preparation method comprises the following steps: subjecting a carbon fiber braid ply and a glass fiber braid ply to superposition so as to obtain an inner fiberboard; mixing graphene oxide and first resin so as to obtain mixed resin; covering the surface of the superposed carbon fiber braid ply and glass fiber braid ply with the mixed resin and carrying out primary compression molding so as to obtain an inner composite board; and covering the outer side of the inner composite board with a hybrid braid ply prepared through two-dimensional hybrid braiding of aramid fiber and polyethylene fiber, covering the surfaces of the hybrid braid ply and the inner composite board with second resin and a foaming agent and carrying out secondary compression molding so as to obtain the composite reinforced board. The composite reinforced board prepared by using the method has high strength, high modulus and good impact resistance.

Owner:BEIJING AUTOMOTIVE IND CORP +1

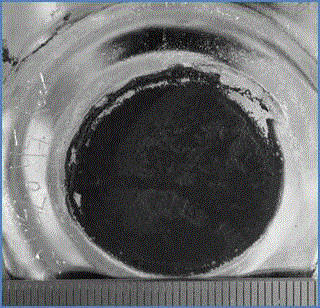

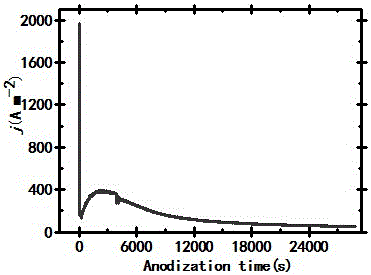

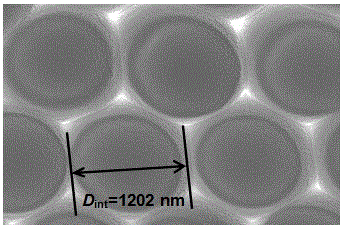

Ordered extralarge-hole-pitch alumina film and preparation method thereof

The invention discloses an ordered extralarge-hole-pitch alumina film and a preparation method thereof. The alumina film has high hardness and elastic modulus, low reflectivity and obvious photoluminescence performance. The surface of the film is composed of innumerable holes. The bottoms of the holes are distributed in ordered hexagons. According to the ordered extralarge-hole-pitch alumina film and the preparation method thereof, macromolecular organic acid serves as an electrolyte, the electrolyte and an aluminum base are effectively cooled simultaneously, and the aluminum base is stably oxidized under extra-high voltage. The alumina film can serve as an ideal template for preparing various ordered major-cycle nano array structures of metal, polymer and the like, and can also be used for developing three-dimensional channel alumina films of micro and nano composite structures. The major-cycle alumina film is an excellent bioactivator carrier and has wide application prospects in the aspects of biosensors, medicine transport platforms, solar cells and the like.

Owner:SHAANXI NORMAL UNIV

Light magnetic ball and preparation method thereof

InactiveCN110818443ALow densityStable structureElectrotherapyPermanent magnetsWear resistanceCeramic

The invention relates to the technical field of magnet therapy, in particular to a light magnetic ball and a preparation method thereof. The light magnetic ball comprises a ceramic hollow ball and a magnetic resin material layer attached to the outer surface of the ceramic hollow ball. The internal ceramic hollow ball is small in density and firm in structure, and can provide stable support for the magnetic resin material layer on the outer layer. The magnetic resin material layer is formed by mixing magnetic powder and resin, wherein the magnetic powder can generate a stable magnetic field toachieve magnetic therapy effect, and the resin can reduce foreign body sensation generated in the using process of the light magnetic ball, thereby effectively improving comfort degree in use. The light magnetic ball provided by the invention has the advantages of small density, firm structure, wear resistance, corrosion resistance and the like, can meet the demand for magnetic therapy when arranged on products such as quilts, greatly reduces the weight of the products, and is more comfortable to use.

Owner:HEYE HEALTH TECH CO LTD

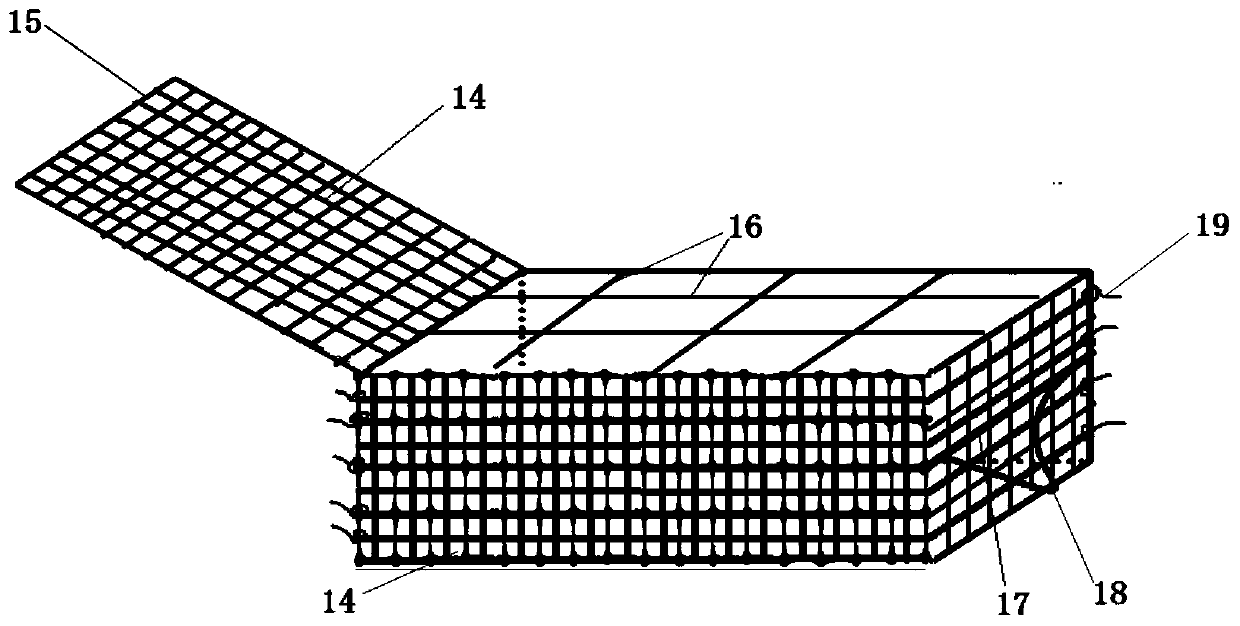

Prestress FRP and high-strength steel wire rope combined wood beam reinforcing device and method

PendingCN112392288AReduce disturbanceImprove reliabilityBuilding repairsBuilding material handlingIndustrial engineeringWire rope

The invention relates to a prestress FRP and high-strength steel wire rope combined wood beam reinforcing device and method. The device comprises FRP cloth pasted to the bottom face of a log beam in the length direction, a middle supporting piece is installed in the middle of the log beam, end reinforcing anchoring pieces are installed at the two ends of the log beam correspondingly, a plurality of layers of FRP hoops are pasted on the log beam and located between the middle supporting piece and the end part reinforcing anchoring pieces at intervals in the length direction, and high-strength steel wire ropes with the two ends connected to the corresponding end part reinforcing anchoring pieces are arranged on the two sides of the middle supporting piece correspondingly. The device and themethod overcome the defects of rigidity, bearing capacity and the like of flexural members such as wood beams in actual engineering, and meanwhile, through combined use of a prestress steel wire ropeand the FRP cloth, the safety reserve is improved, two defense lines are provided for the damaged wood beams, and the ductility is improved.

Owner:FUZHOU UNIV

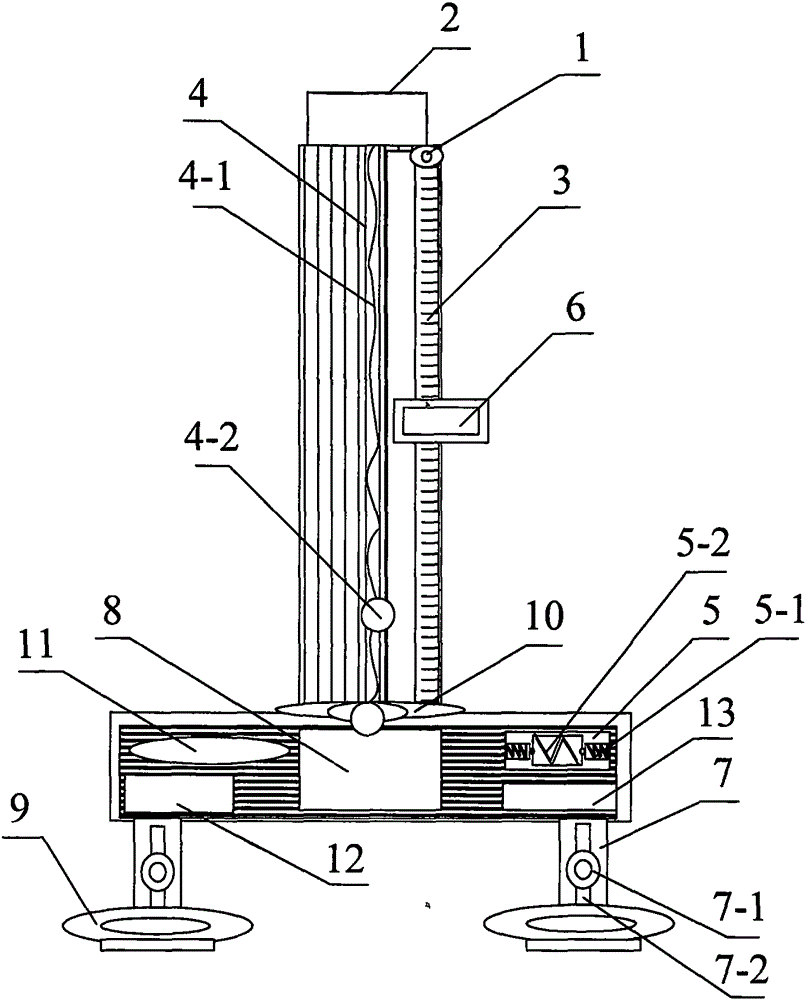

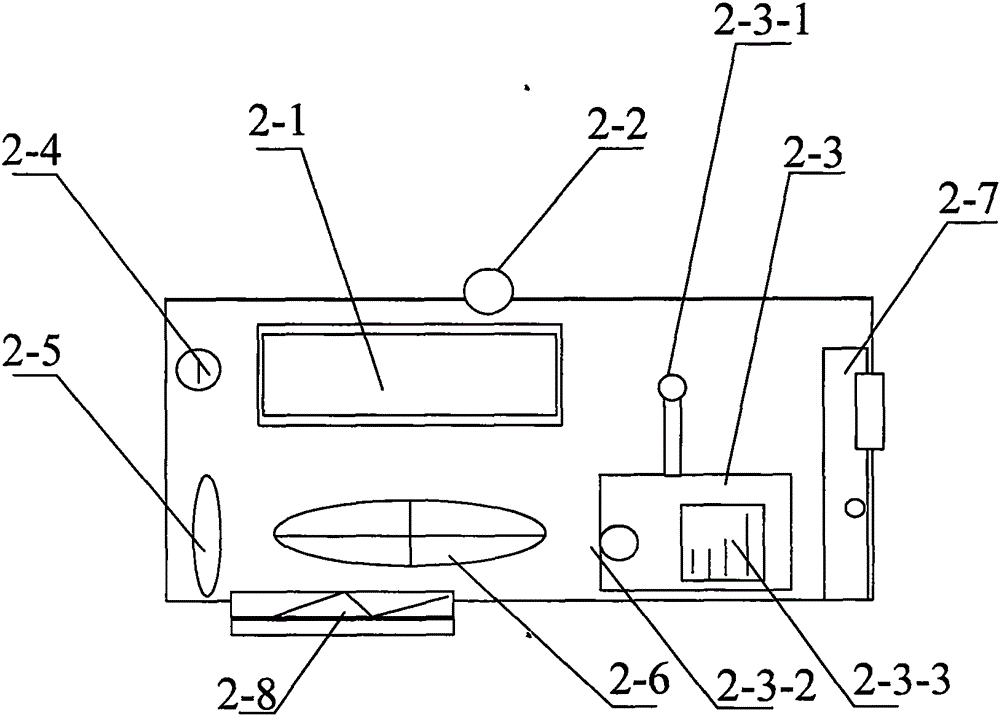

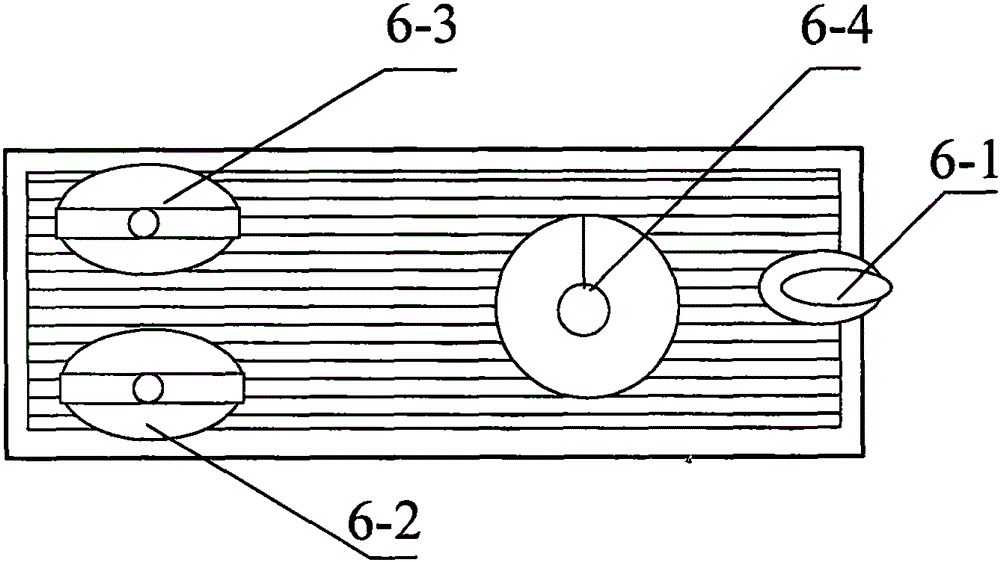

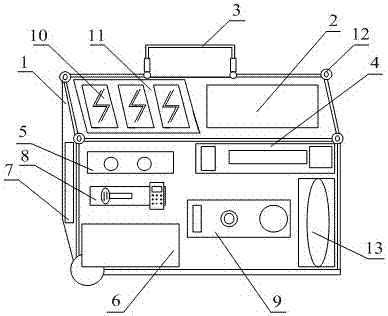

Environment monitoring instrument based on IOT

InactiveCN105258726AReduce manufacturing costImprove safety and reliabilityMeasurement devicesEnvironmental monitorMeasurement device

The present invention provides an environment monitoring instrument based on an IOT. The environment monitoring instrument comprises a micrometer head, a control device, a calibrated scale, a circuit board, battery equipment, a measuring device, lifting adjustment equipment, a monitoring device, base equipment, rotation equipment, a level gauge, a guide plate and a sliding groove. The micrometer head is arranged at the lower part right side position of the control device. The calibrated scale is arranged at the right side position of the circuit board. The battery equipment is arranged at the upper part position of the sliding groove. The measuring device is arranged at the middle position of the calibrated scale. The lifting adjustment equipment is arranged at the upper part connection position of the base equipment. According to the environment monitoring instrument, through arranging the control device, the measuring device and the monitoring device, the environment monitoring instrument is convenient to use, the operation is fast, the measurement effect is improved, thus the functional diversity is improved, the maintenance cost is reduced, and a best use effect is achieved.

Owner:刘强

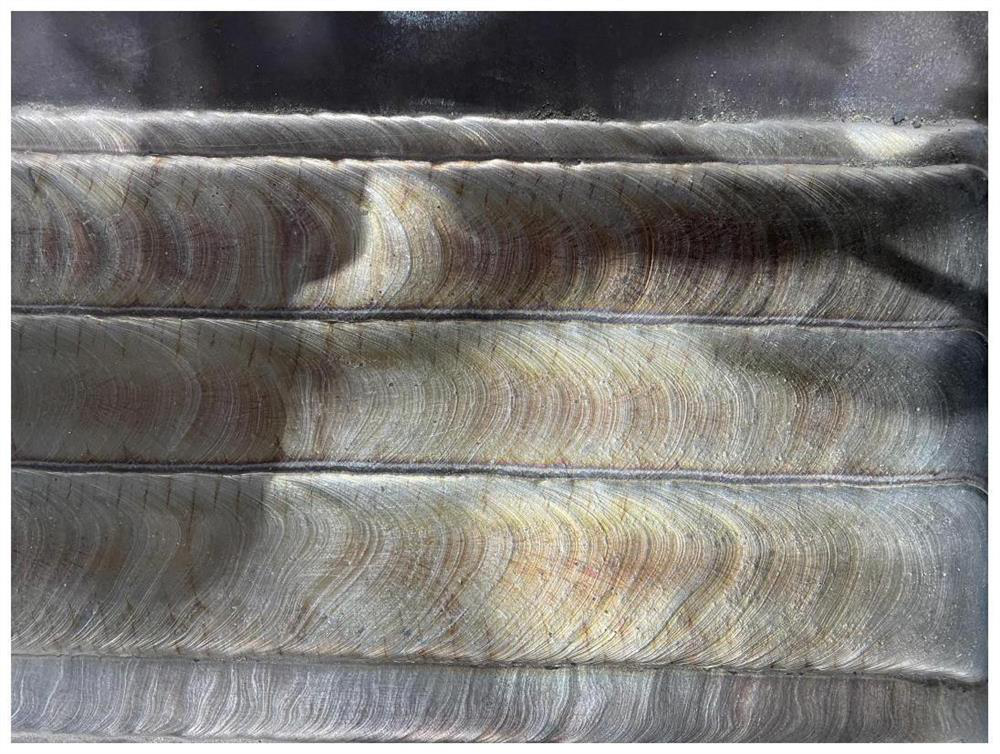

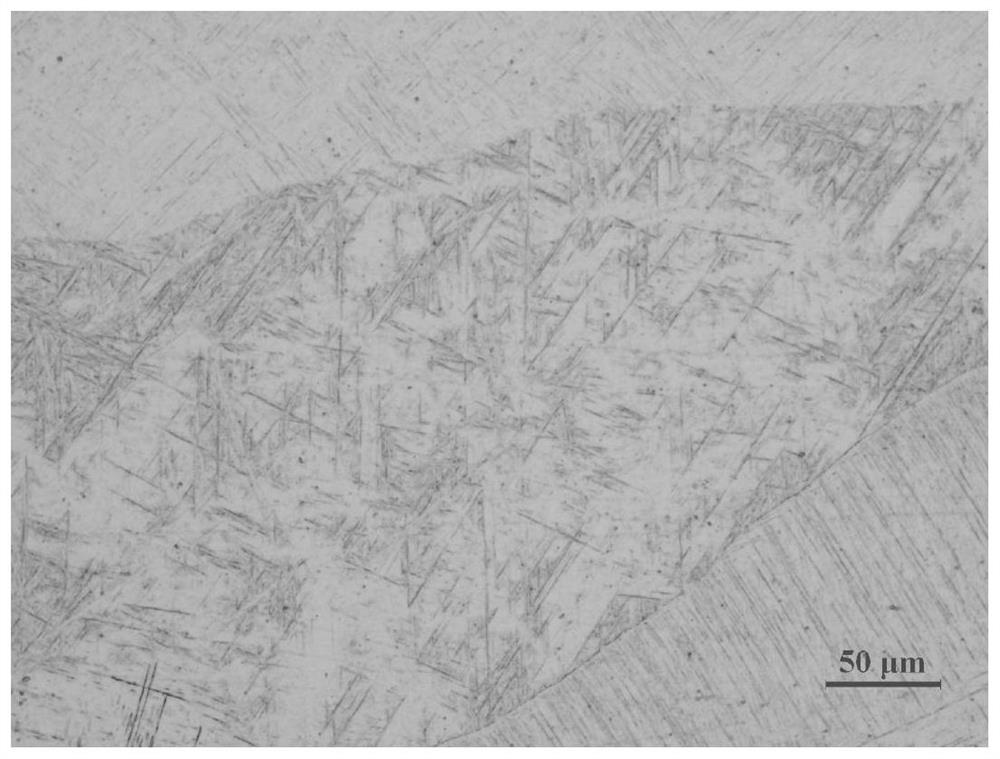

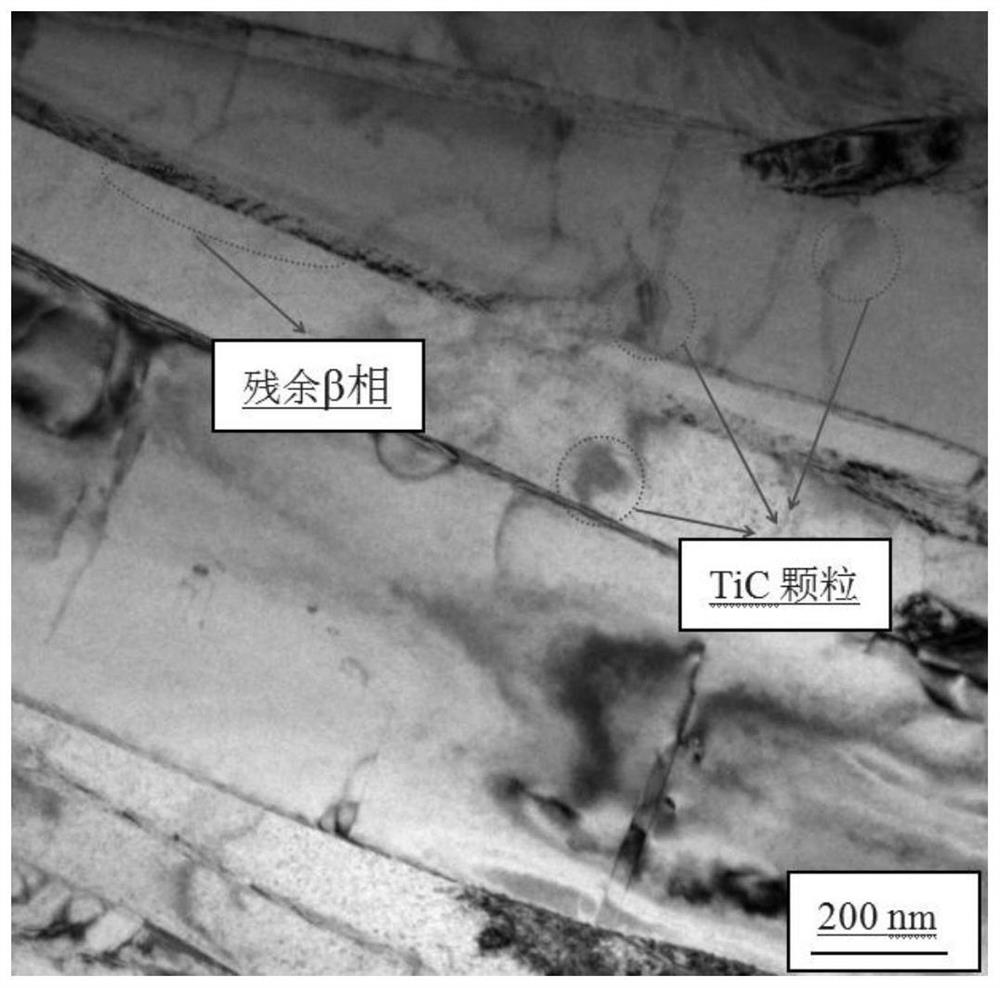

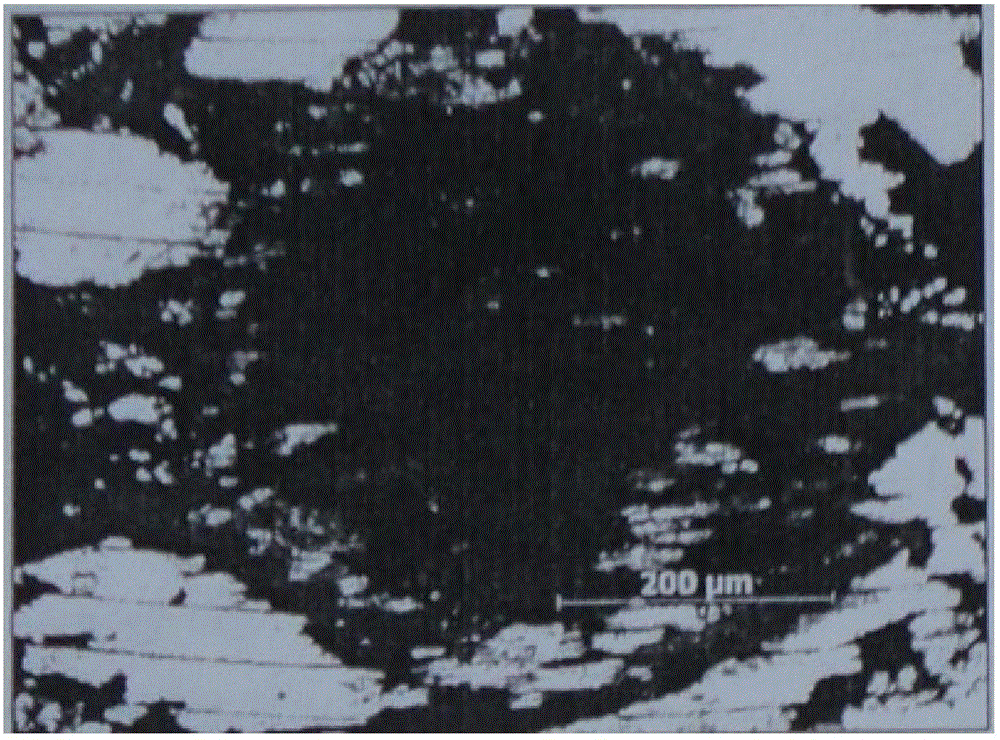

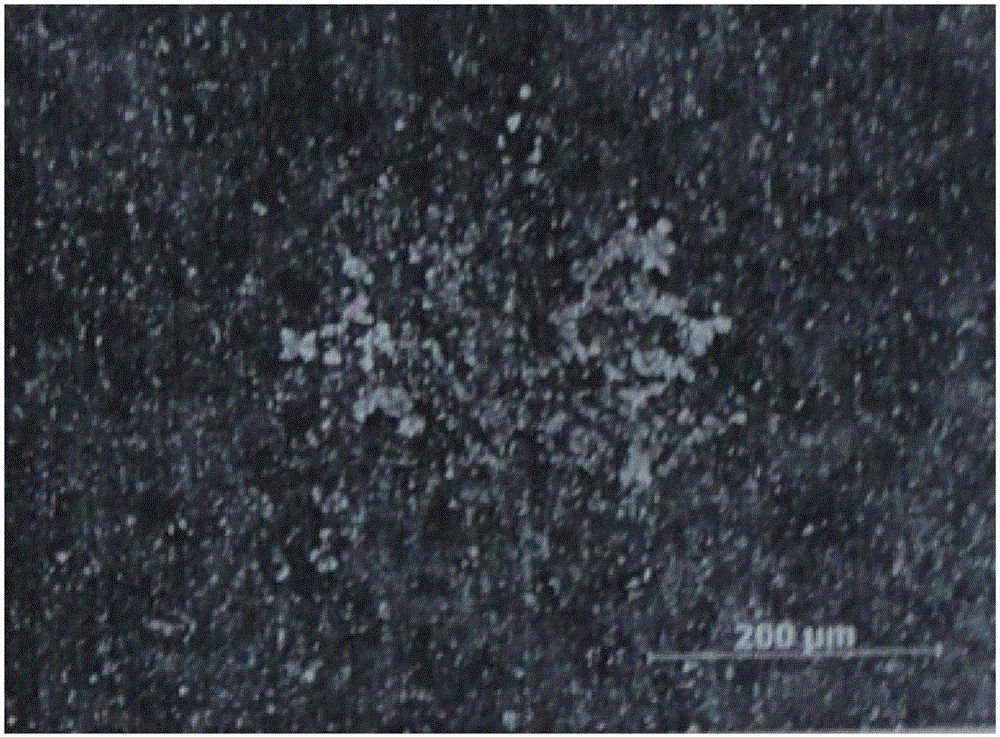

TC4 titanium alloy metal powder core flux-cored welding strip and preparation method thereof

ActiveCN114654128AIncreased residual beta contentImprove plastic toughnessWelding/cutting media/materialsSoldering mediaAl powderTitanium alloy

The invention discloses a TC4 titanium alloy metal powder core flux-cored welding strip and a preparation method thereof. The invention belongs to the technical field of welding material preparation. The titanium alloy solid welding strip aims at solving the technical problems that components of an existing titanium alloy solid welding strip for titanium alloy strip electrode submerged arc surfacing are not easy to regulate and control, and a surfacing cladding layer is difficult to meet comprehensive performance indexes such as strength, plasticity, toughness, abrasion resistance and corrosion resistance. The welding strip is composed of a Ti-9Mo-3Nb-3V titanium alloy skin and a metal powder core filled in the Ti-9Mo-3Nb-3V titanium alloy skin. The metal powder core is formed by mixing, by mass, 5%-7% of vanadium powder, 12%-17% of aluminum powder, 3%-5% of molybdenum powder, 3%-5% of iron powder, 1%-3% of silicon powder, 5%-8% of nickel powder and the balance titanium powder. By adding beneficial elements and supplementing burning elements in the welding process, the production cost is greatly reduced, the production efficiency is improved, a surfacing cladding layer has the advantages of being high in strength, good in plasticity and toughness and resistant to abrasion and corrosion, welding flux is not needed for molten pool protection and metallurgical regulation, and slag removal treatment is not needed after surfacing.

Owner:HARBIN WELDING INST LTD

Surface treatment method of aluminum alloy piston and precision friction pair

ActiveCN103484849BHigh densityLow friction factorMaterial nanotechnologyMetallic material coating processesVolumetric Mass DensityMachining

The invention relates to a method of processing the surfaces of light alloy, in particular to a method of processing the surfaces of aluminium alloy pistons and precision friction pairs. The method comprises the steps that (1) washing is performed; (2) oxidization is performed; (3) hole plugging is performed. Nanoscale metal matrix ceramic oxidation film layers with the density up to the standard are respectively grown on the aluminium alloy pistons and precision friction pairs processed in the method, the density is increased, the diameters of blind holes are decreased obviously, nanometer penetrant blind holes are sealed, roughness is reduced, the friction coefficient is reduced, and the geometric dimensions are unchanged basically. The aluminium alloy pistons and precision friction pairs processed in the method can be installed for use in a matched mode without finish machining, industrial mass production can be achieved, and the method reduces production cost greatly compared with original technical methods.

Owner:邓才松 +1

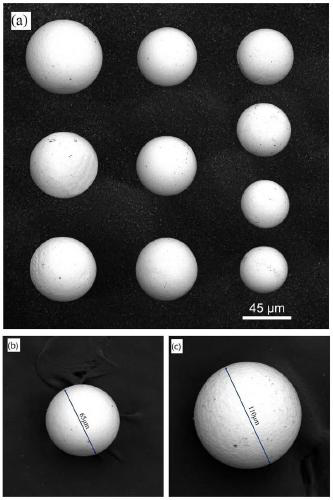

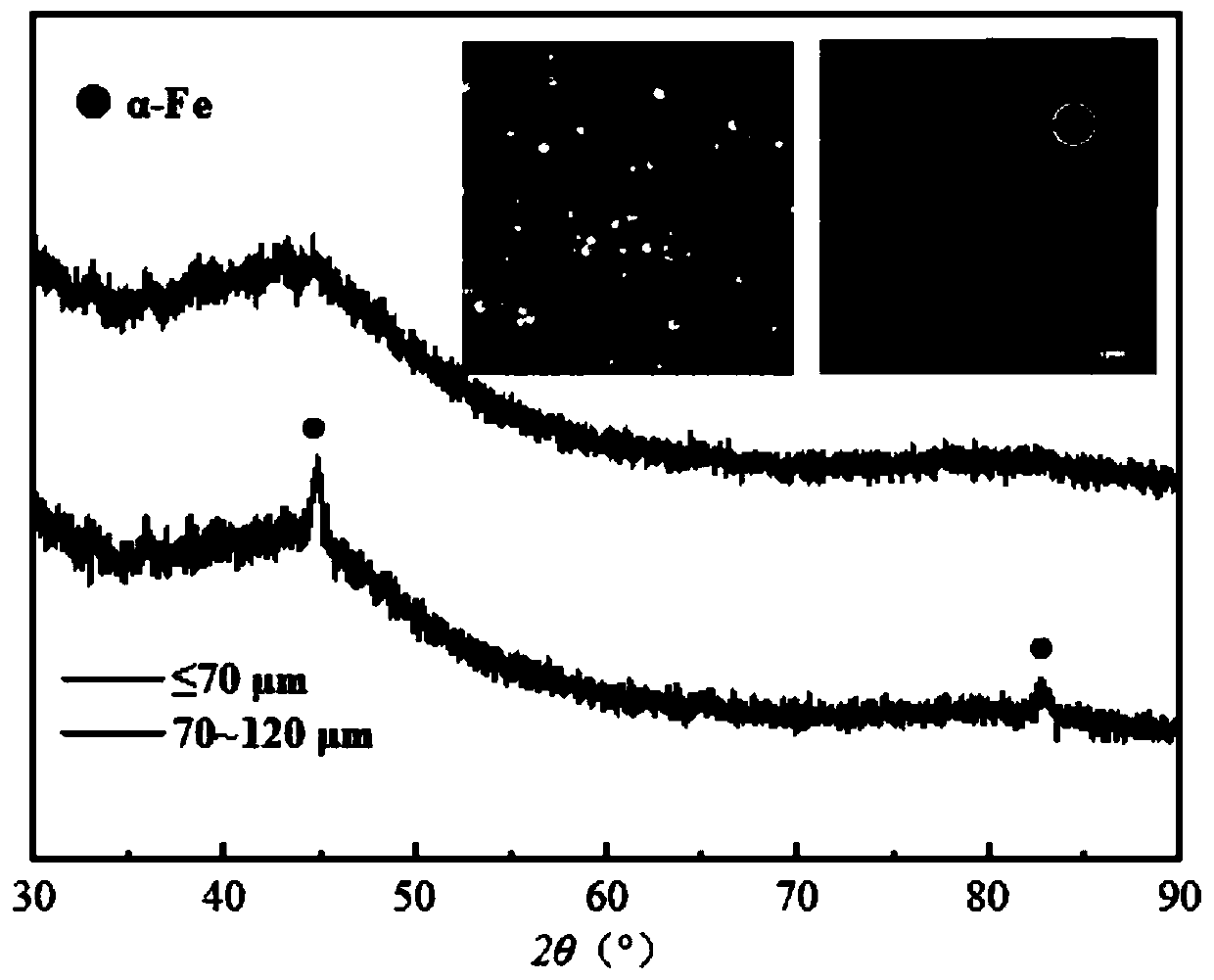

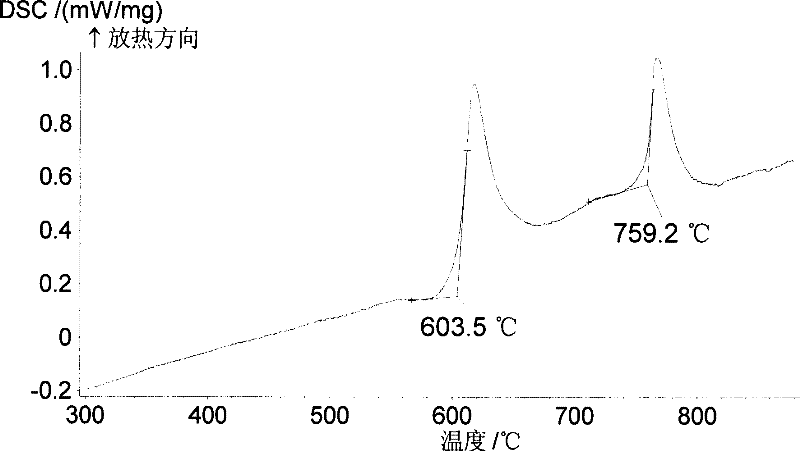

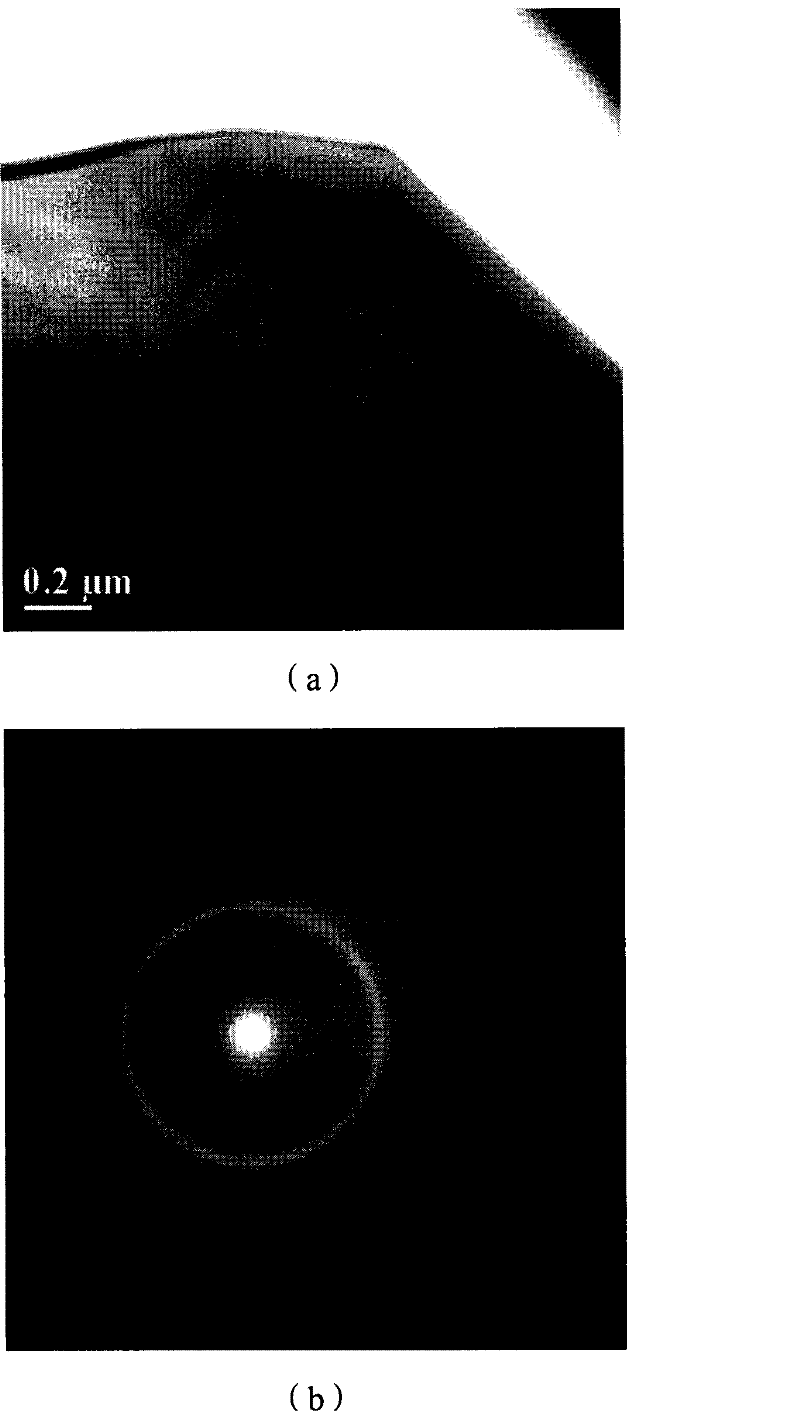

Iron-silicon-boron amorphous nanocrystalline composite microsphere material and preparation method thereof

ActiveCN110423956ARaise the ratioLow costTransportation and packagingMetal-working apparatusMicrosphereMicroparticle

The invention belongs to the technical field of iron-based amorphous nanocrystalline alloys, and particularly discloses an iron-silicon-boron amorphous nanocrystalline composite microsphere material and a preparation method thereof. The selected alloy component is FexSicyBz, wherein x, y and z are atomic percentages of corresponding components, the x is equal to 75-78, the y is equal to 9-12, andthe z is equal to 100-x-y. The drop tube without container rapid solidification preparation method is adopted and comprises the following steps of weighing and preparation, master alloy smelting, sample installing, vacuumizing, heating and blowing, particle collecting, particle screening and the like, and an alloy microsphere with the grain diameter d being less than or equal to 120 microns are screened and collected. The method has the advantages that raw materials are easy to obtain, the amorphous preparation process flow is simple, the amorphous critical dimension is large, the prepared amorphous nanocrystalline composite microsphere material has the advantages of high strength, high hardness, wear resistance, corrosion resistance and the like, and the material can be applied to the fields of amorphous coatings, sensing elements, precision instruments, precision processing technologies and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Pipeline or pipe fitting provided with silicon carbide ceramic abrasion-resisting and corrosion-resisting liner and preparation method thereof

ActiveCN106917918AImprove wear resistanceHigh strengthCorrosion preventionPipe protection against corrosion/incrustationCarbide siliconPipe fitting

The invention relates to a metal pipeline or pipe fitting surface abrasion-resisting and anticorrosion protection technology, in particular to a pipeline or pipe fitting provided with a silicon carbide ceramic abrasion-resisting and corrosion-resisting liner and a preparation method thereof. The pipeline or the pipe fitting is composed of the abrasion-resisting and corrosion-resisting liner and a metal layer from inside to outside. The abrasion-resisting and corrosion-resisting liner is composed of a surface layer and a compounded layer. The surface layer is a compact ceramic layer. The compounded layer is a foam ceramic layer and directly grows on the back face of the compact ceramic layer. The preparation process comprises the following steps of preparation of mixed powder, preparation of slurry, preparation of a foam precursor in a tape casting mode, bonding, thermocuring forming in a mould, machining, bonding forming, pyrolysis, sintering, and compounding to obtain afinished product. According to the ceramic liner abrasion-resisting and corrosion-resisting pipeline or pipe fitting prepared through the preparation method, the abrasion-resisting service life can be five to ten times that of a rubber-lined abrasion-resisting layer, the resistance to acid and alkaline corrosion and high-temperature impact is excellent, the replacement period of the pipeline or pipe fitting can be effectively prolonged, accordinglythe operation cost of enterprises is lowered, and emission of particulate pollutants is reduced.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Elastic middle coating

InactiveCN105331227AIncrease elasticityImprove tack and elasticityAnti-corrosive paintsIonTriple superphosphate

The invention discloses an elastic middle coating, which comprises components with parts by weight: deionized water 30-35 parts, titanium dioxide 8-12 parts, talcum powder 4-6 parts, calcium triple superphosphate 3-5 parts, acrylic emulsion 22-28 parts, moist dispersant 0.5-0.9 part, defoamer 0.2-0.3 part, ethylene glycol 3-6 parts, propylene glycol benzoate 0.3-0.5 part, hydroxyethyl cellulose 0.2-0.3 part, plant cellulose 4-9 parts, polyethylene glycol 3-5 parts, bentonite 3-5 parts, antiseptic Antimildew agents 0.5-0.8 part and flatting agents 0.1-0.3 part. The elastic middle coating has excellent elasticity and adhesiveness, does not have poison to human bodies, and is healthy and environmentally friendly.

Owner:CHANGSHU WANXIANG PAINT

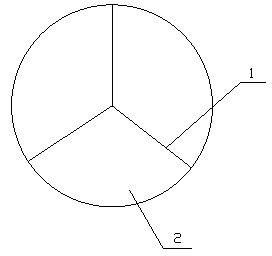

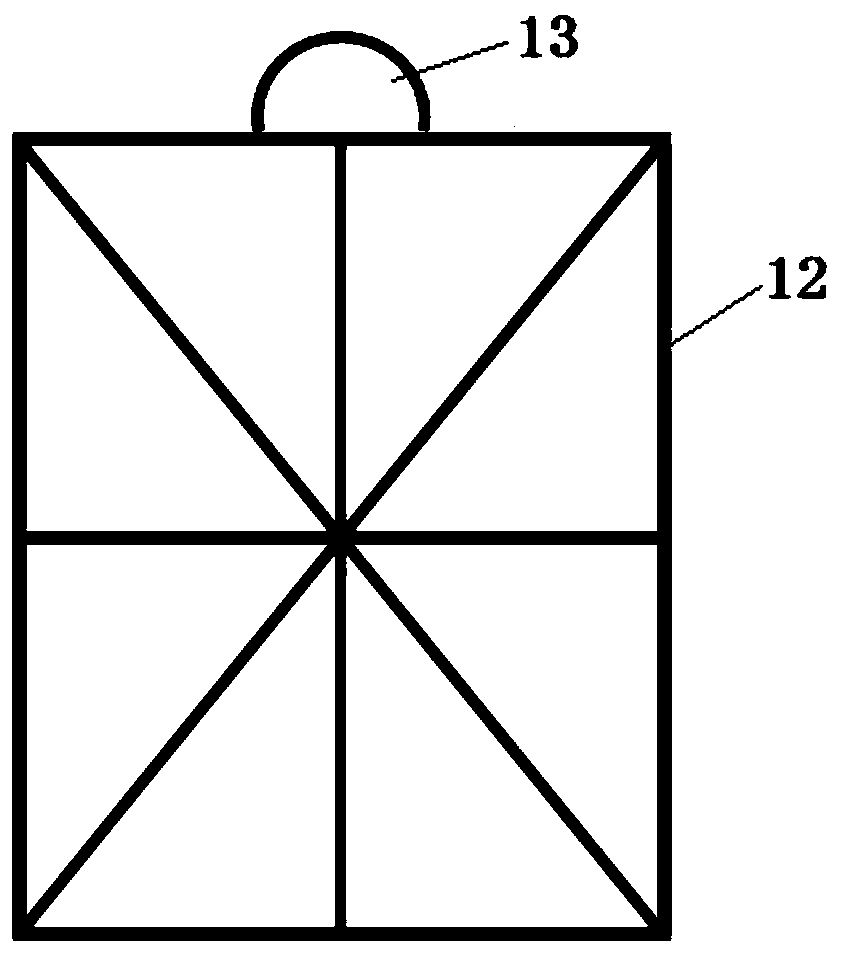

Novel combination mold

The invention discloses a novel combination mold. The novel combination mold comprises a mold body and a partition plate, wherein the mold body is a cylindrical shell; the diameter of the transverse section of the mold body is 150mm, and the height of the mold body is 50mm; the partition plate is independent of the mold body and is formed by connecting the single edges of three square partition plates; an opening angle of 120 degrees is formed between each two square partition plates; the length of each square partition plate is equal to the diameter of the mold body; the width of each square partition plate is equal to the height of the mold body; each of the mold body and the partition plate is made of stainless steel; the surface of the stainless steel is subjected to electrolytic treatment. In the mode, the novel combination mold has the advantages of smooth surface, high firmness, durability, abrasion resistance and corrosion resistance, delicate shape, excellent convenience and practicality and the like.

Owner:CHANGSHU CITY YINGTENGMOLD PARTS MFG

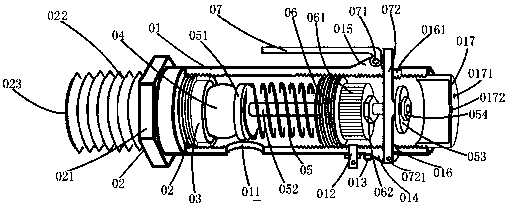

Multi-purpose safety valve

InactiveCN108799580ASimple structureExtend the lifespanEqualizing valvesSafety valvesSlurryEngineering

The invention discloses a multi-purpose safety valve. The multi-purpose safety valve is composed of a valve body, a diversion port, a pressure adjusting hole bolt, a chain pile, a valve opening rod base, a scrabbling rod base, a valve opening rod front window, a valve opening rod back window, a valve deck, a vent hole, a jacking bolt hole, a valve base, a hexagonal turn knob body, an external connector, a medium inlet, a valve element cylinder sleeve, a valve round ball, a jacking spring, a spring pressing disc, a pressing disc connecting rod, a clamping disc, a nut, a screw plug, a gear body,a sealing bolt, a quick opening scrabbling rod, a scrabbling rod shaft, a valve opening rod and a valve opening rod shaft. The multi-purpose safety valve can be suitable for different devices such asslurry pumping equipment, a pressure container, a boiler and an oil and gas storing tank and has the characteristics that the structure is simple and durable, the size is small, the valve element andthe valve can be replaced, the application range is wide, and the service life is long.

Owner:应鸽龙

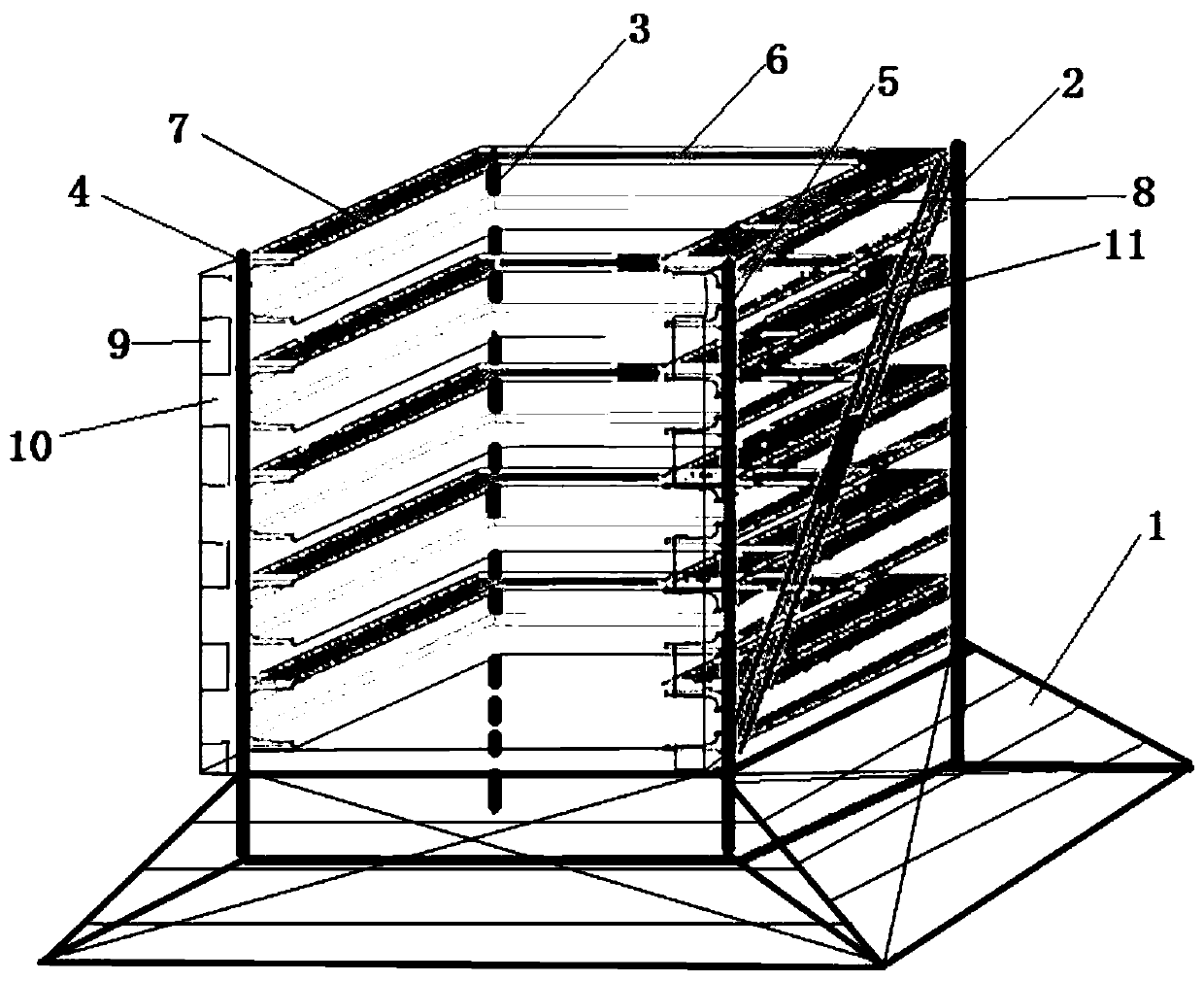

Scallop and stichopus japonicus bottom layer ecological comprehensive breeding device and use method thereof

ActiveCN110583544AIncrease growth rateIncrease profitClimate change adaptationPisciculture and aquariaStichopusFrame based

The invention discloses a scallop and stichopus japonicus bottom layer ecological comprehensive breeding device and a use method thereof, and belongs to the technical field of aquaculture. The scallopand stichopus japonicus bottom layer ecological comprehensive breeding device comprises a multi-layer stereoscopic supporting frame and breeding boxes. The multi-layer stereoscopic supporting frame is provided with a rectangular-pyramid-shaped frame base and a cuboid frame. A plurality of horizontal groove rail layers are arranged in the cuboid frame. Scallop or stichopus japonicus can be placedin a breeding net and placed in horizontal groove rails. A fence is installed for fixing breeding baskets, after the breeding baskets are put to a seabed, excrements of scallop bred on the upper layerand humus formed after scallop dies deposit and then enter the breeding baskets on the bottommost layer to become the food of stichopus japonicus, and the ecological comprehensive breeding effect isrealized.

Owner:大连市水产研究所 +1

Metal-based polymer material, polymer composite material and mold prepared from polymer composite material

The invention belongs to the technical field of composite materials, and particularly relates to a metal-based polymer material which comprises epoxy resin, modified epoxy resin, an epoxy diluent, a dispersing agent, an anti-settling aid, a polymerization aid, a defoaming agent, Ti, iron oxide powder, electrolytic iron powder, reduced iron powder, carbon black, Cr, Mn, Mg, Zn, Wc, Al and ceramic micro powder. The metal-based polymer composite material comprises a metal-based polymer material and a curing agent. The mold is made of a polymer composite material. The prepared mold is high in strength and hardness, small in contractibility and good in sedimentation resistance.

Owner:江苏九铸合金新材料有限公司

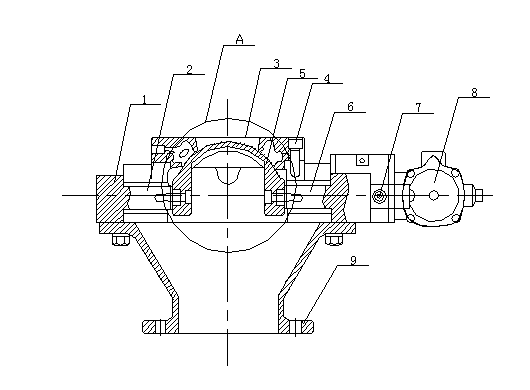

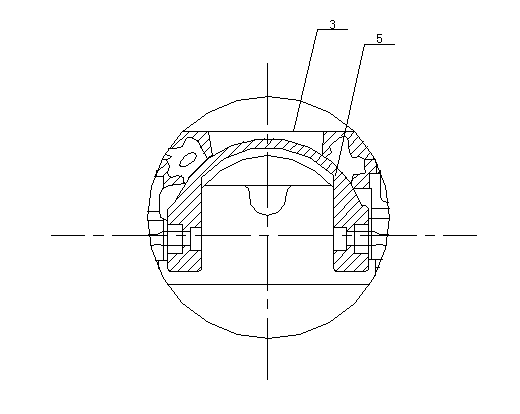

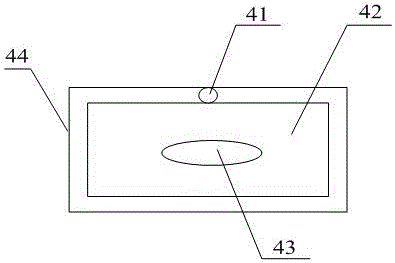

Novel dome valve

The invention discloses a novel dome valve and relates to the technical field of valves. A driven shaft (2) is arranged in a valve body (1), a top plate (3) is arranged at the upper end of the valve body (1), an expandable sealing ring (4) is arranged in the top plate (3), an arched valve clack (5) is arranged in the middle of the valve body (1), the driven shaft (2) is connected with a driving shaft (6), a proximity switch (7) is arranged on one side of the valve body (1), one end of the valve body (1) is connected with a double-acting air cylinder (8), and an outlet connector (9) is arranged at the lower end of the valve body (1). The novel dome valve is compact in structure, convenient to use, small in size, light, good in sealing effect, resistant to wear and corrosion, long in service life, suitable for processing dusty gas and erosiveness bulk materials and wide in application range.

Owner:KUNSHAN SHANGDAZHI MACHINERY

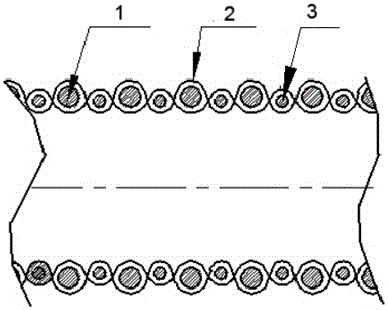

Woven multi-purpose exhaust-suction dual-use pipe and preparation technology thereof

The invention discloses a woven multi-purpose exhaust-suction dual-use pipe and a preparation technology thereof. The multi-purpose exhaust-suction pipe comprises a smooth inner rubber layer, a high-strength enhancement layer and a corrugated outer rubber layer, wherein the enhancement layer is woven through polyester monofilaments and plied polyester threads. The woven multi-purpose exhaust-suction dual-use pipe not only can transport liquids and gases but also can transport particles like cement powder, has the advantages of being light in weight, quick in water outlet, easy to be bent and coiled, high pressure resistant, negative pressure resistant, corrosion resistant, and the like, and the service life is prolonged.

Owner:NANTONG BECA MACHINERY TECH

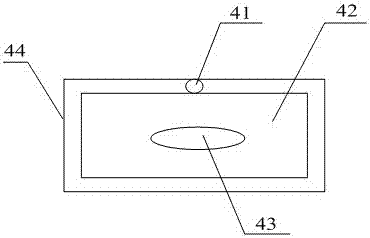

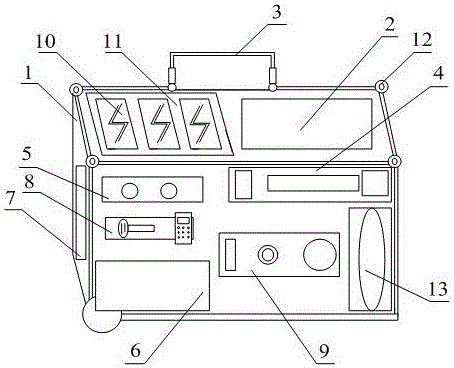

New energy battery device

InactiveCN107968176AReduce manufacturing costImprove work efficiencyBattery isolationSecondary cellsElectricityManufacturing cost reduction

The invention discloses a new energy battery device which includes a battery body, a battery, a handle, a detection device, an electric quantity detection lamp, a charging interface, a fixing plate, abar code marking apparatus, a converter, a battery assembly, a battery protective cover, a fixing nut, and a high-quality intelligent chip. The detection device is disposed on the front surface of the battery body. The electric quantity of the new energy battery device can be observed by means of the electric quantity detection lamp, so that manufacturing cost is reduced. Due to the fixing nut arranged on the outer part of the handle, the new energy battery device is flexible and practical and can increase work efficiency. By means of battery, the device has convenience in electricity storageand application, so that the device has completed functions. The device has a shell and is safe to use, has good waterproofing and insulation effect, and has wear-resistance and corrosion-resistance.The device solves the problems that a conventional battery structure is inconvenient to use, is high in cost, is poor in reliability and is incomplete in functions.

Owner:孝感市奇乐创意设计有限公司

New energy battery structure

InactiveCN106410306AWear-resistant and corrosion-resistantReduce manufacturing costBattery isolationSecondary cellsManufacturing cost reductionElectricity

The invention discloses a new energy battery structure. The new energy battery structure comprises a battery main body, a battery, a handle, a detection device, an electric quantity detection lamp, a charge port, a fixed plate, barcode mark equipment, a converter, battery modules, a battery protection sleeve, a fixed nut and an excellent intelligent chip, wherein the detection device is arranged on a front surface of the battery main body. In the new energy battery structure, the electric quantity can be viewed by the electric quantity detection lamp which is arranged, and the manufacturing cost is reduced; the fixed nut is arranged outside the handle, the new energy battery structure is flexible and practical, and the working efficiency is improved; by matching of the battery, power storage and power utilization are facilitated, and thus, the function diversity is improved; and moreover, the shell is beneficial for safety application, the new energy battery structure has a good waterproof insulation effect and has functions of wear resistance and corrosion resistance, and the problems that a traditional battery structure is not convenient to use, is high in cost and poor in reliability and is not perfect in function are effectively solved.

Owner:襄城县创世纪科技咨询有限公司

Preparation method of carbon fiber composite reinforced plate for vehicle and composite reinforced plate

ActiveCN106494061BHigh bonding strengthImprove impact resistanceSynthetic resin layered productsLaminationComposite plateAramid

The invention discloses a preparation method for a carbon fiber composite reinforced board used for a vehicle, and the composite reinforced board. The preparation method comprises the following steps: subjecting a carbon fiber braid ply and a glass fiber braid ply to superposition so as to obtain an inner fiberboard; mixing graphene oxide and first resin so as to obtain mixed resin; covering the surface of the superposed carbon fiber braid ply and glass fiber braid ply with the mixed resin and carrying out primary compression molding so as to obtain an inner composite board; and covering the outer side of the inner composite board with a hybrid braid ply prepared through two-dimensional hybrid braiding of aramid fiber and polyethylene fiber, covering the surfaces of the hybrid braid ply and the inner composite board with second resin and a foaming agent and carrying out secondary compression molding so as to obtain the composite reinforced board. The composite reinforced board prepared by using the method has high strength, high modulus and good impact resistance.

Owner:BEIJING AUTOMOTIVE IND CORP +1

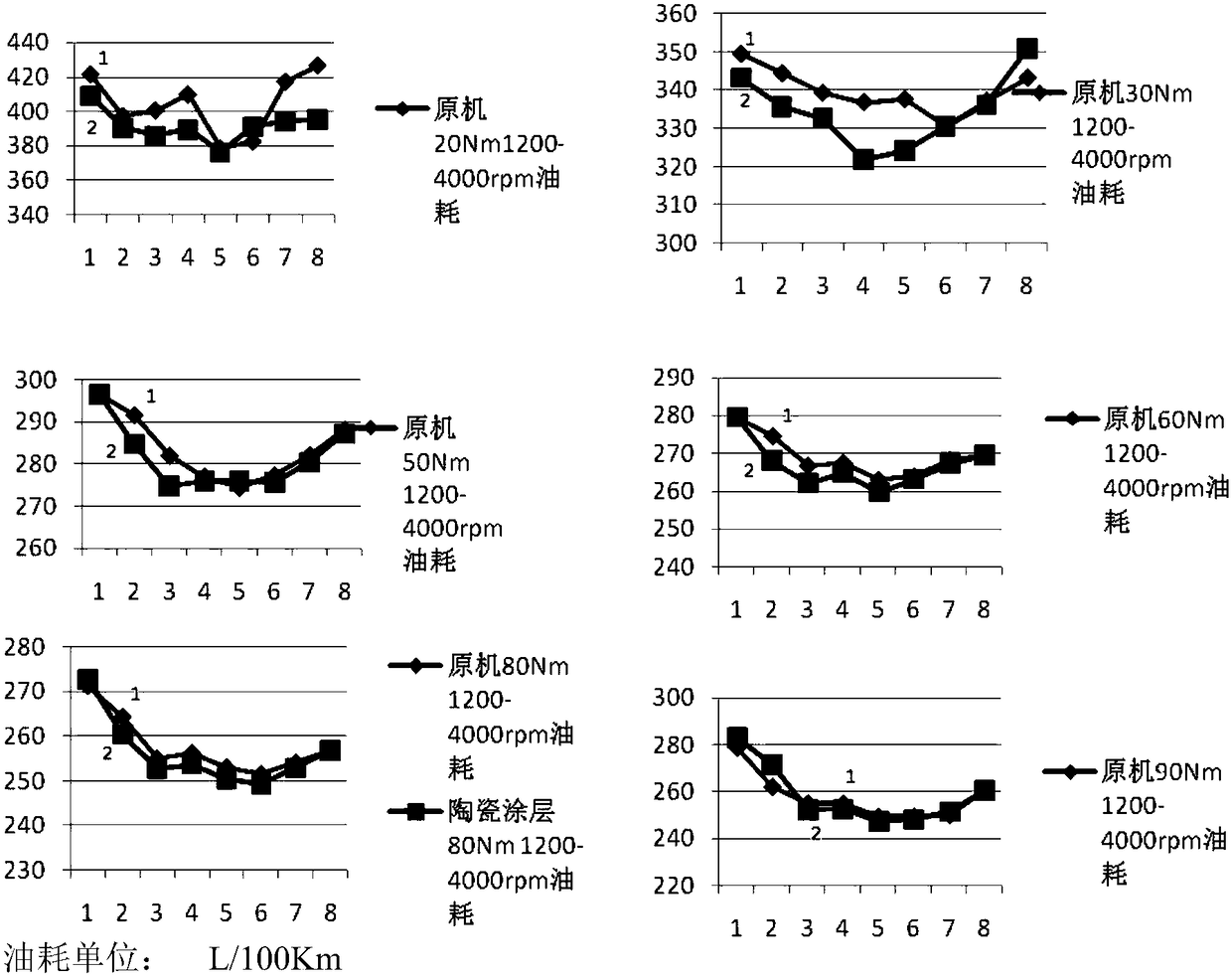

Nano graphene reflective heat insulation composite multifunctional ceramic coating and preparation method thereof

ActiveCN105951151BAchieve thicknessAchieve hardnessAnodisationCombustion chamberPlasma electrolytic oxidation

The invention discloses a reinforced alloy material; and a surface layer of the alloy material contains such elements as aluminum oxide, silicon dioxide and nanometer graphene. The alloy material is deeply extended on the basis of anodic oxidation, microarc oxidation and multi-component composite oxidation, and is a result under a complex effect of instant high temperature, multi-component composite oxidation liquid and nanometer penetrant through applying positive and negative high voltage, high current and positive and negative pulses by using unique structures, physical and chemical characteristics as ultrahigh hardness and high-temperature resistance, small size effects and surface and interface effects of such nanometer materials as nanometer graphene and nanometer silicon dioxide. The method comprises the steps of: (1) surface cleaning; (2) oxidation; and (3) penetration. The light alloy material after surface reinforcement by the method, in particular a combustion chamber of an internal combustion engine with fuel combustion consumption and generating a pollution source is prominent in reflection thermal insulation anti-carbon self catalysis function, and is higher in high-temperature erosion resistance and wear resistance.

Owner:四川鸿森达铝业科技有限公司

Amorphous soft magnetic alloy coatings and preparation method thereof

ActiveCN101441915BSimple processLess stress sensitiveMolten spray coatingMagnetic/electric field screeningMetallurgyMaterials science

The present invention relates to an amorphous soft magnetic alloy coating and the preparation method thereof, particularly relates to Fe-Co base amorphous soft magnetic alloy coating, characterized in that: (1) the sum of atom percentage content of Fe and Co is no less than 70&; (2) basically the coating is in amorphous structure. The invention also relates to the usage of the coating and the preparation method thereof.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com