Fire-resistant weather-proof steel plate for 690MPa-grade building structure and manufacturing method thereof

A building structure, fire-resistant and weather-resistant technology, applied in the field of fire-resistant and weather-resistant steel plates for building structures, can solve problems such as poor welding performance, intensification strength, and pass deformation rate limitation, and achieve high temperature strength and weather resistance. The effect of improving product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

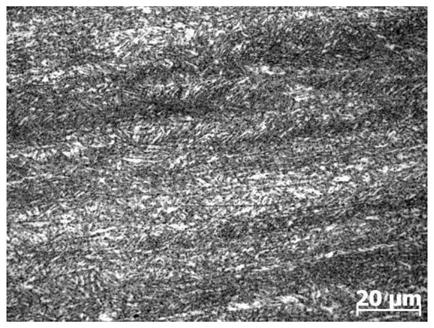

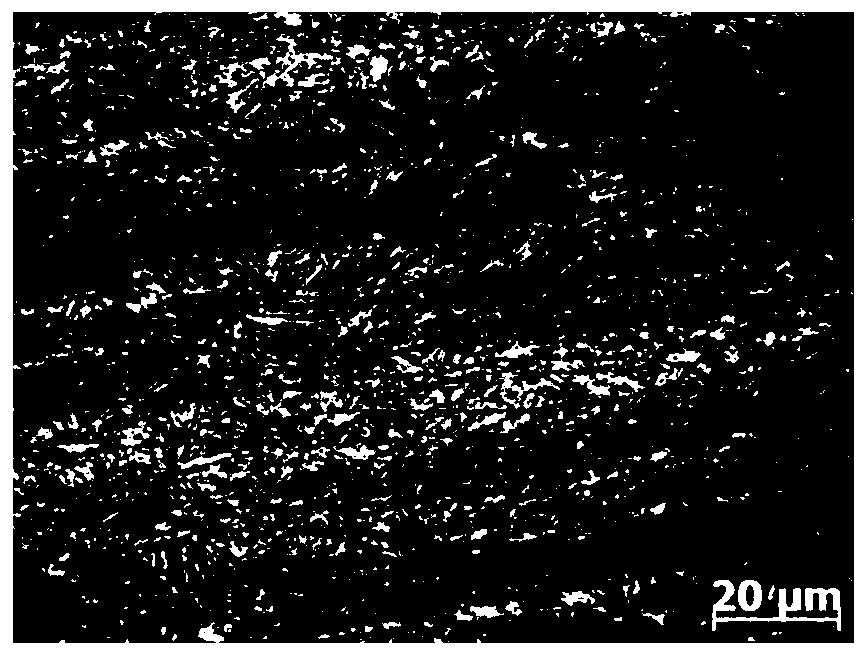

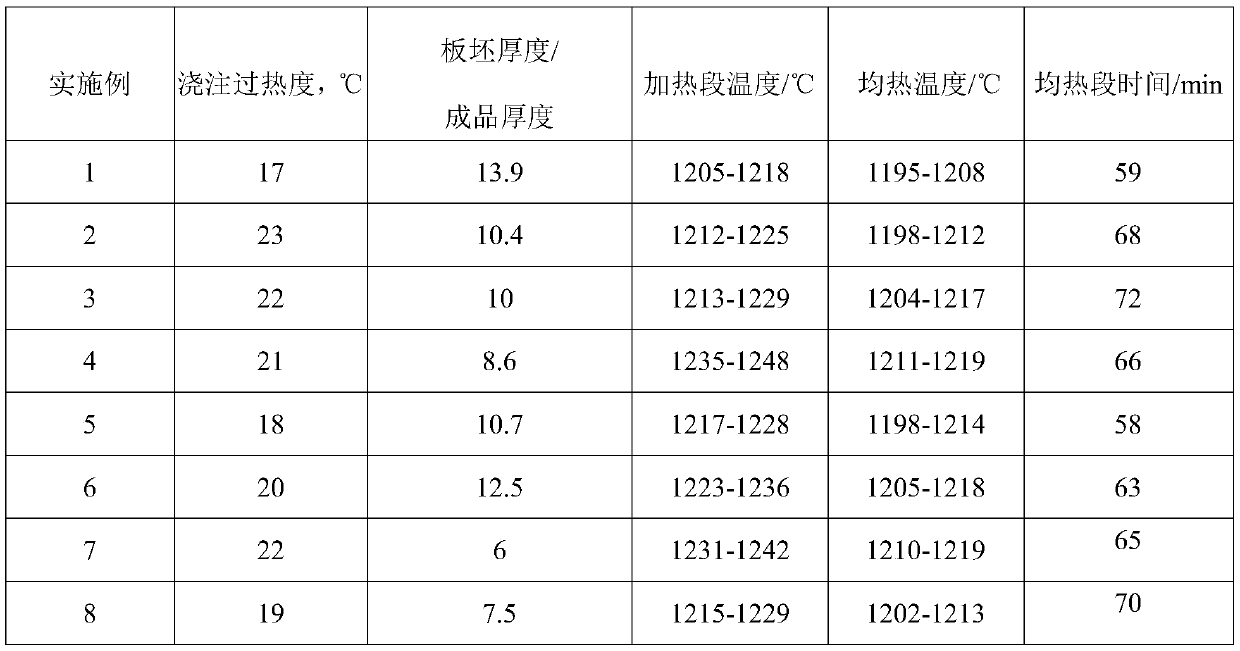

[0049] The chemical composition of the embodiment of the present invention is shown in Table 1; the smelting continuous casting and slab heating process of the corresponding embodiment is shown in Table 2; the rough rolling process of the corresponding embodiment is shown in Table 3; the finish rolling process of the corresponding embodiment is shown in Table 4; The cooling and heat treatment systems of the examples are shown in Table 5; the properties and microstructure ratios of the corresponding examples are shown in Table 6; the corrosion rates of the corresponding examples are shown in Table 7. The metallographic structure diagram of embodiment 3 is as figure 1 shown.

[0050] The chemical composition wt% of the embodiment of the present invention in table 1

[0051] Example C Si mn P S Ni Cu Mo Nb V Ti B Al 1 0.064 0.25 1.42 0.009 0.003 0.71 0.72 0.23 0.078 0.064 0.020 0.0023 0.015 2 0.072 0.36 1.22 0.008 0.002 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com