Reversing mechanism of tubular textile and method thereof

A technology for tubular fabrics and fabrics, applied to circular machines for weft knitting with individual moving needles, knitting, weft knitting, etc., which can solve the problems of high cost and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is exemplified and described in detail here to further illustrate the mechanism of the present invention, and the actual effect of the present invention is not limited thereto.

[0044] The embodiment provided by the present invention is a turning mechanism, which can turn the sock body exactly, that is, after the sock body is knitted and the opening is stitched, turn the sock body so that the sutures stay inside the sock body institutions and methods.

[0045] As described in the previous case EP2377979, when the knitting process of the sock body is completed, the toe of the sock is open and the suture of the toe of the sock is still left on the knitting needle of the knitting machine, and a plurality of strip elements and transfer components are used to sew the sock toe of the sock body , These components are opposite in pairs and are located in two facing brackets, just as described in the previous application EP2377979.

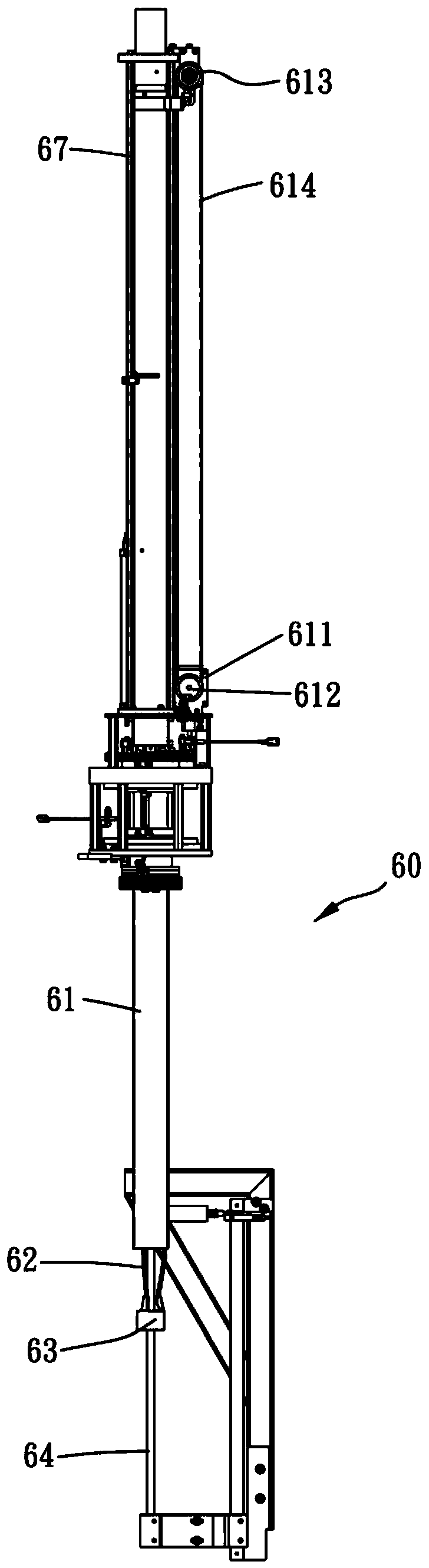

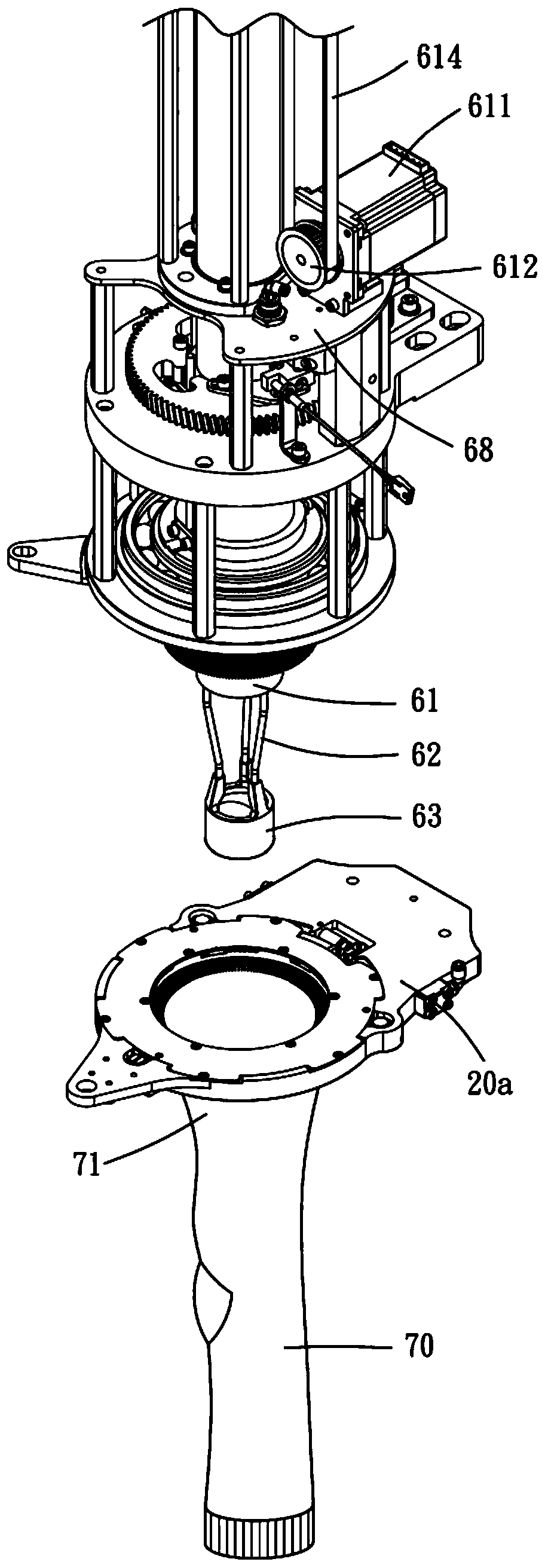

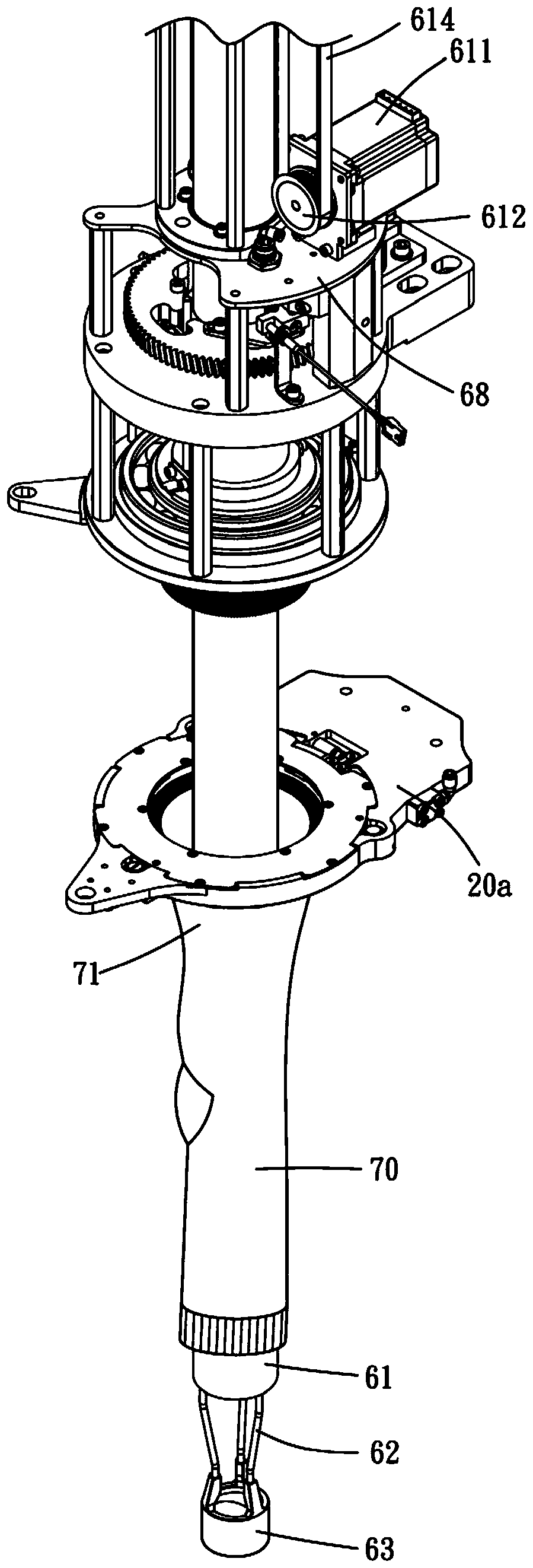

[0046] Such as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com