Planar heterojunction perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of reducing the yield of solar cells, limiting commercial application, low photoelectric conversion efficiency, etc., achieving large-scale production applications, simplifying device structure and preparation process. , Improve the effect of film forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

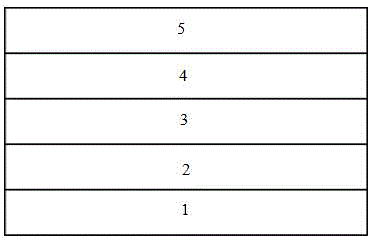

[0034] figure 1 It is a schematic structural diagram of the planar heterojunction perovskite solar cell of the present invention, from bottom to top, there are transparent conductive electrode 1, electron transport layer 2, perovskite light absorption layer 3, hole transport layer 4, and metal electrode 5 . Specifically, the transparent conductive electrode 1 is FTO conductive glass, and the electron transport layer 2 is TiO 2 dense layer, the perovskite light absorbing layer 3 is CH 3 NH 3 PB 3-x Cl x layer, the hole transport layer 4 is a spiro-OMeTAD layer, and the metal electrode 5 is Au.

[0035] The production process includes the following steps:

[0036] Step S1--FTO conductive glass preparation: ultrasonically clean the FTO conductive glass in deionized water, acetone, absolute ethanol, and deionized water for 10 minutes respectively, blow dry under nitrogen, and then subject the FTO conductive glass to oxygen plasma body processing.

[0037] In this step, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com