Ordered extralarge-hole-pitch alumina film and preparation method thereof

An aluminum oxide film, super-porous technology, applied in anodizing, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of high price of ethylphosphoric acid, difficult practical application, poor reproducibility, etc., and achieve obvious results. Photoluminescence performance, good industrial application prospect, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing an aluminum oxide film with an ordered ultra-large pore spacing, comprising the following steps:

[0028] Step 1: Prepare polished aluminum sheet: use high-purity aluminum sheet (≥99.999%) as the anode, perform electrochemical polishing in a mixture of perchloric acid and absolute ethanol with a volume ratio of 1:4, and the polishing voltage is 20 V , the polishing temperature is 0 ºC, and the polishing time is 10 minutes to obtain a polished aluminum sheet;

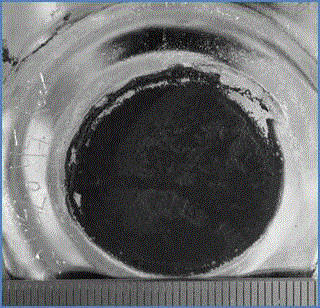

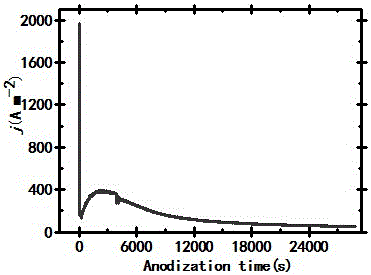

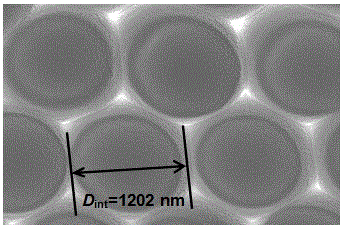

[0029] Step 2: Preparation of aluminum oxide film: use a polished aluminum sheet as the anode, and perform anodic oxidation in a citric acid electrolyte with an oxidation voltage of 560 V, an oxidation temperature of 10 ºC, and an oxidation time of 7 h to form an aluminum oxide film with an aluminum substrate. film, the optical image of the oxide film is shown in the attached figure 1 , the current density-time variation curve of the oxidation process is as follows figure 2 , it can be se...

Embodiment 2

[0035] A method for preparing an aluminum oxide film with an ordered ultra-large pore spacing, comprising the following steps:

[0036]Step 1: Prepare polished aluminum sheet: use high-purity aluminum sheet (≥99.999%) as the anode, perform electrochemical polishing in a mixture of perchloric acid and absolute ethanol with a volume ratio of 1:3, and the polishing voltage is 18 V , the temperature was -5°C, and the polishing time was 11 minutes to obtain a polished aluminum sheet;

[0037] Step 2: Preparation of aluminum oxide film: use the polished aluminum sheet as the anode, perform anodic oxidation in the electrolyte of malic acid and methanol, the oxidation voltage is 800 V, the oxidation temperature is -10 ºC, and the oxidation time is 8 h to form a band Aluminum oxide film with aluminum substrate;

[0038] Step 3: Prepare an aluminum sheet with ordered pits: immerse in a mixture of 6 wt% chromic acid and 7 wt% phosphoric acid to remove the aluminum oxide film. The immers...

Embodiment 3

[0042] A method for preparing an aluminum oxide film with an ordered ultra-large pore spacing, comprising the following steps:

[0043] Step 1: Prepare polished aluminum sheet: use high-purity aluminum sheet (≥99.999%) as the anode, perform electrochemical polishing in a mixture of perchloric acid and absolute ethanol with a volume ratio of 1:3.5, and the polishing voltage is 20 V , the polishing temperature is 20°C, and the polishing time is 9 minutes to obtain a polished aluminum sheet;

[0044] Step 2: Preparation of aluminum oxide film: use the polished aluminum sheet as the anode, and the graphite electrode as the cathode, perform anodic oxidation in the electrolyte of citric acid and methanol, the oxidation voltage is 580 V, the oxidation temperature is 5 ºC, and the oxidation time is 6 h, forming an aluminum oxide film with an aluminum substrate;

[0045] Step 3: Form the aluminum sheet with ordered pits: immerse in a mixture of 4 wt% chromic acid and 8 wt% phosphoric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com