Method for preparing b-axial oriented ZSM-5 molecular sieve nano-ceramic composite membrane

A nano-ceramic, ZSM-5 technology, applied in the fields of inorganic porous materials, membrane separation and membrane catalysis, to achieve the effect of improving completeness, promoting directional growth and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

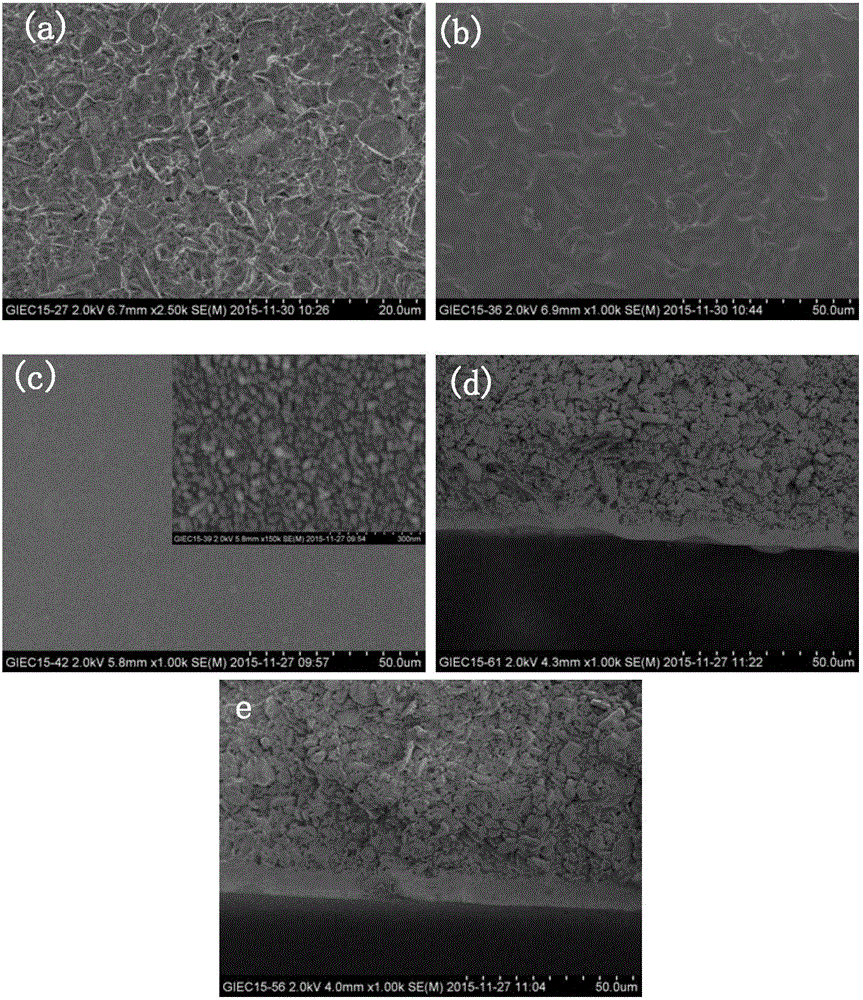

Image

Examples

preparation example Construction

[0029] A method for preparing a b-axis oriented ZSM-5 molecular sieve nano-ceramic composite membrane, comprising the steps of:

[0030] (1) Preparation of ZSM-5 molecular sieve seed crystal: using aluminum source, silicon source, organic template and water as raw materials, the molar composition of raw materials in the reaction system is calculated as oxide: 1Al 2 o 3 :aSiO 2 :bTemplate:cH 2 O, a=10~1000, b=0.5~3, c=4.5~100, Template is an organic template, according to the above dosage, add the silicon source into the water, stir until it is completely dissolved and become a silica sol, under stirring, The aluminum source and the organic template are gradually added dropwise to the silica sol, and the stirring is continued until uniform, and the pH of the reaction solution is adjusted to 11-12 to obtain the ZSM-5 molecular sieve synthetic solution;

[0031] Put the ZSM-5 molecular sieve synthesis solution into a reaction container, then put the reaction container into a h...

Embodiment 1

[0038] (1) Preparation of ZSM-5 molecular sieve seed crystals

[0039] According to 1Al 2 o 3 :1000SiO2 2 :3TEA:100H 2 The material ratio of O is used to prepare the synthetic liquid. The aluminum source and silicon source in the reaction are AlCl 3 And ethyl orthosilicate, while using triethylamine as template agent. Add a certain amount of NaOH in pure water, so that the pH value of the solution is 11-12, dissolve ethyl orthosilicate for 5 hours under stirring conditions, and make it completely hydrolyzed; after the aqueous solution is clarified, add a proportioned amount of AlCl 3 , stirring and dissolving for 3 hours. After the substances are completely dissolved, adjust the pH value of the reaction solution to 11-12, and age it at room temperature for 10 hours, and then add it to the reaction kettle. Place the reaction kettle in an oven that has been heated to 140°C, and react under stirring conditions for 100 hours. After the reaction is completed, the reaction ket...

Embodiment 2

[0048] (1) Preparation of ZSM-5 molecular sieve seed crystals

[0049] It is basically the same as Example 1, except that in the process of preparing the ZSM-5 molecular sieve synthetic solution, the aluminum source and silicon source used are respectively pseudo-boehmite and water glass, and tetrapropylammonium bromide is used as a template .

[0050] (2) Preparation of aluminum sol

[0051] It is basically the same as Embodiment 1, except that aluminum sulfate is used as the aluminum source.

[0052] (3) Preparation of ZSM-5 molecular sieve nano-ceramic composite membrane with b-axis orientation

[0053] Basically the same as Example 1, the difference is that the carrier used is porous stainless steel, and the air flow rate becomes 1m 3 / h, the calcination temperature becomes 480°C.

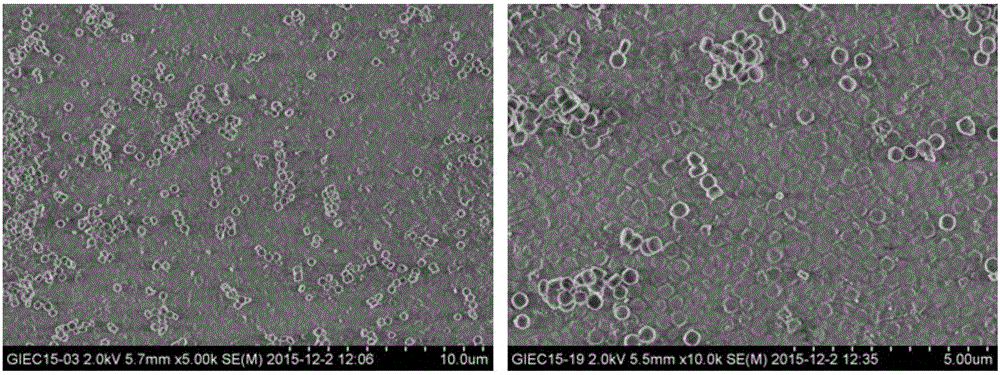

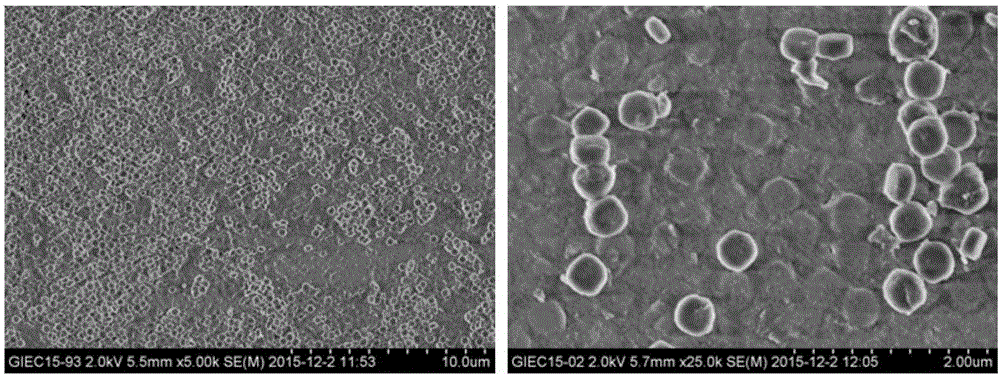

[0054] The ZSM-5 molecular sieve nano-ceramic composite membrane prepared by embodiment 2 is detected by SEM, and the results are as follows: image 3 It can be seen that the prepared ZSM-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com