Vapor chamber semi-shearing forming method

A technology of vapor chamber and cover plate, which is applied in the direction of semiconductor devices, indirect heat exchangers, lighting and heating equipment, etc. It can solve the problems of weak support and negative impact on the strength of the vapor chamber, so as to maintain integrity and avoid deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

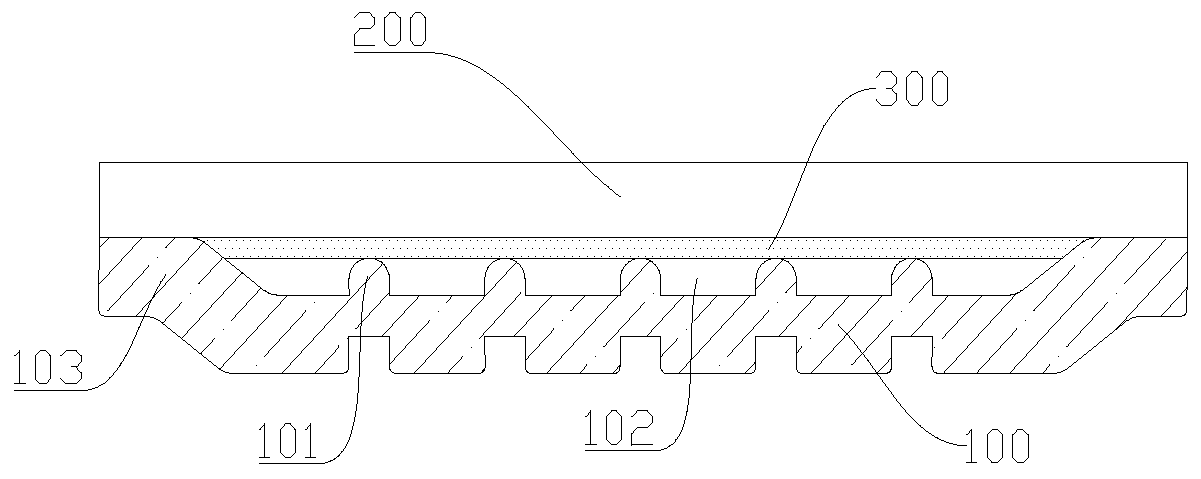

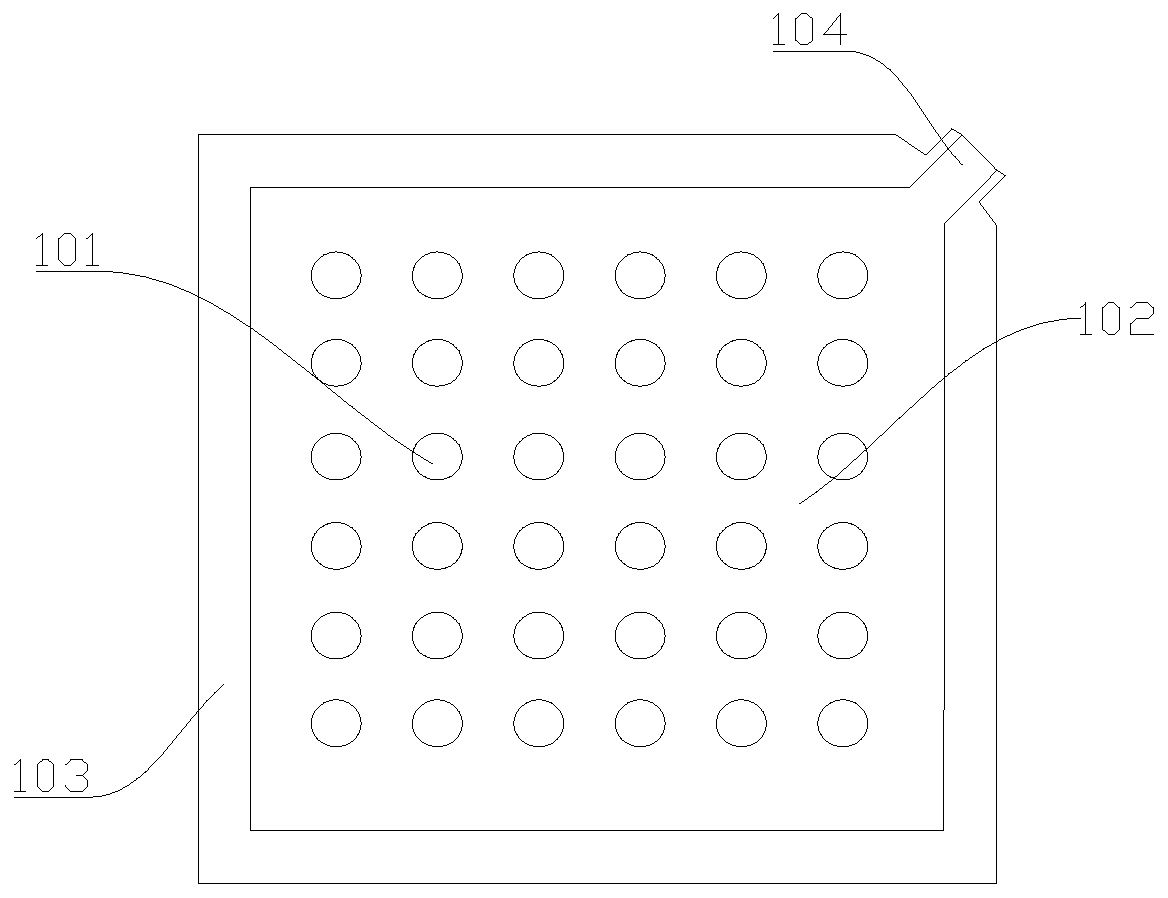

[0033] figure 1 and figure 2 A vapor chamber according to the method of the present invention is schematically shown. The vapor chamber stamping method provided by the present invention includes the following steps:

[0034] (1) Two plates are provided, which are divided into the first cover plate 100 and the second cover plate 200 . The first cover plate 100 and the second cover plate 200 are square copper plates with the same size.

[0035] (2) Use a punch press to perform semi-shear punching on the middle part of the first cover plate 100 from the bottom to form a plurality of support columns 101 . There are gaps 102 between the support columns 101 , and the gaps 102 between the plurality of support columns 101 communicate with each other. After the half-shear stamping, there is a certain connection thickness between the support column 101 and the starting plate surface. In this way, the first cover plate 100 can be prevented from being broken due to the half-shearing ...

Embodiment 2

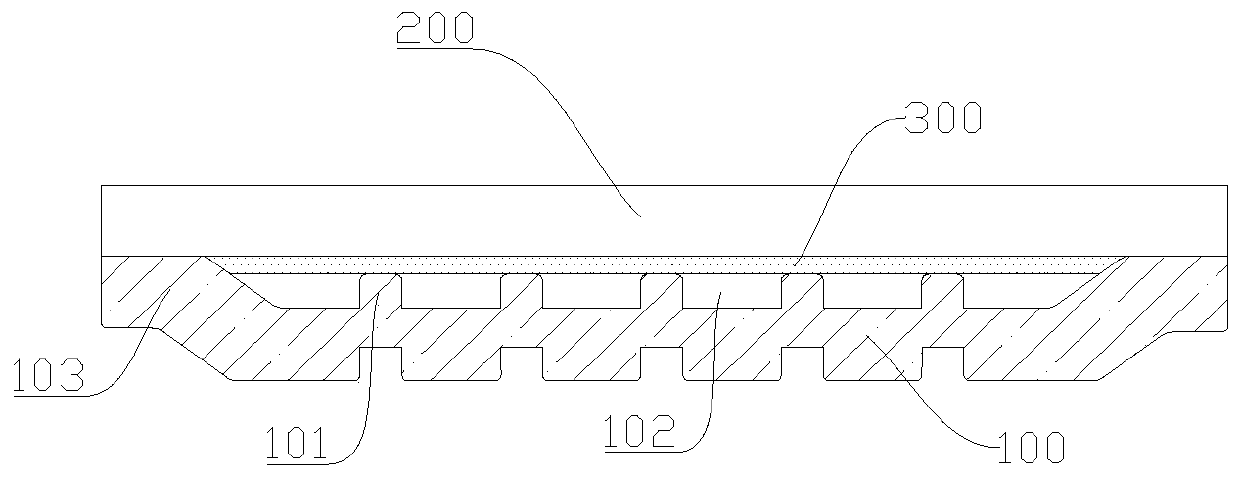

[0043] image 3 and Figure 4 Schematically shows another vapor chamber according to the method of the present invention. The difference from Embodiment 1 is that the first cover plate 100 and the second cover plate 200 are both metal aluminum plates, and the first cover plate 100 is The half-cut support column 101 is a square cylinder, and the support column 101 is in contact with one side of the liquid-absorbent core 300 .

[0044] In addition, in the process, the liquid-absorbent core 300 is fixed at the middle position of the second cover plate 200 by sintering, and when the first cover plate 100 and the second cover plate 200 are attached to each other, the liquid-absorbent core 300 is just in line with the embedded fit in the inside of the welding flange edge 103. In addition, the welding method of the second cover plate 200 adopts diffusion welding.

Embodiment 3

[0046] Figure 5 and Figure 6 Schematically shows the structure of the first cover plate 100 of another heat chamber according to the present invention. The arrangements are different. In this embodiment, the four support columns 101 are close to each other to form a local support unit. The multiple local support units are distributed in an array, and there are gaps 102 inside the local support units, and there are gaps 102 between the multiple local support units. The support column 101 is in contact with one side of the liquid-absorbent core 300 . In addition, the edge of the second cover plate 200 is processed into a positioning block 201 through a bending process, and the positioning block 201 can engage with the welding flange 103 on the edge of the first cover plate 100 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com