Super-amphiphobic composite coating, and preparation method and application thereof

A composite coating and super-amphiphobic technology, applied in coatings, polyurea/polyurethane coatings, primers, etc., can solve the problems of restricting wide application and high energy consumption, achieve broad application prospects, enhance wear resistance, Mature effect of spraying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0068] In this example, three super-amphiphobic composite coatings were prepared, numbered A~C.

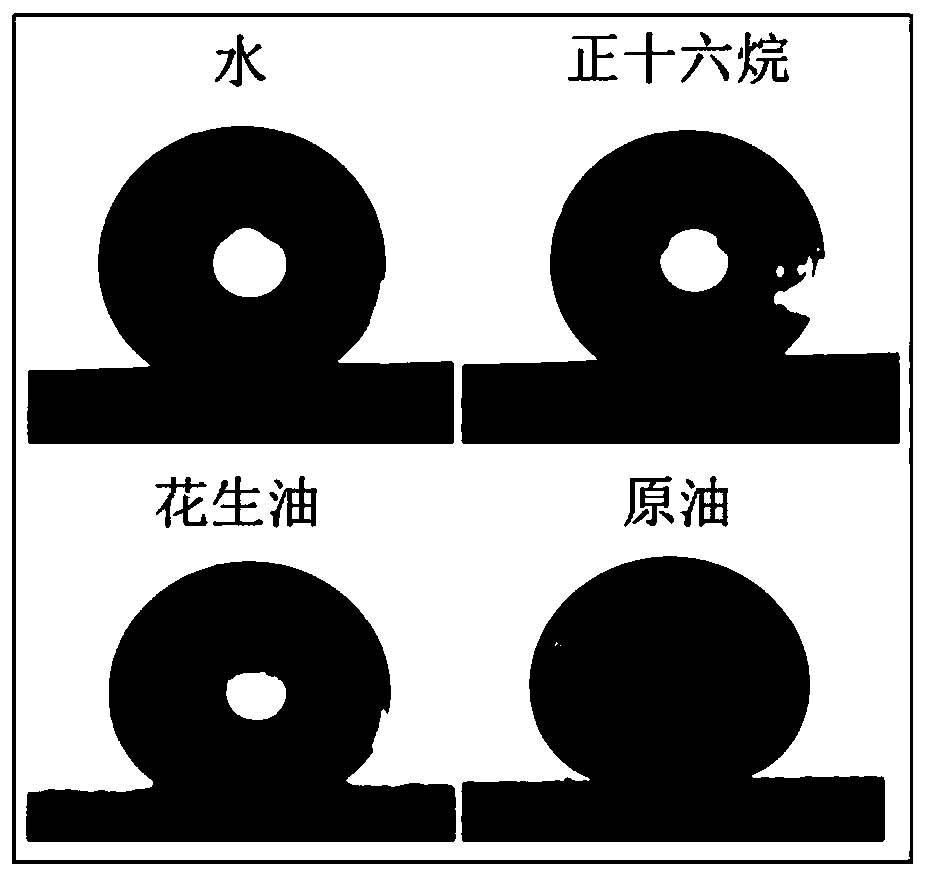

[0069] The superamphiphobic composite coating includes a polyurethane primer layer; and, a superamphiphobic topcoat layer covering the surface of the polyurethane primer layer; micron-sized particles are distributed in the polyurethane primer layer; in the superamphiphobic topcoat layer Nanoscale particles are distributed.

[0070] The preparation method of super amphiphobic composite coating comprises the following steps:

[0071] S1: Prepare polyurethane primer coating and super amphiphobic topcoat coating respectively;

[0072] S2: Spray the polyurethane primer coating prepared in step S1 on the surface of the substrate, and form a polyurethane primer layer after curing;

[0073] S3: Spraying a super-amphiphobic topcoat on the surface of the polyurethane primer layer formed in step S2, and obtaining the super-amphiphobic composite coating after curing.

[0074] In step S1, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com