Mechanism for manufacturing leakage-proof valve port

A material valve, leak-proof technology, used in envelope/bag manufacturing machinery, paper/cardboard containers, containers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

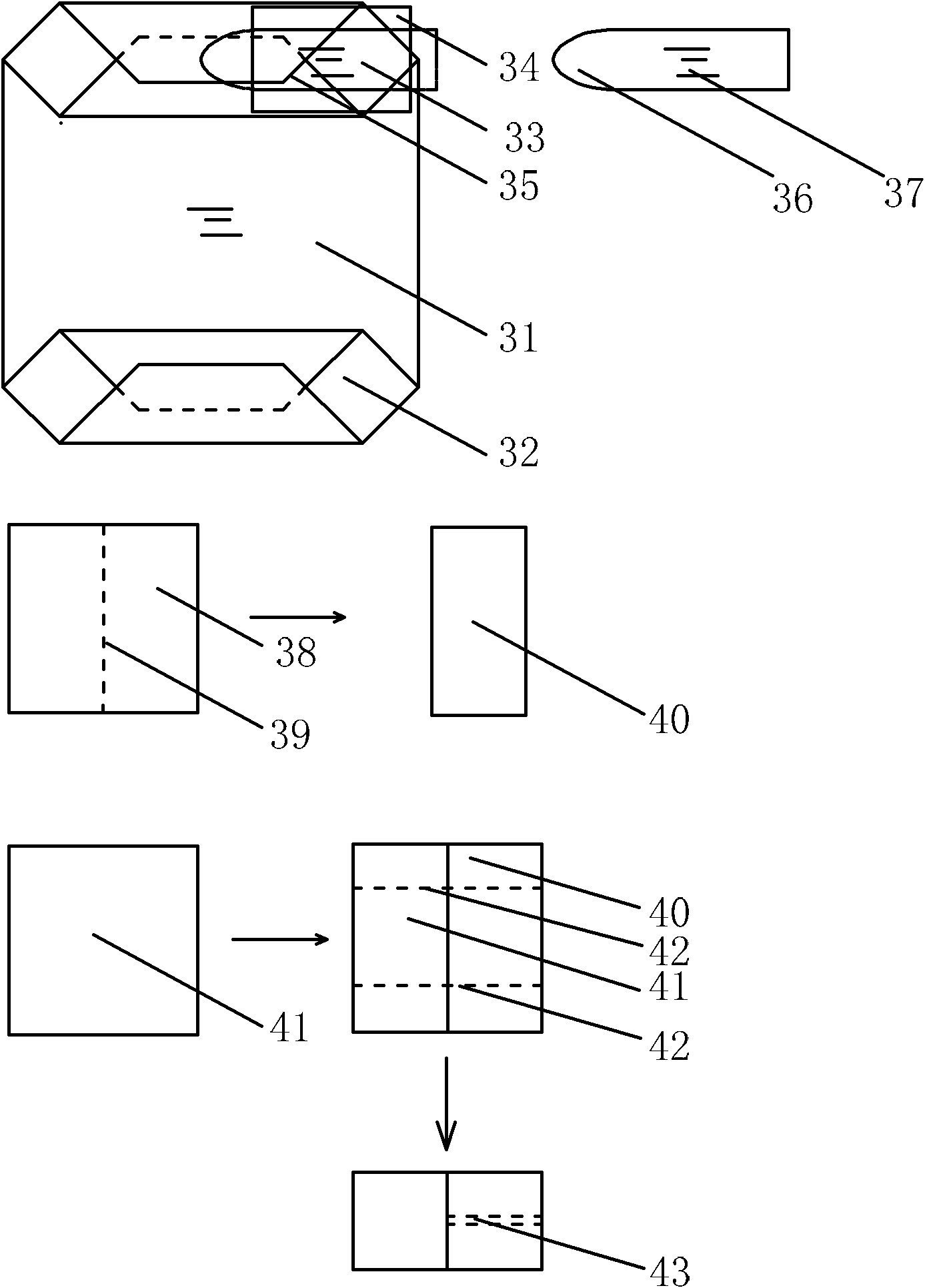

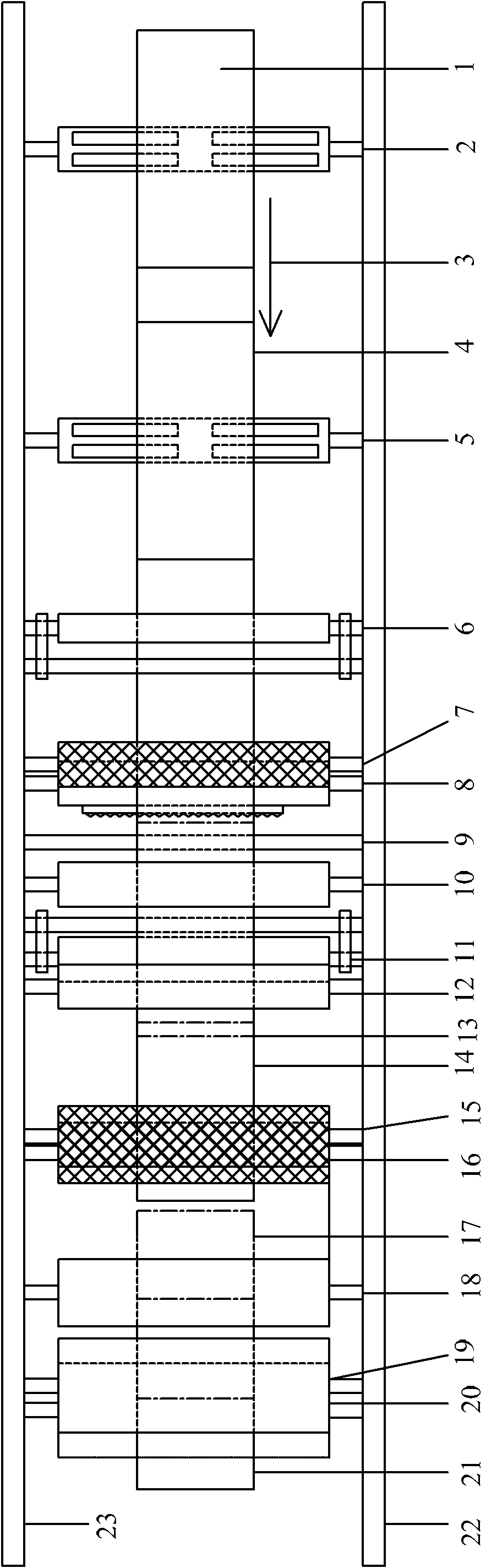

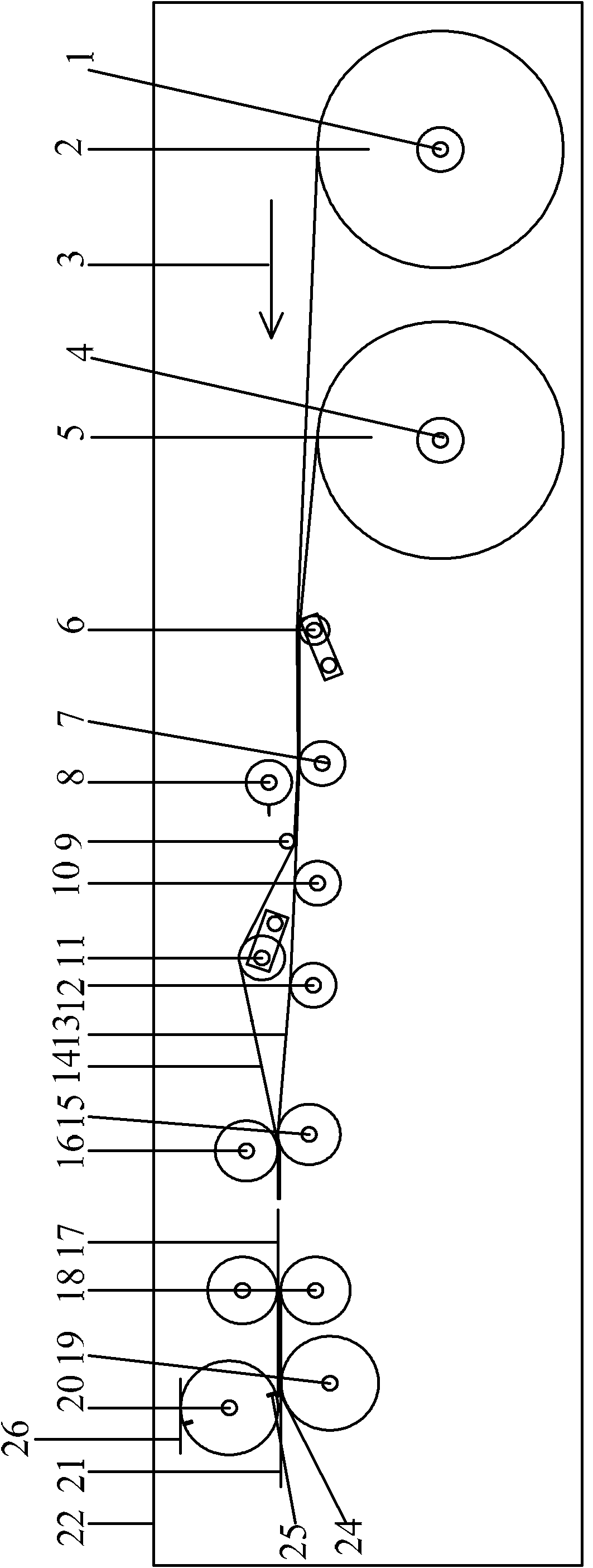

[0009] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

[0010] Such as figure 2 and image 3 As shown, the manufacturing mechanism of the anti-leakage material valve port of the present invention includes a paper holder 1, a PE film holder 4, a tension pendulum roller 6, a knife groove roller 7, a cutter roller 8, a layering roller 9, and the first PE film traction roller 10. Stroke adjustment roller 11, second PE film traction roller 12, first pressure roller 15, second pressure roller 16, tear-off roller 18, nip roller 19, sticker roller 20, base 22, top seat 23, top paper knife 24 and paper clamping knife 25, between base 22 and top seat 23, paper frame 1 is installed, paper roll 2 is housed on paper frame 1, PE film frame 4 is installed on the side of paper frame 1, PE film frame 4 is equipped with PE film roll 5, paper roll 2 and PE film roll 5 are unwo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com