Hot spraying process of metal ceramic coating on surface of valve rod

A technology of ceramic coating and surface metal, applied in the direction of metal material coating process, coating, molten spraying, etc., can solve the problems of low coating adhesion, peeling, easy cracks, etc., to improve wear resistance and corrosion resistance Performance and high temperature thermal shock resistance, improve the bonding strength of the coating, and prevent the coating from overheating and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

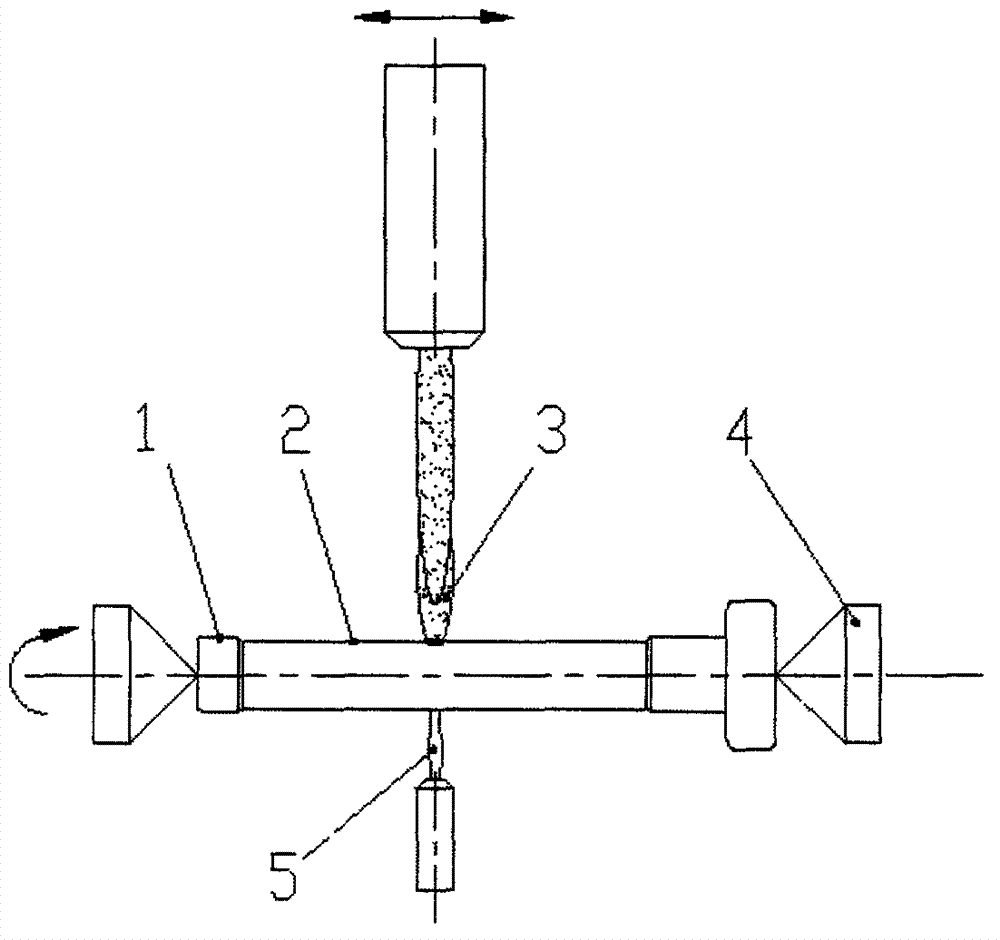

[0018] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. Spray Cr on a stem surface 3 C 2 -NiCr cermet powder as an example, the specific process is as follows:

[0019] Mechanical pre-processing, according to the parts of the valve stem (1) that are easy to be worn or corroded, determine the surface range to be sprayed, leave shoulders at both ends of the sprayed surface, try to avoid the sprayed surface on the end face of the shaft, and in the required sprayed parts (2) The depth of undercut is 0.25mm. The depth of undercut is determined according to the coating thickness of 0.2-0.3mm to be sprayed, and a certain margin is reserved.

[0020] Surface purification, degreasing with organic solvents, washing with water, and drying to purify the surface to be sprayed.

[0021] Surface roughening, use sandblasting equipment to sandblast the surface to be sprayed, the surface is roughened to Ra2.5~13μm, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com