TC4 titanium alloy metal powder core flux-cored welding strip and preparation method thereof

A technology of metal powder core and titanium alloy, which is applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems that the composition of titanium alloy solid welding strip is difficult to control, and the surfacing cladding layer is difficult to meet, so as to increase the strength, The effect of reducing corrosion resistance and improving plastic toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

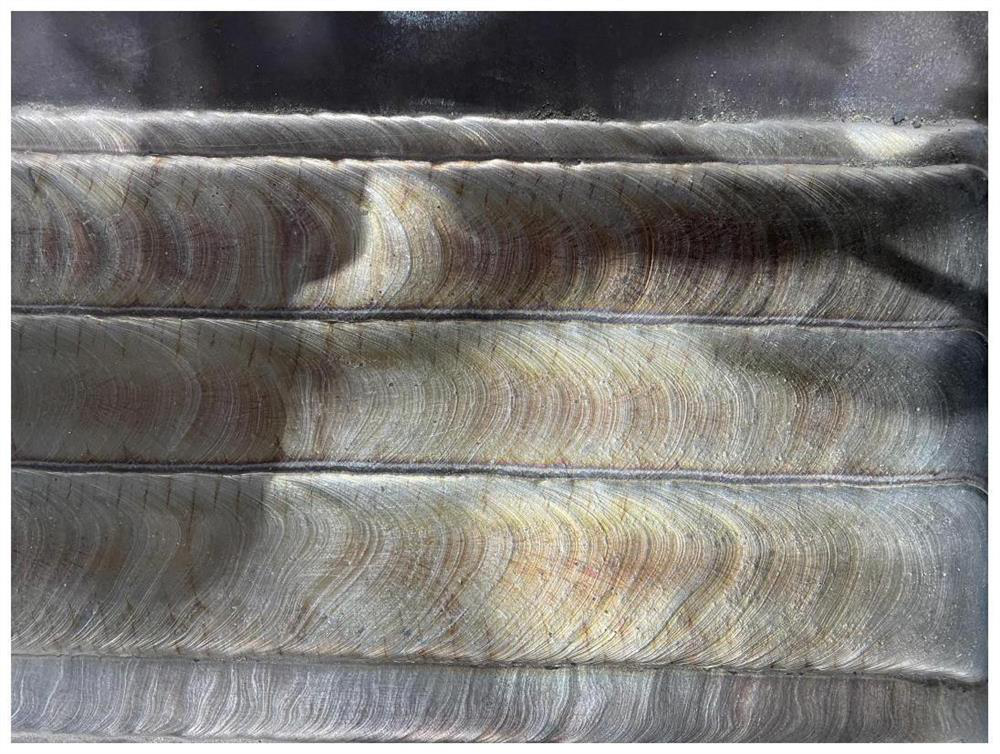

Embodiment 1

[0036]Example 1: A TC4 titanium alloy metal powder core flux cored ribbon of this example is composed of a Ti-9Mo-3Nb-3V titanium alloy skin and a metal powder core filled therein; the metal powder core is composed of vanadium according to mass fraction Powder: 6%, aluminum powder: 13%, molybdenum powder: 3%, iron powder: 4%, silicon powder: 1.5%, nickel powder: 6% and the balance titanium powder are mixed. The particle size of the Ti-9Mo- The element composition and mass content of each element in the outer skin of 3Nb-3V titanium alloy are: Mo: 8.5%, Nb: 3.0%, V: 2.9%, Al: 3.7%, H≤0.010%, O≤0.020%, N≤0.020% , the balance is Ti, the thickness of the Ti-9Mo-3Nb-3V skin is 0.40mm, the width is 16mm, and the length is 100m, and the filling rate of the metal powder core in the TC4 titanium alloy metal powder core flux cored ribbon is 26 %;

[0037] The preparation method of the above-mentioned titanium alloy metal powder-cored flux-cored welding ribbon is carried out according ...

Embodiment 2

[0044] Example 2: A TC4 titanium alloy metal powder core flux cored ribbon of this example is composed of a Ti-9Mo-3Nb-3V titanium alloy skin and a metal powder core filled therein; the metal powder core is composed of vanadium in mass fraction Powder: 7%, aluminum powder: 17%, molybdenum powder: 5%, iron powder: 5%, silicon powder: 3%, nickel powder: 8% and the balance of titanium powder. The particle size of the vanadium powder, molybdenum powder and iron powder is 80 mesh to 200 mesh, the particle size of the silicon powder and nickel powder is 60 mesh to 100 mesh, and the Ti powder The composition of elements and the mass content of each element in the outer skin of -9Mo-3Nb-3V titanium alloy are: Mo: 9%, Nb: 3.1%, V: 3.1%, Al: 4.0%, H≤0.010%, O≤0.020%, N ≤0.020%, the balance is Ti, the thickness of the Ti-9Mo-3Nb-3V titanium alloy skin is 0.50mm, the width is 18mm, and the length is 120m, and the metal powder core in the TC4 titanium alloy metal powder core flux cored rib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com