Preparation method of micro-nano lamination metal base composite material

A technology for laminated metal and composite materials, applied in the field of composite materials, can solve the problems of inapplicable nano-reinforcement, damage to the shape of sheet metal powder, nano-reinforcement structure, and the impossibility of obtaining nano-laminated structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

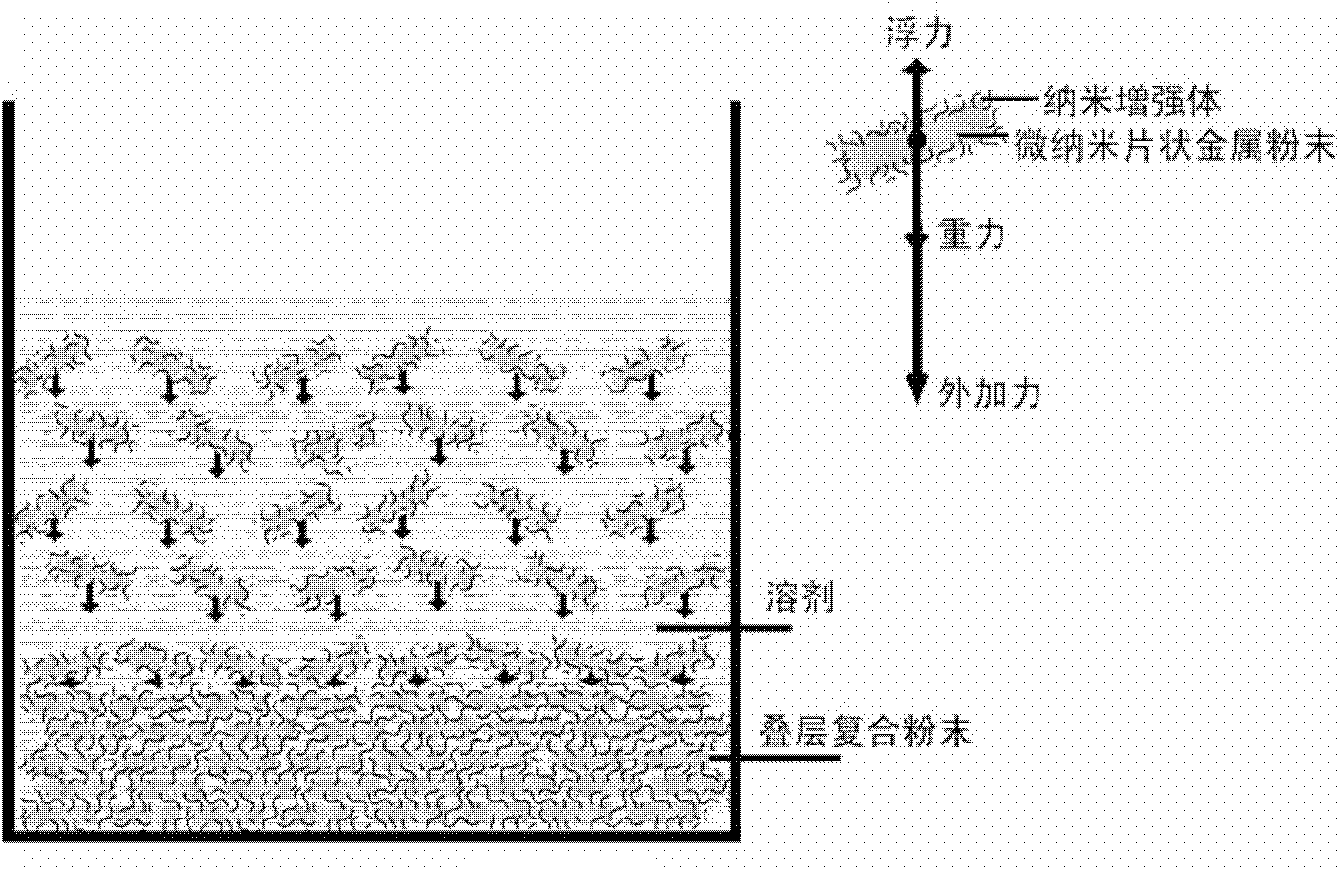

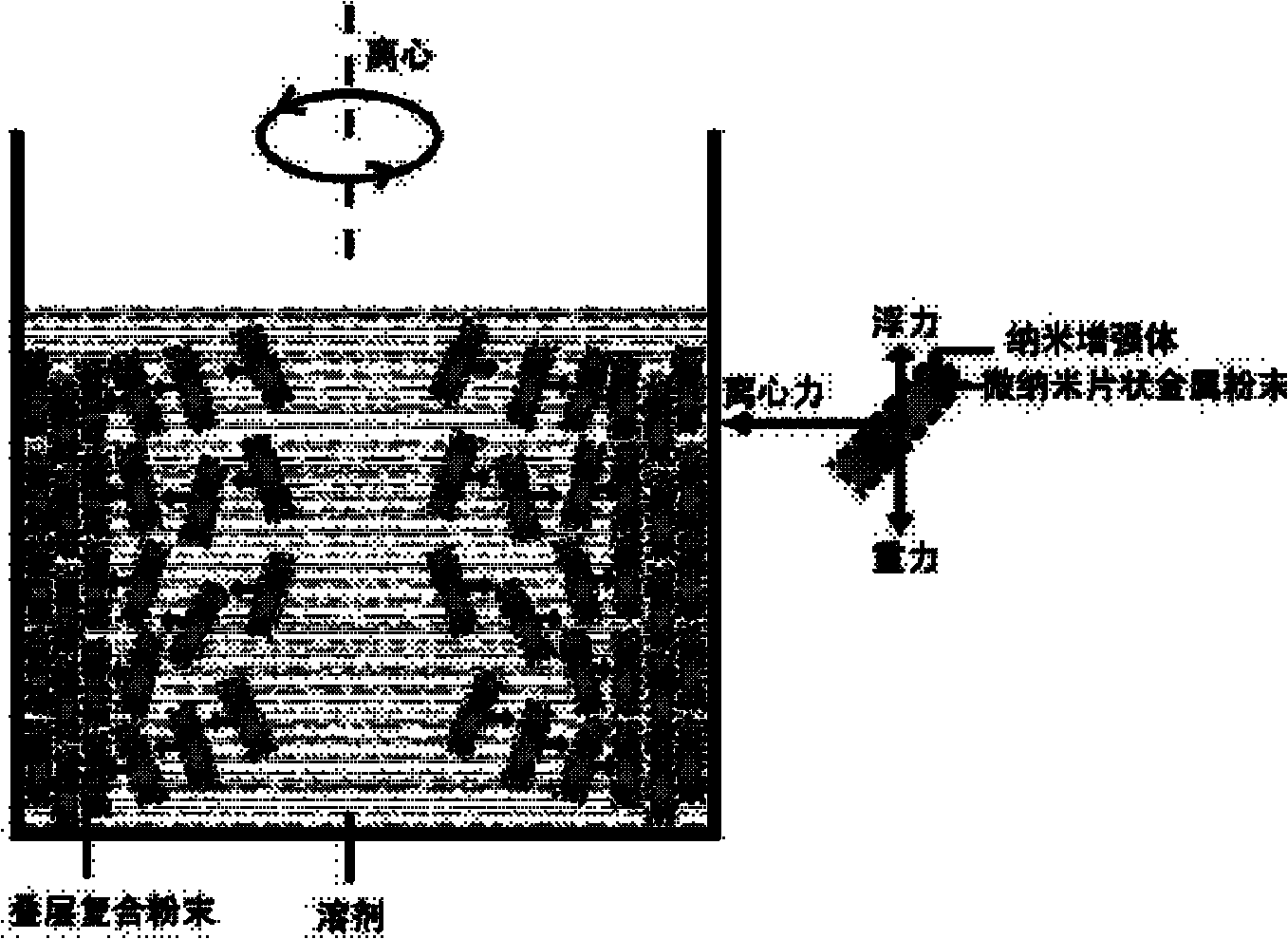

Method used

Image

Examples

Embodiment 1

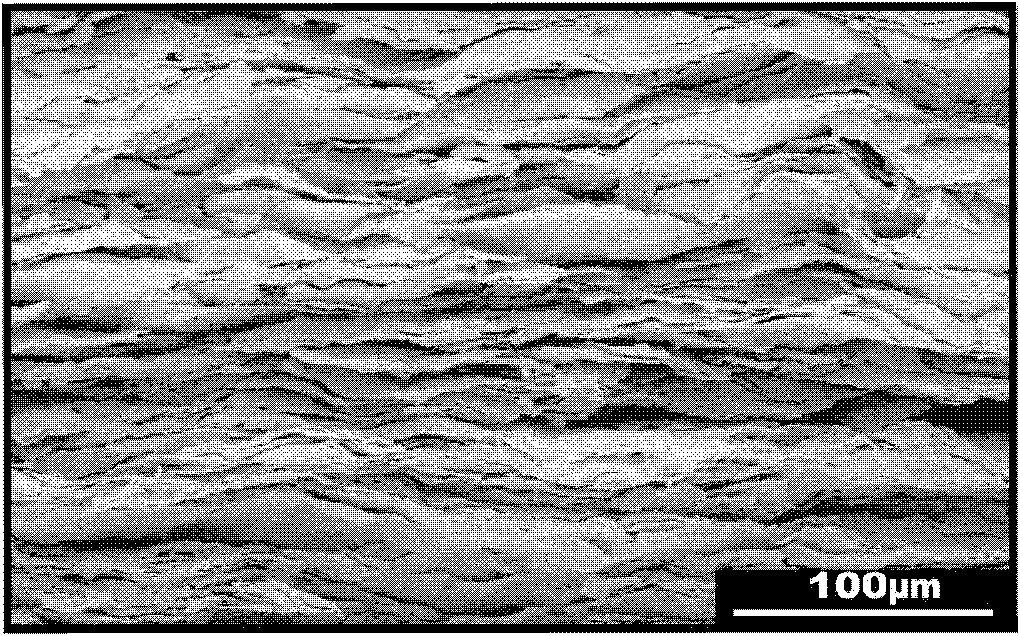

[0030] Carbon nanotube / copper nanolaminate composite material

[0031] The nano-sheet copper powder prepared by ball milling has a sheet diameter of about 40-50 microns, a sheet thickness of about 300-400 nm, and a diameter-thickness ratio greater than 150; it adopts multi-walled carbon nanotubes that have been treated with strong acid and contain carboxyl groups on the surface. The diameter is 20-60 nanometers.

[0032]Add carbon nanotubes, surfactant sodium lauryl sulfate, and defoamer octanol into deionized water, and ultrasonically disperse them for 2 hours to disperse the carbon nanotubes evenly, then add deionized water to adjust the concentration of carbon nanotubes to obtain a concentration of 5mg / ml carbon nanotube slurry;

[0033] Adding the nano-flaky copper powder and the surfactant polyethylene glycol into absolute ethanol, stirring mechanically until the polyethylene glycol is completely dissolved, to obtain a nano-flaky copper powder slurry with a solid phase v...

Embodiment 2

[0038] Boron carbide / aluminum micron laminated composites

[0039] The micro-flaky aluminum powder prepared by ball milling has a sheet diameter of about 50-70 microns, a sheet thickness of about 2-3 microns, and a diameter-to-thickness ratio greater than 25; the nano-reinforcement uses nano-boron carbide with a particle size of about 50 nanometers particles.

[0040] Add nano boron carbide particles and surfactant sodium dodecylbenzene sulfonate into deionized water, ultrasonically disperse for 0.5 hours to uniformly disperse nano boron carbide particles, and obtain nano boron carbide slurry with a solid phase volume content of 5%;

[0041] Add polyvinyl alcohol into deionized water, heat up to 95°C, and stir mechanically until the polyvinyl alcohol is completely dissolved to obtain a polyvinyl alcohol aqueous solution with a concentration of 3 wt%. Add micron flake aluminum powder into the polyvinyl alcohol aqueous solution, and Stirring to obtain a micron flake aluminum po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com