Full-automatic material transportation and cooling system without manual work station

A cooling system, fully automatic technology, applied in coolers, refrigerators, household refrigeration devices, etc., to achieve the effects of reducing energy consumption, saving space, and facilitating the expansion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

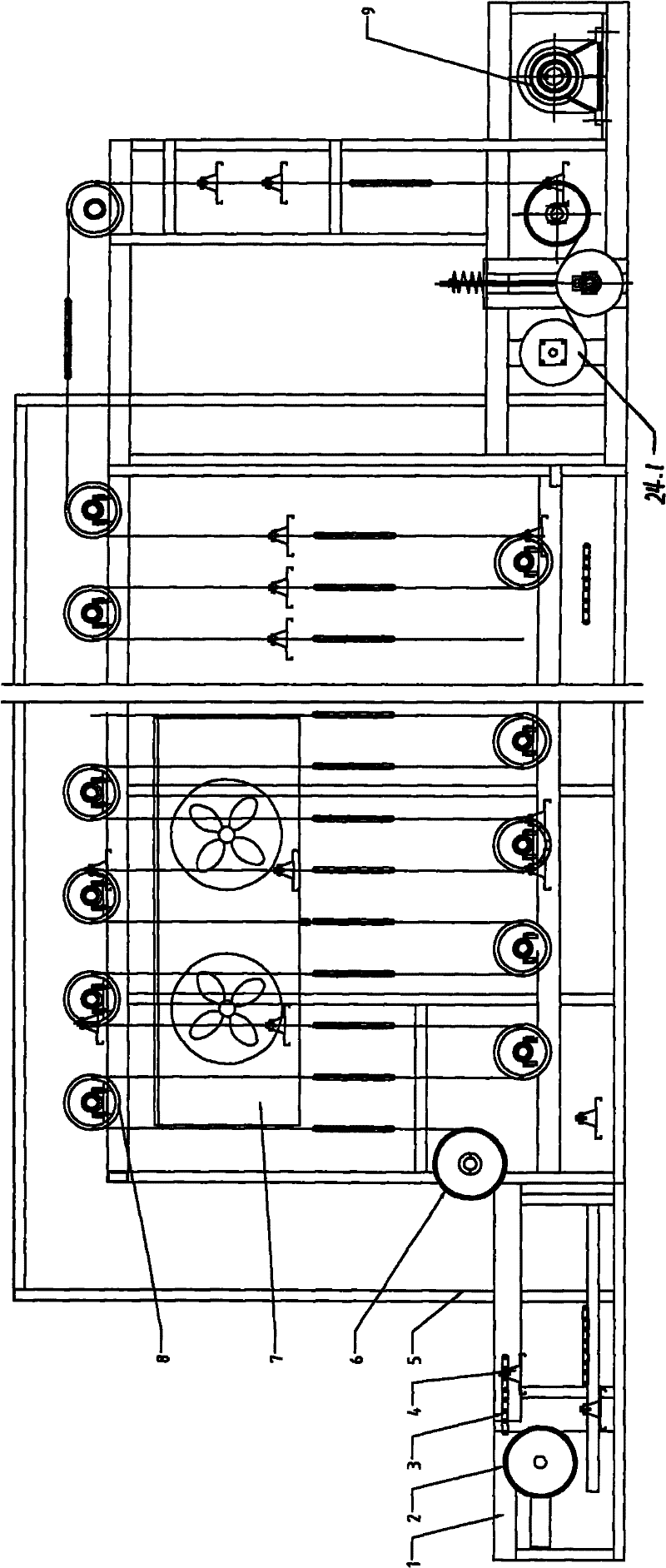

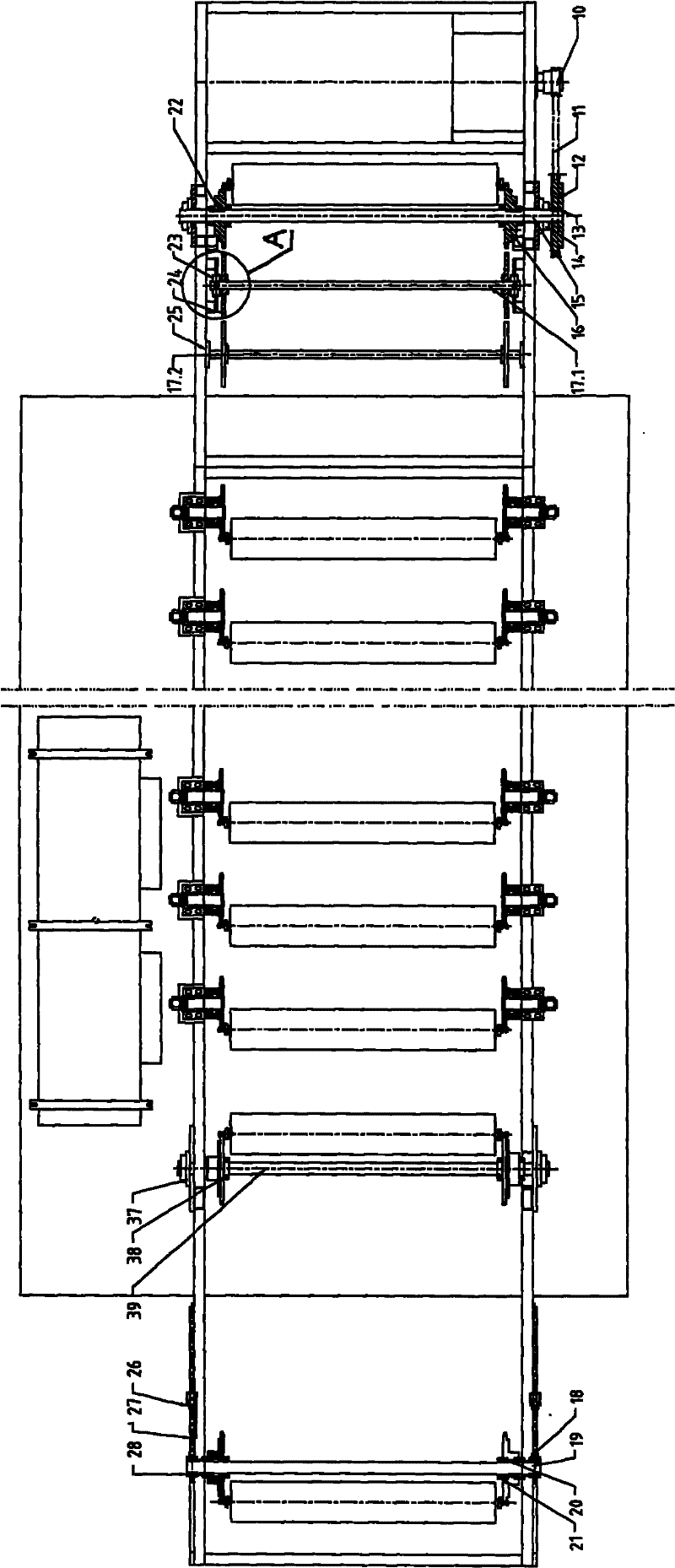

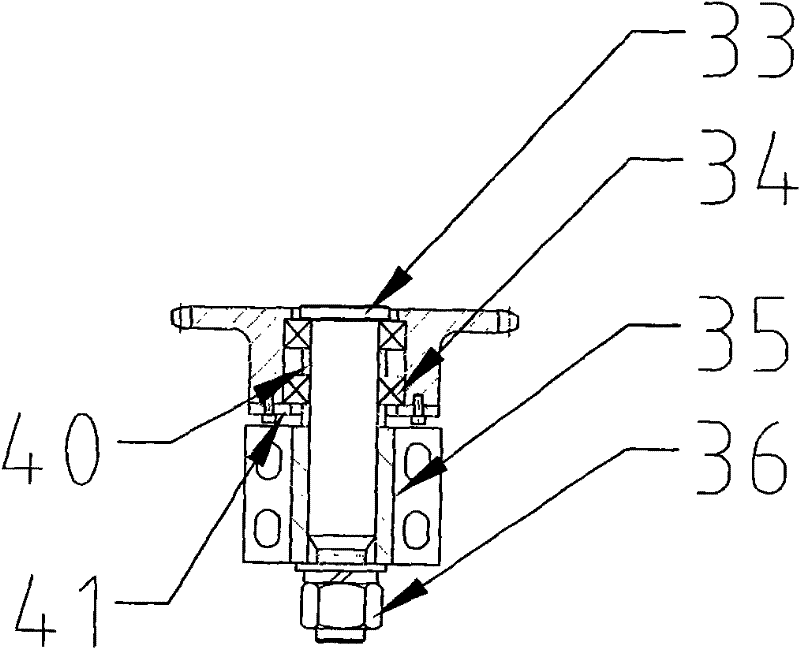

[0020] In the figure, 1. rack; 2. return sprocket; 3. main drive chain; 4. cooling line support plate; 5. cooling room; 6. lifting sprocket; 7. refrigeration system; Main motor; 10, (motor) driving sprocket; 11, chain; 12, passive sprocket; 13, main transmission key; 14, (UCF) first belt seat bearing; 15, driving shaft; 16, driving sprocket; 17.1. Tensioning shaft; 17.2. Tensioning shaft; 18. Spacer; 19. Passive shaft; 20. Bearing; 21. Limiting ring; 22. Driving shaft key; , expansion wheel; 25, (UCF) belt seat bearing; 26, adjustment nut; 27, adjustment screw; 28, moving block; 29, expansion screw; 30, compression spring; 31, compression spring seat; 32, Nut; 33, shaft; 34, bearing; 35, fixed seat; 36, fixed nut; 37, (UCF) the third belt seat bearing; 38, limit ring; 39, lifting sprocket shaft; 40, spacer ring; 41, Gland.

[0021] This mechanism is composed of cooling line transmission device and refrigeration device. figure 1 figure 2 It mainly shows the overall struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com