Pneumatic-electronic control system of filter element welding machine

An electronic control system, welding machine technology, applied in the direction of fluid pressure actuation system components, welding equipment, auxiliary welding equipment, etc., can solve the problems of complex structure, low production efficiency, poor welding quality, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

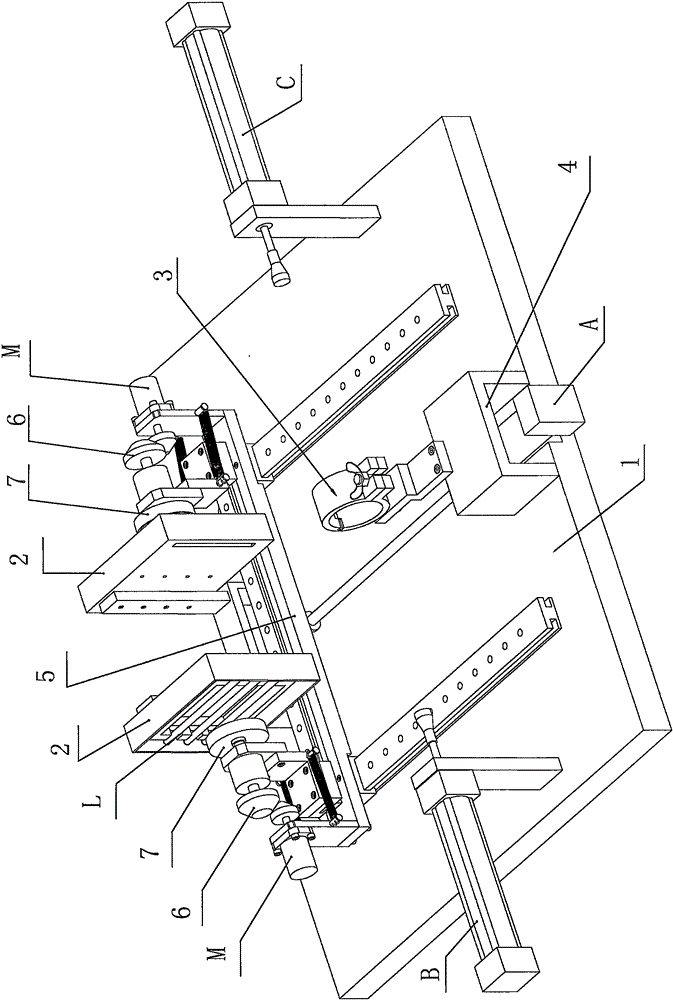

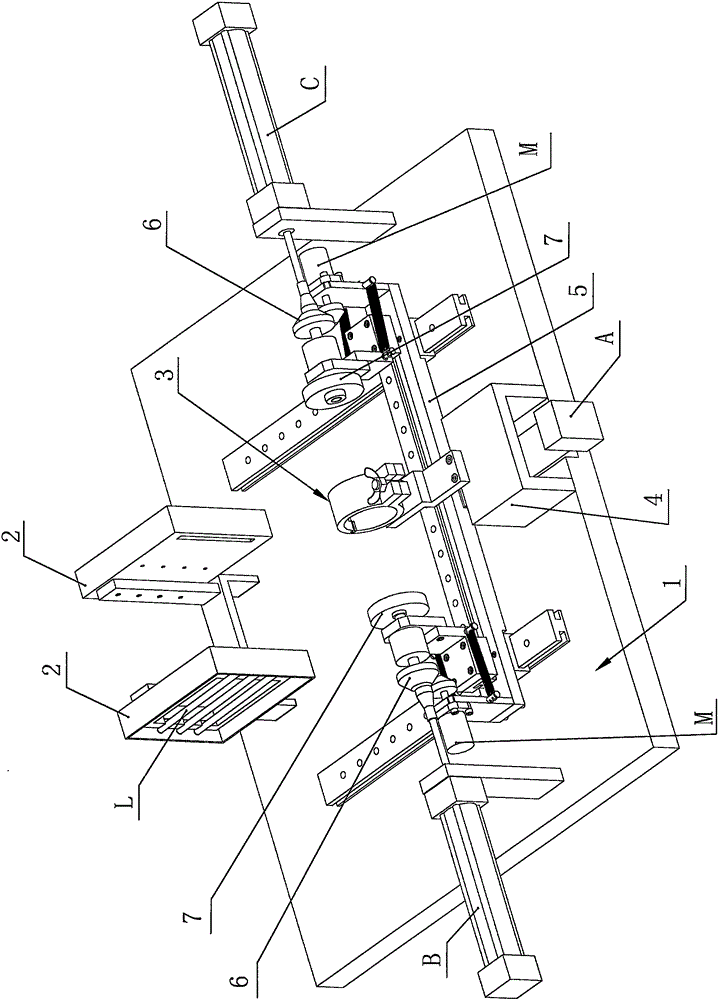

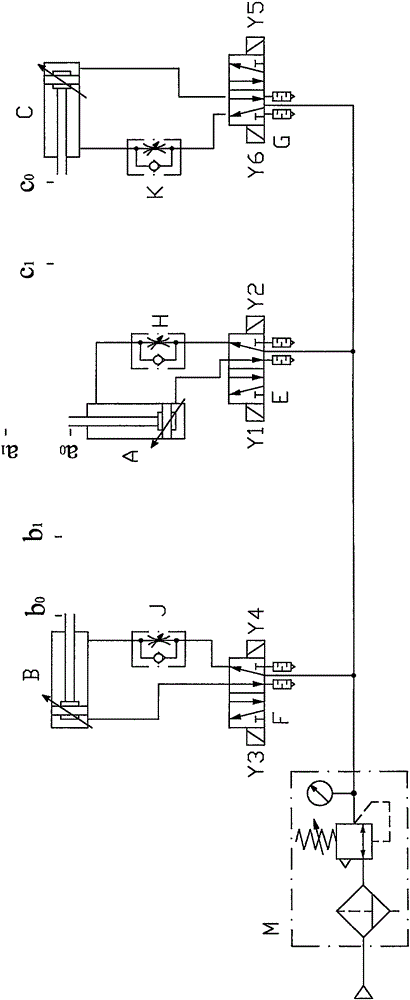

[0023] Such as figure 1 , 2 , 3, and 4, the present invention provides a pneumatic-electric control system of a filter element welding machine, including a pneumatic circuit and a control circuit, and the pneumatic circuit is connected in parallel by a longitudinal branch circuit and two transverse branch circuits Afterwards, the three pneumatic parts M are connected to the same air source to control the actions of the longitudinal drive cylinder A, the transverse drive cylinder B and the transverse drive cylinder C respectively, so as to realize the pneumatic sequential actions of the heating station and welding station of filter element welding. Using the above scheme, before heating, people first put the filter paper tube on the central mesh tube, and install it on the filter paper tube fixture 3, and at the same time, fix the two end covers respectively on the positioning installation discs 7 symmetrically arranged at the two ends of the horizontal direction. Above, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com