Preparation method of ultra-thin two-way titanium-dioxide nanopore-array film with adjustable aperture and thickness

A technology of nanoporous film and nanopore array, applied in the field of nanomaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

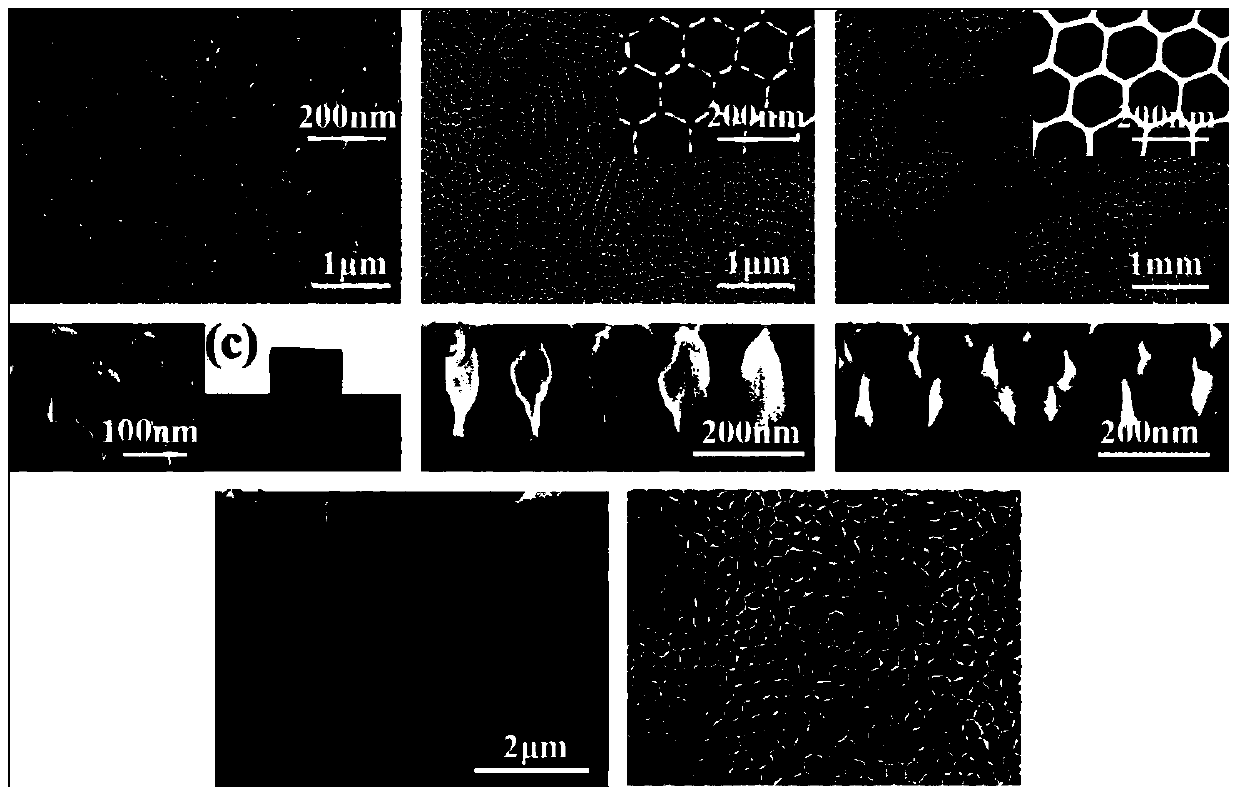

Image

Examples

Embodiment Construction

[0026] 1. Pre-treatment of titanium sheet

[0027] The high-purity titanium sheet (purity of 99.6%, purchased from Baoji Tianmai Titanium Industry Co., Ltd.) was ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 10 minutes, and then dried in the air at 50°C.

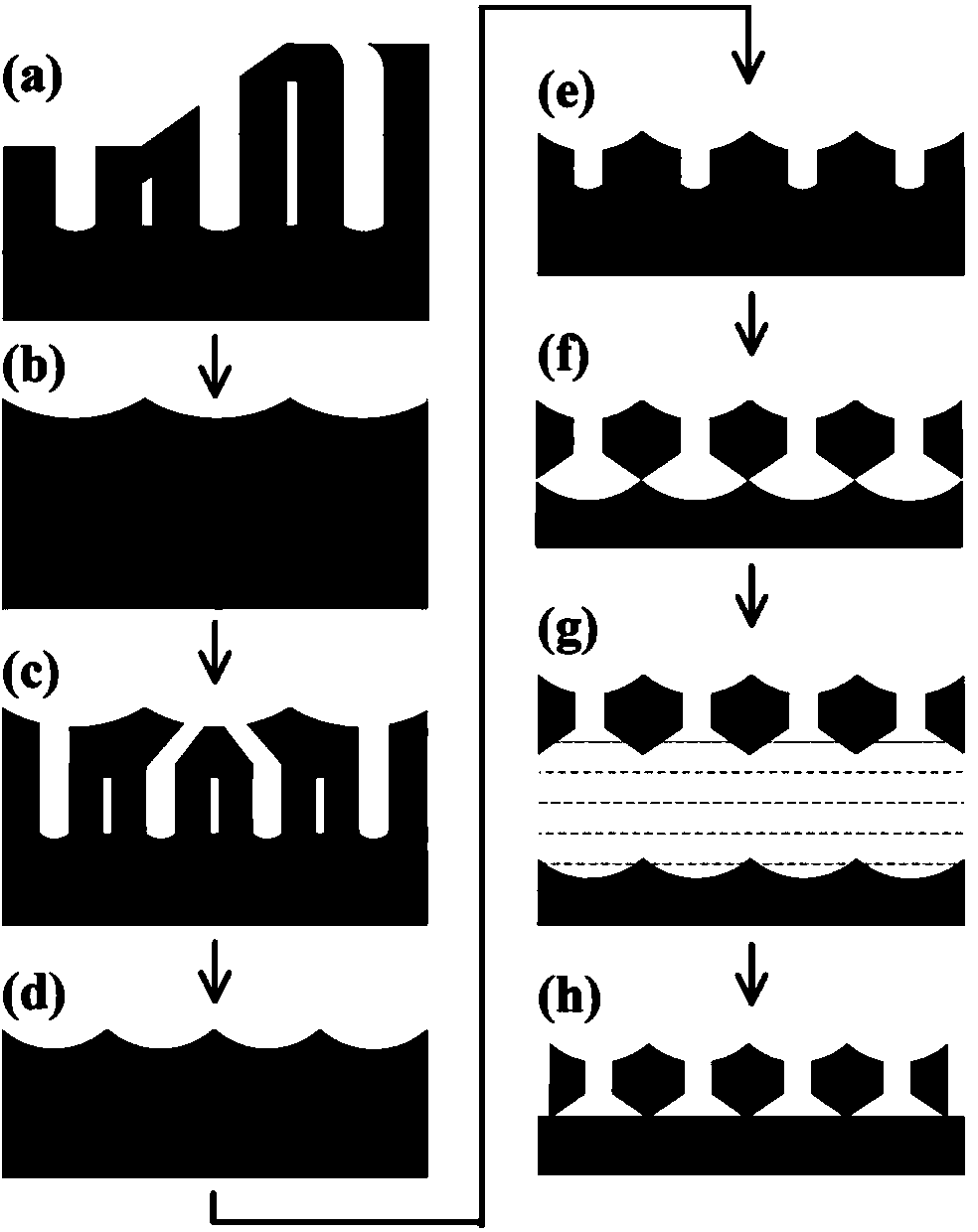

[0028] 2. Preparation of ultra-thin double-pass titanium dioxide nanoporous film

[0029] The preparation process is as figure 1 As shown, it is specifically divided into four steps: two pre-oxidation, film-forming oxidation, and high-pressure vias. Firstly, the treated titanium sheet was pre-oxidized in an aqueous glycol electrolyte (0.3 wt% NH4F, 2 vol% H2O) at a constant pressure of 60V and a constant temperature of 15°C for 2 hours to obtain a titanium dioxide nanotube layer. Treatment, remove the formed titanium dioxide layer. Through the above-mentioned pre-oxidation, the scratches on the surface of the titanium sheet can be smoothed, and regularly arranged pits are formed on the surface of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com