Automatic production line assembly for young silkworm feeding

An automatic production line and automatic technology, applied in the direction of conveyor control device, stacking of objects, de-stacking of objects, etc., can solve the problems of hindering the development of sericulture industry, low efficiency, not reaching the degree of mechanization, etc. Leaf efficiency, convenient extrusion and transfer, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

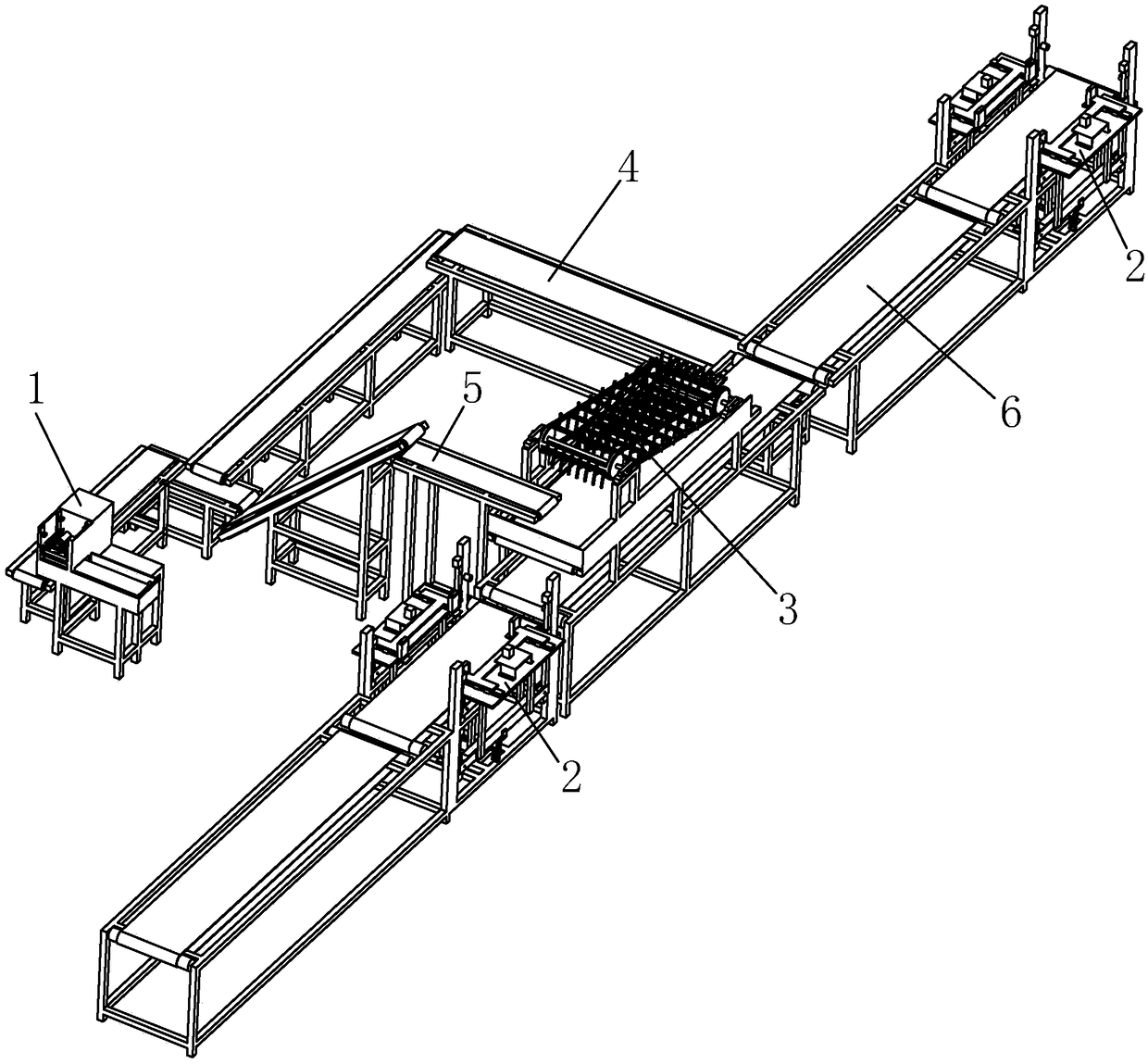

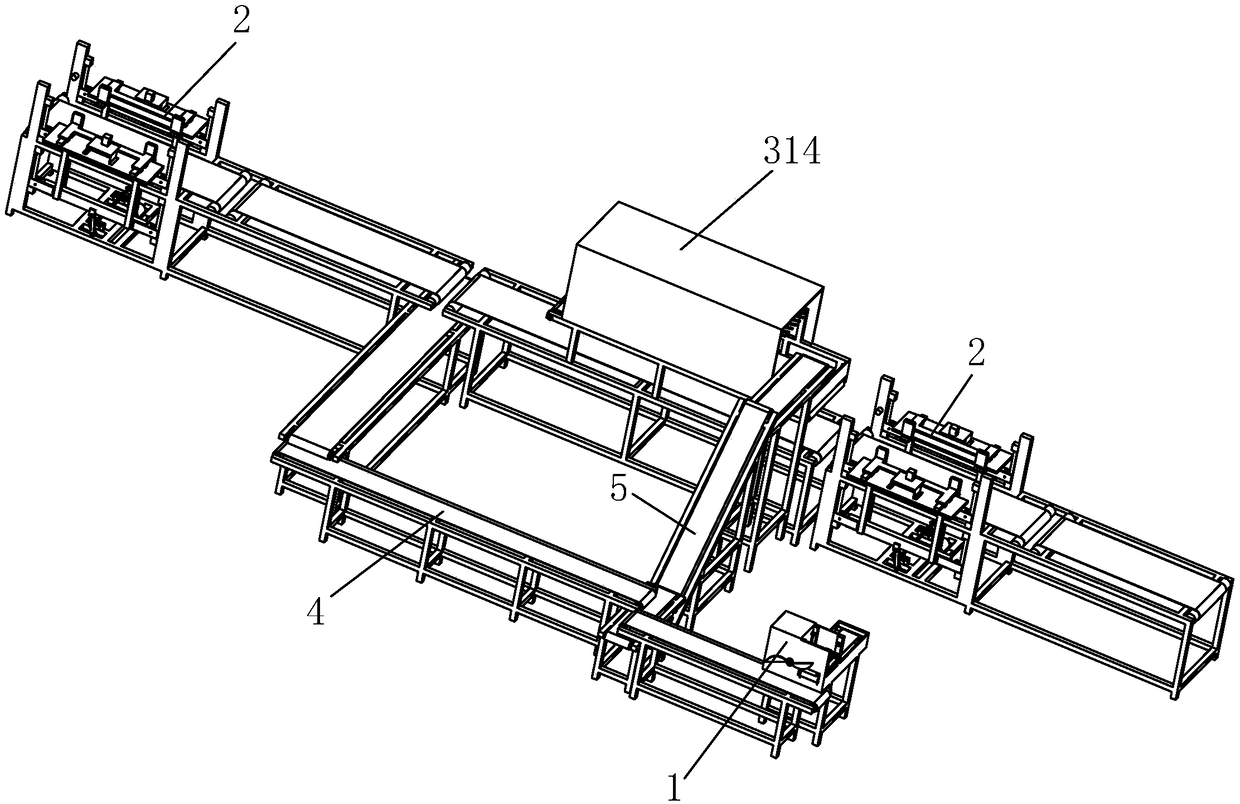

[0034] An automatic production line assembly for small silkworm breeding, an automatic leaf cutter, an automatic silkworm feeding system, an automatic depalletizing and palletizing machine for silkworm plaques, a control system, a reset car, a silkworm frame and a power mechanism. The power mechanism can be a power mechanism such as a motor, a stepping motor, and a cylinder. The power unit is used to power the required components. The control system includes an inductor and a single-chip microcomputer. The inductor is arranged on the palletizing machine body, and the power mechanisms such as the inductor, the cylinder and each motor are respectively connected with the single-chip microcomputer.

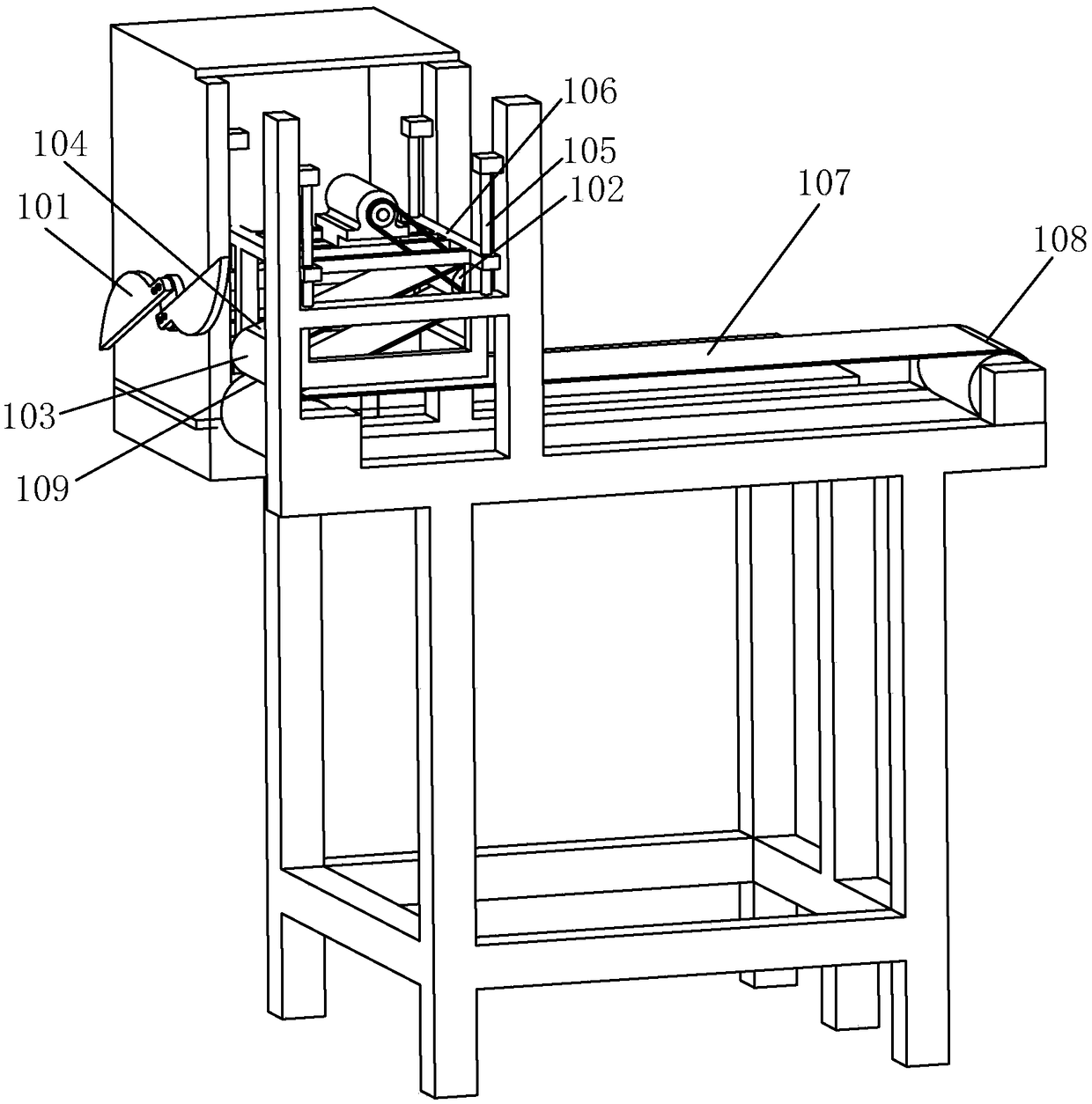

[0035] The automatic silkworm feeding system includes a silkworm feeding body, a silkworm feeding machine mulberry leaf conveyor belt, a comber and a silkworm feeding machine silkworm plaque conveyor belt, and the silkworm feeding machine mulberry leaf conveyor belt, the silkworm feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com