1,3-piperlene alternating copolymer based cyclized compound and preparation method thereof

A technology of alternating copolymers and piperylene, which is applied in the field of cyclization and its preparation, can solve the problems of difficulty in the preparation of alternating copolymers, great differences in polyreactivity ratio, and improved branched structure, and achieve high heat resistance , Narrow molecular weight distribution and high degree of cyclization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] A second aspect of the present invention provides a method for preparing a cyclized product based on piperylene alternating copolymers, the method comprising the following steps:

[0069] (1) using an organic alkali metal as an initiator to copolymerize piperylene monomers and styrene monomers shown in formula (8) in a solvent, and then terminate the polymerization with water;

[0070] (2) Contacting the copolymerization product obtained in step (1) with a cyclization catalyst to carry out a cyclization reaction.

[0071]

[0072] Among them, R 1 and R 2 The meaning of is as above. The styrene-based monomer may be, for example, styrene, methylstyrene, or diphenylethylene.

[0073] The mechanism of the method of the present invention can be tried to be explained by the following formula.

[0074]

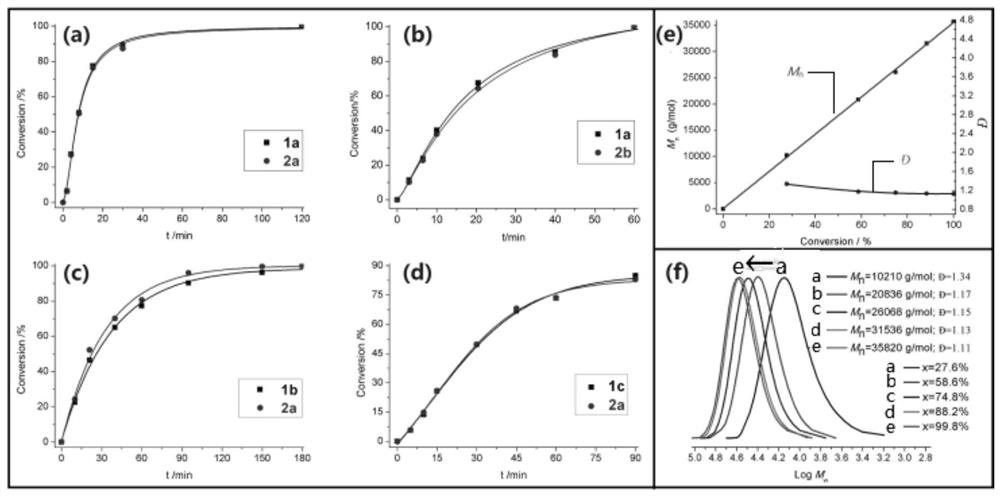

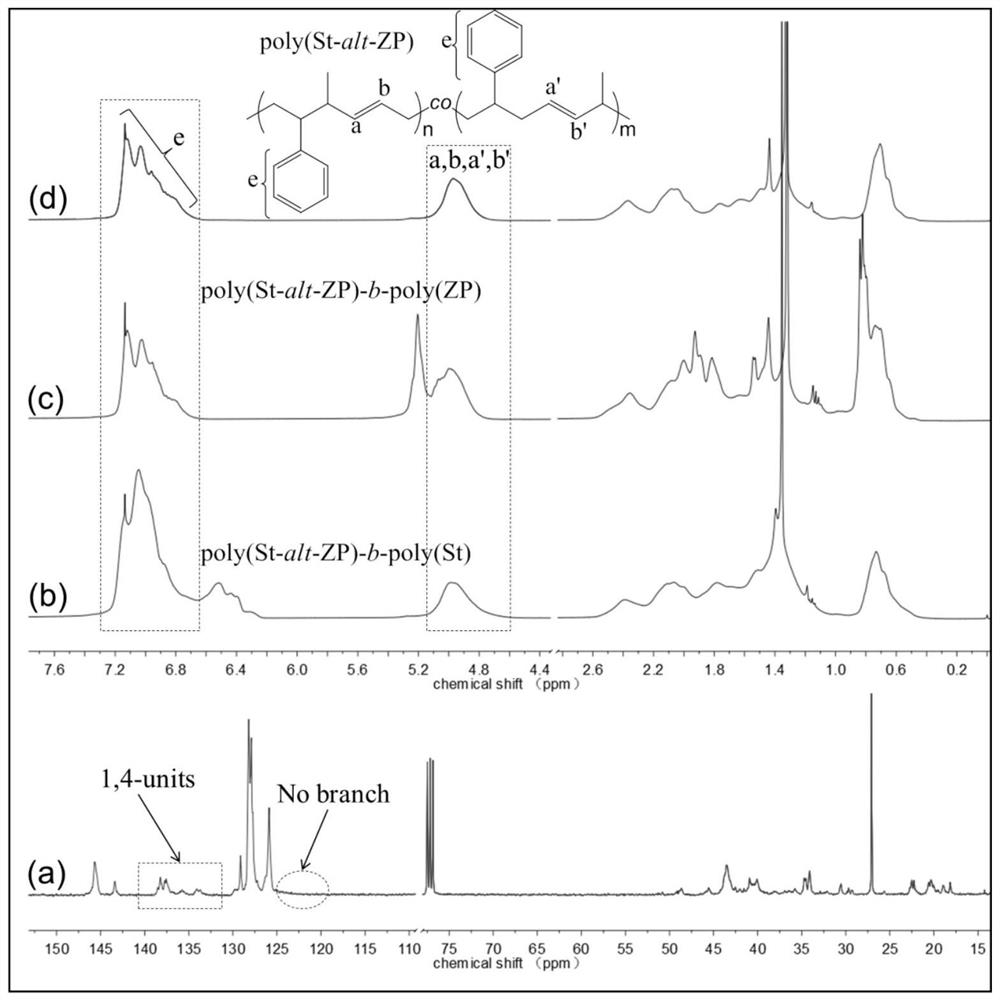

[0075] Among them, the composition ratio of piperylene / styrene-based monomer anionic copolymerization unit and the data and kinetic characteristics of the reactivity...

specific Embodiment approach

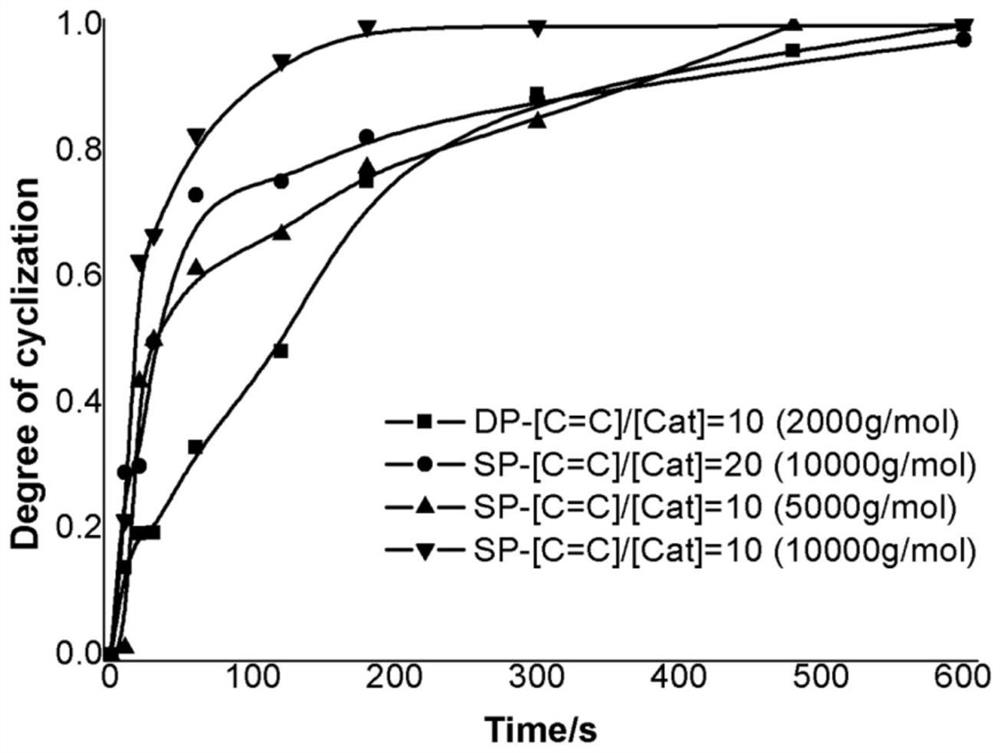

[0098] According to a specific embodiment of the present invention, the production process of the cyclized styrene-piperylene alternating copolymer comprises: adding piperylene monomer and styrene monomer into cyclohexane in an equimolar ratio, stirring and dissolving Then add the regulator tetrahydrofuran, then add the initiator butyllithium to initiate, control the temperature at 60-80°C, and carry out the polymerization reaction in the polymerization kettle for 0.5-3h. After the molecular weight and viscosity of the polymerization reaction product meet the requirements, add the terminator water The polymerization reaction is stopped, and at the same time, the temperature is lowered to 20-40° C., and the material is transferred to the cyclization kettle. Add a cyclization reaction catalyst to carry out the cyclization reaction. When the cyclization reaction has progressed to a certain extent, add a cyclization reaction terminator, enter the washing tower and add water to full...

Embodiment 1

[0105] Add piperylene and diphenylethylene monomers into cyclohexane (3.0mL per 0.4mL monomer) in equimolar ratio, stir and dissolve, add regulator tetrahydrofuran (1mg / 100g monomer), and then add initiator Initiated by n-butyllithium (3.0mmol / L), the temperature was controlled at 70°C, and the polymerization reaction was carried out in the polymerization tank for 1 hour to obtain a prepolymer. The measured number average molecular weight of the prepolymer is 100,000, the molecular weight distribution is 1.04, the structure content of 1,4-piperylene is 85%, and the glass transition temperature is 88°C. At this point, water as a terminator was added to the polymerization kettle to stop the polymerization reaction, and at the same time, the temperature was lowered to 30° C., and the product was transferred to the cyclization kettle. Add the cyclization reaction catalyst to carry out the cyclization reaction of xylene sulfonic acid (1g / 100g monomer) for 5 hours, add the cyclizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com