Enhanced self-lubricating joint bearing gasket material preparation method

A technology for spherical plain bearings and lining materials, which can be applied to coatings and other directions, can solve the problems of limited selection range of inorganic core layer nanoparticles and complex preparation process, achieve adjustable shell thickness, simple and efficient preparation process, and improve friction and wear. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

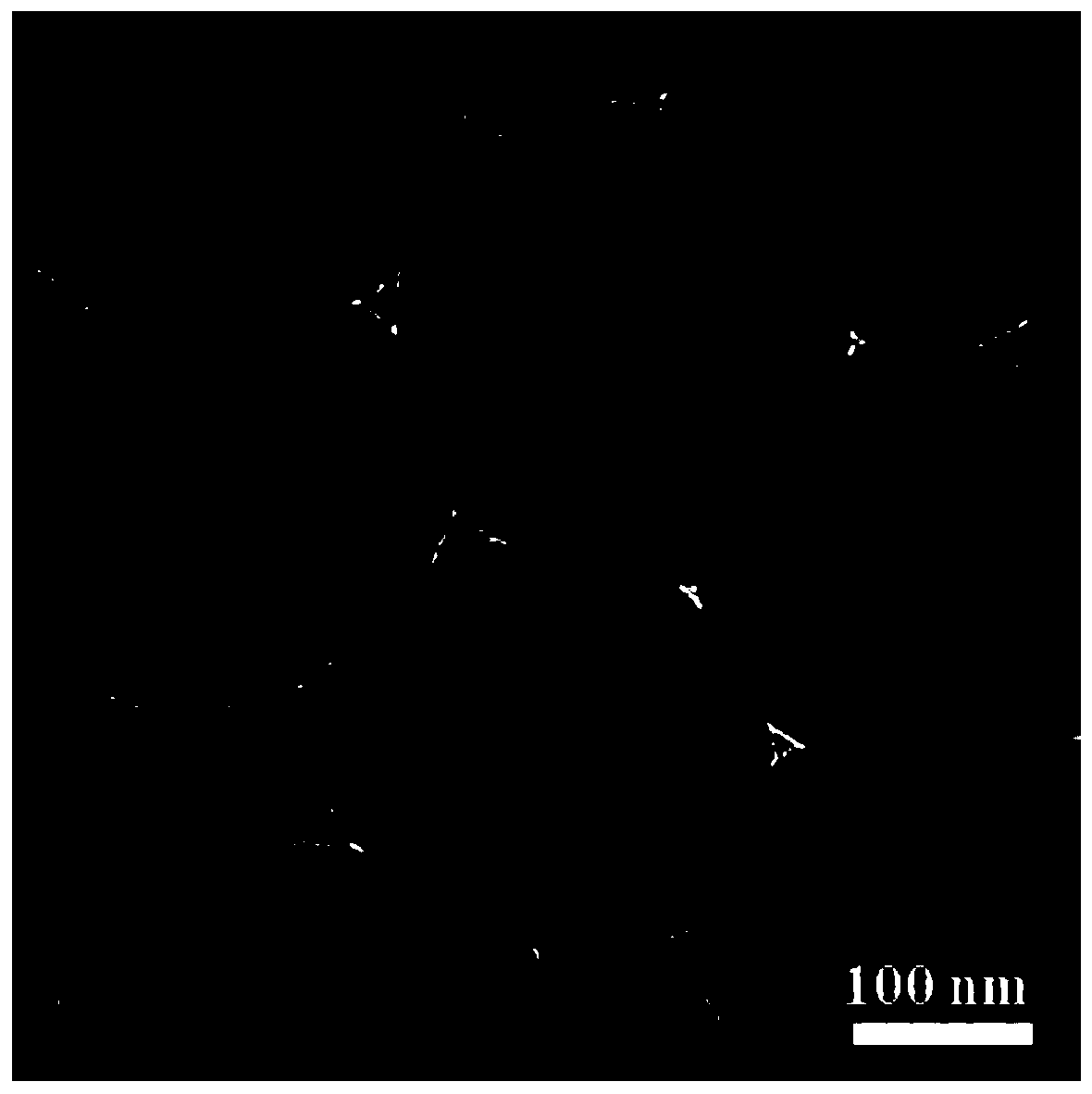

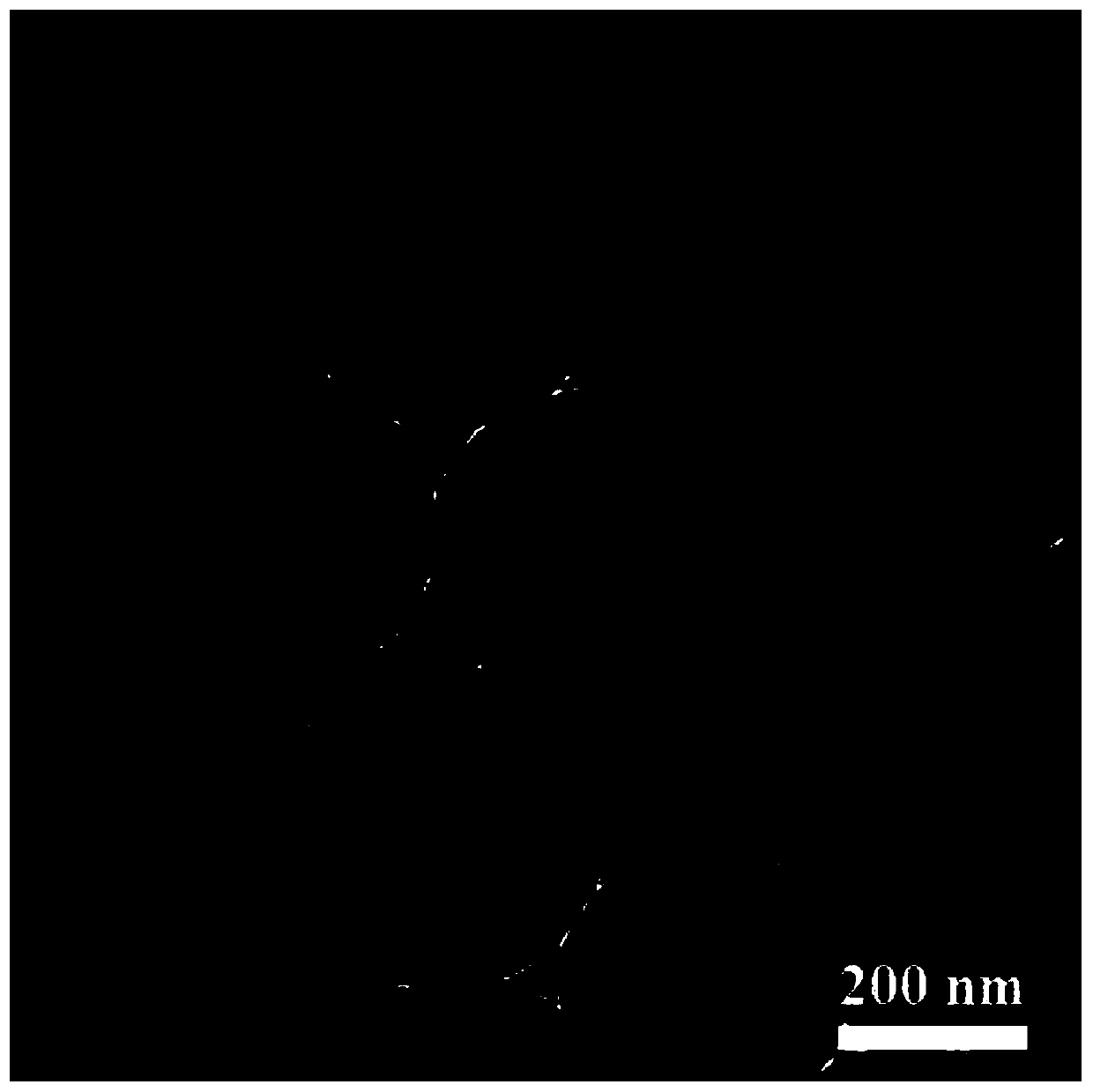

[0036] 1. Preparation of core-shell nanopowder:

[0037] Preparation of core-shell structure nano-powder A and core-shell structure nano-powder B

[0038] Disperse 2g of inorganic nanopowder (corresponding to core-shell structure nanopowder A is nano-zinc oxide, and corresponding to core-shell structure nanopowder B is nano-silicon oxide) in 5L of ethanol solution, add 0.1g bis Functional catechol monomer Im-Ca was uniformly stirred for 5 minutes, and then 0.1 g of bifunctional phenylboronic acid monomer Im-BA was added, and stirred at room temperature for 6 hours to obtain nanopowder with core-shell structure.

[0039] 2. Preparation of enhanced self-lubricating coating material:

[0040] 70g matrix resin polyimide, 2g polytetrafluoroethylene powder, 0.5g graphene powder, 3g BYK161, 2g core-shell structure nano-powder A, 1g core-shell structure nano-powder B, 30g solvent by ultrasonic and mechanical stirring Mix and disperse uniformly in the same way to obtain self-lubricat...

Embodiment 2

[0042] 1. Preparation of core-shell nanopowder:

[0043] Preparation of core-shell structure nano-powder A and core-shell structure nano-powder B

[0044] Disperse 5g of inorganic nanopowder (corresponding to core-shell structure nanopowder A is nano-zinc oxide, and corresponding to core-shell structure nanopowder B is nano-silicon oxide) in 10L of ethanol solution, add 0.5g bis Functional catechol monomer Im-Ca was uniformly stirred and reacted for 20 minutes, then 1 g of bifunctional phenylboronic acid monomer Im-BA was added, and stirred and reacted at room temperature for 12 hours to obtain a core-shell structure nanopowder.

[0045] 2. Preparation of enhanced self-lubricating coating material:

[0046]100g matrix resin polyphenyl sulfide, 5g polytetrafluoroethylene powder, 1g graphene powder, 2g BYK-307, 4g core-shell structure nano-powder A, 5g core-shell structure nano-powder B, 50g solvent through ultrasonic, Mix and disperse evenly by means of mechanical stirring to...

Embodiment 3

[0048] 1. Preparation of core-shell nanopowder:

[0049] Preparation of core-shell structure nano-powder A and core-shell structure nano-powder B

[0050] Disperse 7g of inorganic nano-powder (corresponding to the core-shell structure nano-powder A is nano-zinc oxide, and corresponding to the core-shell structure nano-powder B is nano-silicon oxide) in 10L of ethanol solution, add 0.7g bis Functional catechol monomer Im-Ca was uniformly stirred and reacted for 30 minutes, and then 0.4 g of bifunctional phenylboronic acid monomer Im-BA was added, and stirred and reacted at room temperature for 12 hours to obtain a core-shell structure nanopowder.

[0051] 2. Preparation of enhanced self-lubricating coating material:

[0052] 80g matrix resin PEEK, 2g polytetrafluoroethylene powder, 1.5g graphene powder, 3g BYK101, 2.5g core-shell structure nano-powder A, 3g core-shell structure nano-powder B, 35g solvent through ultrasonic, mechanical Mix and disperse evenly by means of stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com