Multi-purpose safety valve

A safety valve, multi-purpose technology, applied in the direction of safety valve, balance valve, valve device, etc., can solve the problems of not being able to use one valve for multiple purposes, less versatility, and the valve sealing structure has particles, etc., and achieves simple and convenient manufacturing and adjustment. The effect of convenience and extended use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

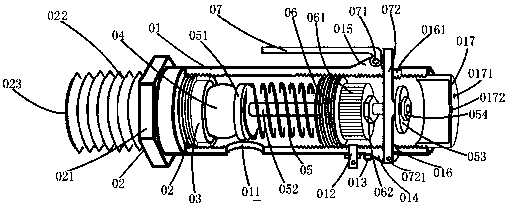

[0018] Such as figure 1 As shown, the multipurpose safety valve of the present invention can be installed horizontally on the upper part of the material box wall of pumping machinery such as slurry, putty, and paint after the working pressure is adjusted, and the device is fixed by the external joint 022 and then transported with the slurry, putty, and paint. The mechanical feeding pipe is connected by a three-way connection, and the diversion port 011 faces the material box. During the feeding process of the machine, if the feeding pipe is blocked or the front tool is temporarily closed and no feeding is required, the slurry in front of the valve ball 04 in the feeding pipe The pressure of the material, putty and paint increases, and when the pressure is stronger than the pressure of the top pressure spring 05, the pressure of the slurry, putty and paint presses the ball 04 of the valve core to separate from the cylinder liner of the valve core, and the slurry, putty and paint...

Embodiment 2

[0020] Such as figure 1 As shown, the multi-purpose safety valve of the present invention is connected with the air storage tank of the air compressor or a separate high-pressure air storage tank, and the gear body 061 is moved with a screwdriver, and the required working pressure is adjusted through the pressure gauge indication, so that the pressure can be kept constant. Balanced, play a safe explosion-proof role.

Embodiment 3

[0022] Such as figure 1 As shown, the multi-purpose safety valve of the present invention after being checked and debugged by the relevant quality inspection department is connected to the toxic chemical gas storage tank. When the pressure exceeds the specified value, the valve ball 04 will automatically open, and the toxic chemical gas will be transferred to the empty tank of harmful chemical gas through the diversion port. When the pressure of the toxic chemical gas is within the specified value range, the valve ball 04 will be automatically closed, so as to achieve explosion-proof , Anti-leakage safety protection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com