Bean curd sheet preparation equipment

A tofu and equipment technology, applied in the field of 100-page tofu production equipment, can solve problems such as difficulty in adapting to modern large-scale production, inconsistent format size and shape, and difficulty in ensuring hygienic conditions, and achieve large-scale continuous production, convenient operation, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

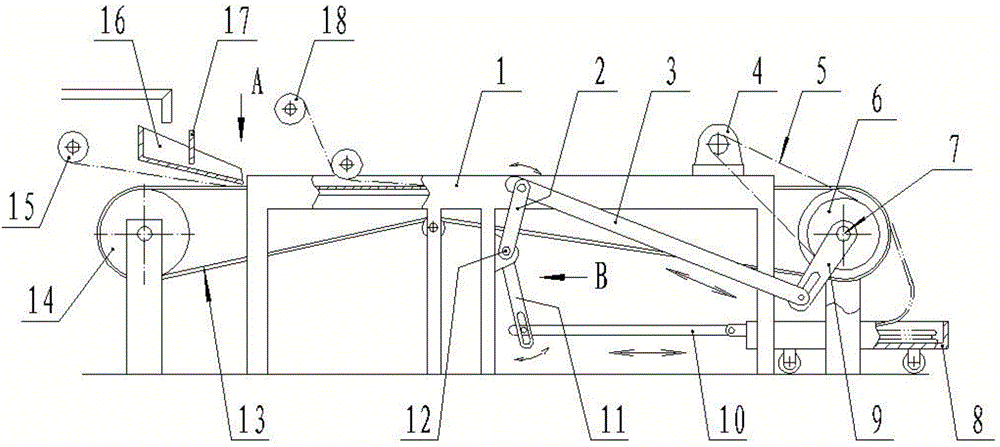

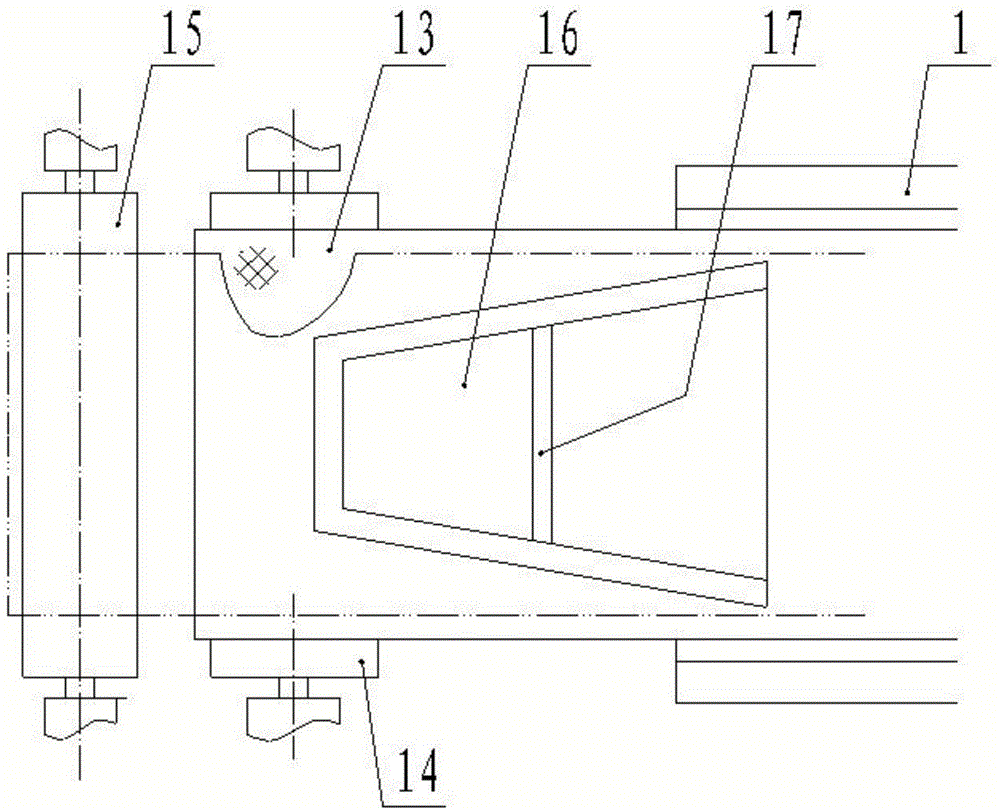

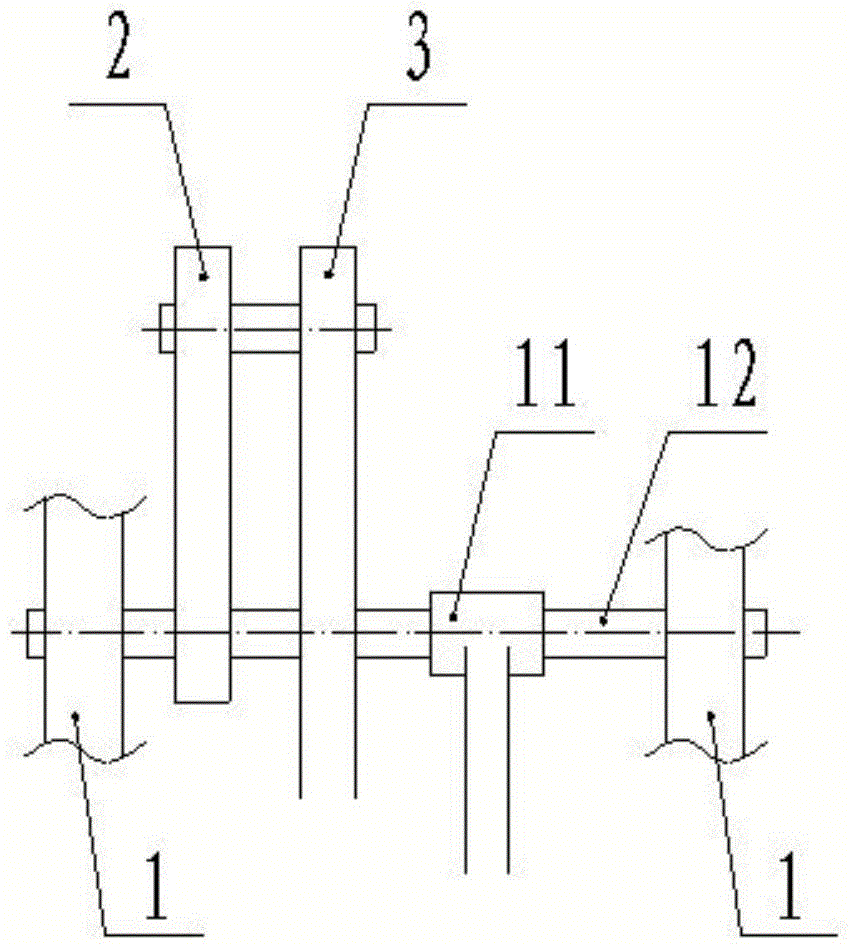

[0015] Such as Figure 1~3 As shown: two rollers 14 are respectively supported on the frame 1 by the roller shaft 7, and the cooling net is stretched between the two rollers to form a conveyor belt 13, which is driven by a motor fixed on the frame 1 4 Driven by a transmission mechanism. The transmission mechanism is composed of a small sprocket (not shown in the figure) fixed on the motor shaft, a large sprocket 6 fixed on the roller shaft 7, a chain 5 connecting the small sprocket and the large sprocket 6; Bottom layer filter cloth roll 15, surface layer filter cloth roll 18 and slurry tank 16 are arranged above belt 13, and the slurry tank is located between bottom layer filter cloth roll 15 and surface layer filter cloth roll 18.

[0016] In order to facilitate the collection of strip-shaped bean curd sheets, improve efficiency, and also in orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com