Patents

Literature

71results about How to "Thickness control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

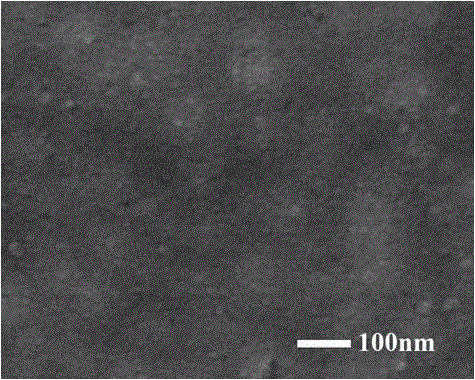

Si@C lithium-ion battery negative electrode material of core-shell structure and preparation method thereof

ActiveCN107359326AFacilitated DiffusionImproved magnification performanceMaterial nanotechnologyCell electrodesCarbon layerChemical reaction

The invention discloses an Si@C lithium-ion battery negative electrode material of a core-shell structure and a preparation method thereof. The material uses a metal organic frame compound MOFs as a carbon source, and comprises a core and a cladding layer, the core is spherical nanometer silicon, and the cladding layer is an amorphous carbon layer of a porous structure. The material is prepared through the following steps: A, surface activation of nanometer silicon; B, preparation of an Si@MOFs precursor; and C, preparation of Si@C. The carbon layer in the obtained composite material is of good electrical conductivity and an abundant porous structure, quick transfer of electrons and diffusion of electrolyte ions are facilitated, the volume expansion of the core in the electrochemical reaction process can be effectively buffered, and the composite material has excellent electrochemical performance; and the preparation method is simple in production technology, easily controlled for reaction conditions and environmentally-friendly, and is beneficial for performance optimization and industrial production of silicon negative electrode materials.

Owner:XUZHOU NORMAL UNIVERSITY

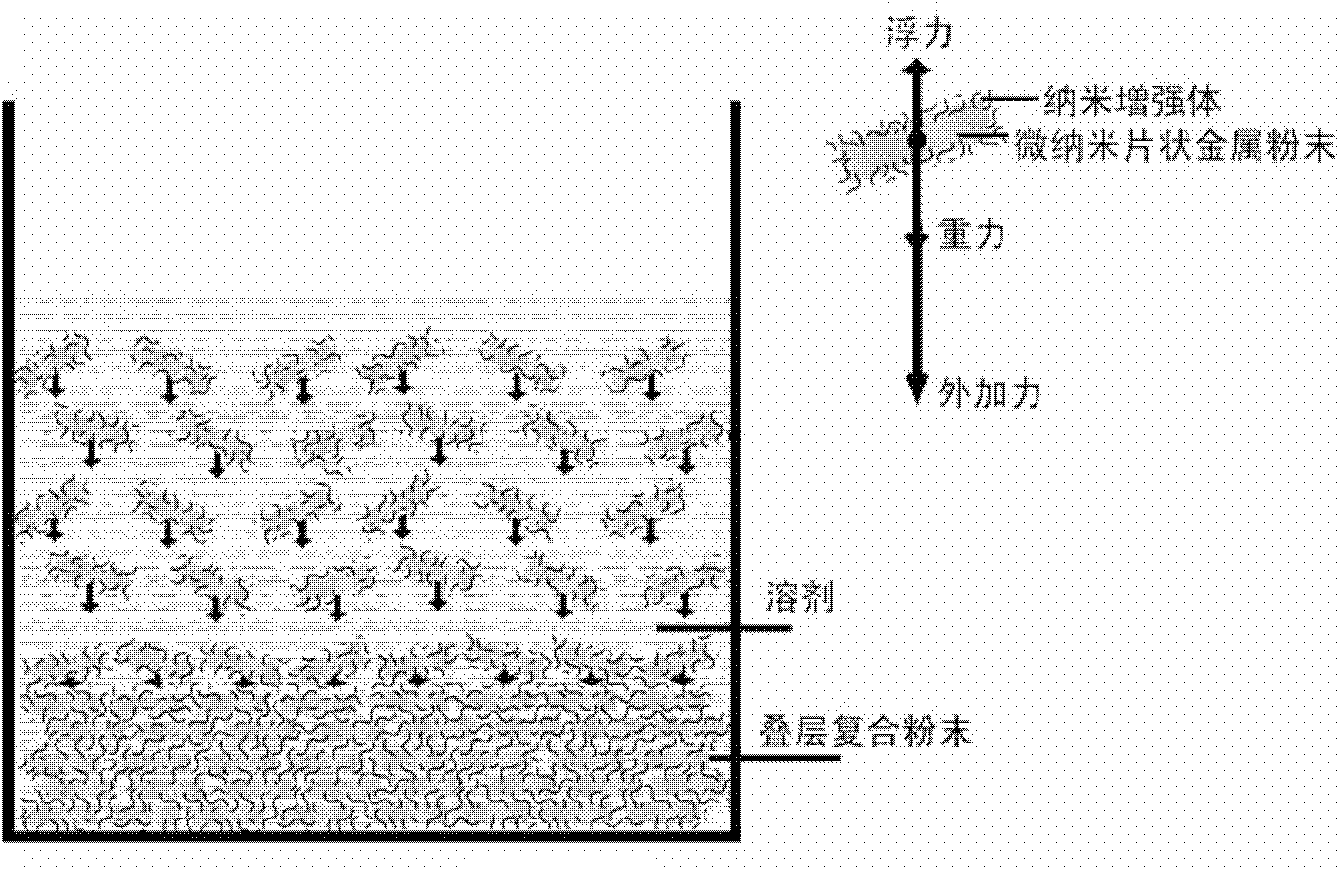

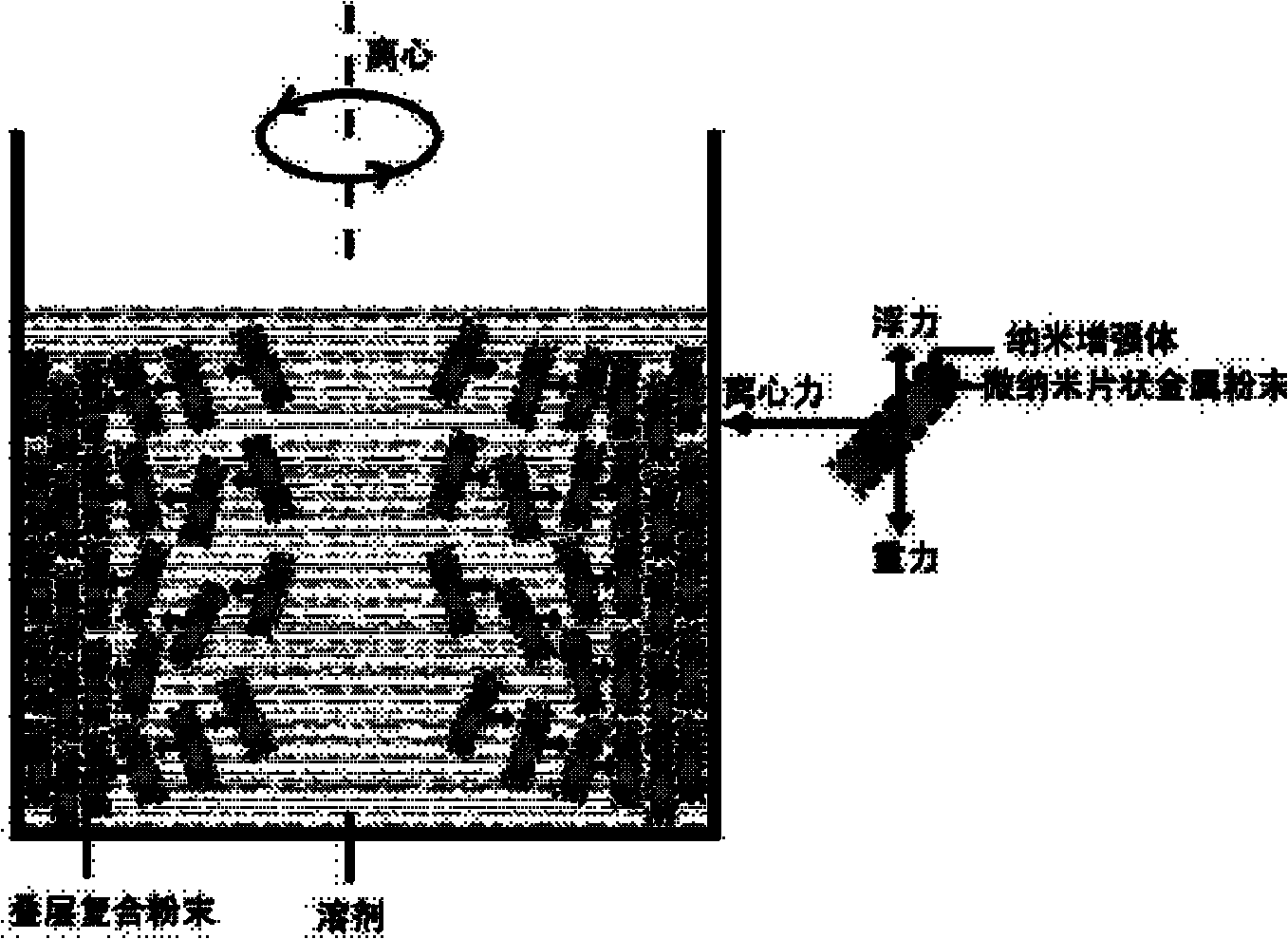

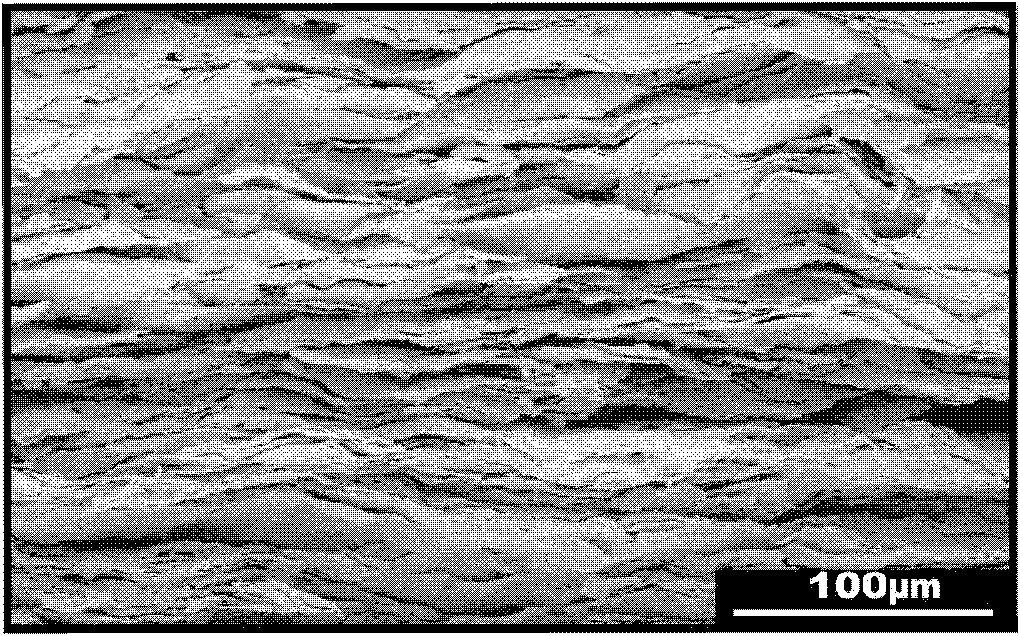

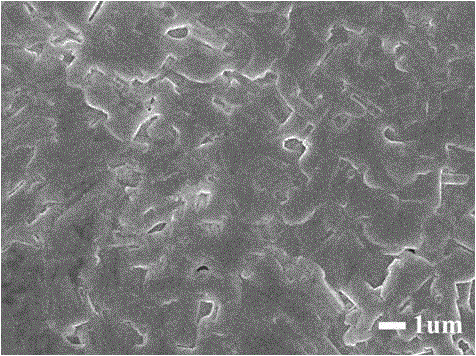

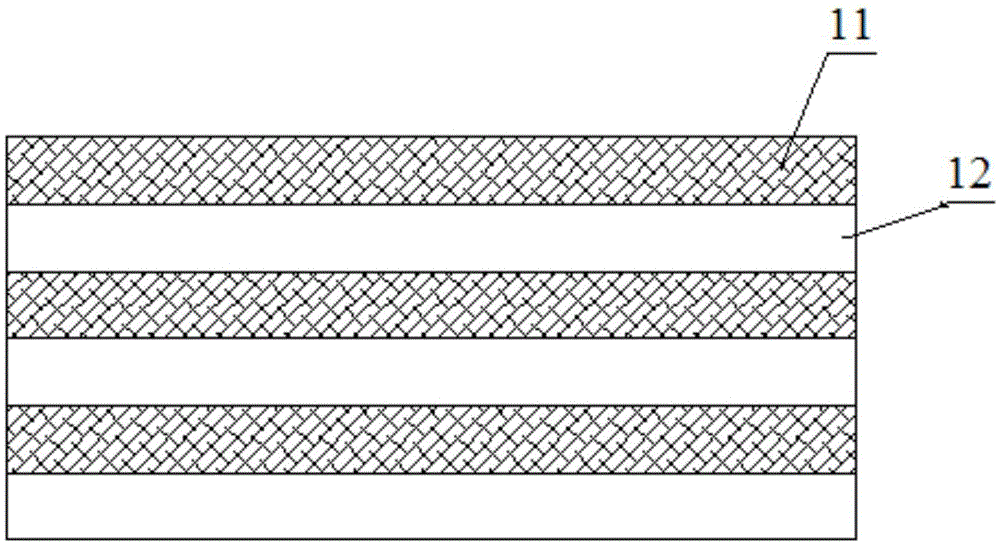

Preparation method of micro-nano lamination metal base composite material

The invention discloses a preparation method of micro-nano lamination metal base composite material. Micro-nano flaky metal powder is added into solvent and then is prepared into flaky metal powder slurry, and the flaky metal powder slurry and nano reinforcement slurry are blended to ensure that the surface of the flaky metal powder evenly adsorbs the nano reinforcement and forms composite powder slurry; the metal powder slurry naturally stands to ensure that the flaky metal powder is parallel to the horizontal direction and subsides under the action of gravity, or an external force field is applied to accelerate flaky metal powder to be horizontally arranged and piled up; the solvent is removed to obtain lamination composite powder; and finally, the lamination composite powder is performed with densifying treatment to obtain compact micro-nano lamination metal base composite material. The method of the invention can prepare block micro-nano lamination metal base composite material, is environment-friendly, is simple, has high efficiency and is suitable for volume production.

Owner:SHANGHAI JIAO TONG UNIV

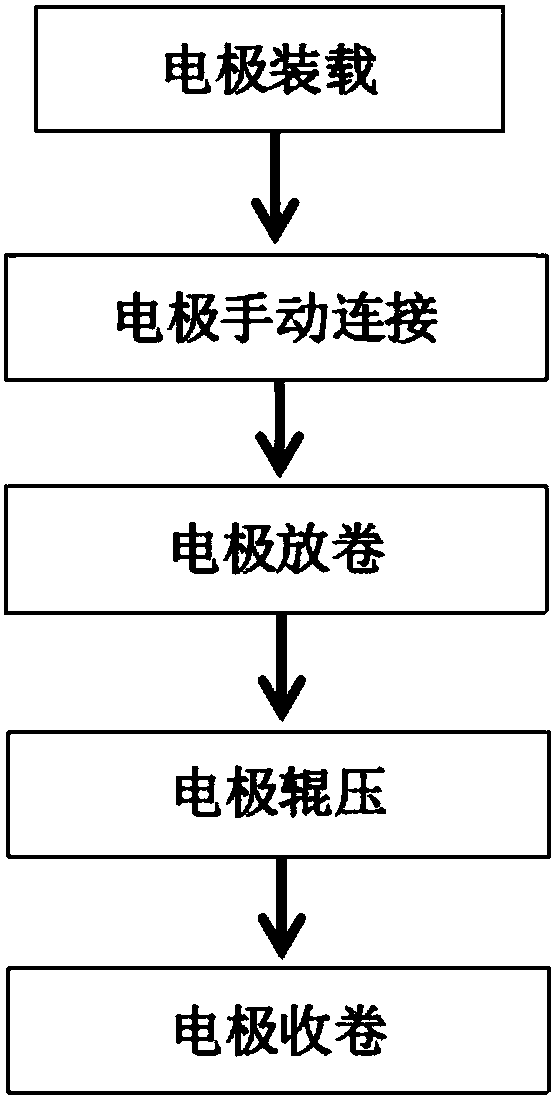

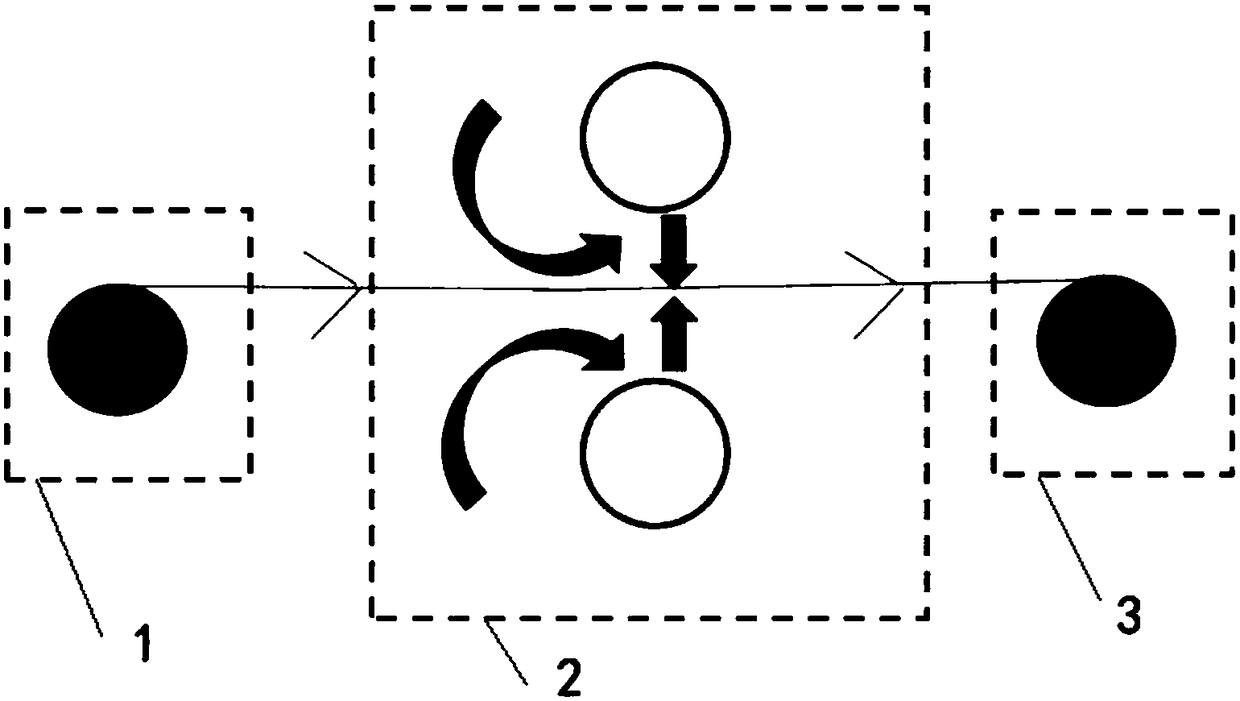

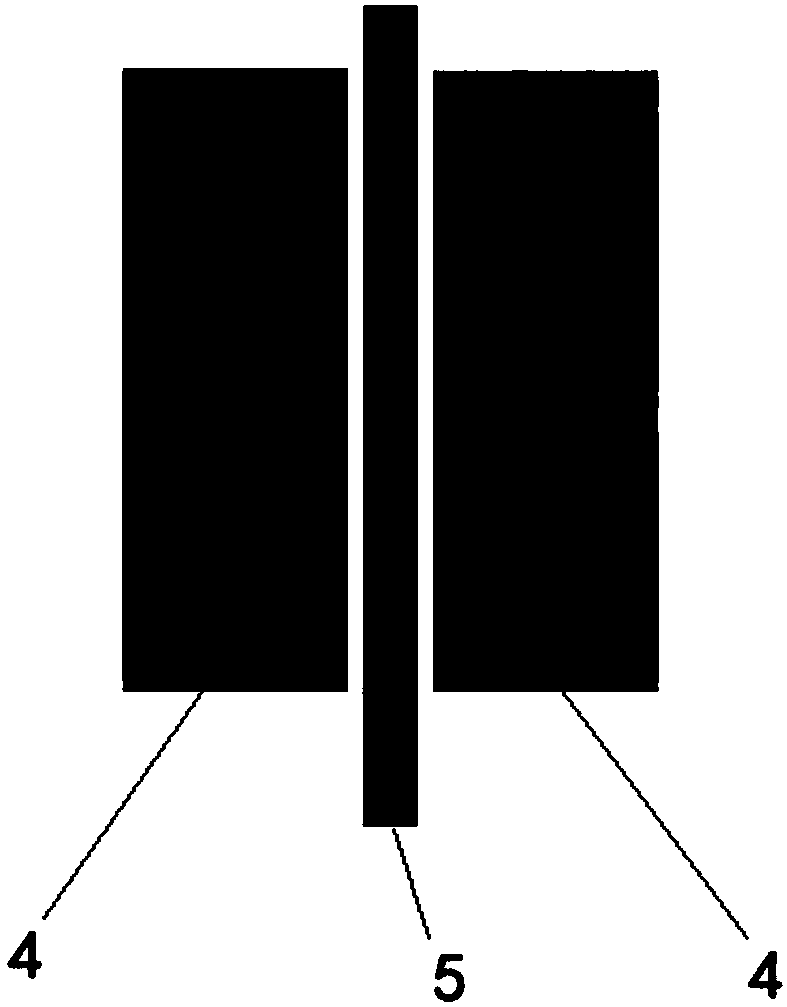

Rolling method and equipment for battery pole piece

ActiveCN108199005AImprove consistencyImprove defects such as poor snake shapeElectrode manufacturing processesElectrical batteryPole piece

The invention relates to the technical field of lithium-ion battery manufacturing, in particular to a rolling method for a battery pole piece. The method comprises the steps of making the coated and dried battery pole piece pass through a foil heating device, an electrode preheating device, an electrode rolling device and a thickness curing device in sequence; when the battery pole piece passes through the foil heating device, heating a foil area of the battery pole piece by using the foil heating device; when the battery pole piece passes through the electrode preheating device, heating a coating area of the battery pole piece by using the electrode preheating device; when the battery pole piece passes through the electrode rolling device, applying rolling force of different sizes to theedge part and the middle part of the battery pole piece by using the electrode rolling device to roll the battery pole piece; and when the battery pole piece passes through the thickness curing device, sequentially baking and cooling the battery pole piece by using the thickness curing device. The invention further provides rolling equipment for the battery pole piece. According to the rolling method and the rolling equipment, the thickness consistency of the rolled battery pole piece is effectively improved.

Owner:ZHEJIANG FOREVER NEW ENERGY TECH CO LTD +1

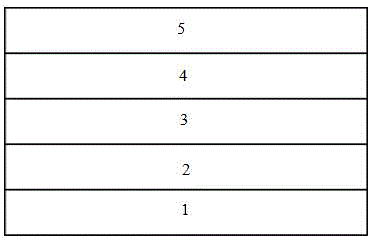

Method for preparing graphene/Ag composite conductive film

The invention belongs to the technical field of inorganic functional materials, and discloses a method for preparing a graphene / Ag composite conductive film. The method provided by the invention is characterized in that a graphene oxide / Ag sol precursor is adopted; and the graphene / Ag composite conductive film which is transparent is obtained by a dip-coating method and heat treatment. The method provided by the invention has the advantages that the dip-coating method is adopted; the viscosity of the graphene oxide / Ag sol precursor is changed by control of a volume ratio of graphene oxide to Ag sol; control of film thickness, film transmittance and film conductivity is realized through control of frequency of dip-coating processes; the method provided by the invention has a simple flow and can be operated easily.

Owner:JIANGSU UNIV

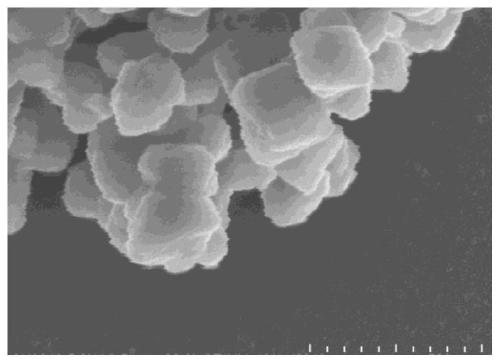

Preparation method of MOF-metal nanoparticle-COF-based composite material

The invention discloses a preparation method of the MOF-metal nanoparticle-COF composite material. The method comprises the following steps: dispersing MOF into a solution containing a metal ion precursor, adding a sodium borohydride solution or performing illumination reduction, or performing hydrogen reduction after centrifugation to obtain the MOF-metal nanoparticle composite material. Activating at a high temperature of 120-150 DEG C and then dispersing in 1, 3-butanediol; the method comprises the following steps: adding 1, 4-dioxane and mesitylene into a mixed solvent of 1, 4-dioxane andmesitylene; then adding a small amount of aldehyde group organic ligand and ultrasonically and uniformly mixing; subsequent addition of acetic acid, adding a corresponding amount of amino organic ligand, and continuously stirring for a period of time to obtain an MOF-metal nanoparticle-COF seed crystal compound; and adding an aldehyde group organic ligand and an amino group organic ligand, uniformly stirring and mixing, adding a corresponding amount of acetic acid, and continuously stirring, heating and preserving heat to obtain the MOF-metal nanoparticle-COF compound. Covalent binding of thetwo materials is achieved through a Schiff base reaction between aldehyde groups on the surfaces of the seed crystals and amino groups on the surfaces of the MOF materials, the binding force is stableand firm, the preparation method is simple, the method can be used for mass production, and traditional high-temperature and high-pressure reaction conditions are not needed in the compounding process.

Owner:UNIV OF SCI & TECH BEIJING

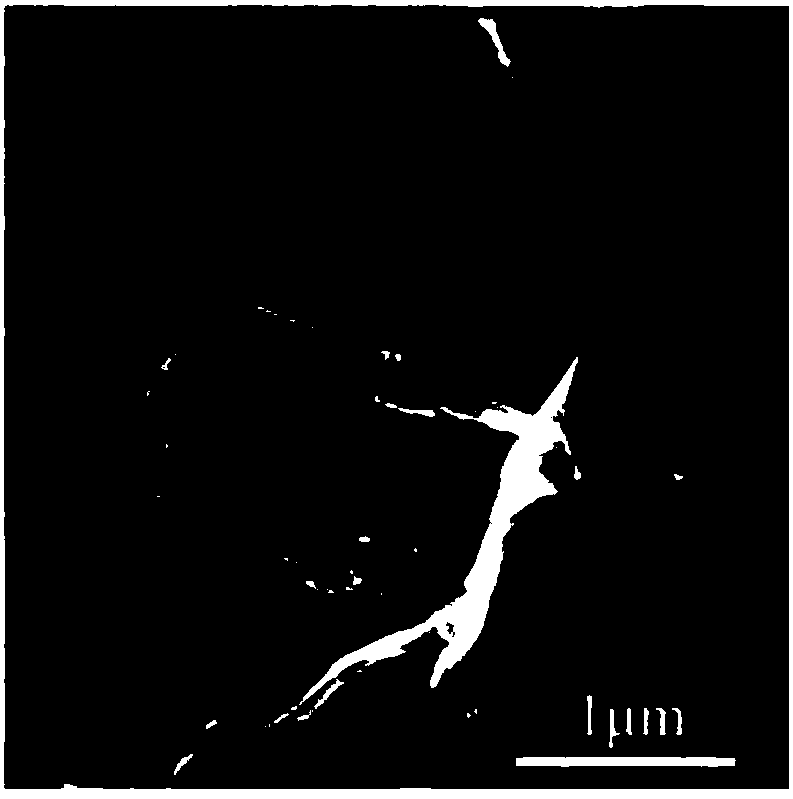

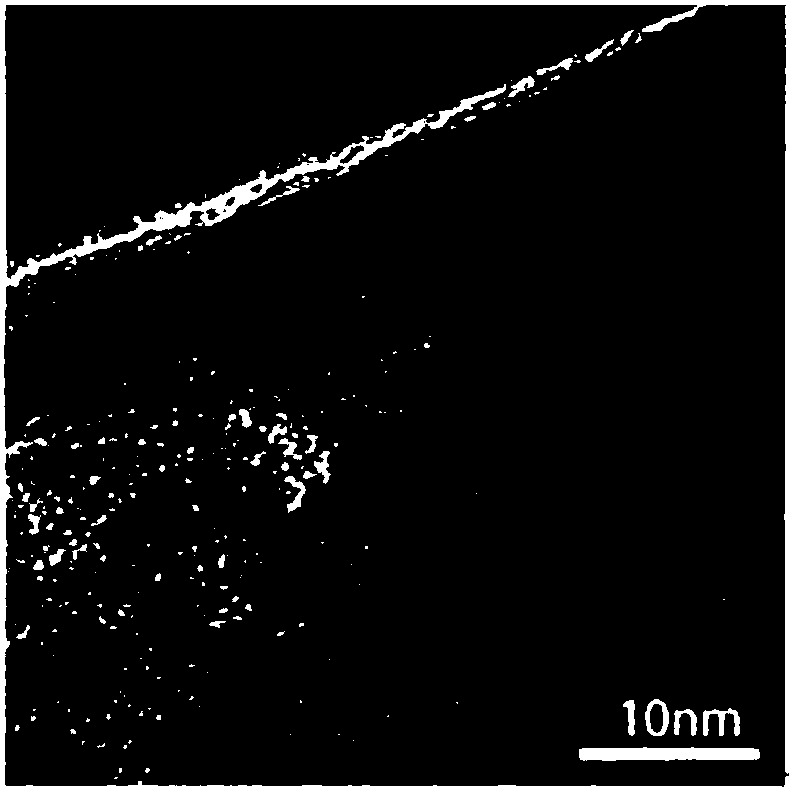

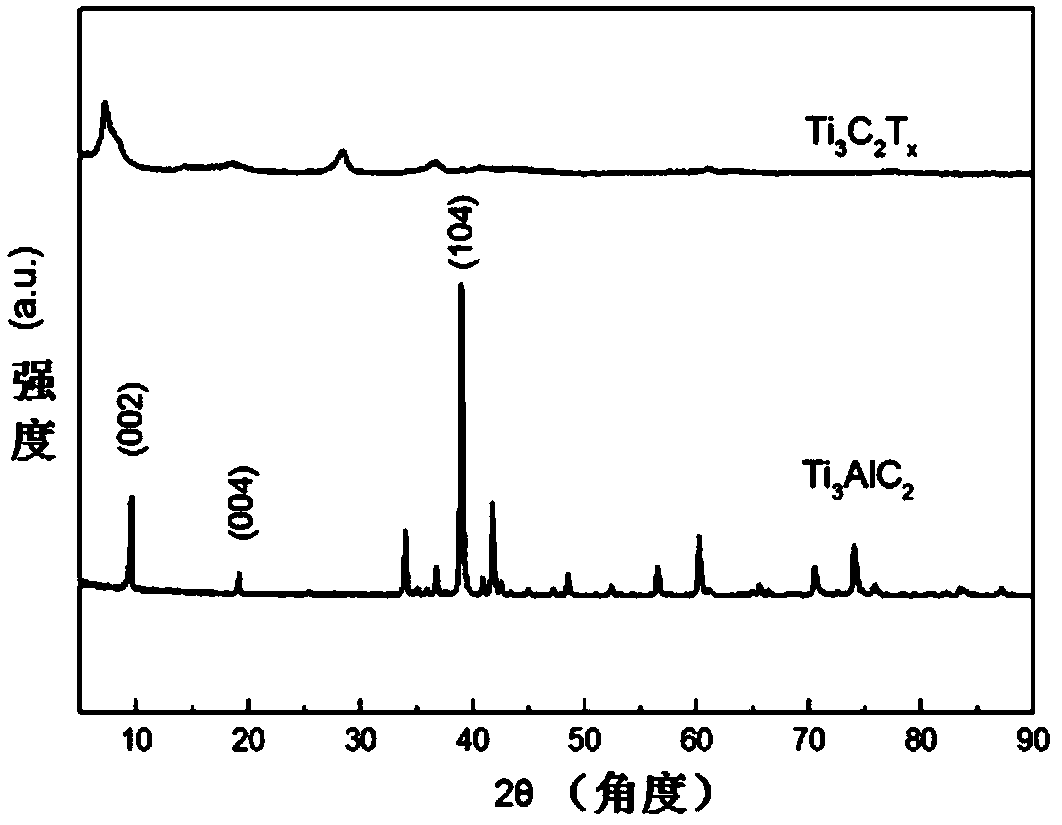

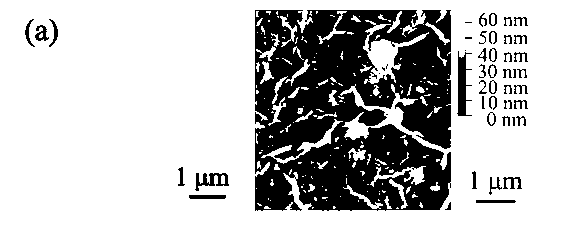

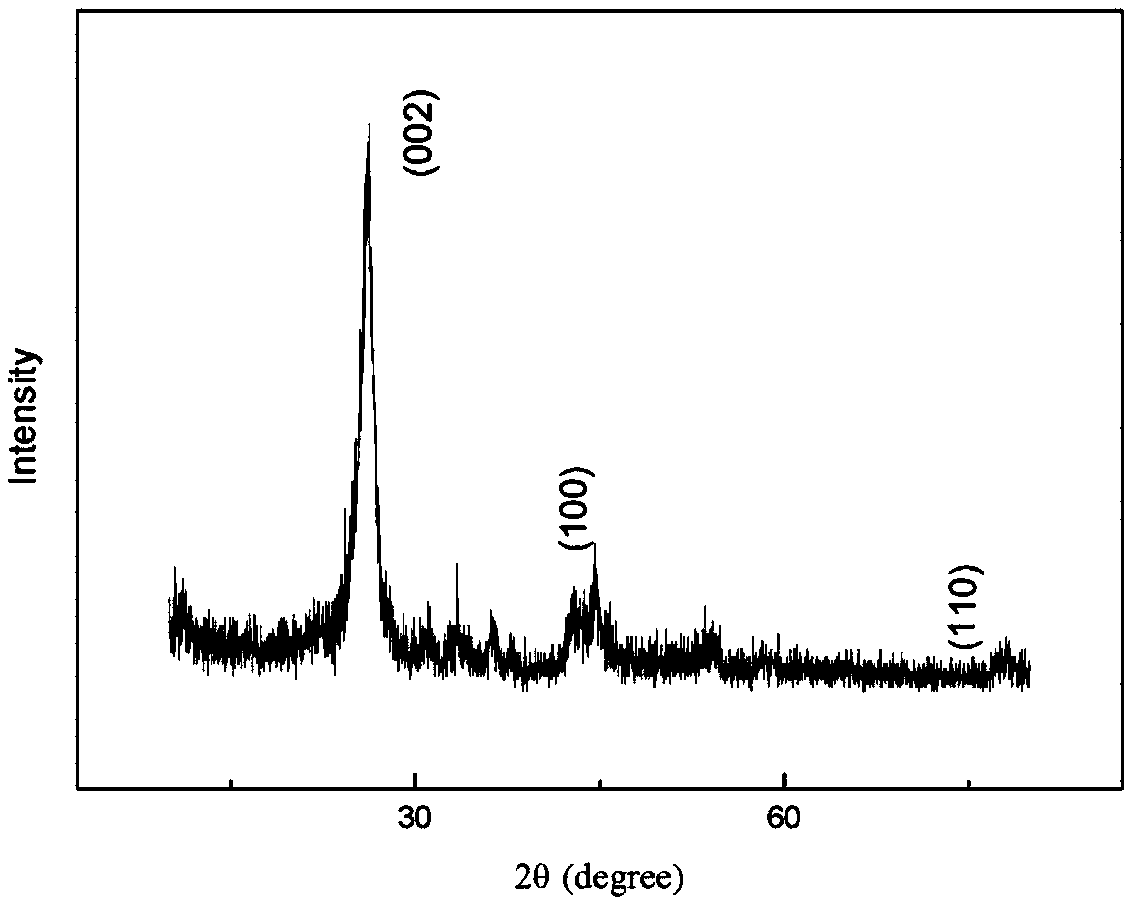

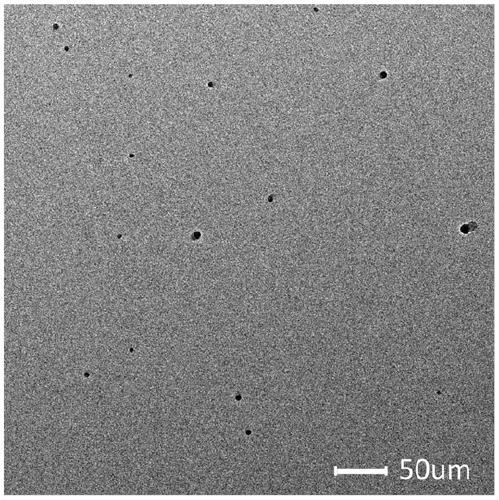

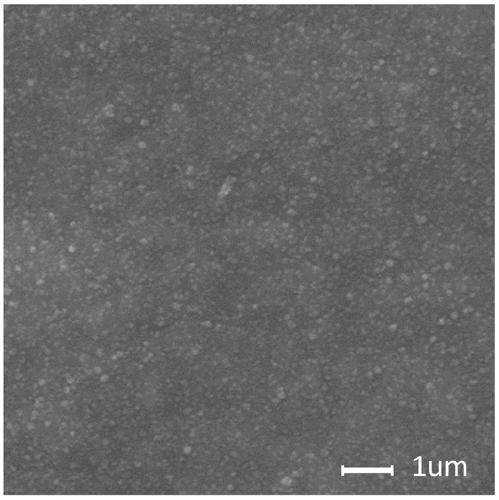

Method for preparing self-support layered materials MXenes and application of self-support layered materials MXenes as Raman substrates

The invention discloses a method for preparing self-support layered materials MXenes and application of the self-support layered materials MXenes as Raman substrates. Ti3C2Tx which is prepared after Ti3AlC2 is etched by HF (hydrofluoric acid) is used as the SERS (surface enhanced Raman scattering) substrates, organic dye probe molecular solution with different degrees of concentration is coated onTi3C2Tx materials by the aid of dispensing processes, and then substrate materials with adsorbed probe molecules can be aired on glass slides to be used for Raman detection. The method and the application have the advantages that the Ti3C2Tx with a large specific surface area is excellent in adsorption performance for dye molecules, alkali metal ions and the like, and the quantities of hot spotscan be increased; the Ti3C2Tx substrates are good in homogeneity and high in stability and universality when used for detecting the dye molecules; the method for preparing the SERS substrates is simple and can have a broad application prospect in the field of food additives, pesticide residue detection and the like.

Owner:TIANJIN UNIV

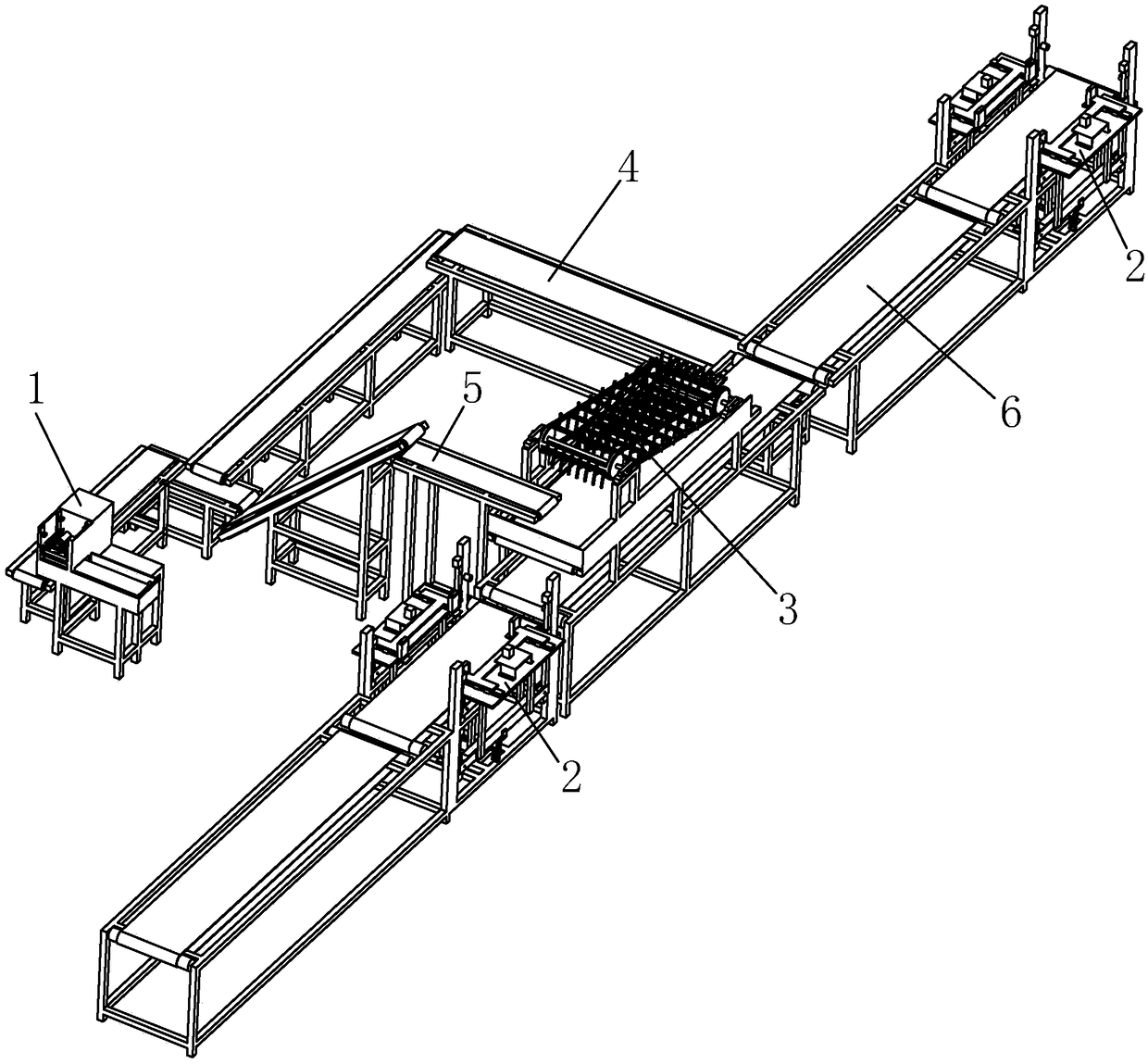

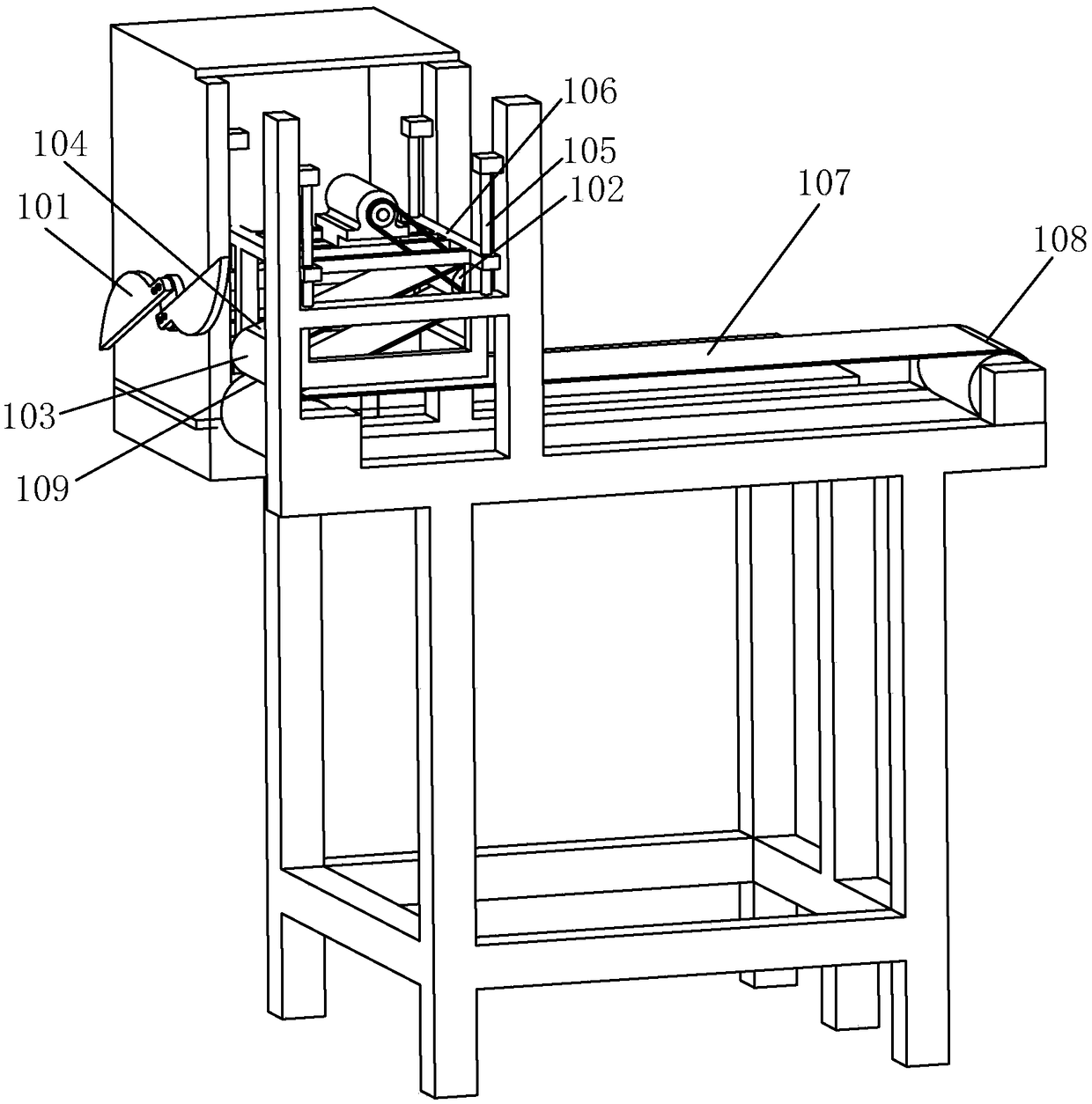

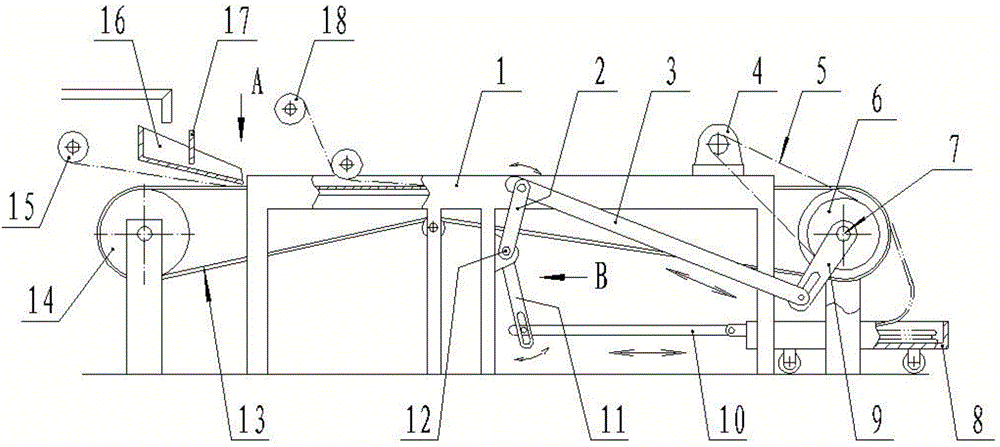

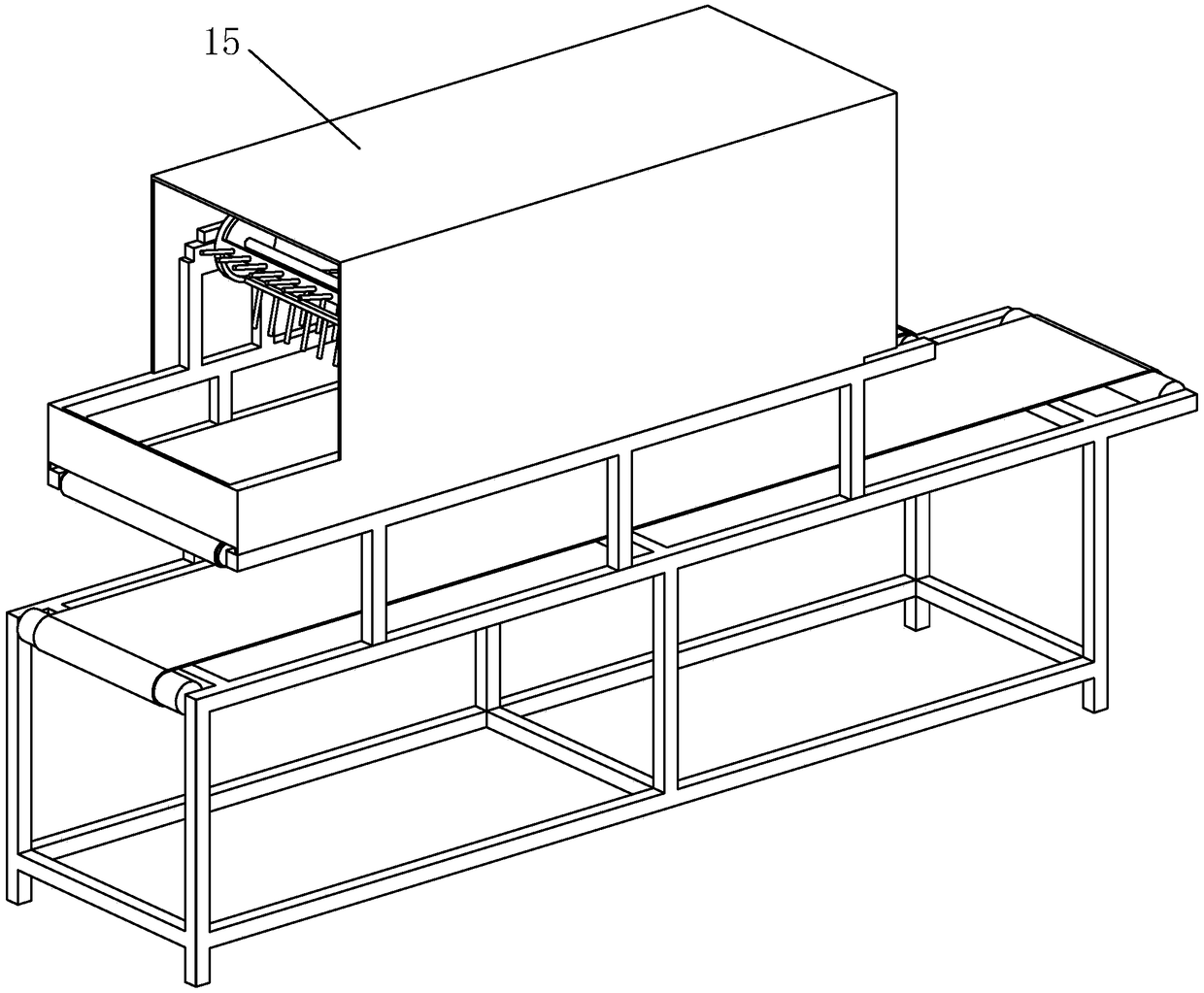

Automatic production line assembly for young silkworm feeding

PendingCN109436862AAchieve automated productionRealization of automatic silkworm feedingControl devices for conveyorsStacking articlesMicrocomputerProduction line

The invention relates to an automatic production line assembly for young silkworm feeding. The automatic production line assembly comprises an automatic leaf cutting machine, an automatic silkworm feeding system, an automatic silkworm plaque destacking and stacking machine, a control system and a power mechanism. The control system comprises an inductor and a single-chip microcomputer. The inductor is arranged on a stacking machine body, and the inductor and the power mechanism are connected with the single-chip microcomputer. Folium mori is cut through the automatic leaf cutting machine, then, the cut folium mori is conveyed into the automatic silkworm feeding system through a conveying-out belt, the folium mori falls into silkworm plaques conveyed out of a silkworm feeding machine silkworm plaque conveying belt for feeding after being evenly scraped in the automatic silkworm feeding system, and stacked silkworm plaques can be conveyed into the automatic silkworm feeding system one byone for silkworm feeding through the automatic silkworm plaque destacking and stacking machine. The automatic production line assembly achieves automatic silkworm feeding, accordingly, young silkwormfeeding automatic production is achieved, and the work efficiency is improved.

Owner:柳州蚕润丝圆蚕业机械科技有限公司

Planar heterojunction perovskite solar cell and preparation method thereof

InactiveCN105280819AReduce manufacturing costSimple preparation processFinal product manufactureSolid-state devicesHeterojunctionMetallic electrode

The invention belongs to the technical field of solar cells and specifically discloses a planar heterojunction perovskite solar cell and a preparation method thereof. The planar heterojunction perovskite solar cell comprises a transparent conductive electrode, an electron transmission layer, a perovskite luminous absorption layer, a cavity transmission layer and a method electrode in sequence from down to up. The electron transmission layer is a TiO2 compact layer. The perovskite luminous absorption layer is made of a chloride-ion-doped perovskite material. According to the invention, a TiO2 mesoporous layer in a conventional sensitized solar cell is rejected, and the device structure and the preparation technology are simplified; the chloride-ion-doped perovskite material is used as the luminous absorption material, the film forming ability of a film is improved, and the diffusion and separation of carriers are facilitated; aimed at the processing of the transparent conductive electrode and the TiO2 compact layer, an oxygen plasma processing technology is provided, and the film forming effect is improved; and aimed at the thickness control problem of the perovskite luminous absorption layer, a layer-by-layer spin coating technology is adopted, and the photoelectric performance of the luminous absorption layer and the integral cell is regulated and controlled.

Owner:ZHENGZHOU UNIV

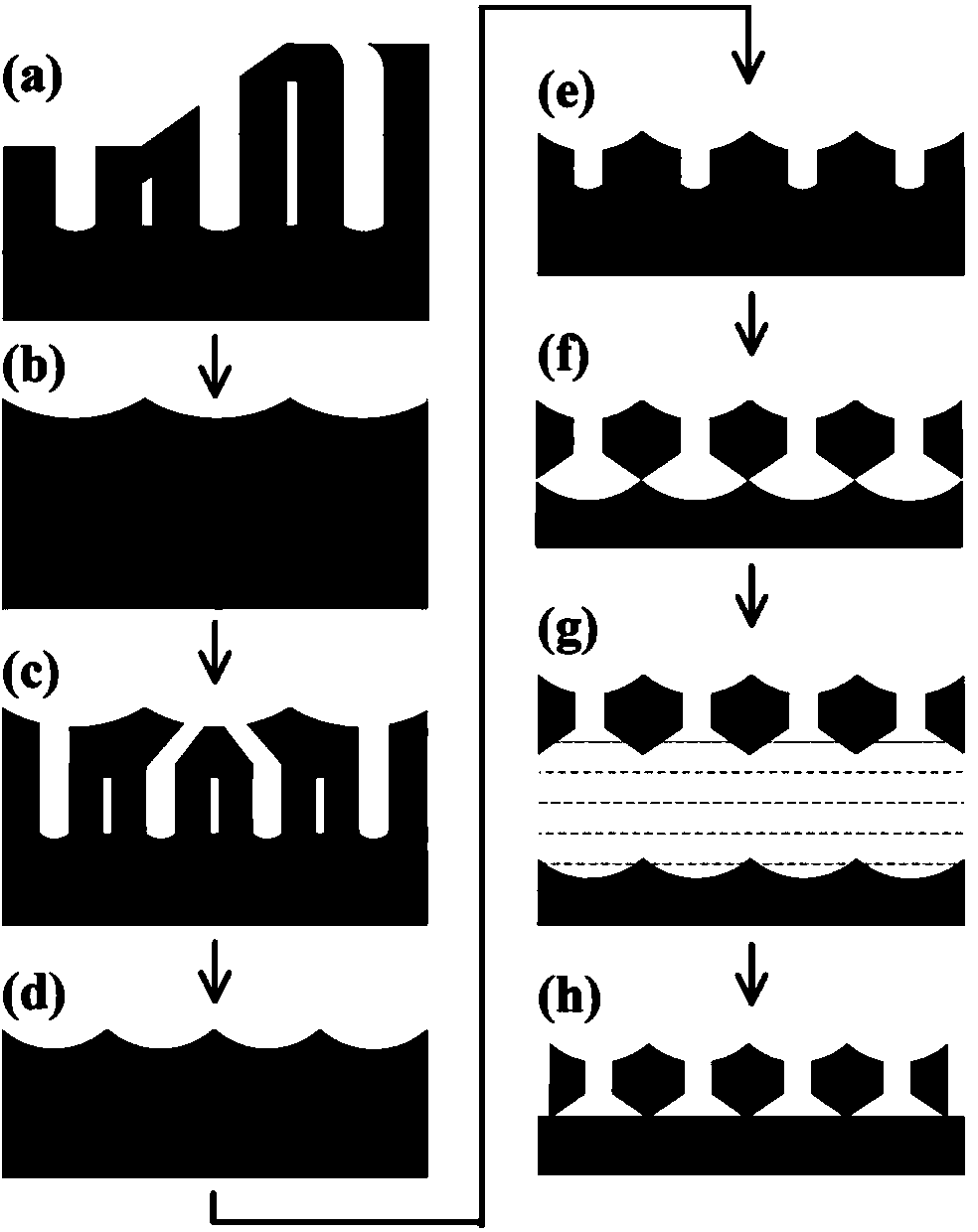

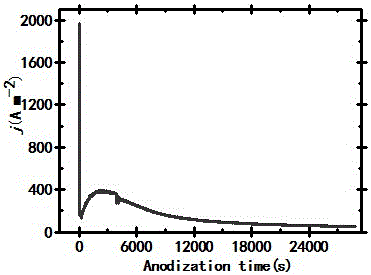

Preparation method of ultra-thin two-way titanium-dioxide nanopore-array film with adjustable aperture and thickness

ActiveCN103668389AAvoid formingStraight holeMaterial nanotechnologySurface reaction electrolytic coatingHydrofluoric acidNanohole

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Method for preparing b-axial oriented ZSM-5 molecular sieve nano-ceramic composite membrane

ActiveCN106512752AThickness controlImprove completenessSemi-permeable membranesMolecular sieve catalystsCeramic compositeSeed crystal

The invention relates to a method for preparing a b-axial oriented ZSM-5 molecular sieve nano-ceramic composite membrane. The method comprises the following steps: (1) preparing ZSM-5 molecular sieve synthetic liquid by using an aluminum source, a silicon source, an organic template agent and water as raw materials, and reacting the synthetic liquid to obtain a ZSM-5 molecular sieve seed crystal; (2) dissolving the aluminum source in distilled water to prepare alumina sol, heating the alumina sol to 80-95 DEG C, and adding chitosan and dissolving; and (3) adding the ZSM-5 molecular sieve seed crystal into the mixed solution, coating the mixed solution on the outer surface of a carrier, putting the carrier into a heating device, heating to 480-800 DEG C, and keeping temperature constant to obtain the b-axial oriented ZSM-5 molecular sieve nano-ceramic composite membrane. The preparation process is mild in condition and simple in operation, can be used for developing a novel composite membrane, and is beneficial to industrialization of gas separation, purification, alcohol-water low-energy-consumption membrane separation and other technologies by combining the advantages of the oriented ZSM-5 molecular sieve membrane and a nano-ceramic membrane.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

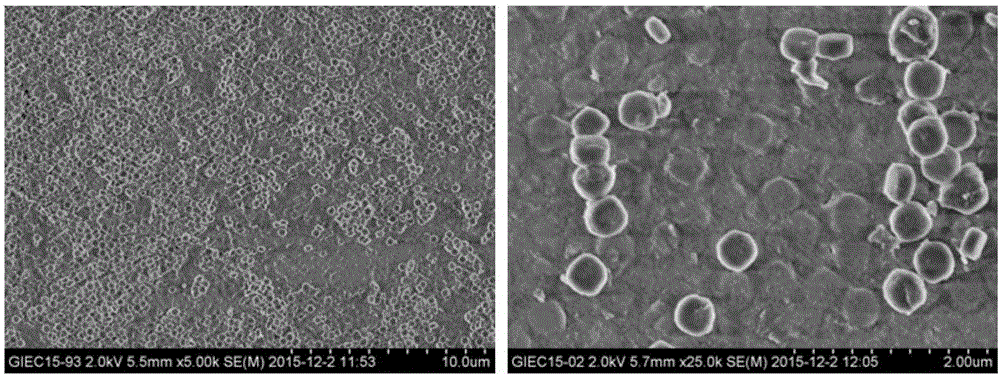

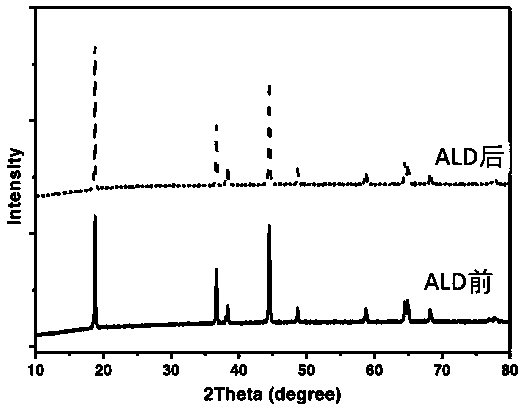

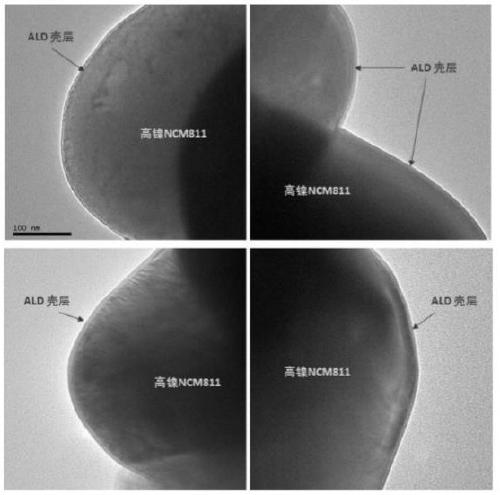

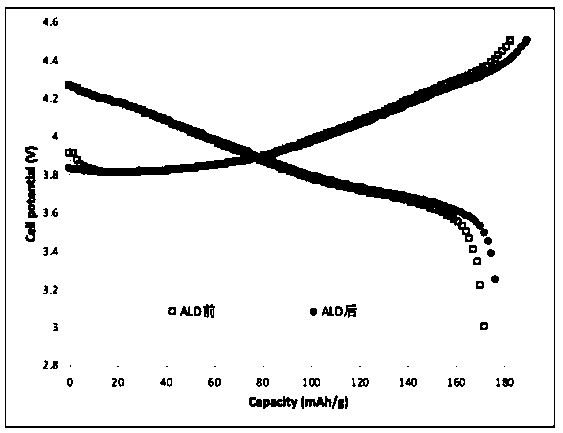

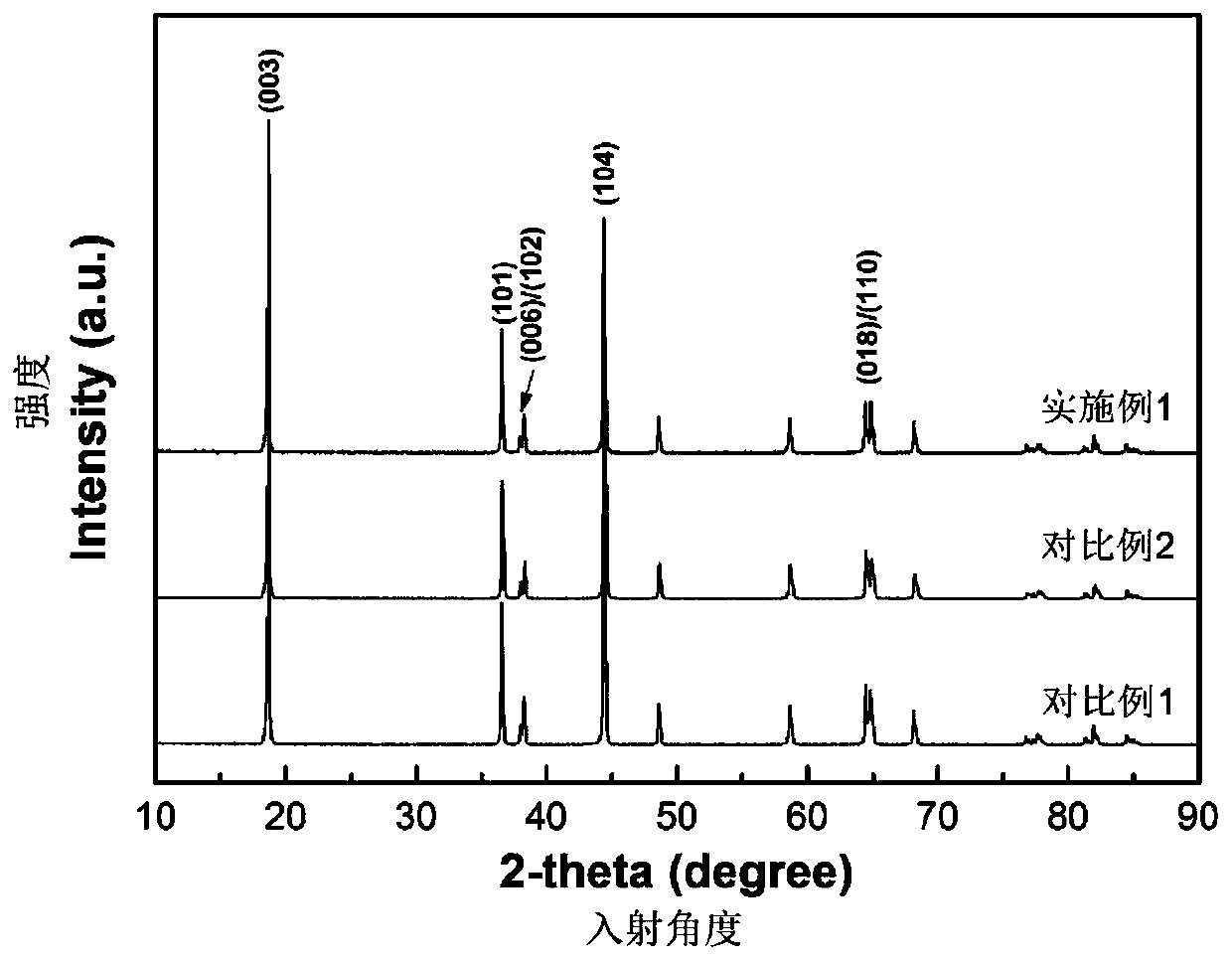

Preparation method of atomic layer deposition coated high-nickel ternary positive electrode material

PendingCN111082025AUniform coatingChange the composition of surface elementsCell electrodesLi-accumulatorsCyclic stabilityReaction chamber

The invention discloses a method for coating a high-nickel ternary positive electrode material by atomic layer deposition. The method mainly solves the problems that the performance of the lithium battery is reduced, the performance of the lithium battery can be improved through positive electrode material wrapping, and existing carbon material wrapping is poor in interface stability and falls offafter being used for a period of time. An existing method for wrapping an oxide with a positive electrode material is complex in process and high in cost, and has the problem that waste liquid needsto be treated subsequently. The preparation method is characterized by comprising the following steps: heating, depressurizing, introducing a precursor A, introducing gas to clean a reaction chamber,introducing a precursor B, introducing gas to clean the reaction chamber, and repeating the reaction steps to obtain a coating layer with a certain thickness. The method has the advantages that the coating layer is uniform, the generated coating layer is a metal oxide and is relatively stable, the cycle stability and the capacity stability of the battery are improved, no waste liquid is generatedin the production process, the method is environment-friendly, the cost for waste liquid treatment is reduced, and the thickness of the coating layer is changed by controlling the cycle number.

Owner:恩创动力设备(南京)有限公司

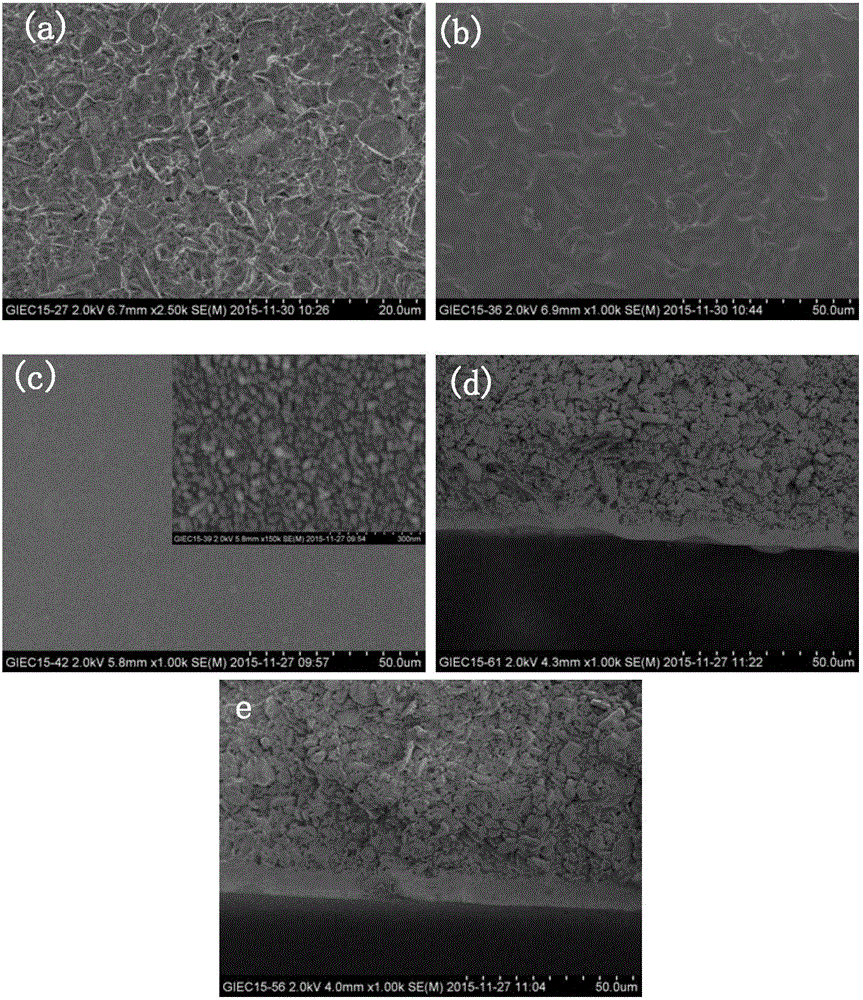

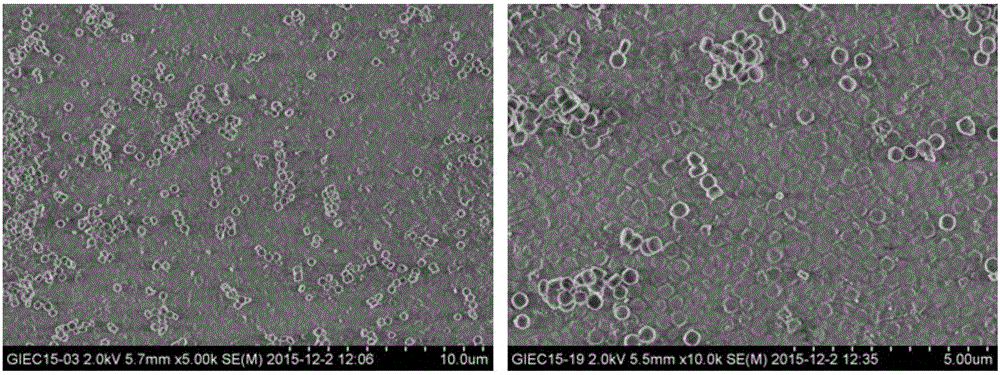

Method for reducing nucleation density of graphene wafers

ActiveCN109609924AImprove production efficiencyAchieve polishAnodisationChemical vapor deposition coatingVolumetric Mass DensityCopper foil

The invention discloses a method for reducing the nucleation density of graphene wafers. The method includes the following steps that firstly, polishing and oxidizing pretreatment is performed on a copper foil surface, and then the graphene wafers are prepared on the treated copper foil surface. The new method for reducing the nucleation density of the graphene wafers is put forward, and the method is simple, convenient, easy to implement and good in effect. Meanwhile, the influences of the roughness and the oxidizing degree of a copper base on the nucleation density of the graphene wafers canbe explored, so that the size of the graphene wafers can be increased further, and the quality of thin graphene films can be improved.

Owner:北京石墨烯技术研究院有限公司

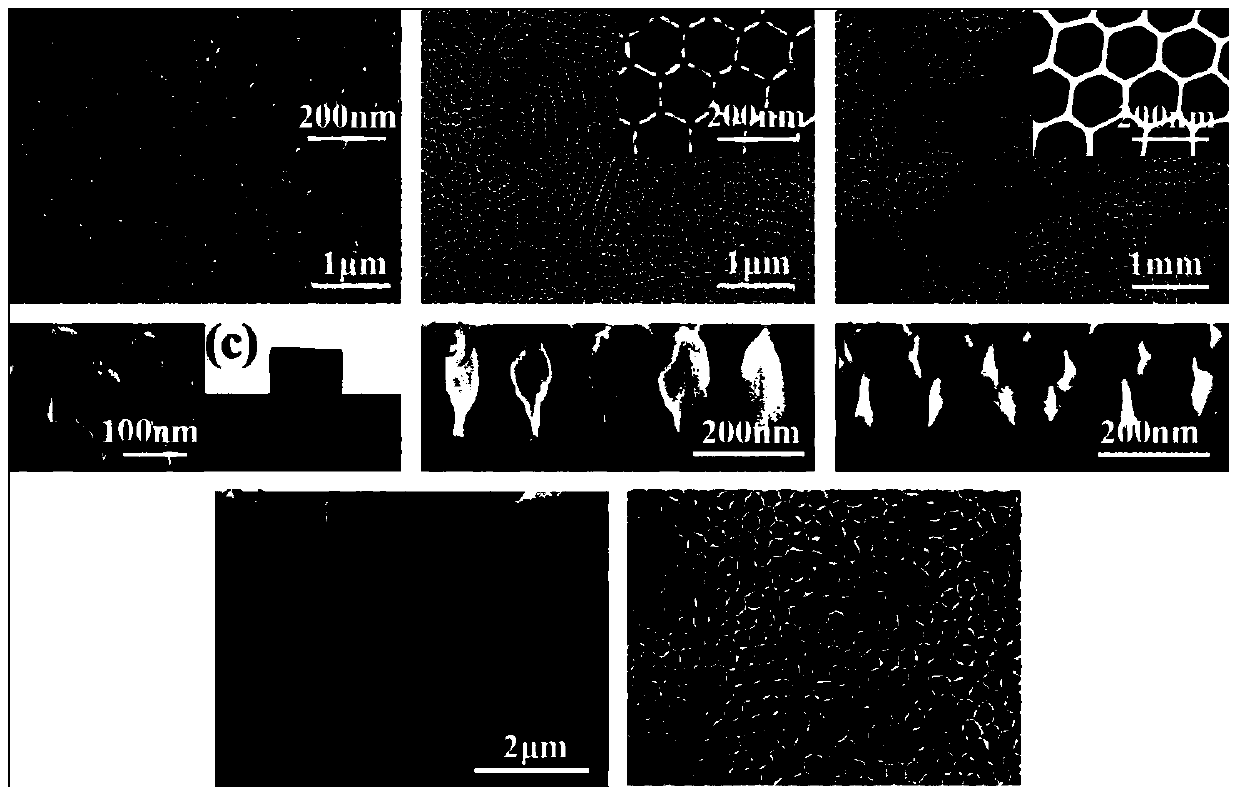

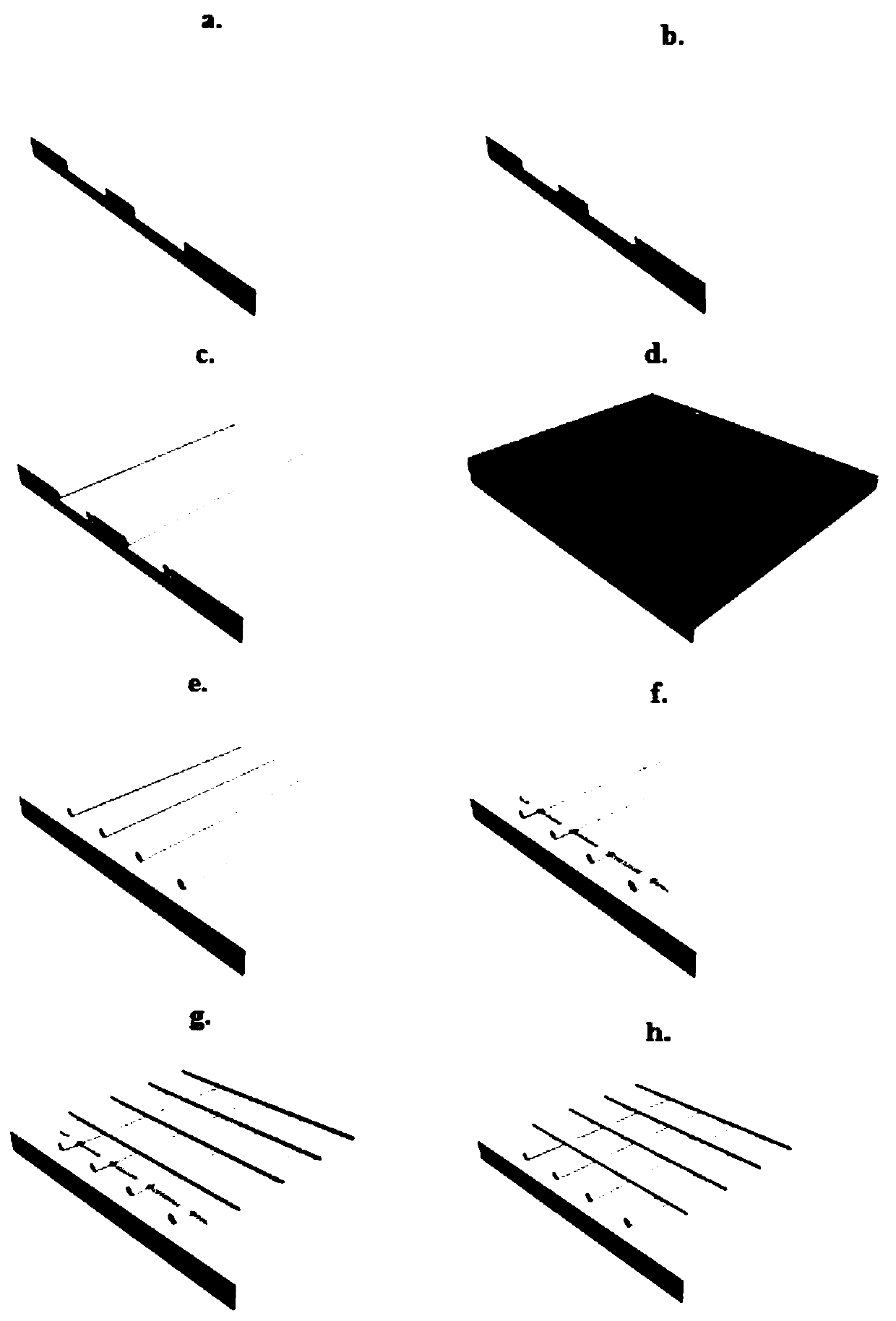

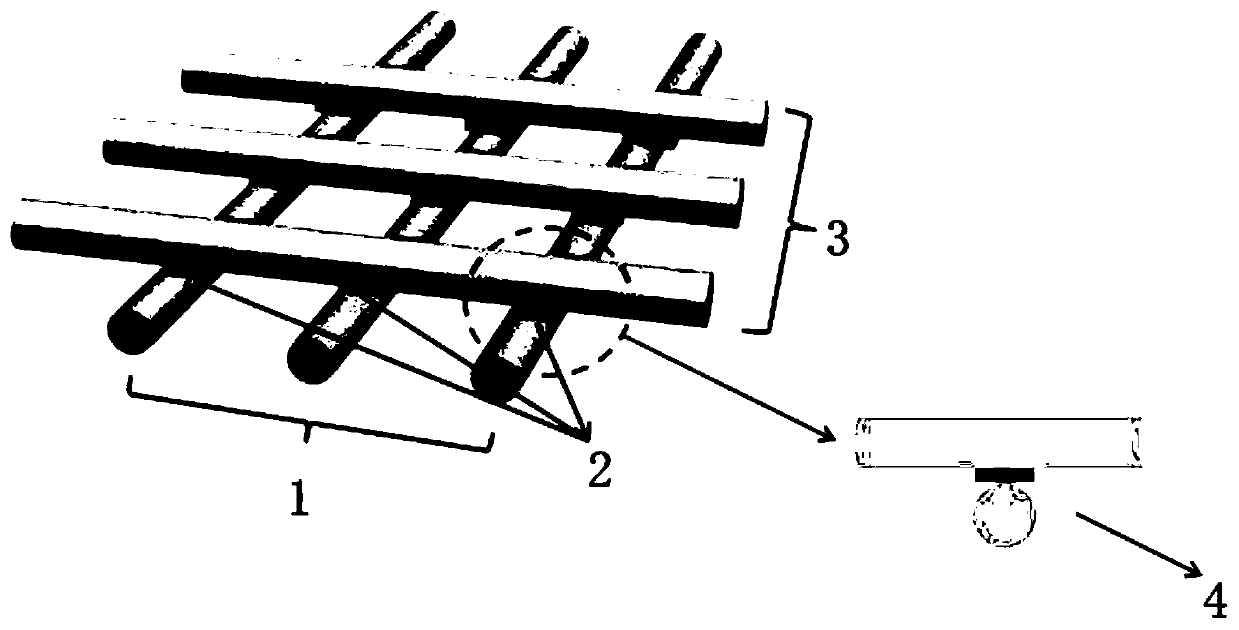

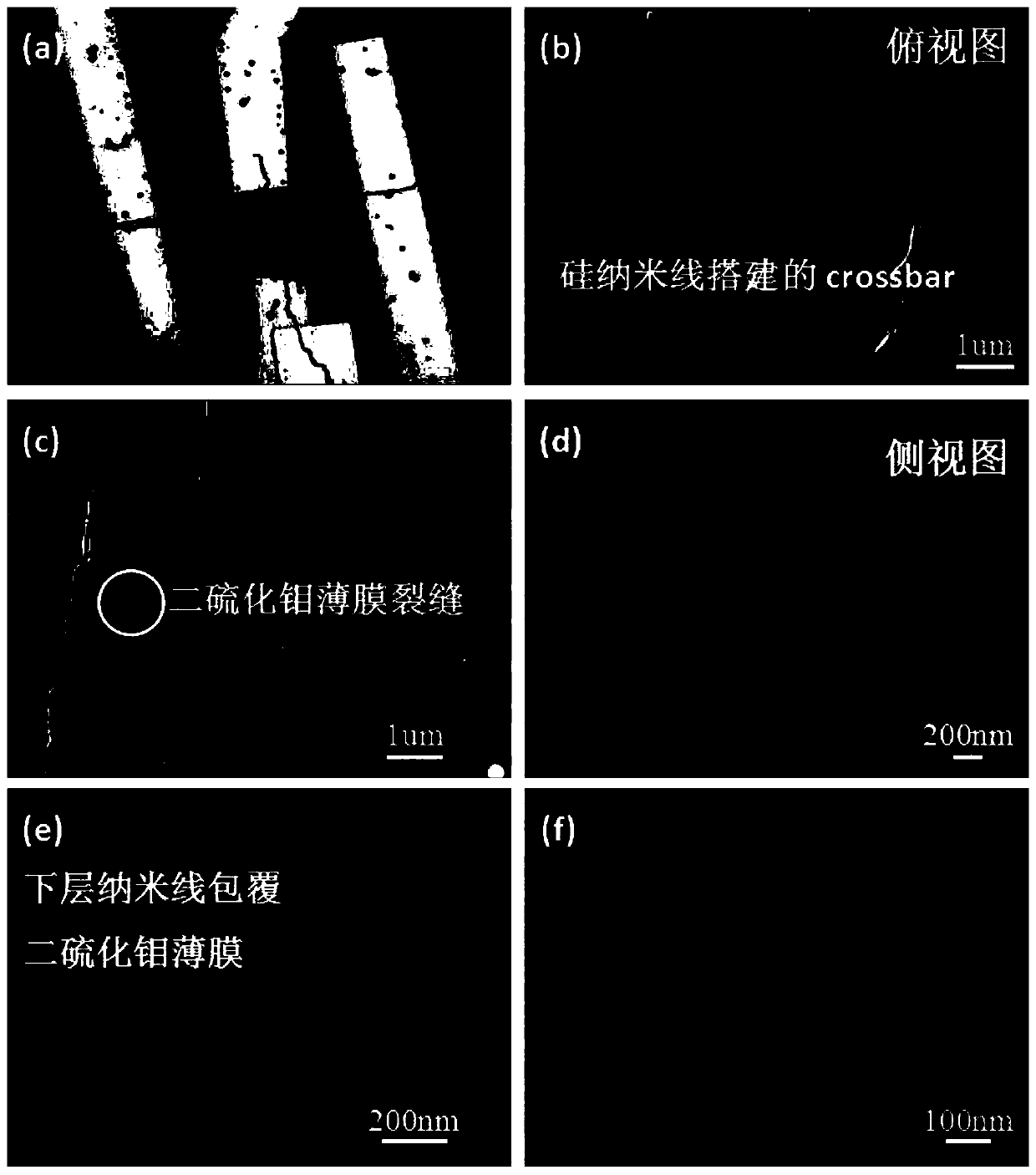

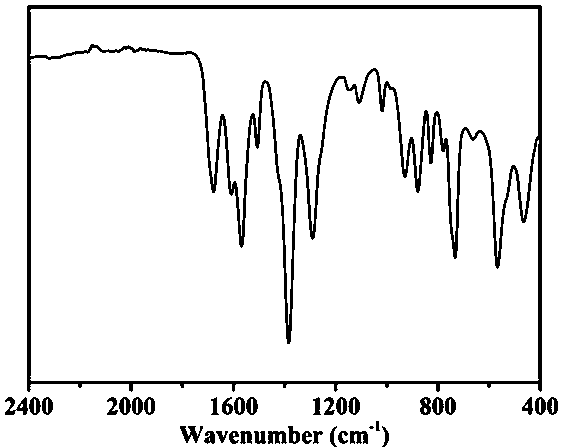

Preparation method of stackable large-area nano wire intersected lattice array resistive switching memory device structure

ActiveCN109950393AThickness controlSolve the key problem that the precision is difficult to reach the nanometer levelElectrical apparatusConductive channelFilm material

The invention discloses a preparation method of a stackable large-area nano wire intersected lattice array resistive switching memory device structure. The preparation method comprises that a resin colloid material transfer method is used to realize alternative stacking and intersected distribution of a silicon nano wire array and a film material, and a film interlayer silicon nano wire intersected lattice array structure of the 3D space is formed; and in the alternative stacking process, the top silicon nano wire serves as a mask, an etching device is used to etch the film material not shielded by nano wires in the grid part, an extremely low point contact structure of a nano wire intersection point and interlayer film material is obtained, and a vertical conductive channel of extremely high alignment is provided for the memory device. According to the method, it is not required to introduce the high-cost micronano control technology (as a nano mechanical arm), only a simple transfertechnology is used to realize directed stacking of the nano material, the silicon nano wire serves as the master to realize accurate etching of the film material, and the electronic device of the nano-level sandwich type point-to-point contact structure is prepared reliably.

Owner:NANJING UNIV

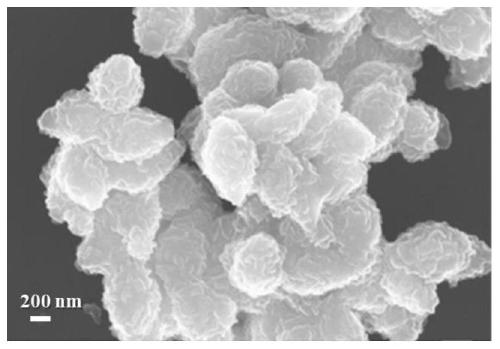

Honeycomb metal-organic framework nanosheet and preparation method thereof

The invention discloses a honeycomb metal-organic framework nanosheet and a preparation method thereof. The honeycomb metal-organic framework nanosheet is prepared by self-assembling a metal ion Cu<2+> and an organic ligand, namely 1,4-terephthalic acid through a coordinate bond. The honeycomb metal-organic framework nanosheet has the advantages of high specific surface area, more surface active sites, high mechanical stability and the like, has a wide application prospect in fields of chemocatalysis, drug sustained release, hydrogen energy reserving, biomedicine and the like, and is simple insynthetic process and low in cost.

Owner:FUZHOU UNIVERSITY

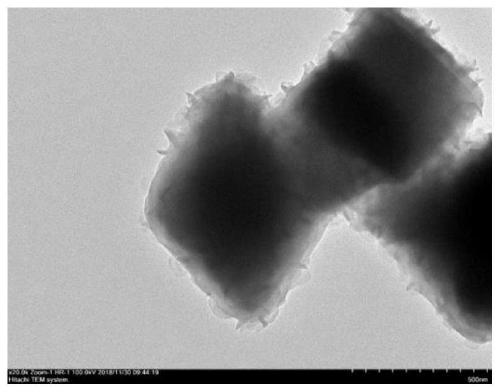

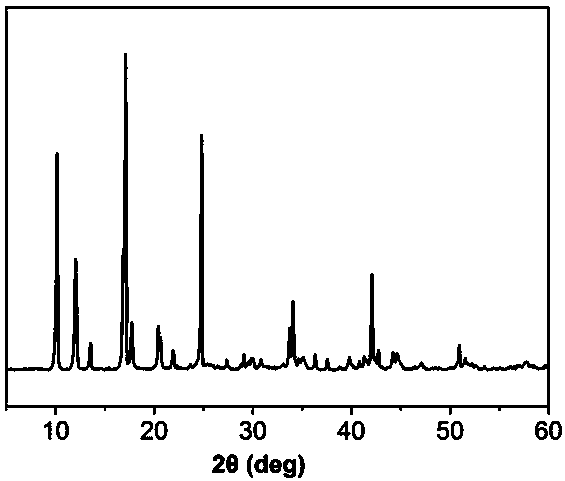

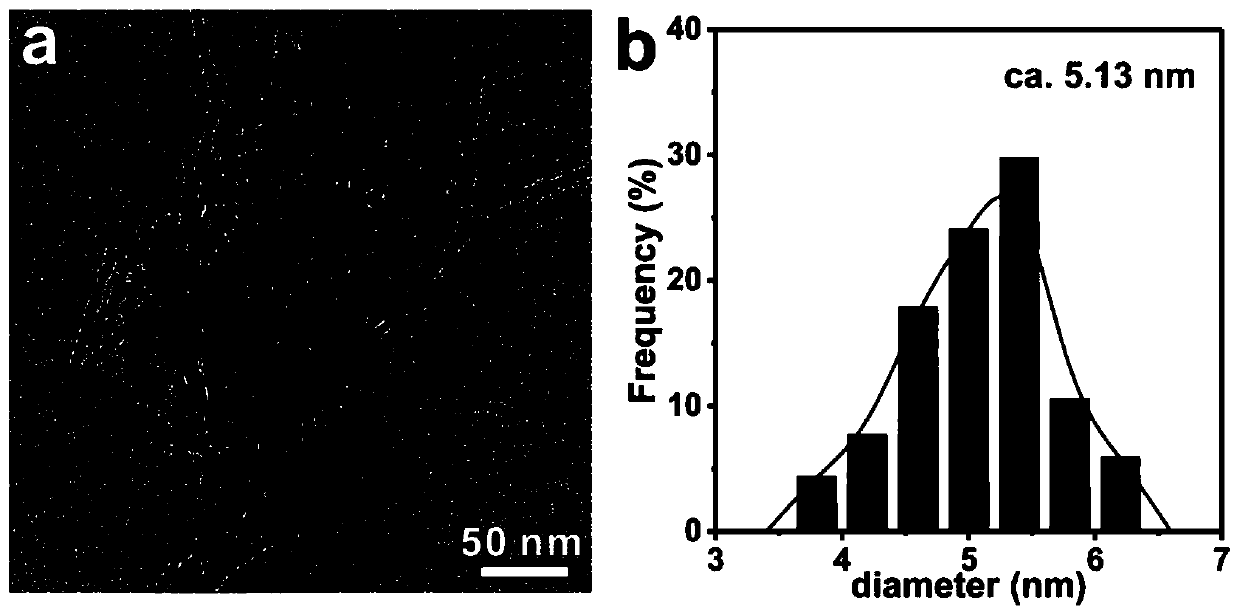

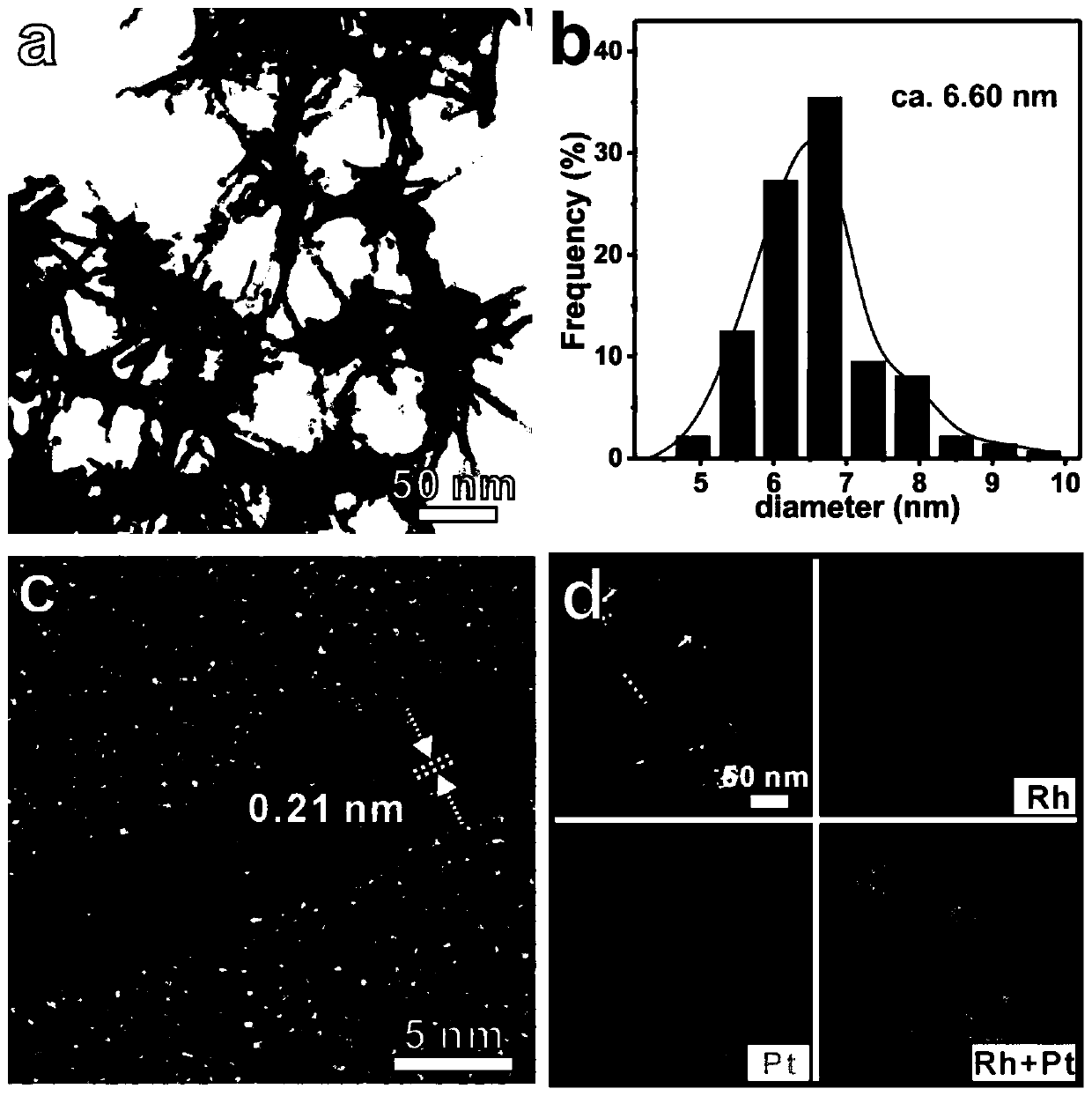

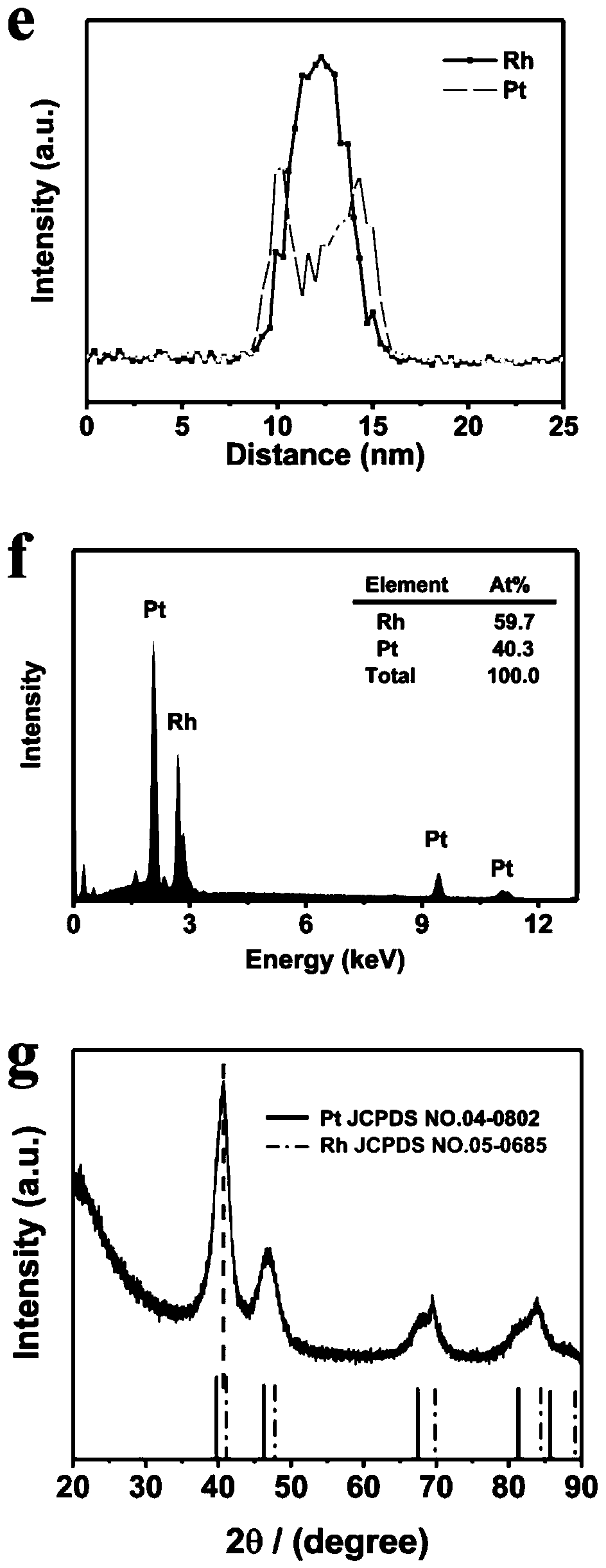

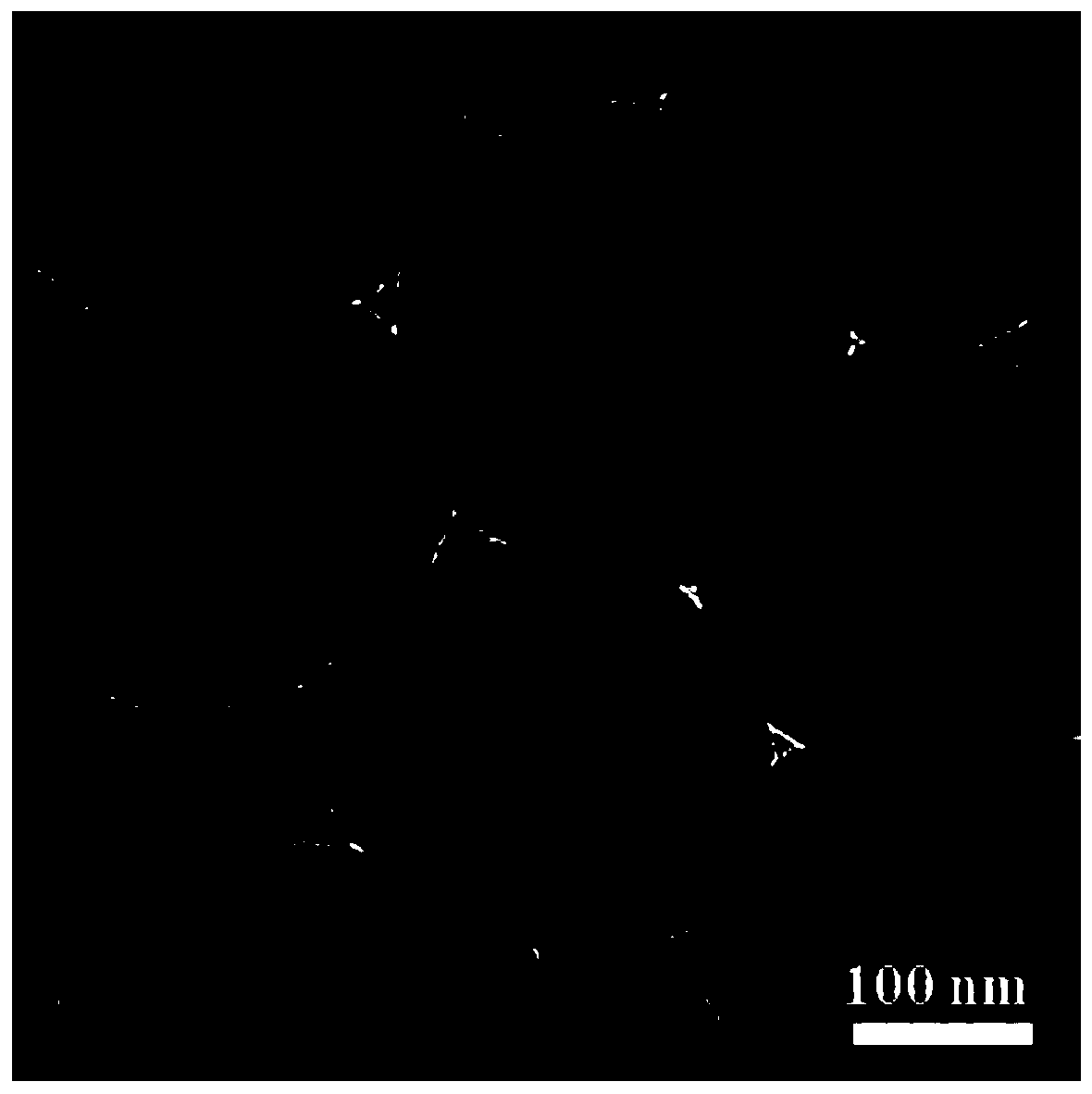

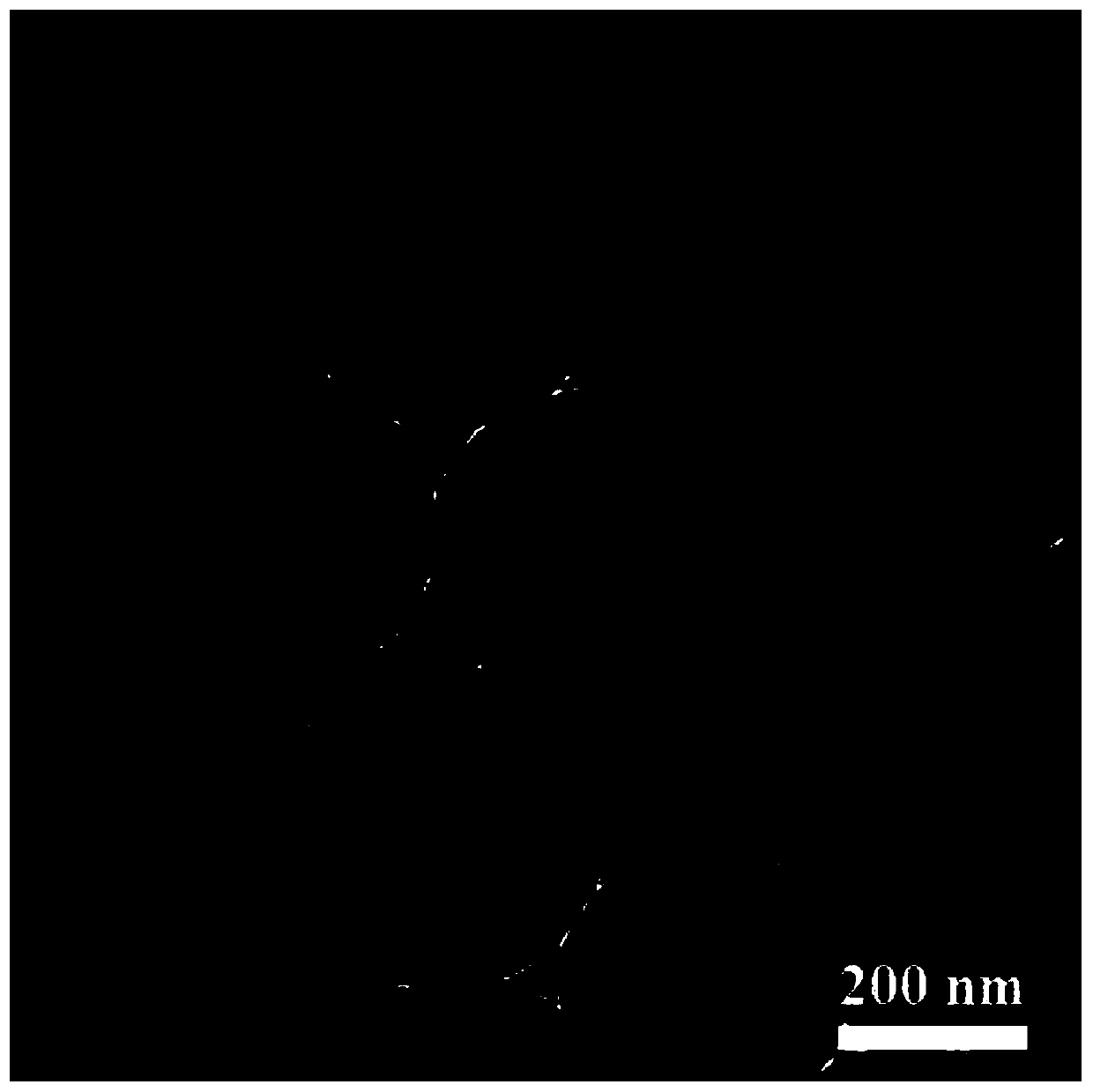

Preparation method of rhodium-platinum core-shell bimetallic nano branch and application

ActiveCN110576189AHigh catalytic activityNot easy to reuniteTransportation and packagingMetal-working apparatusCatalytic oxidationLayer thickness

The invention discloses a preparation method of a platinum layer thickness-controllable rhodium-platinum core-shell bimetallic nano branch. The preparation method comprises the following steps that PVP is used as a surfactant, rhodium chloride is used as metal precursor salt, n-octyl amine serves as a reaction solvent and a reducing agent, high-temperature and high-pressure reaction is carried outin a polytetrafluoroethylene reaction kettle, a pure rhodium nano branch is prepared, then, the pure rhodium nano branch is repeatedly cleaned by using ethanol to remove surface organic matter, thenthe pure rhodium nano branch is dissolved in ethylene glycol, and then a platinum precursor salt solution is injected to deposit a platinum layer on the surface of the pure rhodium branch, thereby obtaining the Rh@Pt core-shell structure bimetallic nano branch. According to the preparation method, by changing the injection amount of the platinum precursor salt, the thickness of the platinum layeris regulated and controlled, the prepared product has an ultrafine core-shell nano-branch structure, and when the prepared product is applied to catalytic aspects such as alcohol electro-catalytic oxidation and hydrogen evolution reaction, the good catalytic performance can be exhibited.

Owner:HUAQIAO UNIVERSITY

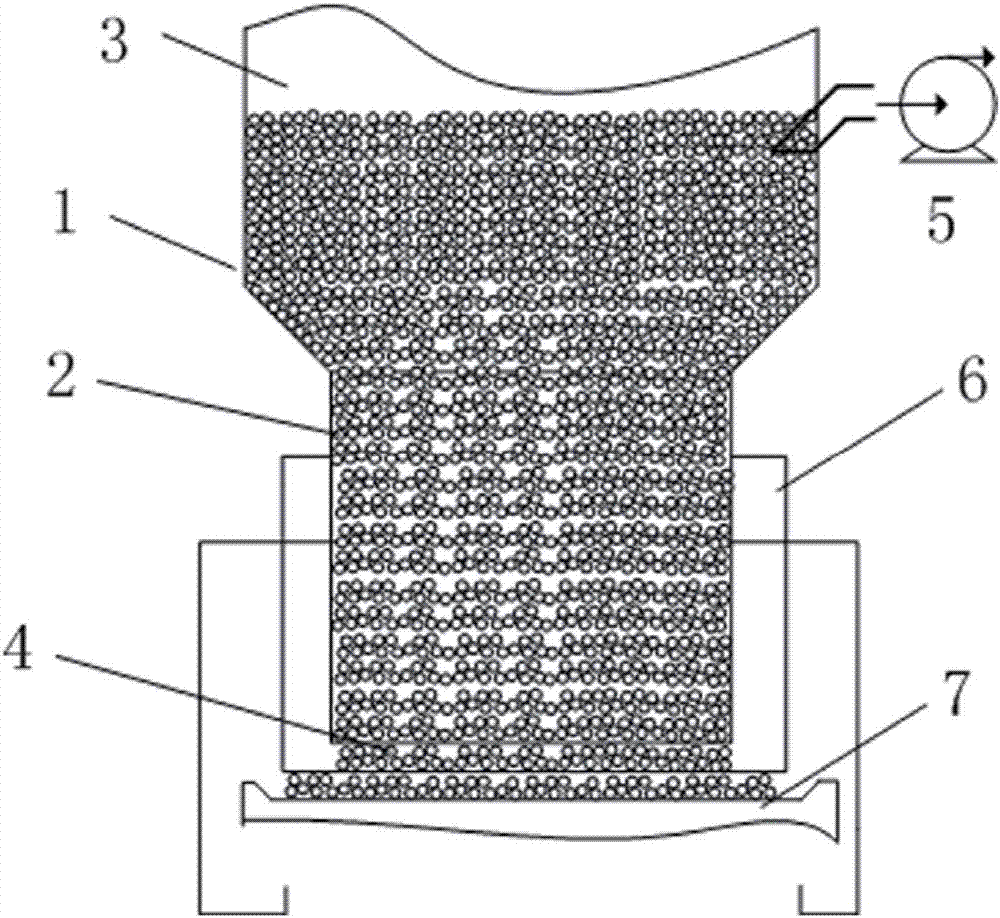

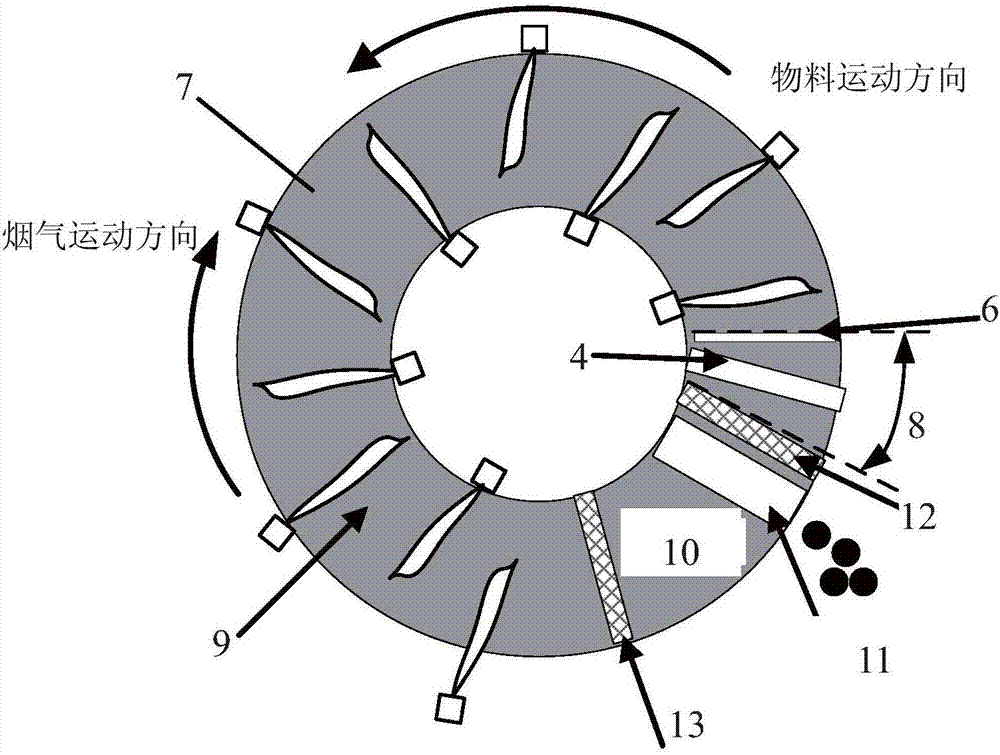

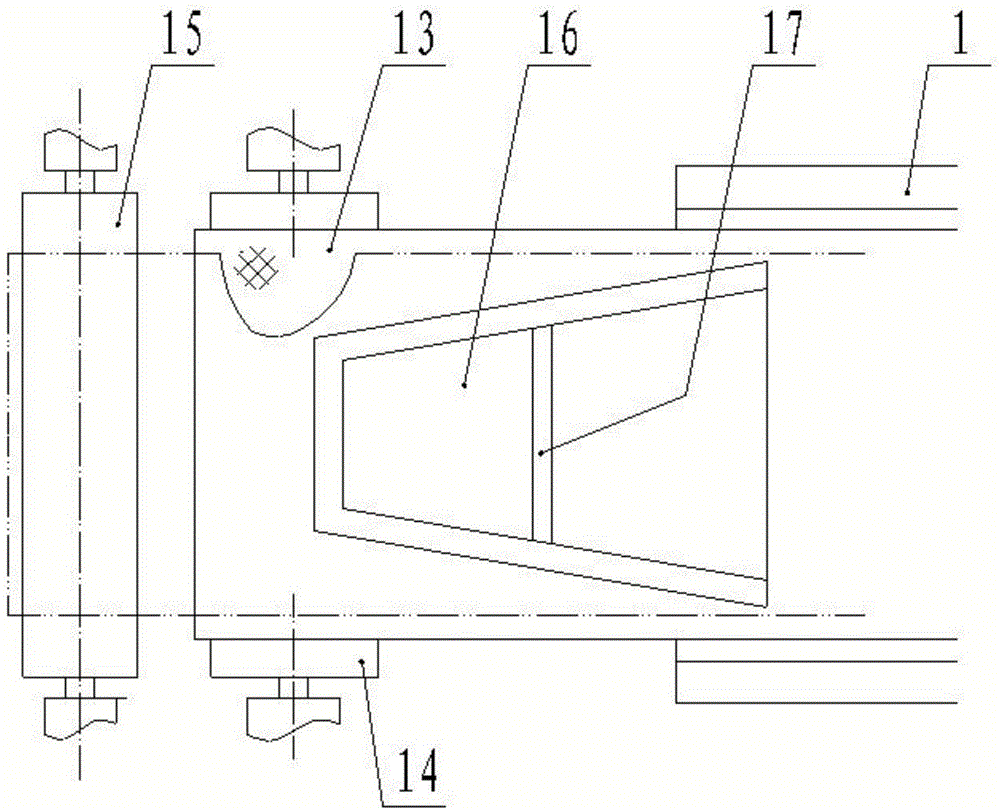

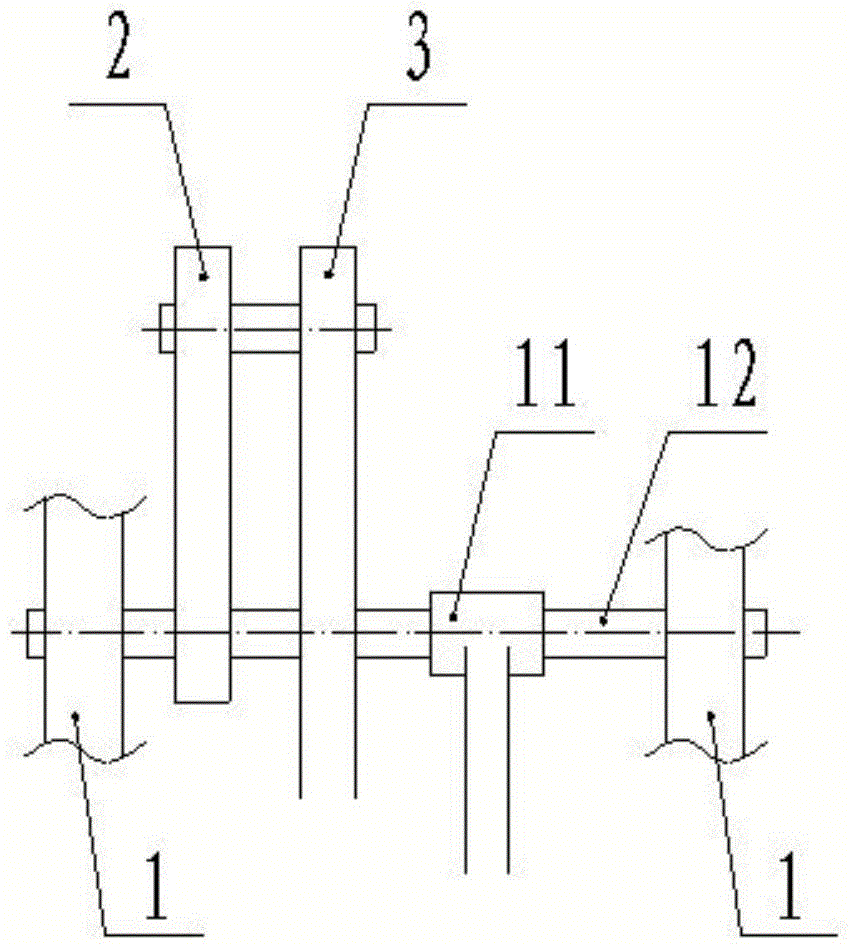

Rotary hearth furnace

The invention relates to a rotary hearth furnace. The rotary hearth furnace comprises an annular furnace body, an annular hearth, a heat power engineering system, a discharge mechanism, a distributionmechanism and a smoke discharge mechanism. The rotary hearth furnace effectively solves low CO utilization rate, and meanwhile, fully uses the smoke afterheat; more CO participates in indirect reduction; materials are preheated by the smoke afterheat; compared with a traditional rotary hearth furnace technology, the rotary hearth furnace can reduce adding of the material carbon dosage, effectively reduces the smelting energy consumption, and reduces the production cost; and the angle of a high-temperature reduction area is increased, so that the reduction time is prolonged, the reduction effect is improved, and meanwhile, the treatment capacity of the rotary hearth furnace is improved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

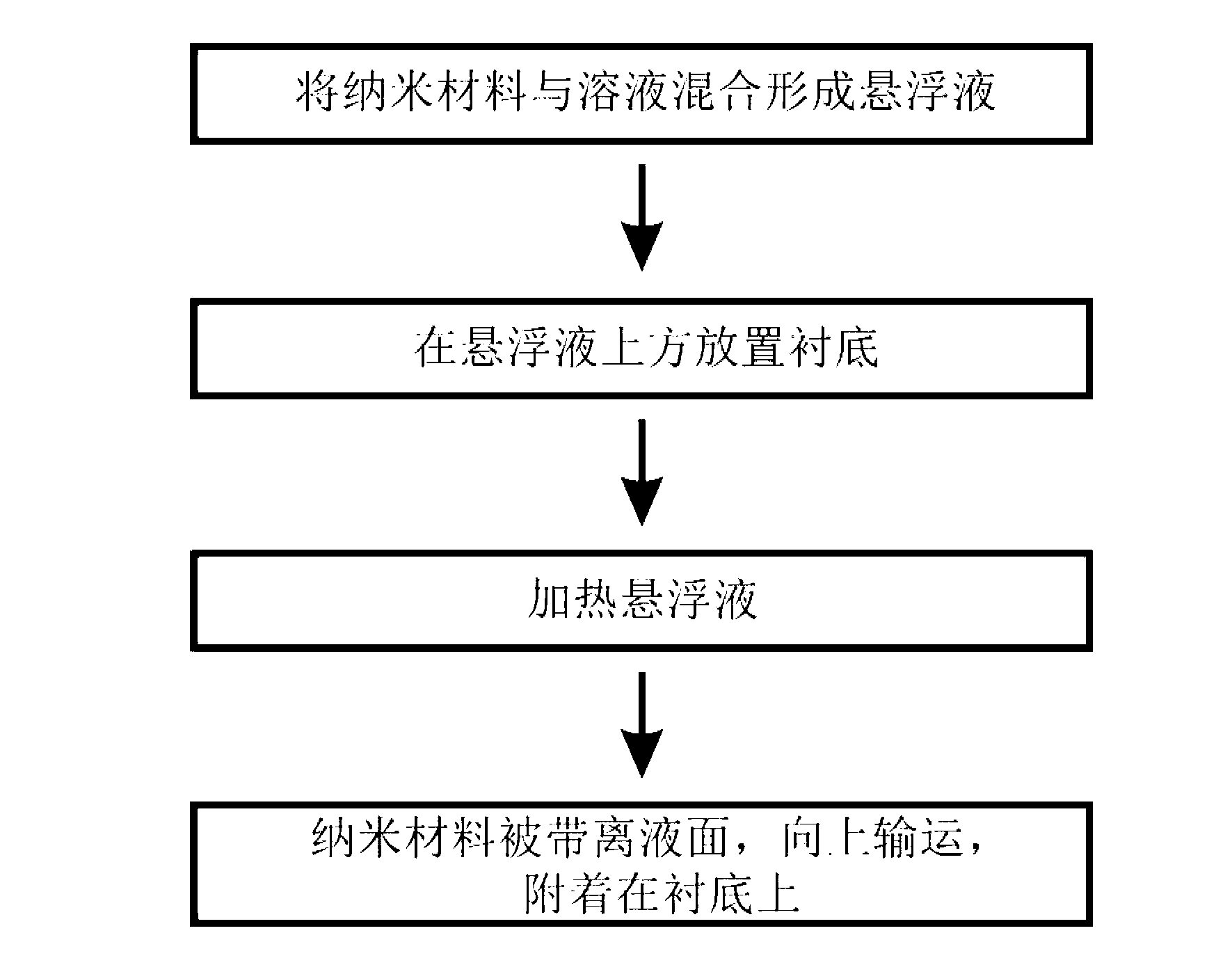

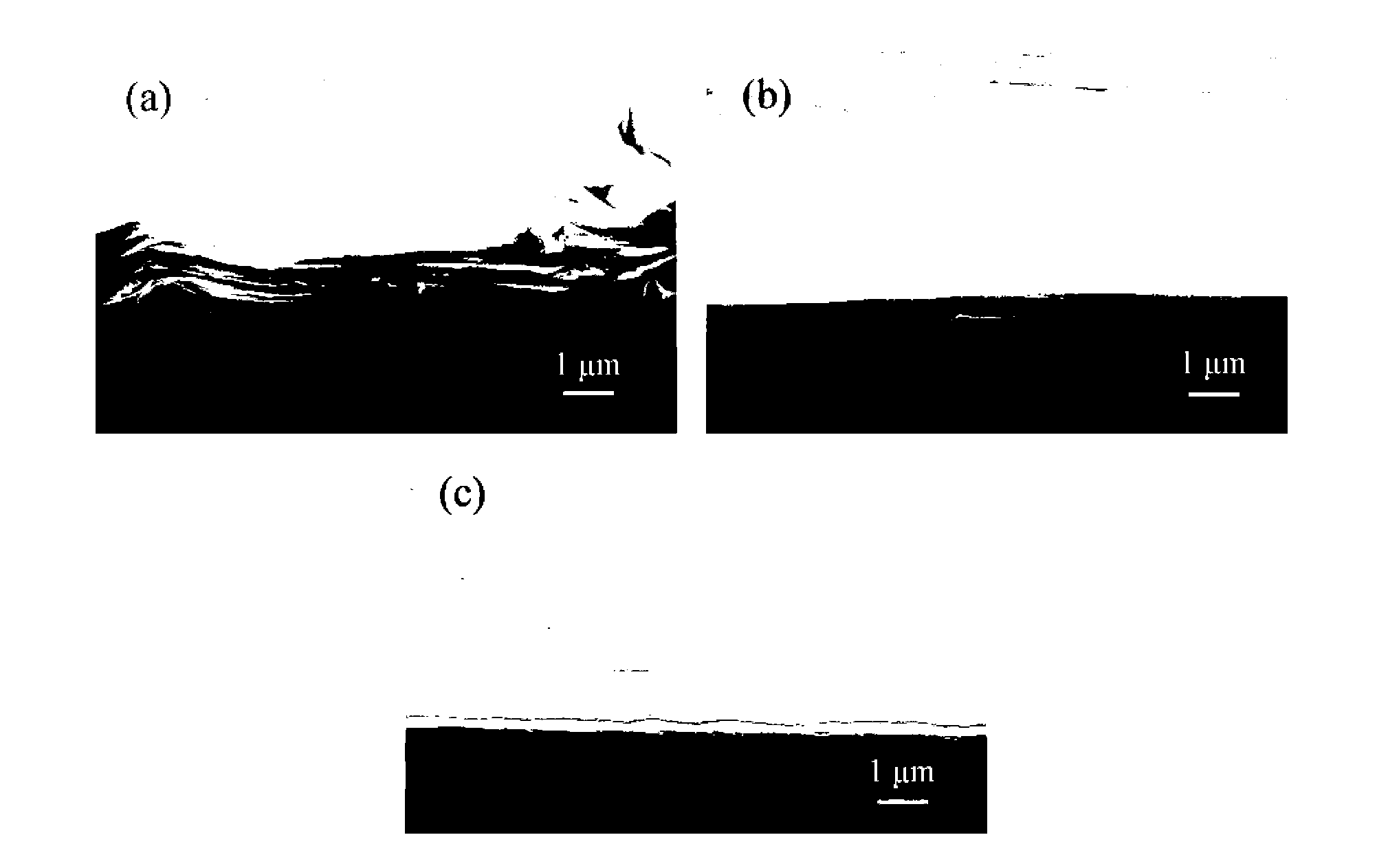

Nano-material transfer deposition method

ActiveCN103290411AThickness controlSurface Roughness ControlLiquid surface applicatorsMetallic material coating processesMaterial transferLiquid surfaces

The invention discloses a nano-material transfer deposition method. The method comprises the following steps: a nano-material is mixed with a solution to form a suspension, and the mixed suspension is heated for realizing the carrying of the nano-material by evaporated solution molecules, so the nano-material adheres to the surface a substrate placed above the liquid surface of the mixed suspension to form a film obtained through stacking the nano-material layer upon layer. The nano-material film having different thickness can be prepared through controlling the deposition time, the concentration of the nano-material in the suspension, the distance between the substrate and a sample and the heating temperature.

Owner:SUN YAT SEN UNIV

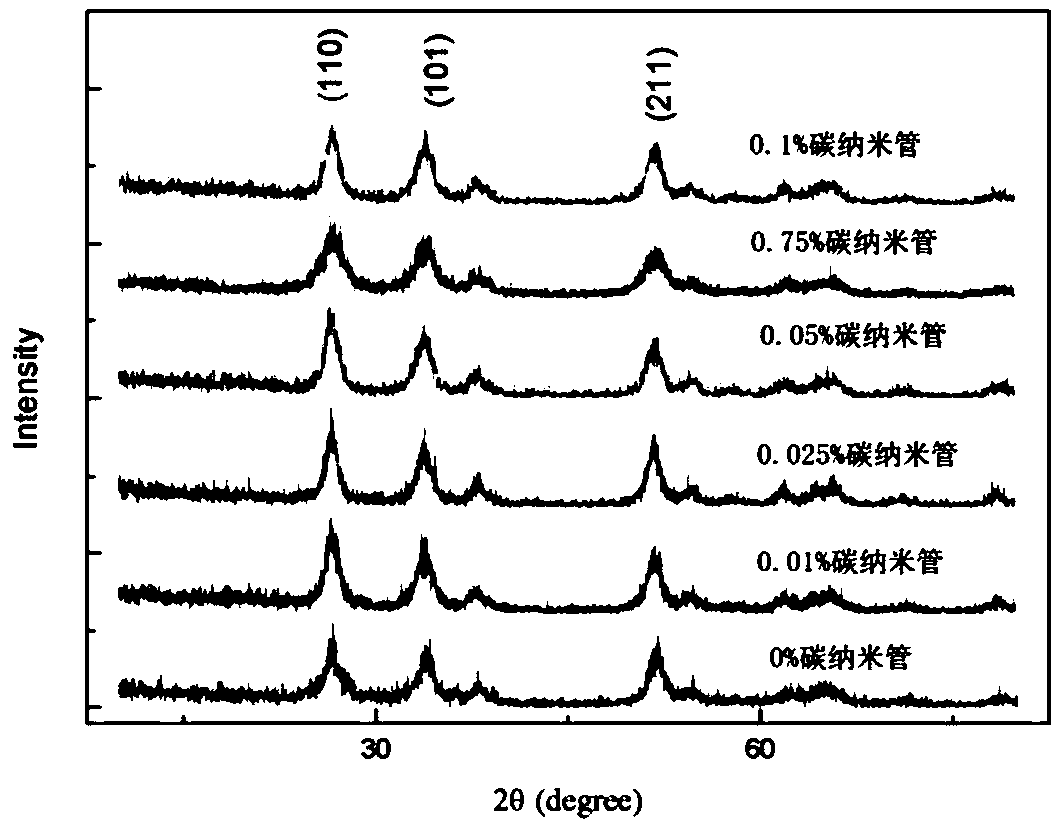

A SnO2 composite carbon nanotube electrothermal film and a preparation method thereof

InactiveCN109068418ALower resistanceGood thermal efficiencyHeating element materialsMass ratioModified carbon

The invention discloses a SnO2 composite carbon nanotube electric heating film and a preparation method thereof. The electric heating film is a tetragonal rutile structure and comprises a carbon nanotube and SnO2 with a mass ratio of 0.0002 to 0.002 : 1; A manufacture method comprises adde tin salt and modifier into a solvent to prepare a mixed solution, SnO2 composite carbon nanotube electrothermal film was prepared by adding modified carbon nanotube and stirring evenly to obtain electrothermal film precursor solution, spraying the electrothermal film precursor solution onto the coated substrate, and then annealing the coated substrate at 470 - 570 DEG C for 10 - 20 min to obtain SnO2 composite carbon nanotube electrothermal film. The electric heating film of the invention has small resistance, high emissivity, excellent thermal efficiency and strong chemical stability, and can replace the existing heating element with poor thermal efficiency and heat resistance, and is energy-savingand environmentally friendly. At that same time, the manufacture method is simple, energy-saving and environment-friendly, and can be industrialized.

Owner:YANCHENG INST OF TECH

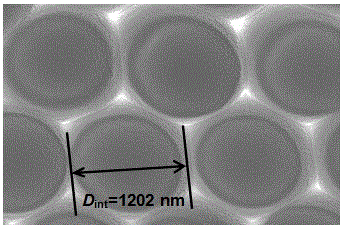

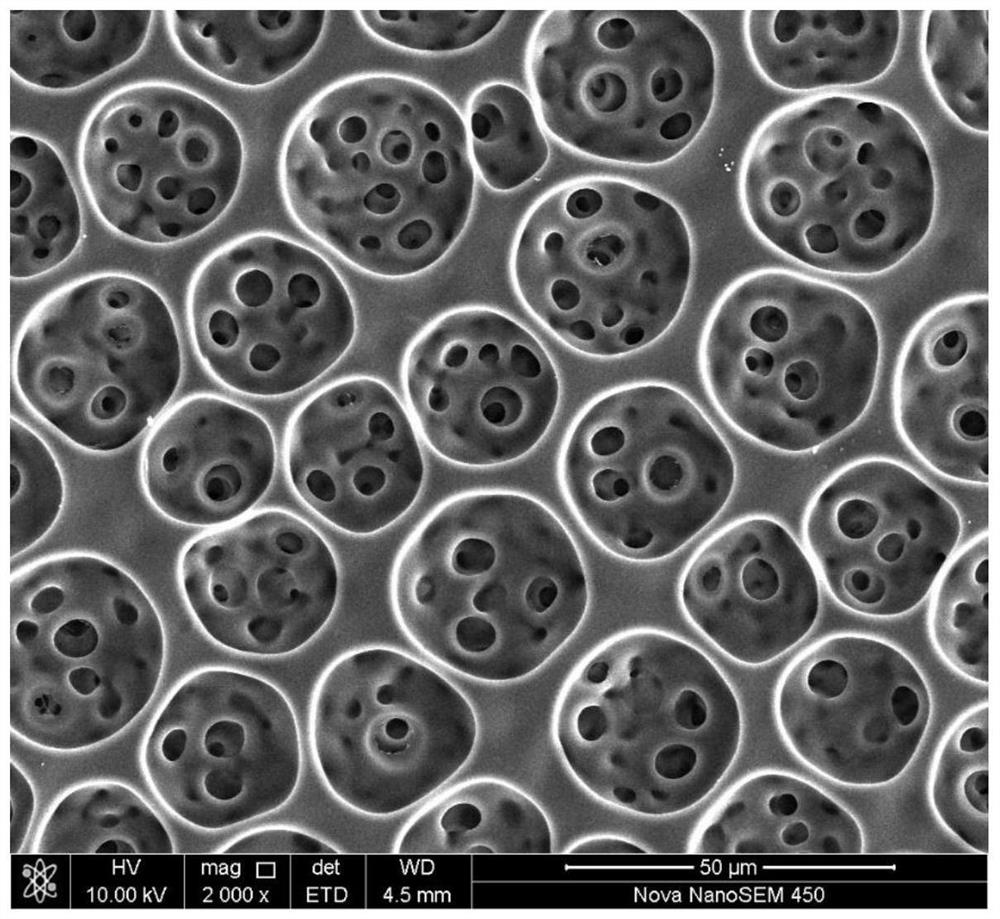

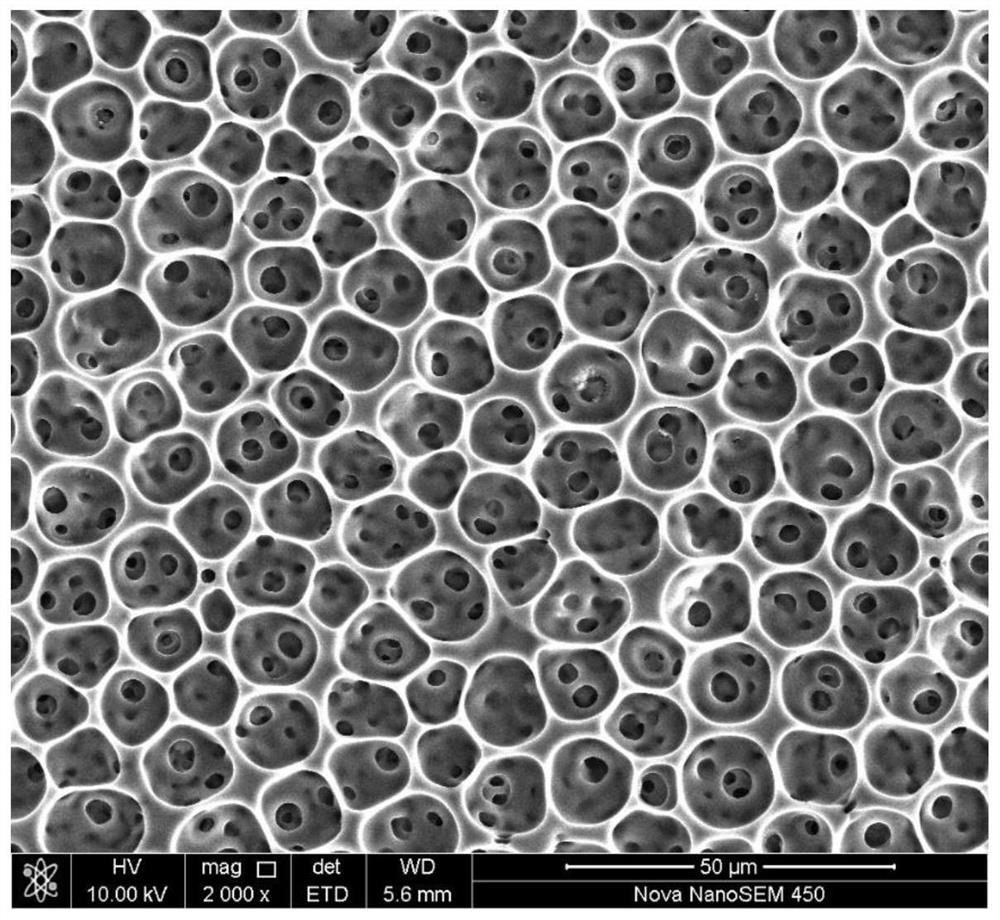

Ordered extralarge-hole-pitch alumina film and preparation method thereof

The invention discloses an ordered extralarge-hole-pitch alumina film and a preparation method thereof. The alumina film has high hardness and elastic modulus, low reflectivity and obvious photoluminescence performance. The surface of the film is composed of innumerable holes. The bottoms of the holes are distributed in ordered hexagons. According to the ordered extralarge-hole-pitch alumina film and the preparation method thereof, macromolecular organic acid serves as an electrolyte, the electrolyte and an aluminum base are effectively cooled simultaneously, and the aluminum base is stably oxidized under extra-high voltage. The alumina film can serve as an ideal template for preparing various ordered major-cycle nano array structures of metal, polymer and the like, and can also be used for developing three-dimensional channel alumina films of micro and nano composite structures. The major-cycle alumina film is an excellent bioactivator carrier and has wide application prospects in the aspects of biosensors, medicine transport platforms, solar cells and the like.

Owner:SHAANXI NORMAL UNIV

Method for preparing Al/Ni reaction laminated foil by EBPVD (electron beam physical vapor deposition)

ActiveCN104911549AUniform structureThe interface is complete and clearVacuum evaporation coatingSputtering coatingElectron beam physical vapor depositionCombustion

The invention relates to a method for preparing Al / Ni reaction laminated foil by EBPVD (electron beam physical vapor deposition), and aims to solve the technical problems that a current Al / Ni laminated foil preparation method is low in production efficiency and high in production cost, impurities are easily led into an Al / Ni layer interface, pollution is caused, and higher self-propagating speed cannot be obtained. The method includes the steps: firstly, previous preparation of EBPVD; secondly, ingot preheating; thirdly, deposition layer separation; fourthly, laminated foil deposition. The Al / Ni reaction laminated foil is uniform in structure, the layer thickness can be controlled, the interface is complete and clear, pollution is avoided, production efficiency is high, cost is low, the temperature of various substrates can be lower than 160 DEG C in the preparation process, combustion of the Al / Ni reaction laminated foil is avoided, and the Al / Ni reaction laminated foil prepared by the method can release great heat in a self-propagating mode within a short time and can be applied to the field of special welding.

Owner:HARBIN INST OF TECH

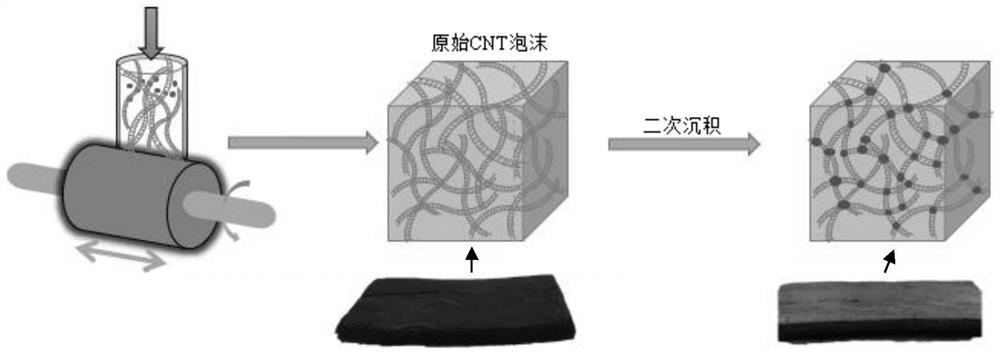

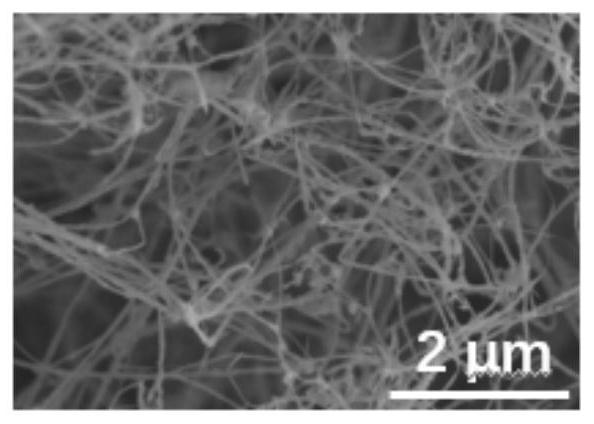

Carbon nanotube foam material with electromagnetic shielding performance, and preparation method and application thereof

ActiveCN112210766AImprove shielding effectControllable densityMagnetic/electric field screeningChemical vapor deposition coatingCarbon nanotubeNetwork structure

The invention discloses a carbon nanotube foam material with electromagnetic shielding performance, and a preparation method and application thereof. The preparation method of the carbon nanotube foammaterial with the electromagnetic shielding performance comprises the following steps: placing carbon nanotube foam into a reaction chamber of chemical vapor deposition equipment; and heating the reaction chamber to 1000-1100 DEG C, and then at least introducing a carbon source and a reducing gas into the reaction chamber, so as to carry out secondary deposition of amorphous carbon on the carbonnanotube foam, thereby obtaining the carbon nanotube foam material with the electromagnetic shielding performance, wherein the carbon nanotube foam material comprises a porous structure composed of a3D network structure with self-supporting capability. According to the invention, the prepared carbon nanotube foam material with the electromagnetic shielding performance has excellent shielding effectiveness, controllable density and thickness, small mass, good flexibility and excellent shielding effectiveness stability; and the preparation process is simple, and batch production can be expanded.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

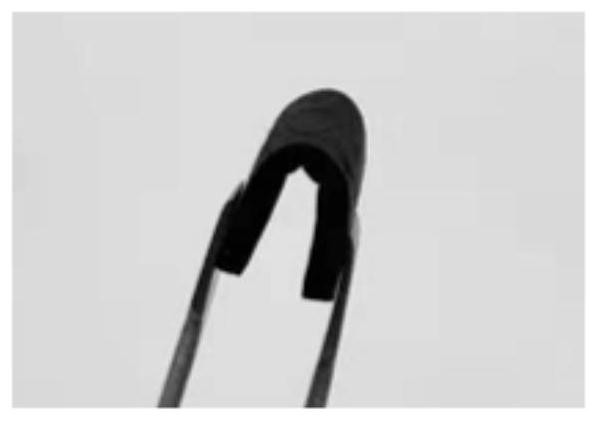

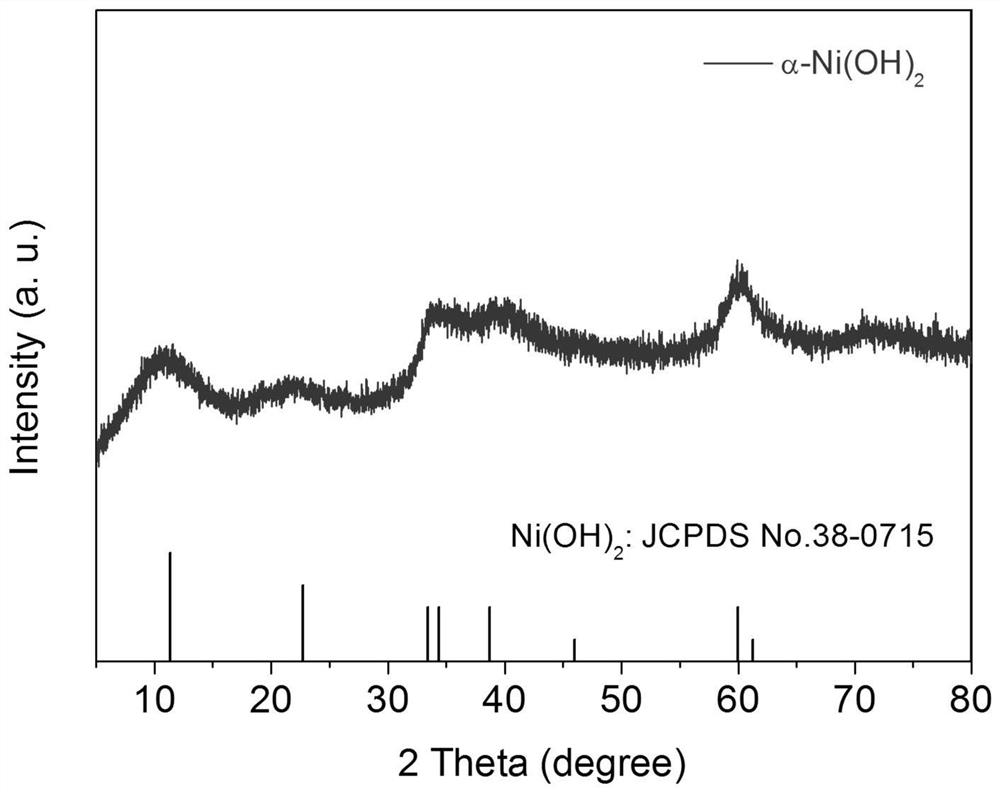

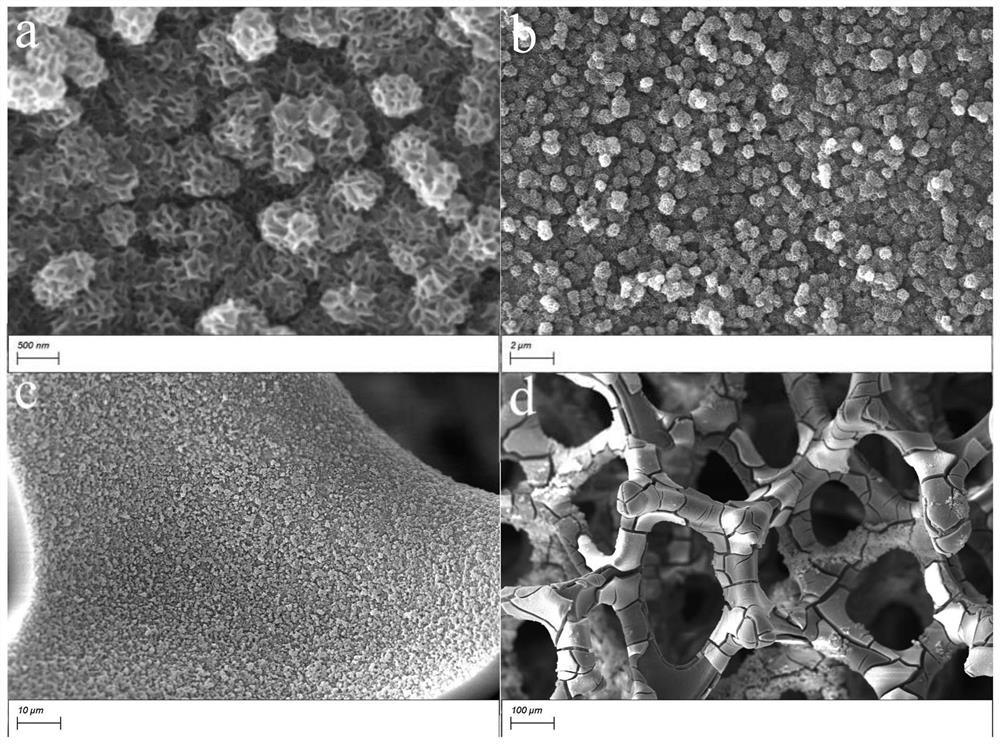

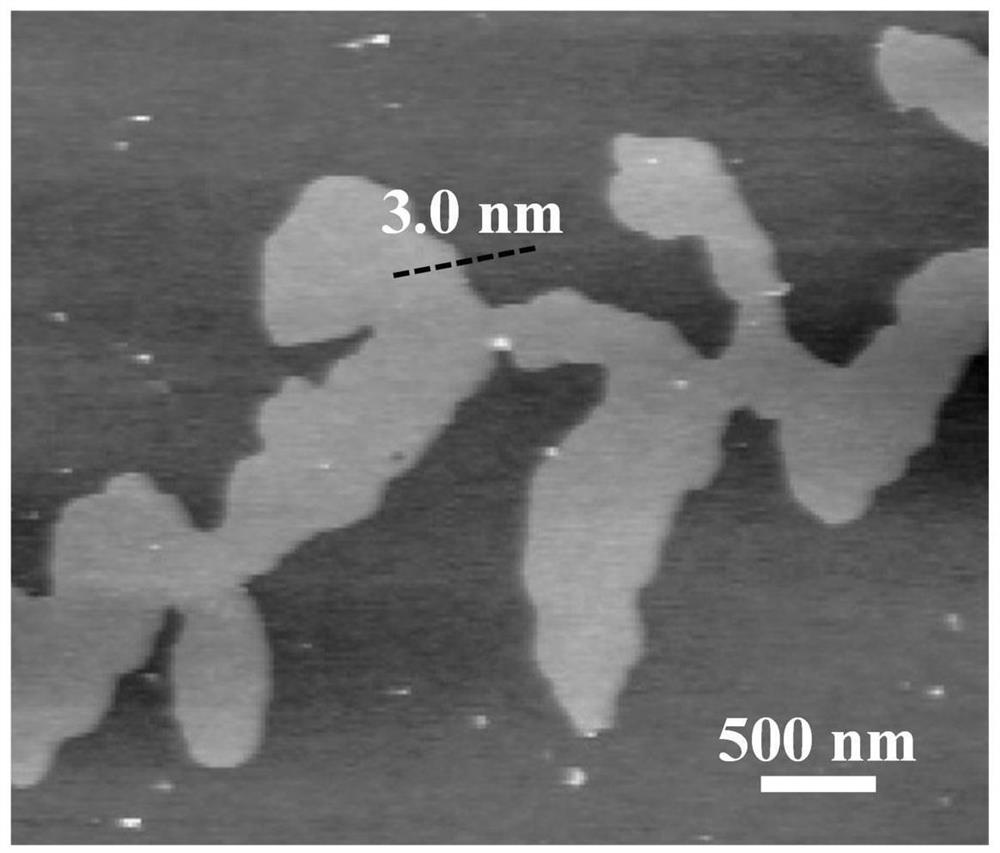

Preparation method and application of nickel hydroxide/nickel electrode

InactiveCN113005476AEasy to prepareRaw materials are cheap and easy to getElectrolytic inorganic material coatingElectrodesElectrolytic agentNickel electrode

The invention discloses a preparation method and application of a nickel hydroxide / nickel electrode. An ultrathin nickel hydroxide (alpha-Ni(OH)2) nanosheet with the thickness of 3.0 nm is directly grown on foamed nickel (NF) through electro-deposition, and an alpha-Ni(OH)2 / NF self-supporting electrode is constructed. The electrode shows excellent OER catalytic performance, the current density of 10 mA*cm<-2> and the current density of 100 mA*cm<-2> can be driven only by low overpotentials of 192 mV and 240 mV in 1.0 M KOH electrolyte solution, and the catalytic performance exceeds that of nickel hydroxide / oxide and reference RuO2 in the prior art. In addition, the alpha-Ni(OH)2 / NF self-supporting electrode can drive a large current density of 500-1000 mA*cm<-2> only with a low overpotential, and has a potential industrial application value.

Owner:JIANGXI NORMAL UNIV

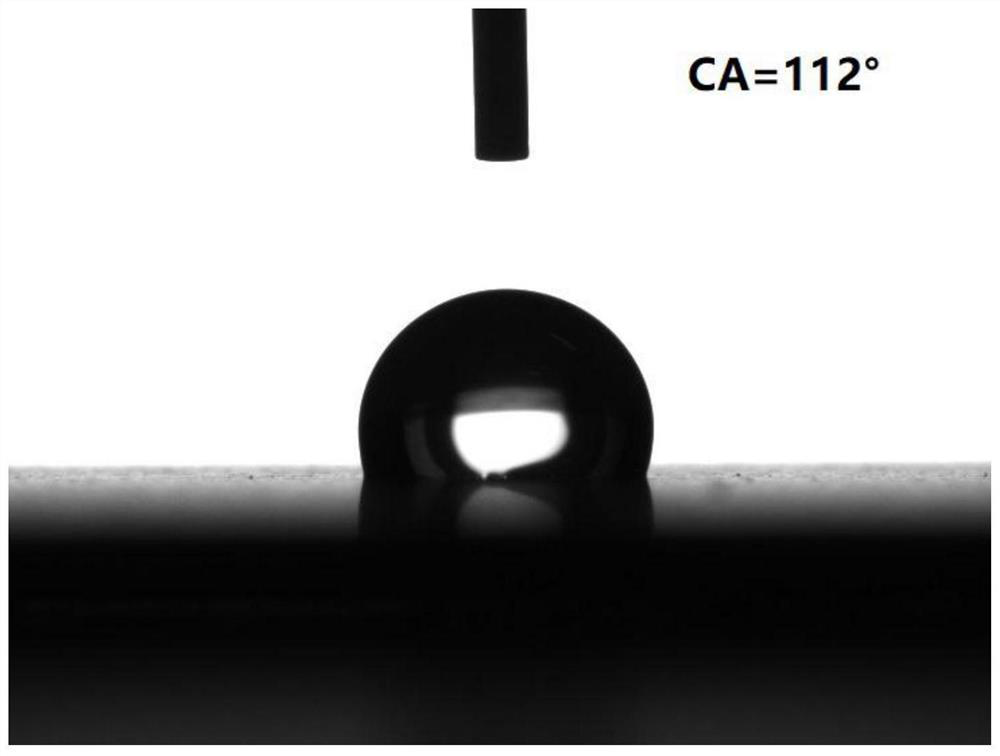

Preparation method for polyurethane nano zinc oxide super-hydrophobic coating

InactiveCN111842090AUniform and controllable thicknessThickness controlPretreated surfacesPolyurea/polyurethane coatingsMicro nanoHigh humidity

The invention discloses a preparation method for a polyurethane nano zinc oxide super-hydrophobic coating. The method comprises the following preparation steps: grinding a base material, cleaning andpre-treating the base material, adopting a mechanical-ultrasonic vibrating way to prepare a polyurethane mixed solution; coating a certain thickness of the polyurethane mixed solution on the surface of a base body, enabling the mixed solution to separate out and cure into a film under a high-moisture environment, cleaning and drying the film, putting the film into an alcohol solution with low-surface-energy substances to modify, and drying the film to the polyurethane nano zinc oxide super-hydrophobic coating with super-hydrophobicity. The preparation method is simple in preparation conditionand operation requirement; the prepared coating has controllable thickness, and uniform and compact surface micro-nano structure distribution; and a coating contact angle can be 160 degrees after thelow-surface-energy substances are modified.

Owner:NANCHANG HANGKONG UNIVERSITY

Method for in-situ preparation of nano-silver/carboxylated chitosan composite films by using electric deposition technology

ActiveCN109518246AThickness controlMild conditionsMaterial nanotechnologyElectrolytic organic material coatingComposite filmChemical reaction

The invention discloses a method for in-situ preparation of nano-silver / carboxylated chitosan composite films by using an electric deposition technology. Metal silver pieces are used as anode materials, metal platinum pieces are used as cathode materials, and carboxylated chitosan solution is used as electric deposition liquid for electric deposition; in the electric deposition process, Ag+ generated by an anode electrochemical reaction generated on the metal silver pieces is used for generating a coordination effect with carboxylated chitosan molecules to form carboxylated chitosan electric deposition films on the metal silver electrodes; meanwhile, carboxylated chitosan is used as a reducing agent for reducing Ag+ in the electric deposition films to obtain nano-silver; and the nano-silver / carboxylated chitosan composite films are prepared in situ on the anode silver pieces. The method is simple in equipment, mild in condition, convenient to operate and low in cost, has the advantagesof space selectivity, controllability, no poison, no pollution, greenness and environmental protection, and can adjust the thickness of the composite films through change of such conditions as electric deposition time and electric deposition voltage.

Owner:WUHAN UNIV OF TECH

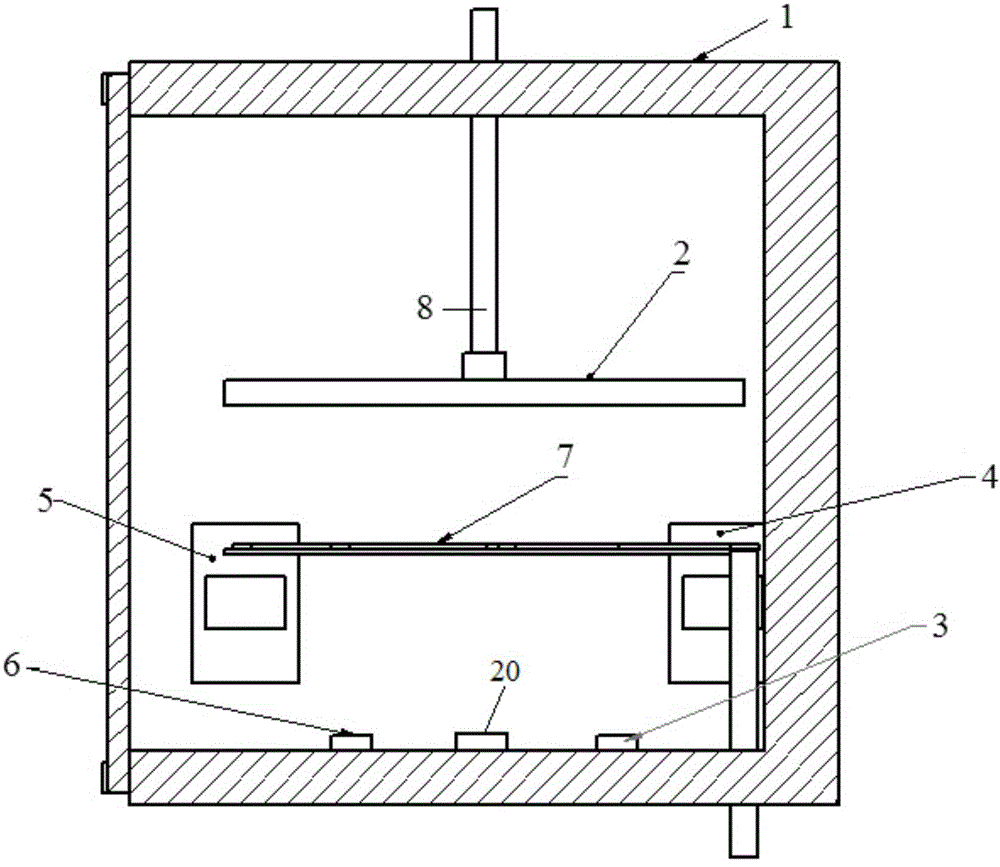

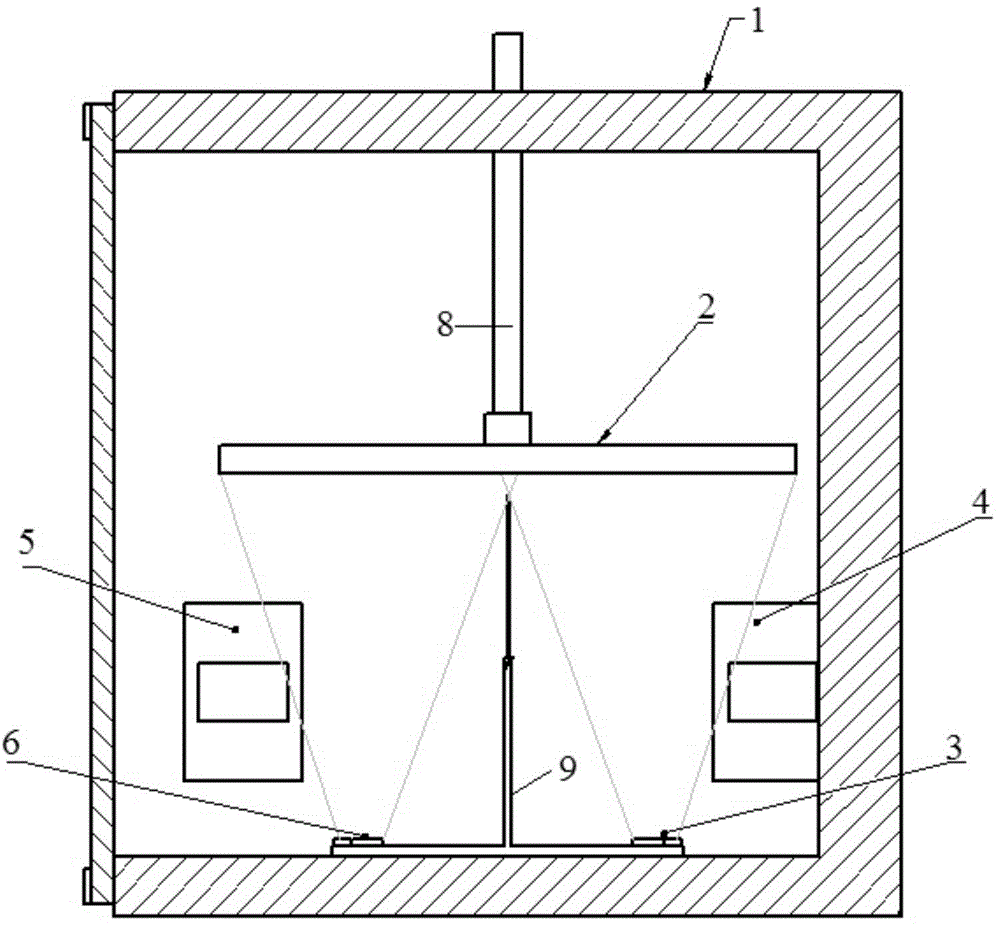

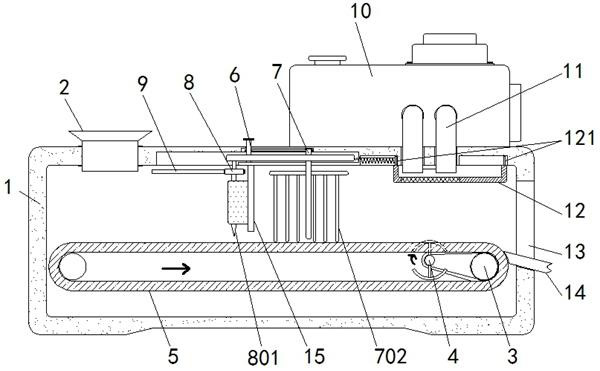

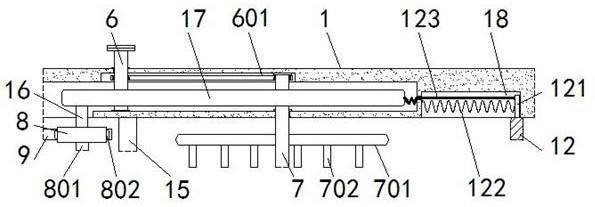

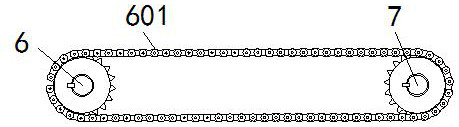

Bean curd sheet preparation equipment

InactiveCN104543021AChange the speed of movementPrevent proliferationCheese manufactureFood scienceProduction rateSurface layer

The invention discloses bean curd sheet preparation equipment and aims to provide thin bean curd sheet processing equipment which is consistent in product size, uniform in thickness and high in yield. The bean curd sheet preparation equipment comprises a net-shaped conveyor belt (13) arranged on a rack (1) through a roller shaft (7), wherein the conveyor belt is driven by a motor (4) fixed on the rack (1) through a transmission mechanism; the motor (4) is fixed on the rack (1); the transmission mechanism consists of a small chain wheel fixed on a shaft of the motor, a big chain wheel (6) fixed on the roller shaft (7), and a chain (5) connecting the small chain wheel with the big chain wheel (6); a bottom-layer filter cloth roller (15), a surface-layer filter cloth roller (18) and a slurry slot (16) are arranged above the conveyor belt (13); the slurry slot is positioned between the bottom-layer filter cloth roller (15) and the surface-layer filter cloth roller (18). The bean curd sheet preparation equipment is simple in structure, convenient to operate, and capable of replacing manual operation to realize continuous production, and is bean curd processing equipment.

Owner:贵州龙缘盛豆业有限公司

Surface coated positive electrode material and preparation method thereof, and battery

ActiveCN109755551AReduce direct contact areaReduce riskCell electrodesSecondary cellsPhysical chemistrySide reaction

The invention relates to a surface coated positive electrode material and a preparation method thereof, and a battery; the preparation method comprises the following steps of surface treatment, metalion adsorption, deposition treatment and oxidation sintering. The method has the beneficial effects that the self-adsorption of metal cations is utilized, so that the obtained coating layer is uniformand complete, the direct contact area of the active substance and the electrolyte can be greatly reduced, and the risk of side reaction is reduced; the in-situ growth mechanism is adopted, so that the size of the deposited particles can be regulated and controlled, the size is between the nanometer crystal and micron interval, and the compactness of the coating layer is controlled; the thicknessof the coating layer can be adjusted and controlled by adjusting the number of deposition times of in-situ growth, so that a better protection effect can be obtained; an agglomeration phenomenon occurring during conventional wet-process coating can be avoided; an and the in-situ coating method is adopted, and severe stirring is not needed, so that physical crushing caused by secondary ball formingis avoided.

Owner:湖南桑瑞新材料有限公司

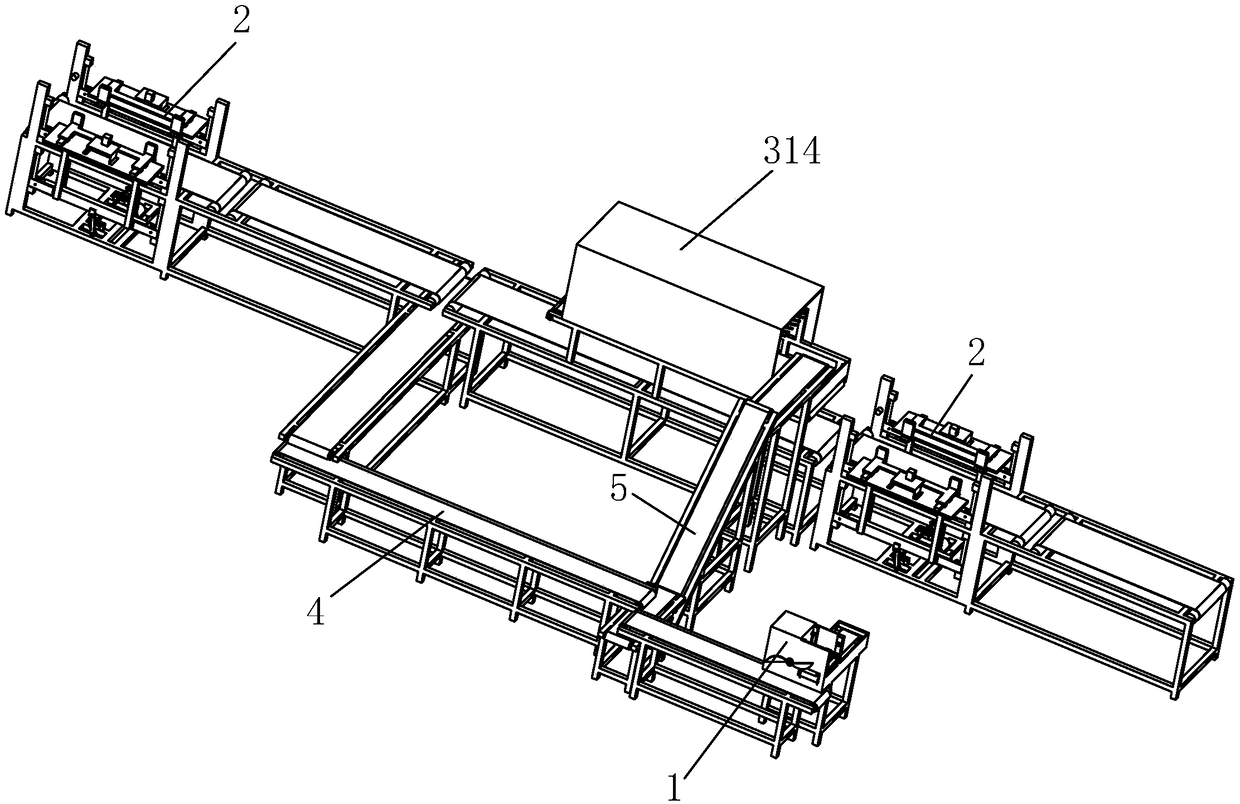

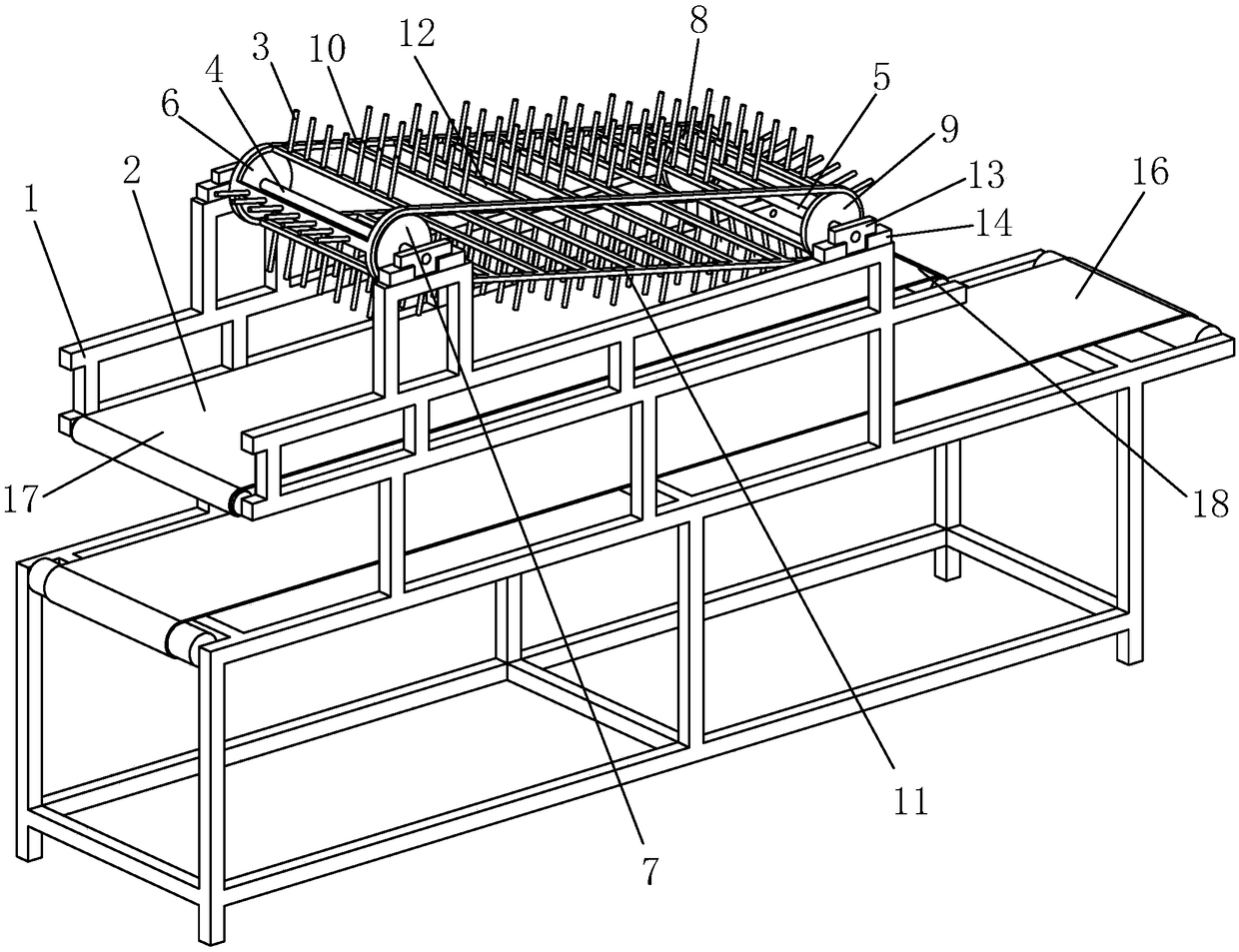

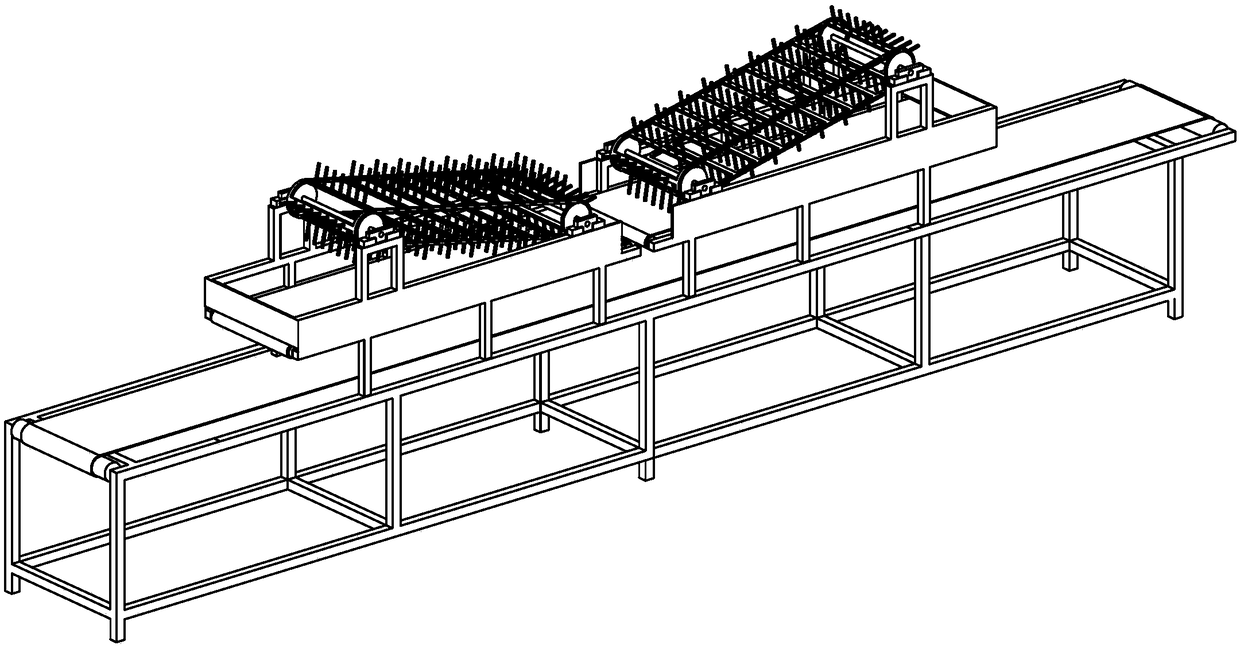

Uniform folium mori releasing automatic silkworm feeding machine with chain plate comb conveyor belt

PendingCN109436861AAchieve the effect of automatic silkworm feedingImprove work efficiencyConveyorsLoading/unloadingEngineeringConveyor belt

The invention relates to a uniform folium mori releasing automatic silkworm feeding machine with a chain plate comb conveyor belt. The uniform folium mori releasing automatic silkworm feeding machinecomprises a rack, a conveyor belt and uniform combers. The conveyor belt and the uniform combers are arranged on the rack, the uniform combers are located above the conveyor belt, one end of the conveyor belt is a folium mori inlet while the other end of the conveyor belt is a folium mori outlet, and one end of each uniform combers is higher than the other end, the end, located at the folium moriinlet, of each uniform comber is higher than the end, located at the folium mori outlet, of the uniform comber. Each uniform comber comprises a transmission device and a plurality of uniform combing rods. The uniform combing rods are arranged on the transmission device, the conveyor and the uniform combers are separately connected to a power mechanism, and the distance from the lowest uniform comber to the conveyor belt is the thickness degree of folium mori falling from the outlet. By combing the folium mori on the conveyor belt flatly and uniformly by the uniform combers and feeding the uniformly scraped folium mori to a rearing tray from the outlet, an automatic folium mori effect is achieved, and the work efficiency is improved.

Owner:柳州蚕润丝圆蚕业机械科技有限公司

Enhanced self-lubricating joint bearing gasket material preparation method

The invention discloses an enhanced self-lubricating joint bearing gasket material preparation method, which comprises: coating inorganic nano-powder with a borate polymer, and under the synergistic effect of organic-metal coordination and B-N coordination, simply and efficiently preparing a core-shell structure nano-powder with an adjustable shell thickness. According to the present invention, byusing the strong affinity between the borate polymer and the matrix resin and the hydrogen-bond interaction between the surplus boric acid or catechol functional group on the surface and the matrix resin, the dispersity of the nanoparticles in the matrix resin is improved, and the comprehensive mechanical properties of the coating material are improved.

Owner:XIAMEN UNIV

Steam humidification based ginned cotton humidifying equipment for cotton production and processing

InactiveCN112726054AThickness controlThickness is easy to adjustTextile treatment by spraying/projectingTextile treatment carriersStructural engineeringMechanical engineering

The invention discloses steam humidification based ginned cotton humidifying equipment for cotton production and processing. The equipment comprises a conveying frame, a feeding port, conveying rollers, a humidifying mechanism and a humidifying pipeline, wherein the feeding port is formed in the upper portion of the left end of the conveying frame; the interiors of the left end and the right end of the conveying frame are connected with the conveying rollers through bearings; the rear end of the conveying roller in the right end of the conveying frame penetrates through the rear side face of the conveying frame; a mounting shaft rod is connected to the interior of the right end of the conveying frame by a bearing; a conveying belt is arranged on the outer side of the conveying roller; and a first vertical rod and a second vertical rod are connected to the interior of the upper surface of the conveying frame by bearings. The steam humidification based ginned cotton humidifying equipment for cotton production and processing is provided with a moving plate and a blocking rod; the moving plate and the blocking rod form a comb structure; and the conveying thickness of cotton can be regulated and controlled through the setting of the distance between the moving plate and the conveying belt and the distance between the blocking rod and the conveying belt, so that the thickness of the cotton is conveniently regulated and controlled and the influence on later humidification work due to relatively thick cotton accumulation is avoided.

Owner:马鞍山鸿儒工业设计有限公司

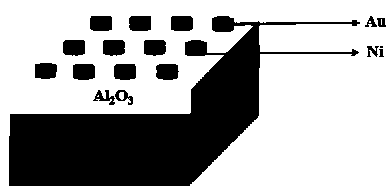

Preparation method of alumina medium-based microwave/radio frequency thin film capacitor

ActiveCN110349749ALittle change in thicknessImprove compactnessThin/thick film capacitorFixed capacitor dielectricMicrowaveDielectric loss

The invention belongs to the technical field of capacitors, and particularly discloses a preparation method of an alumina medium-based microwave / radio frequency thin film capacitor. The method comprises the following steps: S1, growing alumina with the thickness of 25-100 nm on heavily doped silicon by atomic layer deposition through ozone, wherein a precursor is trimethyl aluminum, the growth temperature is 80-300 DEG C, and the ozone flow is 30-50 ml / min; S2, carrying out treatment by an annealing process, wherein the annealing process is divided into a heating stage, a heat preservation stage and a cooling stage; and S3, carrying out assembling to obtain the capacitor. The capacitor provided by the invention has a relatively high breakdown voltage, a relatively low leakage current and arelatively large dielectric constant (close to a theoretical value) and relatively low dielectric loss (less than or equal to 5%). The capacitor is simple in structure, and the production process isrelatively easy to realize.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com