Automatic wood cover cutting device

An automatic cutting and cutting device technology, applied in the engineering field, can solve the problems of single function and low efficiency, and achieve the effect of changing the speed of movement and changing the cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

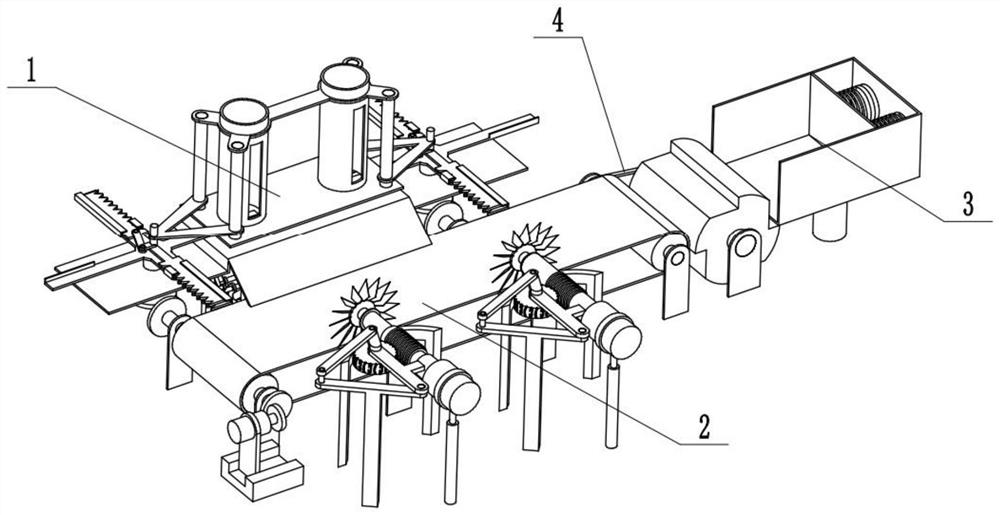

[0023] Combine below Figure 1-7 Description of this embodiment, an automatic wooden cover cutting device, including a cutting device 1, a conveying device 2, a collecting device 3, and a belt 4, the cutting device 1 is connected to the conveying device 2, and the conveying device 2 is connected to the belt 4. Connect, collecting device 3 is connected with belt one 4.

specific Embodiment approach 2

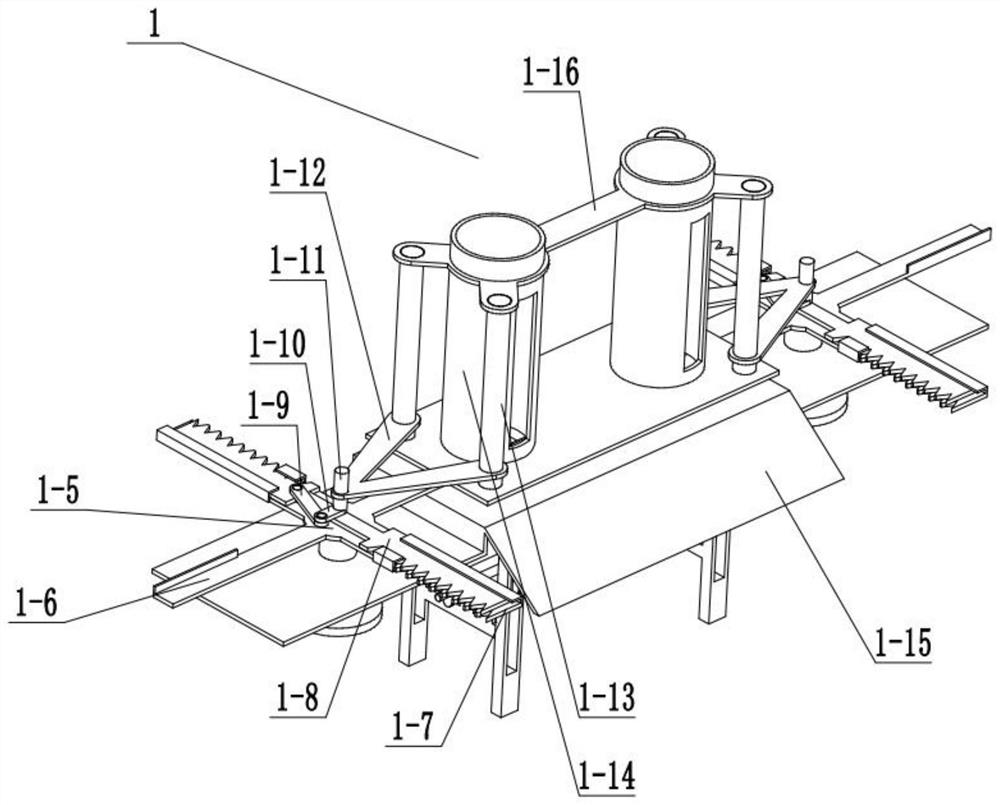

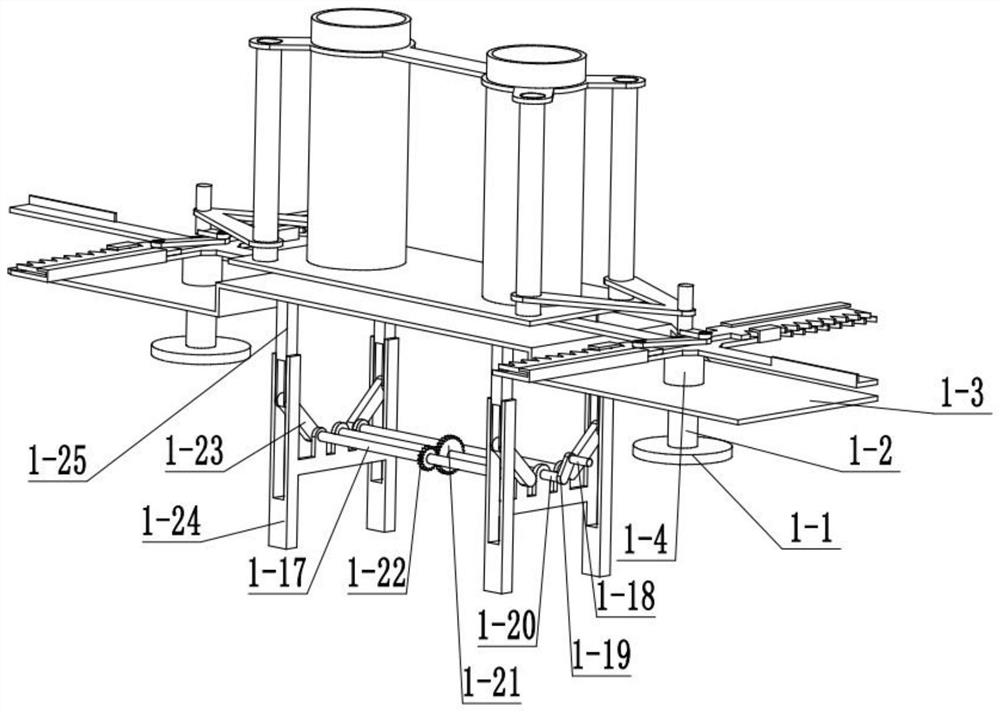

[0025] Combine below Figure 1-7 Describe this embodiment, this embodiment will further explain Embodiment 1, the cutting device 1 includes a runner 1-1, a connecting column 1-2, a boss 1-3, a hollow column 1-4, and a function turntable 1-5, peeling rod 1-6, lower sawtooth 1-7, upper sawtooth 1-8, connecting rod one 1-9, connecting rod two 1-10, small cylinder 1-11, fixed frame one 1-12, fixed Column 1-13, feeding cylinder 1-14, landslide 1-15, fixed frame 2 1-16, connecting rod 3 1-17, handle 1 1-18, handle 2 1-19, functional column 2 1-20, Gear one 1-21, gear two 1-22, support rod 1-23, lower stand 1-24, upper stand 1-25, runner one 1-1 is fixedly connected with connecting column one 1-2, boss 1 -3 is fixedly connected with the hollow column 1-4, the connecting column one 1-2 is rotationally connected with the hollow column 1-4, the connecting column one 1-2 is fixedly connected with the function turntable 1-5, and the two peeling bars 1-6 are all connected with The functi...

specific Embodiment approach 3

[0028] Combine below Figure 1-7 Describe this embodiment. This embodiment will further explain the first embodiment. The transmission device 2 includes a motor one 2-1, a support rod two 2-2, a base 2-3, a runner three 2-4, and a runner four. 2-5, connecting column five 2-6, roller 2-7, runner five 2-8, connecting column six 2-9, runner six 2-10, belt two 2-11, runner seven 2-12, Bracket three 2-13, wide runner 2-14, conveyor belt 2-15, motor two 2-16, pole 2-17, connecting rod ten 2-18, connecting rod eleven 2-19, connecting rod twelve 2 -20, screw rod 2-21, connecting rod 13 2-22, gear three 2-23, arc frame 2-24, connecting column ten 2-25, fan 2-26, motor one 2-1 and support rod two 2-2 is fixedly connected, support rod 2 2-2 is slidingly connected with base 2-3, motor 1 2-1 is fixedly connected with runner 3 2-4, runner 3 2-4 is connected with runner 4 2-5 , the runner four 2-5 is connected with the connecting column five 2-6, the connecting column five 2-6 is fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com