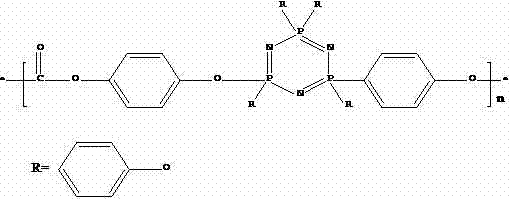

Phosphorus-nitrogen copolyester material containing cyclotriphosphonitrile group and preparation method thereof

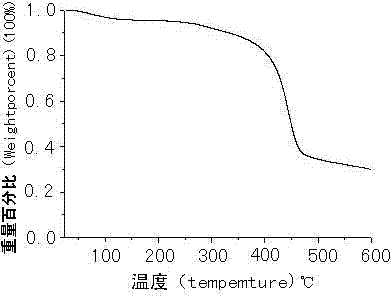

A technology of phosphorus-nitrogen copolyester and cyclotriphosphazene, which is applied in the field of phosphorus-nitrogen copolyester materials and its preparation, can solve the problems of single material solubility and harsh processing and preparation technology, and achieve high carbon residual rate and good electrode quality The effect of good solubility in aqueous solution and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] (1) Dissolve 1 part of polycyclotriphosphazene prepared by multiple sublimation in tetrahydrofuran (THF) solvent, add dropwise the prepared 4 parts of sodium phenoxide THF solution, under nitrogen protection, react at 40°C for 24 hours. Remove THF by rotary distillation, wash with deionized water several times, and vacuum dry at 80°C for 24 hours to obtain a milky white colloid;

[0023] (2) Dissolve 1 part of solid powder obtained in step (1) in THF solvent, then add 6 parts of hydroquinone in THF solution dropwise, under nitrogen protection, react at 40°C for 12 hours. Rotary distillation to remove THF, repeated washing with deionized water and ethanol, and vacuum drying at 40-80°C for 12 hours to obtain a yellow colloid;

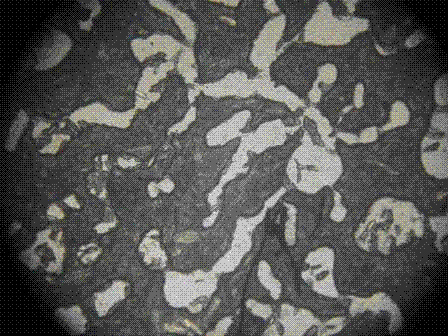

[0024] (3) Heat 1 part of yellow colloid and 0.5wt% anhydrous acetic acid obtained in step (2) to 180°C under vacuum, and add 2 parts of terephthaloyl chloride (TPC). After reacting for 2 hours, wait for the reaction system to stabilize and inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com