Surface coated positive electrode material and preparation method thereof, and battery

A positive electrode material and surface coating technology, which is applied in the field of surface coated positive electrode materials and its preparation, can solve problems such as lithium ion mixing and side reaction intensification, cycle performance deterioration, and restrictions on large-scale application of ternary materials. Direct contact area, good protection effect, uniform and complete coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A method for preparing a surface-coated positive electrode material according to an embodiment of the present invention includes the following steps S1-S4:

[0032] S1. Surface treatment: mix the positive electrode material with a surfactant, let it stand, and filter to get the filter residue to obtain a surface modified positive electrode material. The surface modifier is a solution or water of a compound containing a hydroxyl group, a carboxyl group or a mercapto group.

[0033] S2. Adsorption of metal ions: mix the surface-modified positive electrode material with a coating agent, and filter to obtain the filter residue after standing still to obtain a positive electrode material with metal ions adsorbed on the surface. The coating agent is a solution containing metal cations.

[0034] S3. Sedimentation treatment: mix the positive electrode material with metal ions adsorbed on the surface with a precipitant, filter the filter residue after standing, and obtain the pos...

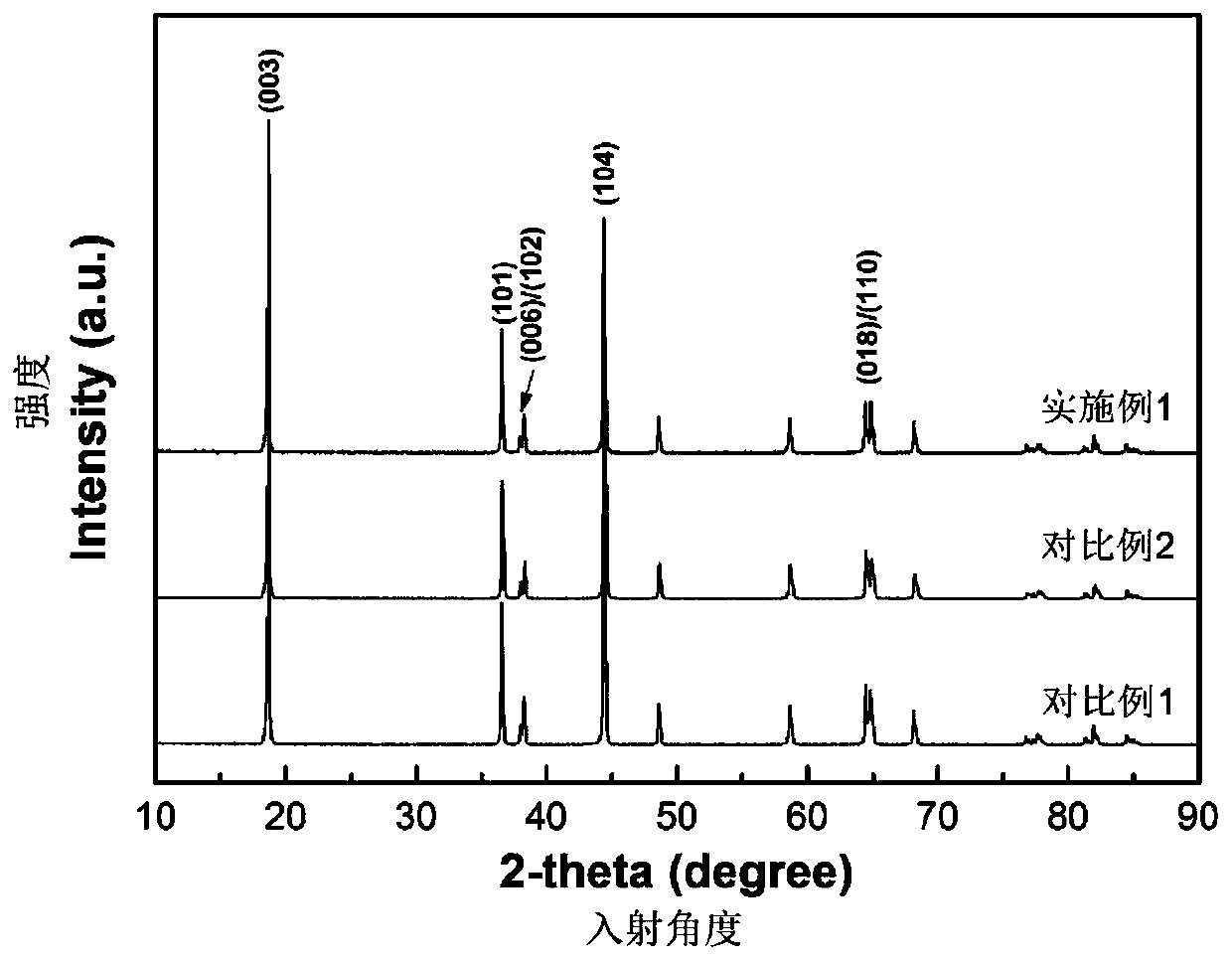

Embodiment 1

[0056] Weigh lithium hydroxide and nickel cobalt manganese precursor Ni according to the molar ratio of 1.08:1 0.8 co 0.1 mn 0.1 (OH) 2 , placed together in a planetary ball mill and mixed evenly. Then the material was heated at 1°C / min to 600°C for 6 hours, kept for 2 hours, then heated at 1°C / min to 800°C, and sintered for 12 hours. Finally, after cooling to room temperature with the furnace, the material is taken out, crushed and sieved to obtain the ternary cathode material.

[0057] Surface treatment: Dissolve an appropriate amount of 3-mercaptopropionic acid in deionized water to obtain solution A with a concentration of 0.5 mol / L. Subsequently, the above-mentioned ternary positive electrode material was dispersed in the solution A, stirred for 2 hours, then left to stand for 2 hours, and then filtered to obtain the filter residue A.

[0058] Metal ion adsorption: Al(NO 3 ) 3 aqueous solution, and the filter residue A was placed in the solution for 2 minutes, and ...

Embodiment 2

[0063] Weigh lithium hydroxide and nickel cobalt manganese precursor Ni according to the molar ratio of 1.08:1 0.8 co 0.1 mn 0.1 (OH) 2 , placed together in a planetary ball mill and mixed evenly. Then the material was heated at 1°C / min to 600°C for 6 hours, kept for 2 hours, then heated at 1°C / min to 800°C, and sintered for 12 hours. Finally, after cooling to room temperature with the furnace, the material is taken out, crushed and sieved to obtain the ternary cathode material.

[0064] Surface treatment: Dissolve an appropriate amount of 3-mercaptopropionic acid in deionized water to obtain solution A with a concentration of 0.5 mol / L. Subsequently, the above-mentioned ternary positive electrode material was dispersed in the solution A, stirred for 2 hours, then left to stand for 2 hours, and then filtered to obtain the filter residue A.

[0065] Metal ion adsorption: prepare SnCl with a concentration of 0.2mol / L 2 aqueous solution, and the filter residue A was placed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com