Preparation method of atomic layer deposition coated high-nickel ternary positive electrode material

A technology of atomic layer deposition and positive electrode materials, applied in the direction of electrical components, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of large differences between carbon materials and ternary oxides, battery capacity attenuation, and carbon coating layer shedding. Achieve the effects of improving cycle stability and capacity stability, changing the composition of surface elements, and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

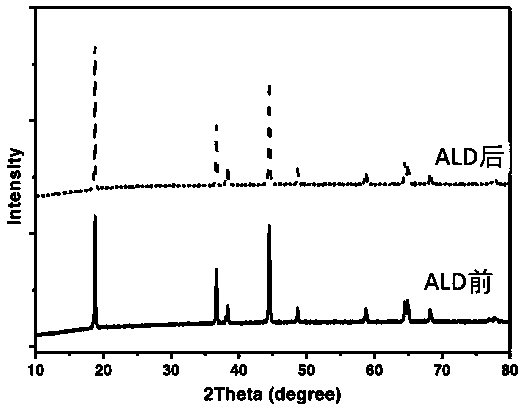

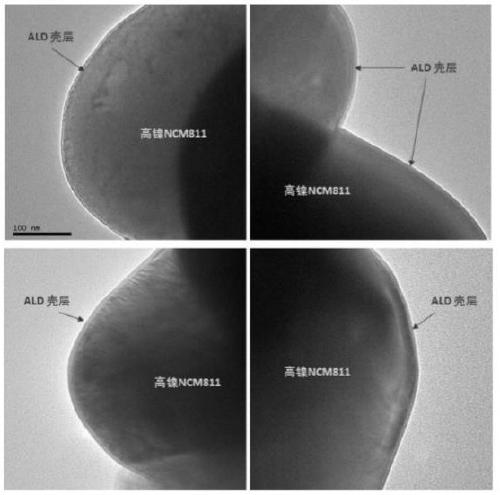

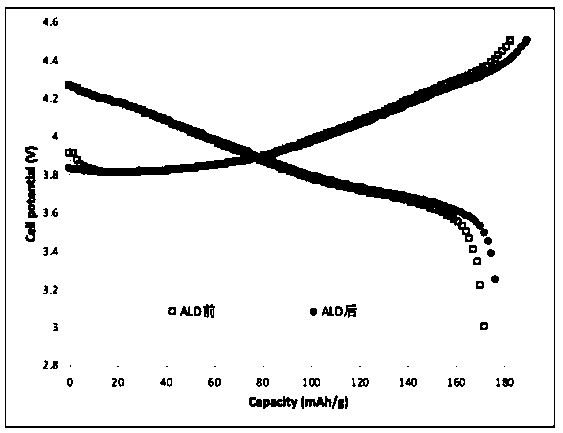

[0029] The use of atomic layer deposition equipment in high-nickel cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 (NCM811) Deposited TiO on the surface 2 For the thin film coating layer, the precursor A is isopropyl titanate, the precursor B is water, and the deposition temperature is 180°C. Put the high-nickel ternary material NCM811 into the ALD reaction chamber. The deposition parameters and deposition process are as follows: (1) Vacuum the reaction chamber until the pressure drops below 10Pa; (2) Open the valve of precursor A to Introduce isopropyl titanate vapor into the chamber and maintain it for 3 seconds; (3) Introduce argon gas into the reaction chamber for 120 seconds, then open the vacuum to take away the unreacted precursor A; (4) Wait until the pressure in the reaction chamber drops to 10Pa, open the valve of precursor B, and pass water vapor into the reaction chamber for 10 seconds; (5) pass argon gas into the reaction chamber for 120 seconds, and then open the...

Embodiment 2

[0031] The use of atomic layer deposition equipment in high-nickel cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 (NCM811) is deposited on the surface of ZrO thin film coating layer, the precursor A is tetrakis (dicarboxamide) zirconium, the precursor B is water, and the deposition temperature is 200 °C. Put the high-nickel ternary material NCM811 into the ALD reaction chamber. The deposition parameters and deposition process are as follows: (1) Vacuum the reaction chamber until the pressure drops below 10Pa; (2) Open the valve of precursor A to Introduce zirconium tetrakis(diformamide) vapor into the chamber and maintain it for 3 seconds; (3) Introduce argon gas into the reaction chamber for 120 seconds, then open the vacuum to take away the unreacted precursor A; (4) Wait for the pressure in the reaction chamber to When the pressure drops to 10Pa, open the valve of precursor B, inject water vapor into the reaction chamber, and maintain it for 10 seconds; (5) inject argon gas...

Embodiment 3

[0033] The use of atomic layer deposition equipment in high-nickel cathode material LiNi 0.6 co 0.2 mn 0.2 o 2 (NCM622) Deposited Al on the surface 2 o 3For the thin film coating layer, the precursor A is trimethylaluminum, the precursor B is water, and the deposition temperature is 160°C. Put the high-nickel ternary material NCM622 into the ALD reaction chamber. The deposition parameters and deposition process are as follows: (1) Vacuum the reaction chamber until the pressure drops below 10Pa; (2) Open the valve of precursor A to Introduce trimethylaluminum vapor into the chamber and maintain it for 3 seconds; (3) Introduce argon gas into the reaction chamber for 120 seconds, then turn on the vacuum to take away the unreacted precursor A; (4) Wait until the pressure in the reaction chamber drops to 10Pa , open the valve of precursor B, pass water vapor into the reaction chamber, and maintain it for 10 seconds; (5) pass argon gas into the reaction chamber for 120 seconds,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com