Preparation method of rhodium-platinum core-shell bimetallic nano branch and application

A bimetallic nano and nano technology, which is applied in metal processing equipment, nanotechnology, chemical instruments and methods, etc., can solve the problems of discounted platinum utilization rate, reduced active sites, and inability to be widely used, and achieves Rh stability and catalytic activity Strong, overpotential reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

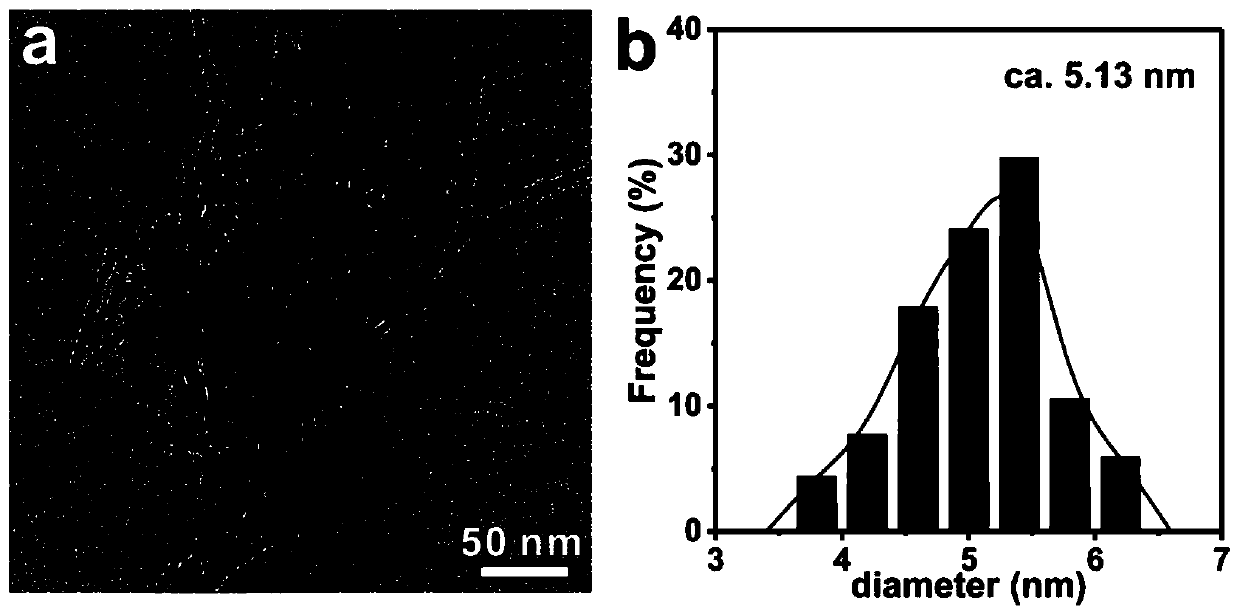

[0030] In a 20-mL Teflon liner, add 8 mg PVP, 5 mg RhCl 3 , and 8 mL of n-octylamine, and then put them into an autoclave, start heating from room temperature, raise the temperature to 200° C., and react for 6 hours. After the reaction was completed, it was naturally cooled to room temperature, and the obtained black product A was washed more than 3 times with ethanol, and then dissolved in 1 mL of ethylene glycol to obtain a pure rhodium nanobranch solution for further use. The black product A after washing is systematically studied on its morphology by modern nano-testing and analysis techniques such as TEM, and TEM ( figure 1 a, b) Characterized by Rh nanobranch structure, the diameter is about 5.13nm.

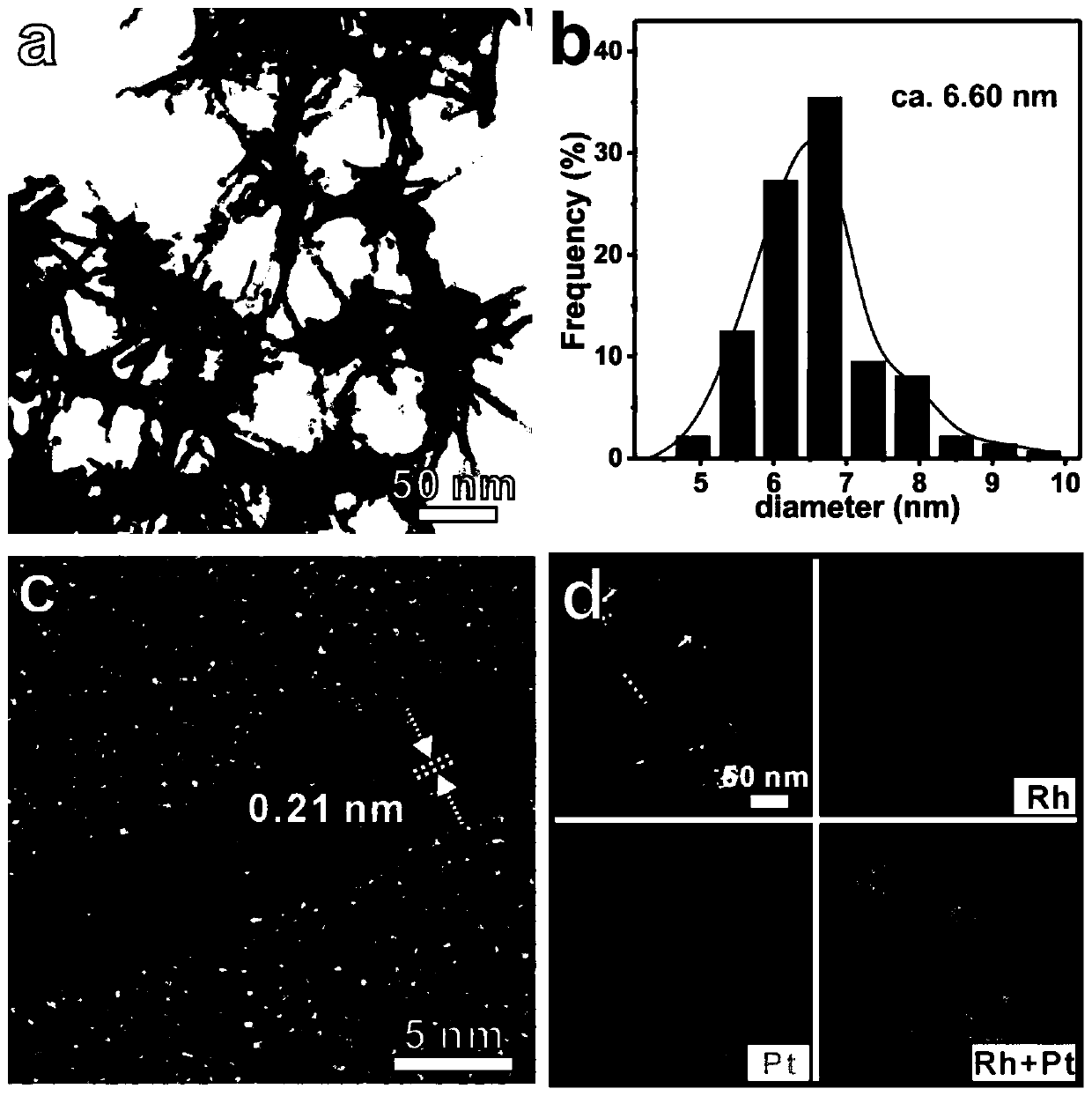

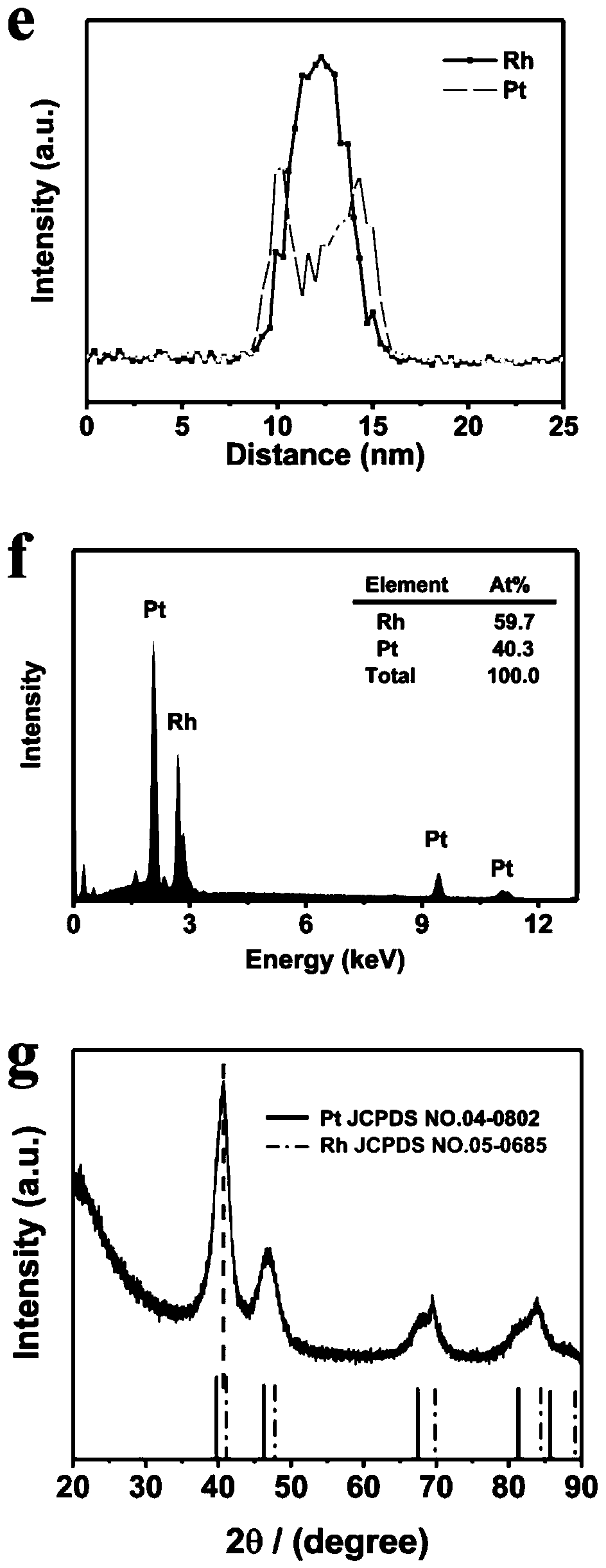

[0031] Dissolve 2.2 mg of chloroplatinic acid and 83 mg of PVP in 1 mL of ethylene glycol, respectively, to obtain a platinum precursor salt solution and a PVP solution. Take 1mL of the above pure rhodium nanobranch solution, add 6mL of ethylene glycol solvent, then ultr...

Embodiment 2

[0034] The preparation of the pure rhodium nanobranch solution is the same as in Example 1.

[0035] Dissolve 2.2 mg of chloroplatinic acid and 83 mg of PVP in 1 mL of ethylene glycol, respectively, to obtain a platinum precursor salt solution and a PVP solution. Take 1mL of the above pure rhodium nanobranch solution, add 6mL of ethylene glycol solvent, then ultrasonically stir for a period of time, react at 150°C for 10min, then inject 0.5mL of platinum precursor salt solution and 2mL of PVP solution, the injection speed is 4mL / h, Continue to react at 150° C. for 4 hours and then cool to room temperature. The obtained black product C is washed with ethanol several times and stored in ethanol.

[0036] The morphology of the black product C was systematically studied by TEM and other modern nano-testing and analysis techniques. TEM( image 3a, 3b) Characterized as Rh@Pt 0.21 Core-shell nano-branch structure with a diameter of about 5.52nm.

Embodiment 3

[0038] The preparation of the pure rhodium nanobranch solution is the same as in Example 1.

[0039] Dissolve 2.2 mg of chloroplatinic acid and 83 mg of PVP in 1 mL of ethylene glycol, respectively, to obtain a platinum precursor salt solution and a PVP solution. Take 1mL of the above pure rhodium nanobranch solution, add 6mL of ethylene glycol solvent, then ultrasonically stir for a period of time, react at 150°C for 10min, then inject 1mL of platinum precursor salt solution and 2mL of PVP solution, the injection speed is 4mL / h, continue After reacting at 150° C. for 4 hours, it was cooled to room temperature, and the obtained black product D was washed several times with ethanol and stored in ethanol.

[0040] The morphology of the black product D is systematically studied by modern nano-testing and analysis techniques such as TEM. TEM( Figure 4 a, 4b) Characterized as Rh@Pt 0.44 Core-shell nano-branch structure with a diameter of about 5.92nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com