Polyimide film, preparation method thereof and graphite film

A polyimide film and polyimide technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of reducing the heat dissipation effect, improve appearance, facilitate gas dissipation, free body base big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] One embodiment of the present application also provides a method for preparing a polyimide film, which includes the following steps:

[0023] Adding the diamine monomer, the dianhydride monomer and the catalyst into an organic solvent, stirring and reacting under a nitrogen atmosphere to obtain a polyamic acid solution;

[0024] Carrying out imidization treatment to the polyamic acid solution to obtain a polyimide solution;

[0025] Coating the polyimide solution on a support plate to obtain a polyimide coating film;

[0026] The polyimide film is baked and cured to obtain the polyimide film.

[0027] The polyimide solution includes the polyimide polymer and the organic solvent, and the polyimide polymer is dissolved in the organic solvent. In some embodiments, the organic solvent accounts for 80-85% by weight of the polyimide solution, in other words, the polyimide solution has a solid content of 15-20%.

[0028] It can be understood that the polyamic acid solution ...

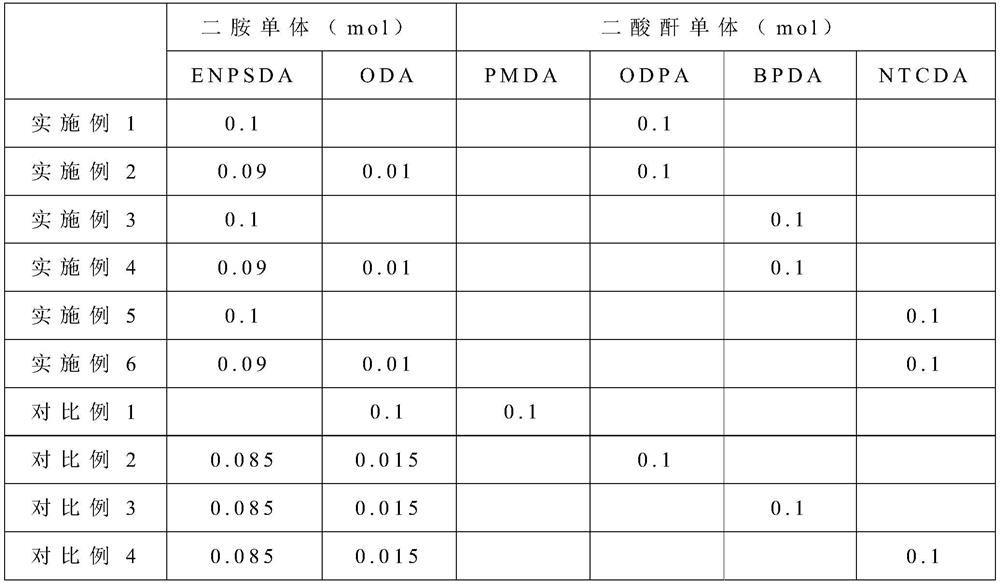

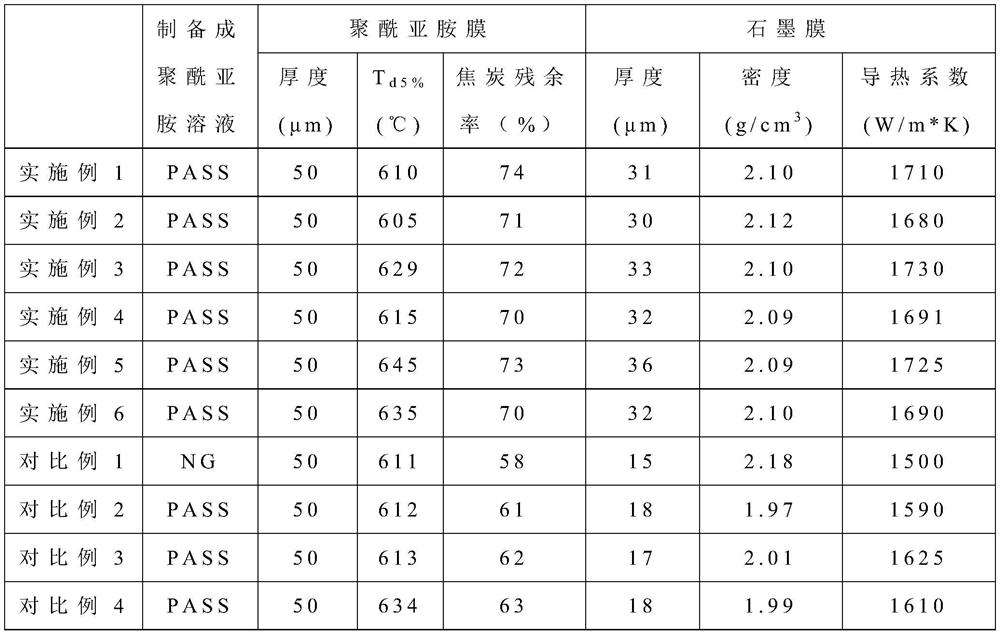

Embodiment 1

[0036] Add diamine ENPSDA (0.1mol, 44.22g), catalyst (0.015g), dianhydride ODPA (0.1mole, 31.02g) and solvent NMP (300.97g) into a 500ml reaction flask to obtain a mixture with a solid content of 15-20%. The solution was stirred for 5 hours under a nitrogen atmosphere, then 60.2 g of xylene (Xylene) was added, and the temperature was raised to 190-200° C. and stirred for 15 hours under a nitrogen atmosphere to carry out dehydration and cyclization to obtain a polyimide solution.

Embodiment 2

[0038]Add diamine ENPSDA (0.09mol, 39.80g), diamine ODA (0.01mol, 2.0g), catalyst (0.015g), dianhydride ODPA (0.1mole, 31.02g) and solvent NMP (291.30g) into a 500ml reaction flask ) to obtain a mixed solution with a solid content of 15 to 20%, stirred for 5 hours under a nitrogen atmosphere, then added 58.30 g of xylene (Xylene), and heated up to 190 to 200° C. and stirred for 15 hours under a nitrogen atmosphere to carry out a water removal ring to obtain a polyimide solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com