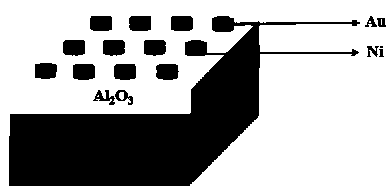

Preparation method of alumina medium-based microwave/radio frequency thin film capacitor

A technology of thin film capacitors and aluminum oxide, which is applied in the field of capacitors, can solve the problems of rare research on miniaturized microwave capacitor thin film dielectrics, large inherent dielectric loss of ferroelectric thin films, difficulty in applying microwave devices, etc., and achieve good compactness and uniformity Good performance and little change in thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

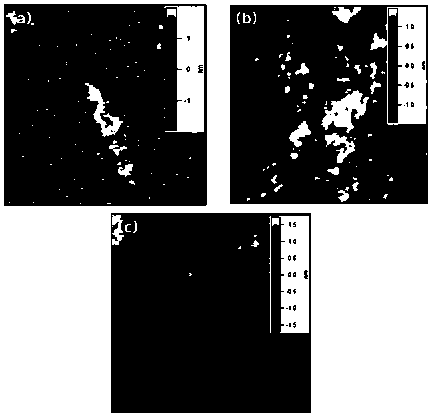

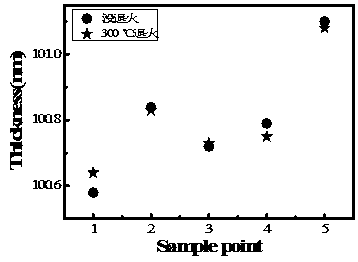

[0029] 1. First, ALD is used to grow aluminum oxide with a thickness of 25 nm (200 cycle), 50 nm (400 cycle), and 100 nm (800 cycle) on the heavily doped silicon substrate, and the precursors are trimethylaluminum and ozone , the ozone flow rate was 40 ml / min, and the growth temperature was 250 °C.

[0030] 2. Use a high-temperature rapid heat treatment annealing furnace (RTP) to anneal the aluminum oxide film at high temperature in an oxygen atmosphere.

[0031] The temperature trend of the annealing treatment is divided into three stages, namely the heating stage, the holding stage, and the cooling stage. The heating stage is a stepwise increase of 180 s, and the holding time of each stage is 100 s. At this time, the holding time is 3600s (1 hour), followed by the cooling stage, which is a stepwise decrease of 180s, and the holding time of each stage is also 100s.

[0032] Figure 8 It is the temperature trend chart of the annealing treatment of the aluminum oxide film on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breakdown voltage | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com