Uniform folium mori releasing automatic silkworm feeding machine with chain plate comb conveyor belt

A conveyor belt and chain plate technology, applied in the field of silkworm feeding machines, can solve problems such as low efficiency and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

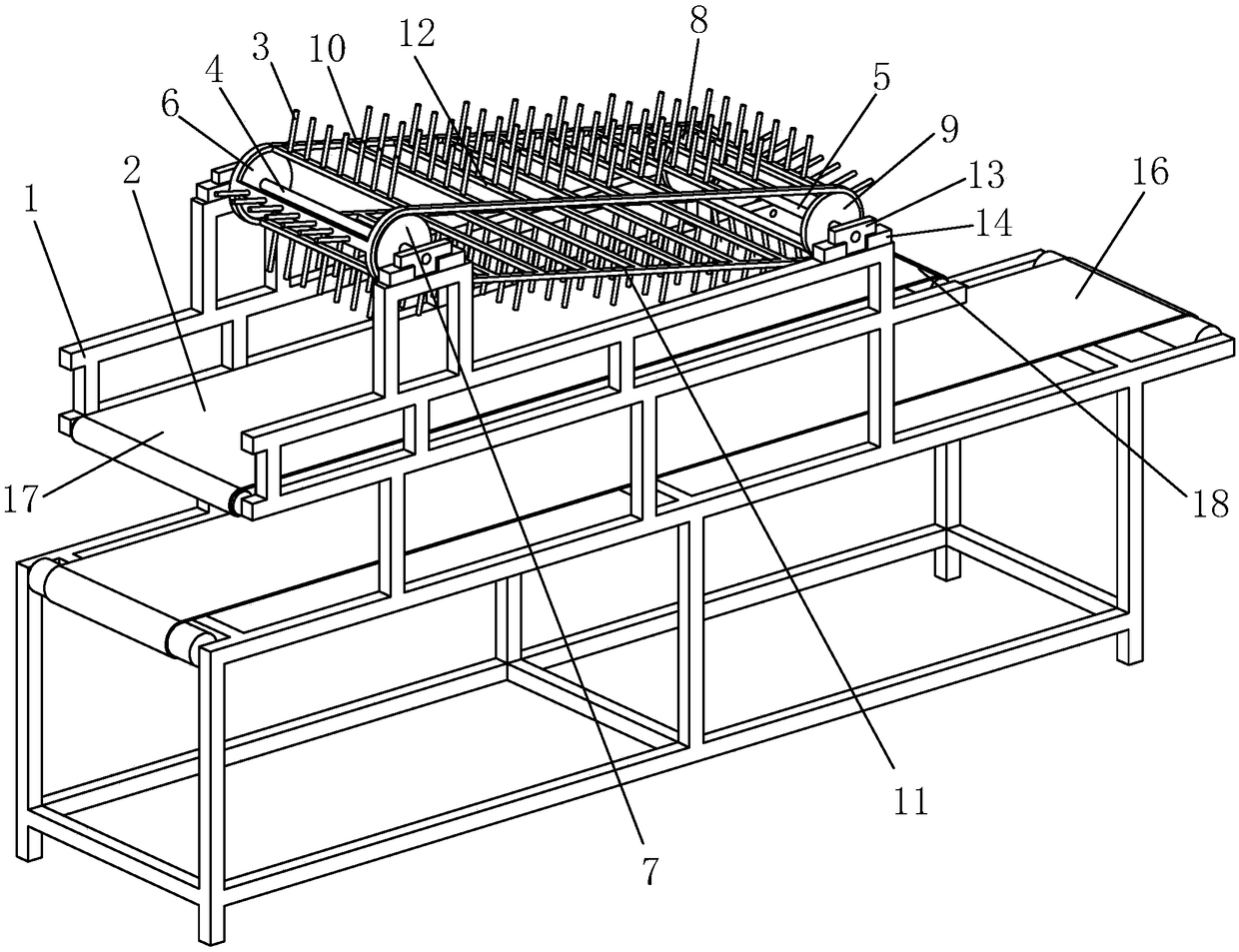

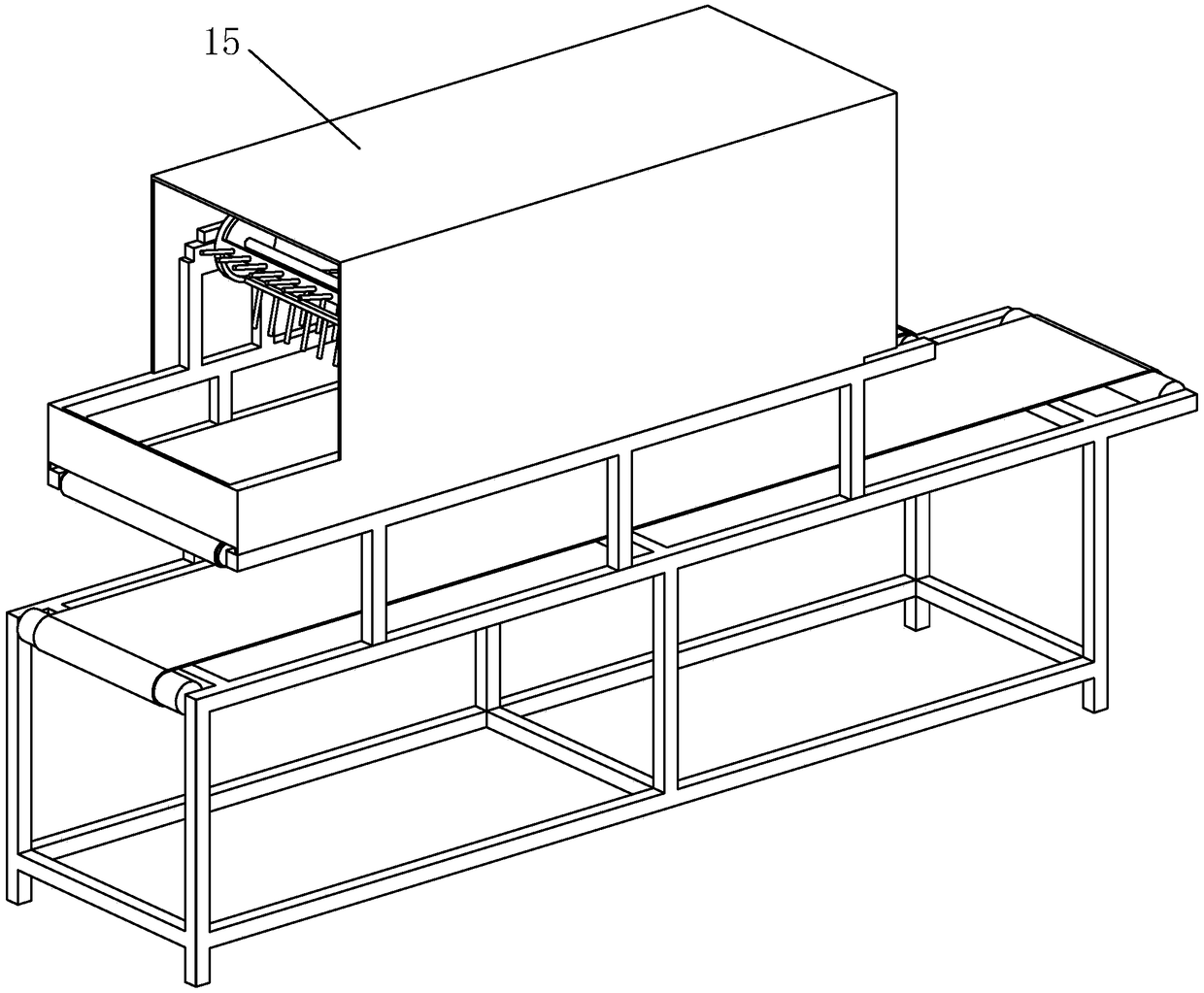

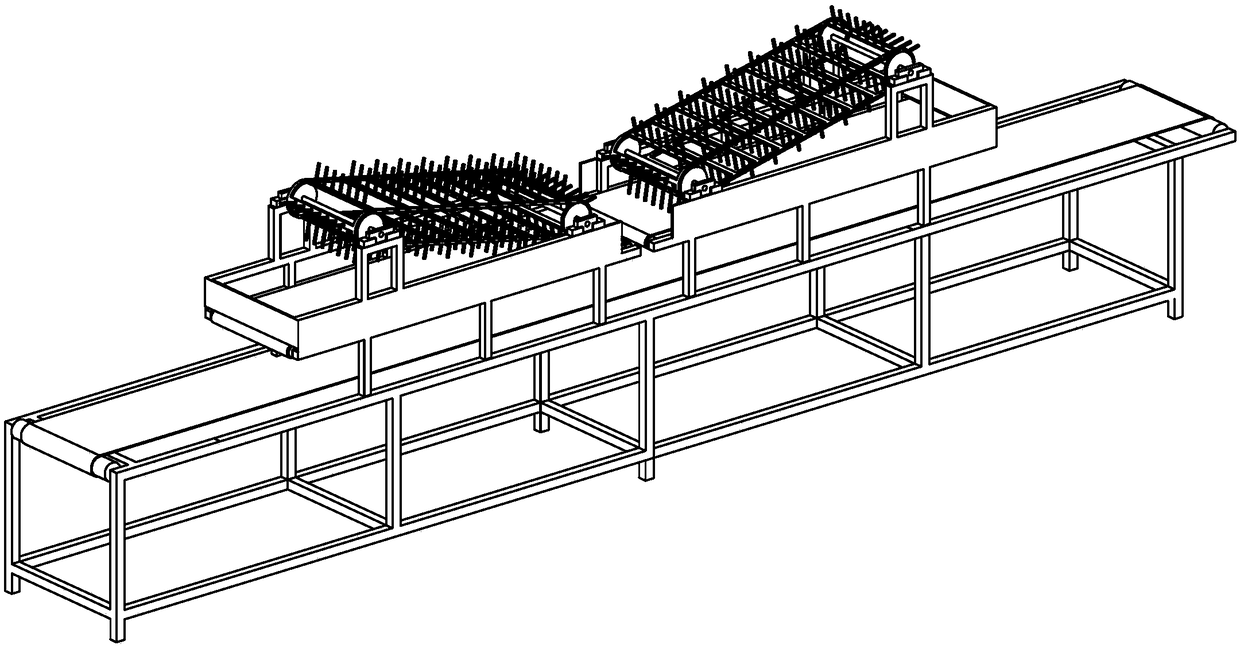

[0024] An automatic silkworm feeding machine for evenly releasing leaves with a chain plate comb conveyor belt, comprising a frame, a conveyor belt and a comber, the conveyor belt and the comber are both arranged on the frame, and the comber is located above the conveyor belt, One end of the conveyor belt is the mulberry leaf entrance, and the other end of the conveyor belt is the mulberry leaf exit. The height of one end of the comber is higher than the other end. The smoother includes a transmission device and a plurality of combing rods, the combing rods are arranged on the transmission device, the conveyor belt and the combing device are respectively connected with the power mechanism, and the distance between the lowest combing device and the conveyor belt is is the thickness of mulberry leaves when they fall from the outlet. The power mechanism can be a power mechanism such as a motor, a stepping motor, and a cylinder. The transmission device includes a roller and a cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com