Patents

Literature

54results about How to "Adjust flow speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

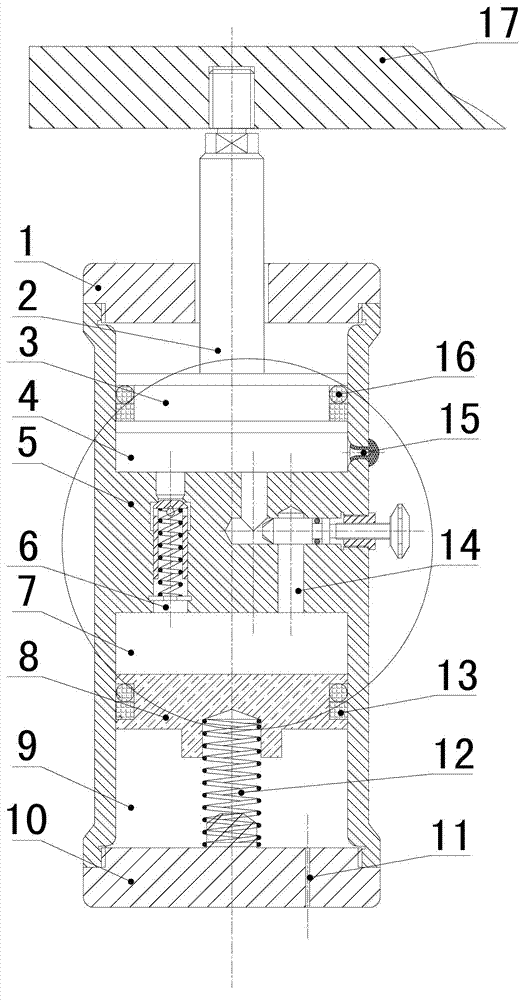

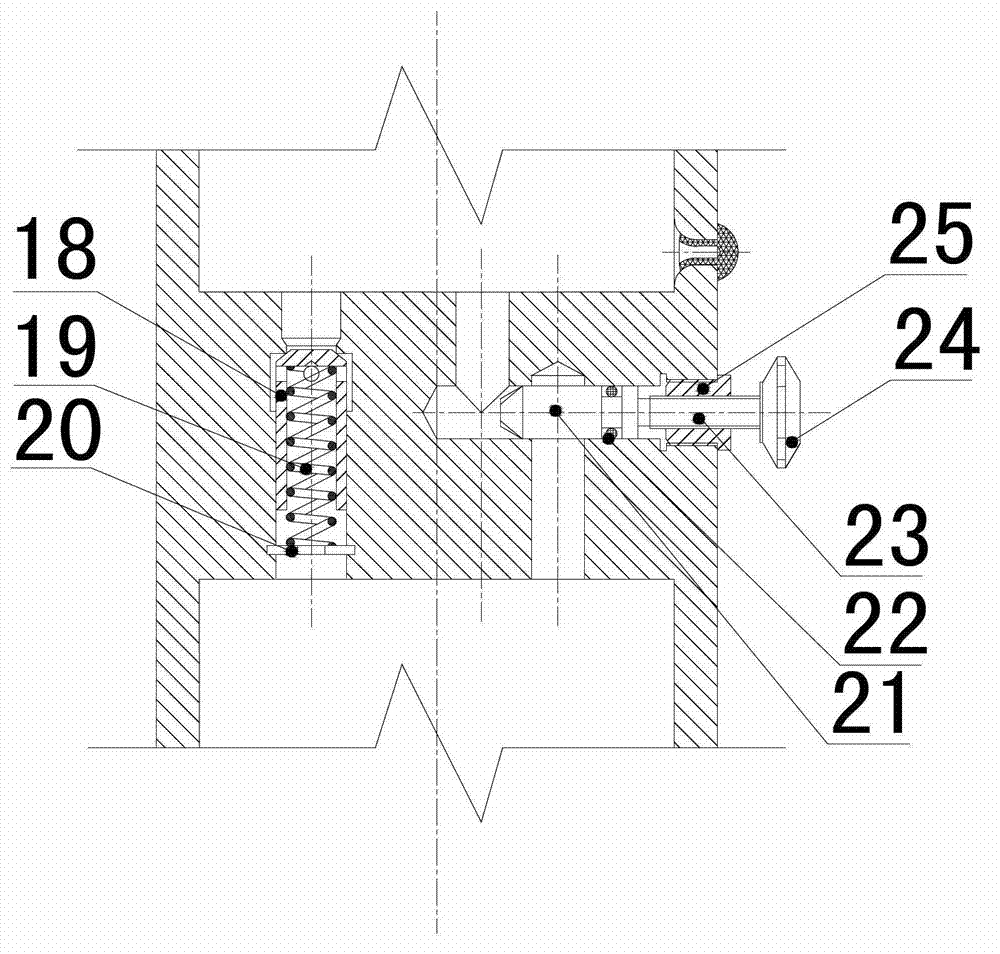

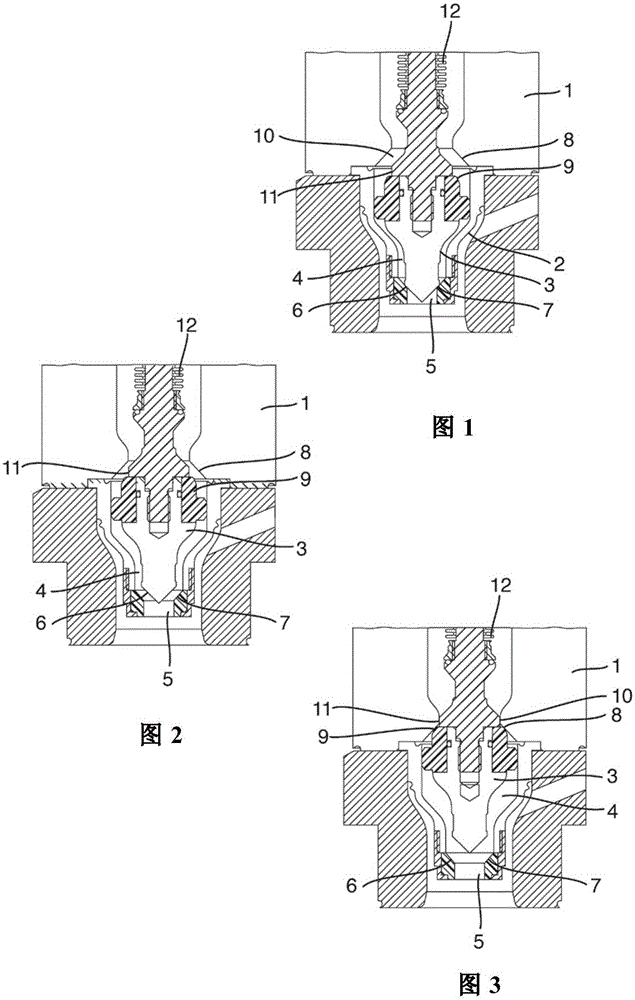

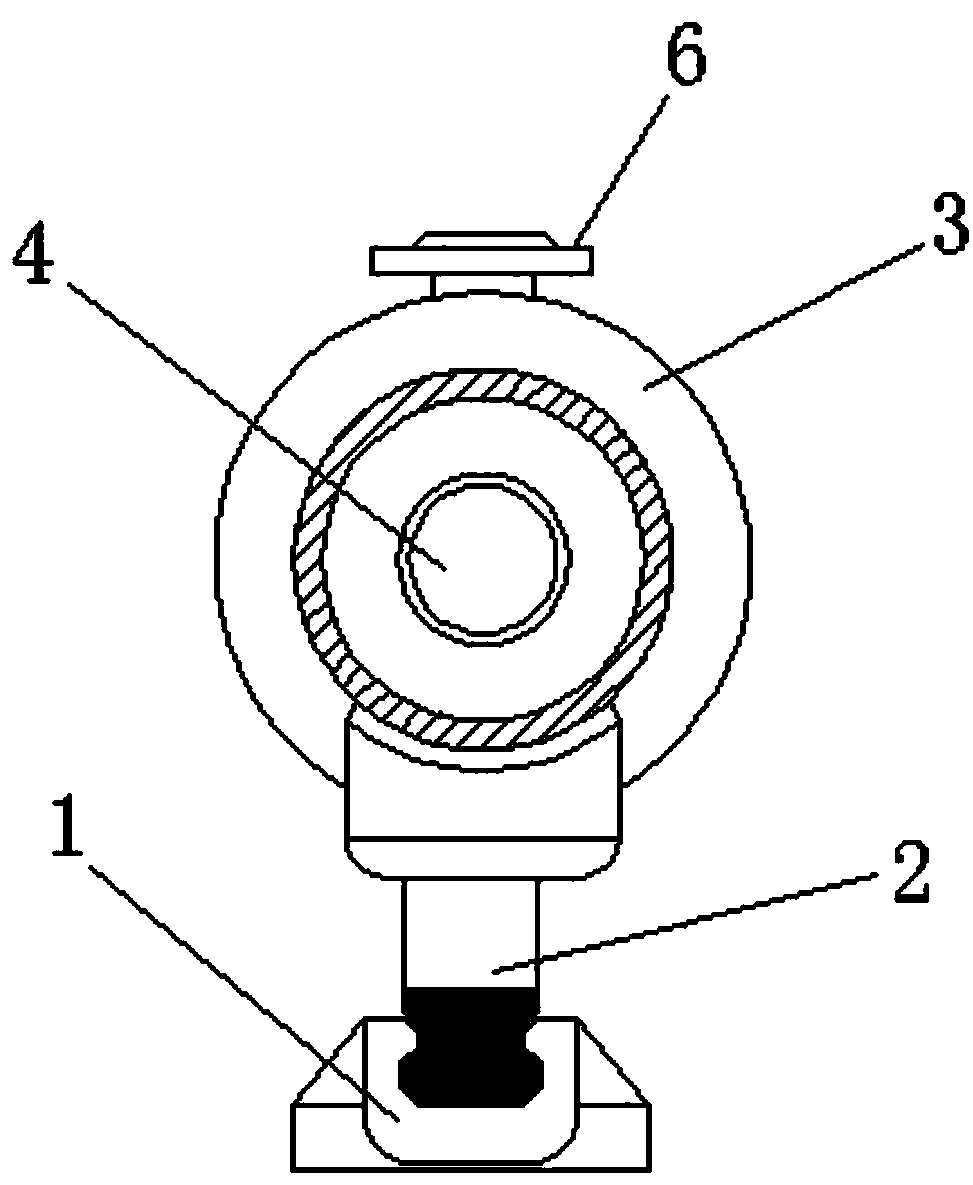

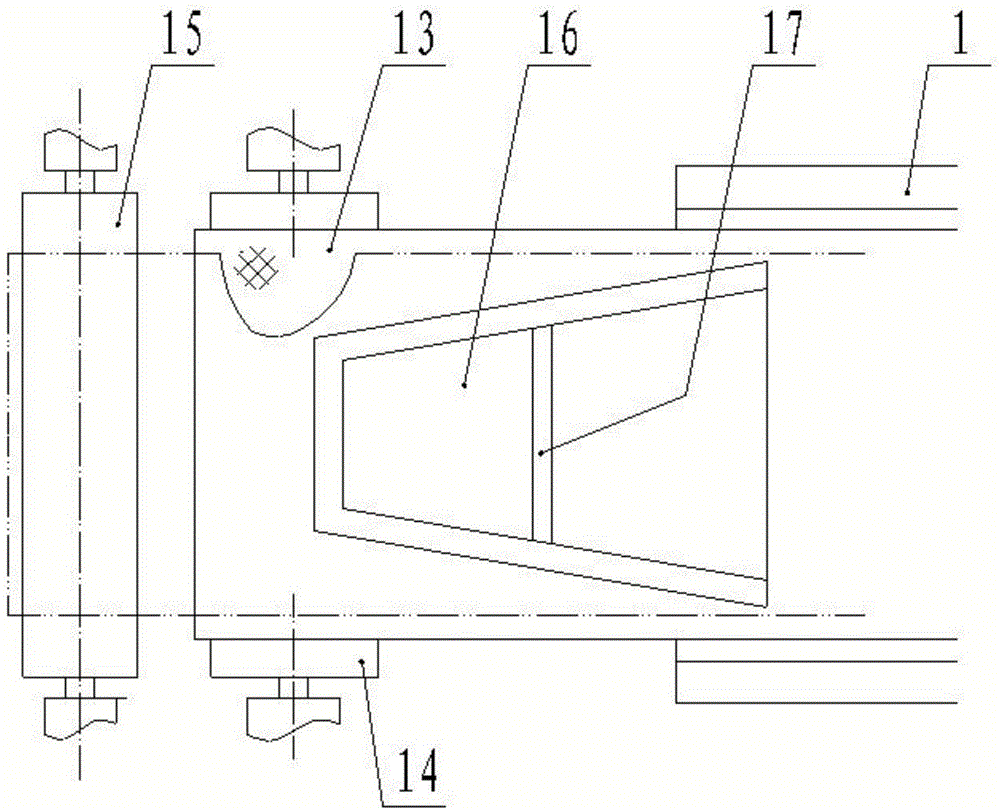

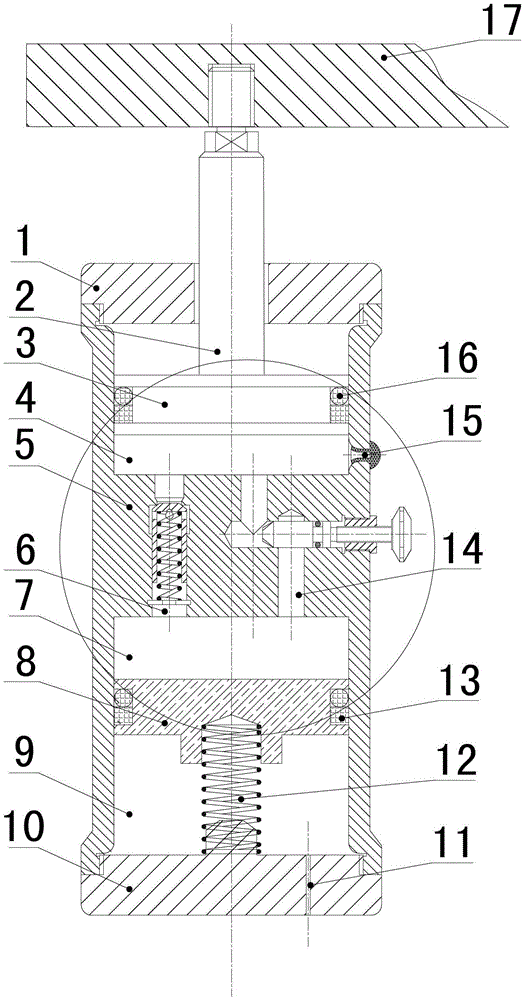

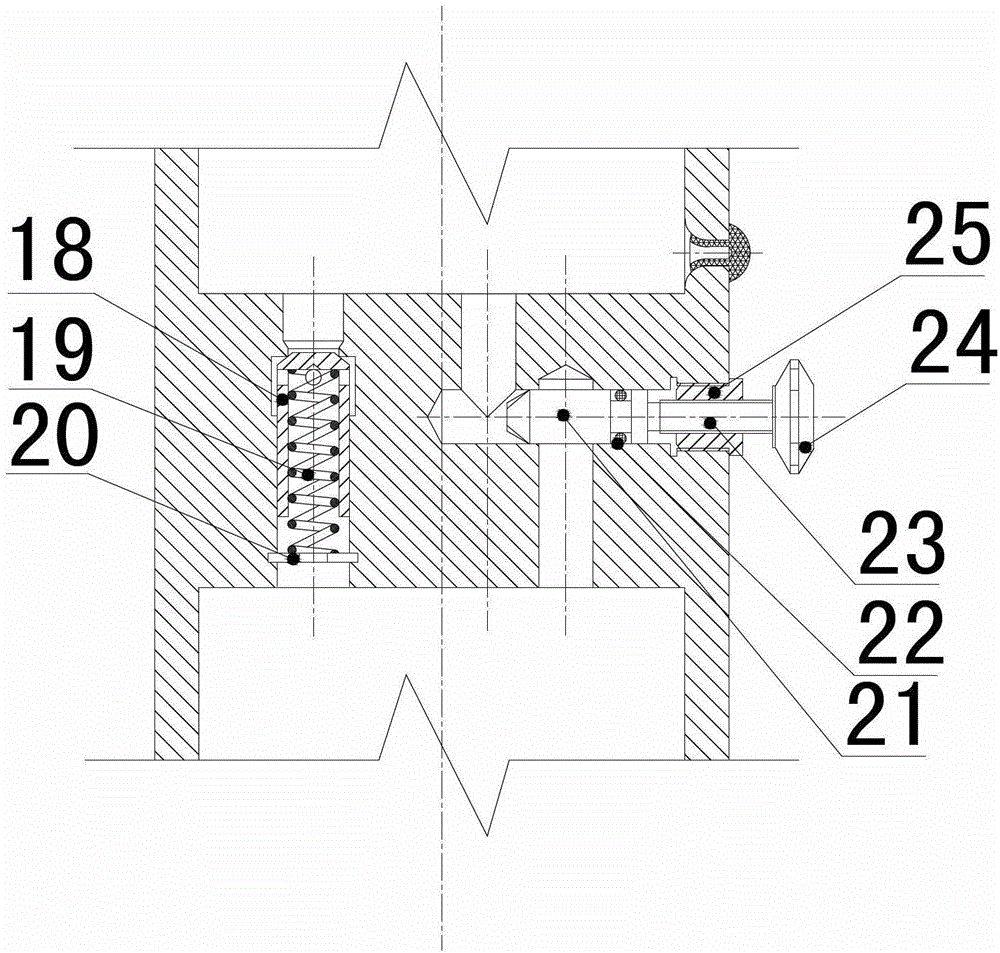

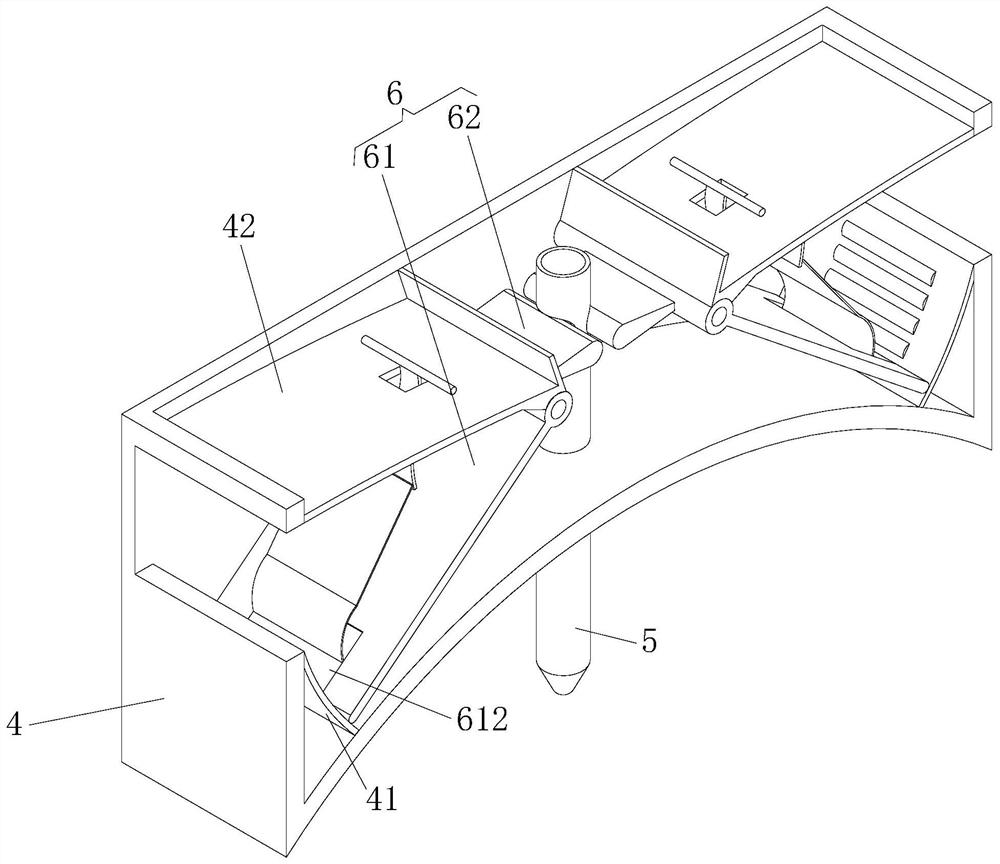

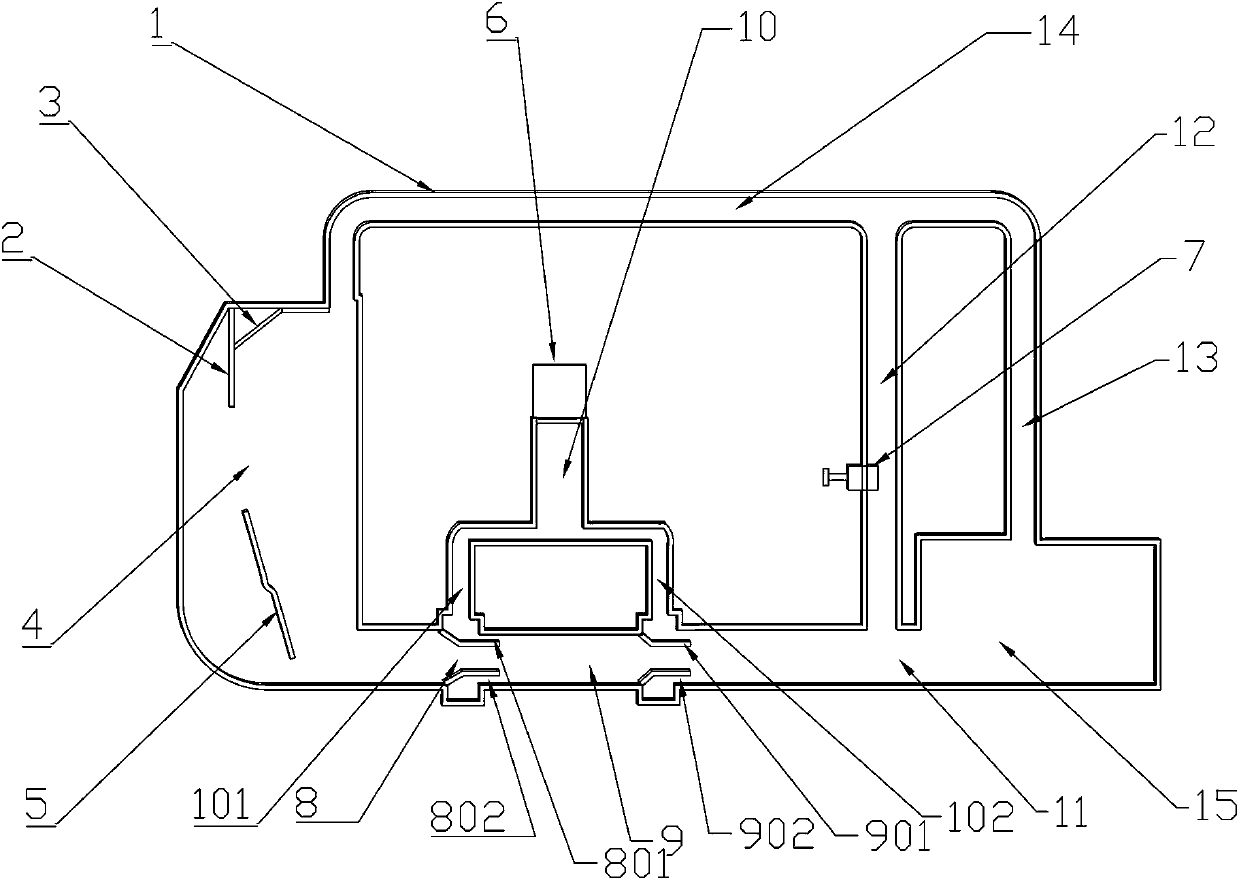

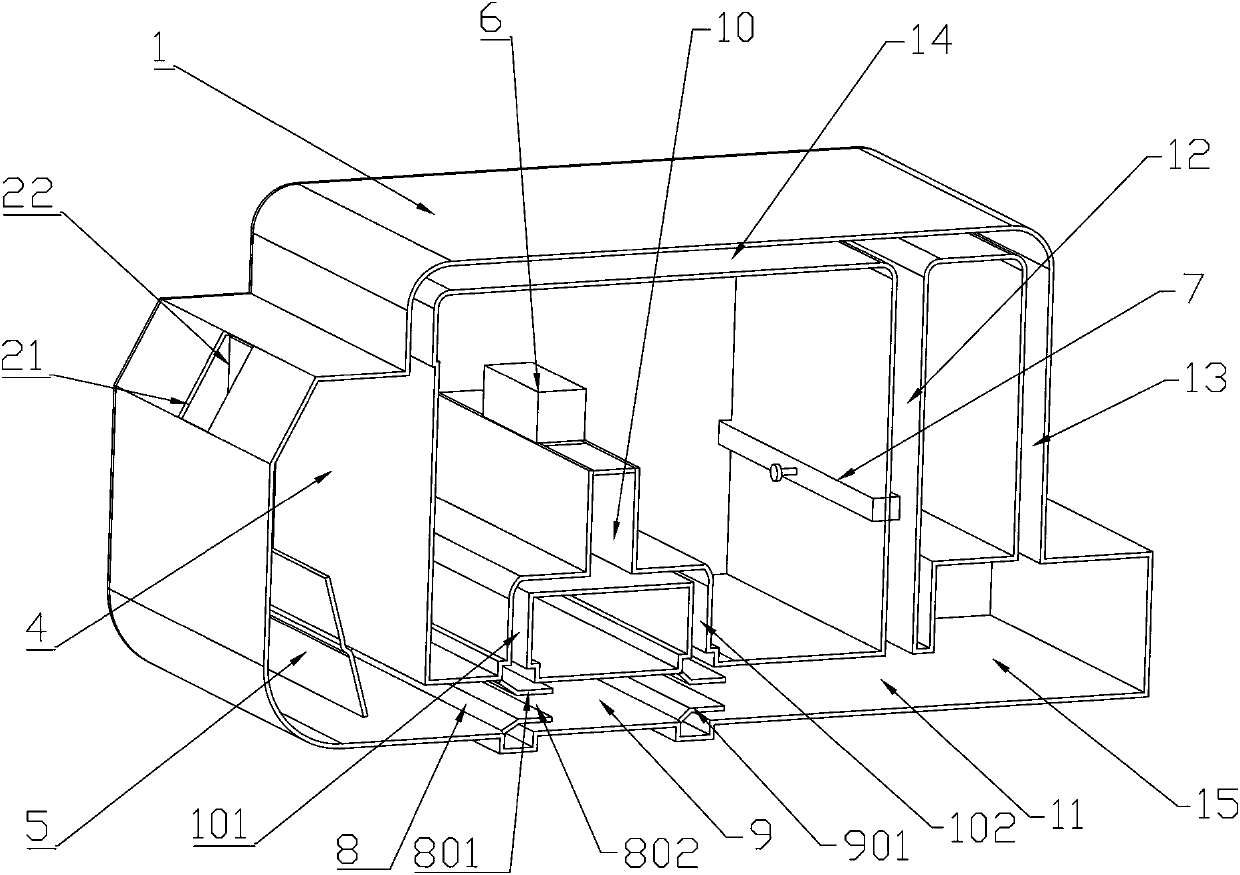

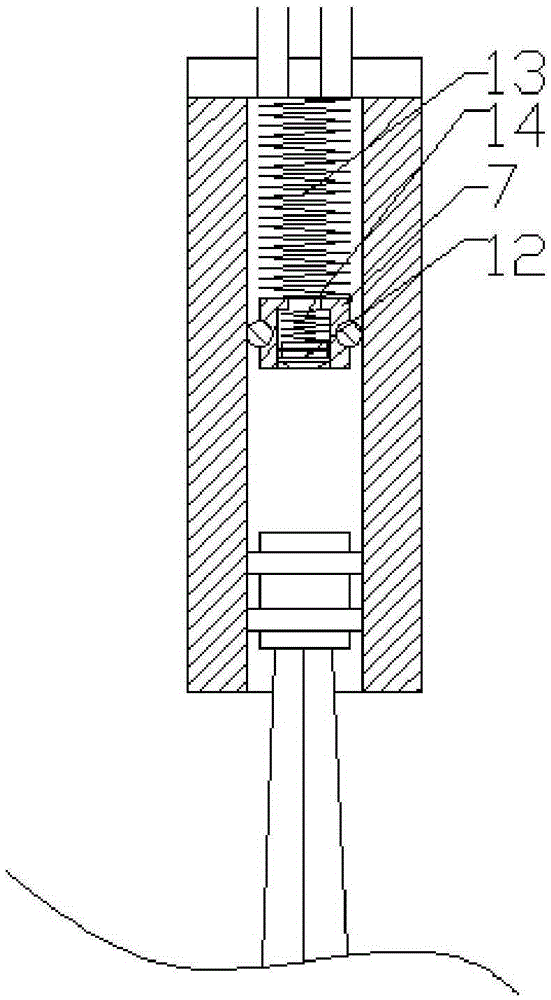

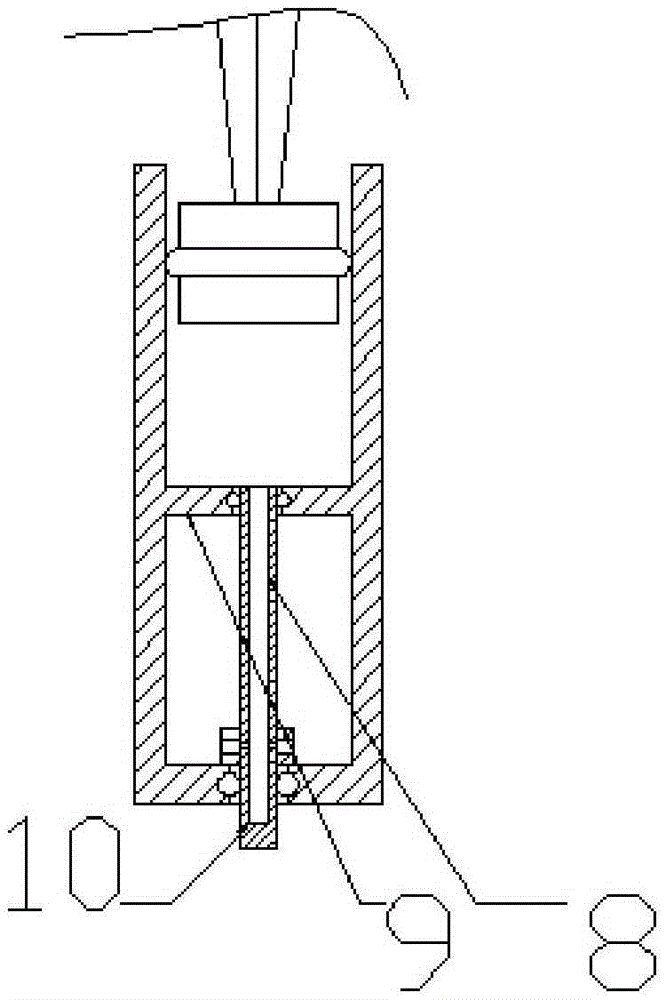

Impulse slow-releasing device

The invention relates to an impulse slow-releasing technology and discloses an impulse slow-releasing device. The impulse slow-releasing device comprises a cylinder body provided with an upper cylinder hole and a lower cylinder hole; an upper piston is matched inside the upper cylinder hole in a sealed manner; a piston rod is connected with the upper part of the upper piston; an upper oil cavity is formed by the bottom of the upper piston and the upper cylinder hole; a lower piston is matched inside a lower cylinder hole in the sealed manner; a lower oil cavity is formed by the top of the lower piston and the lower cylinder hole; a lower end cover is threaded connection with the bottom of the lower cylinder hole; a potential storage slow-releasing spring is arranged between the lower piston and the lower end cover; an air vent is formed in the lower end cover; a cylinder base is arranged between the upper cylinder hole and the lower cylinder hole; a step-shaped vertical hole and a step-shaped bending hole, which are communicated with the upper cylinder hole and the lower cylinder hole, are formed in the cylinder base; a one-way valve for guiding oil from the upper oil cavity to the lower oil cavity is arranged inside the step-shaped vertical hole; and a flow adjusting valve for communicating the upper oil cavity and the lower oil cavity are arranged inside the step-shaped bending hole.

Owner:ARCHITECTURAL ENG INST GENERAL LOGISTICS DEPT P L A

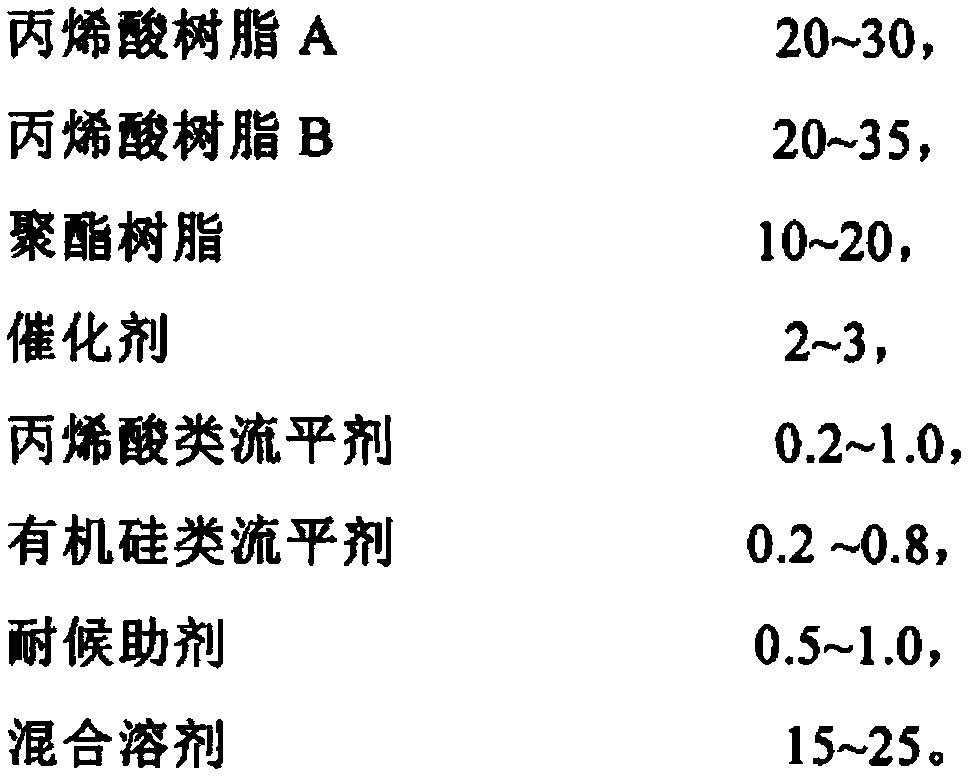

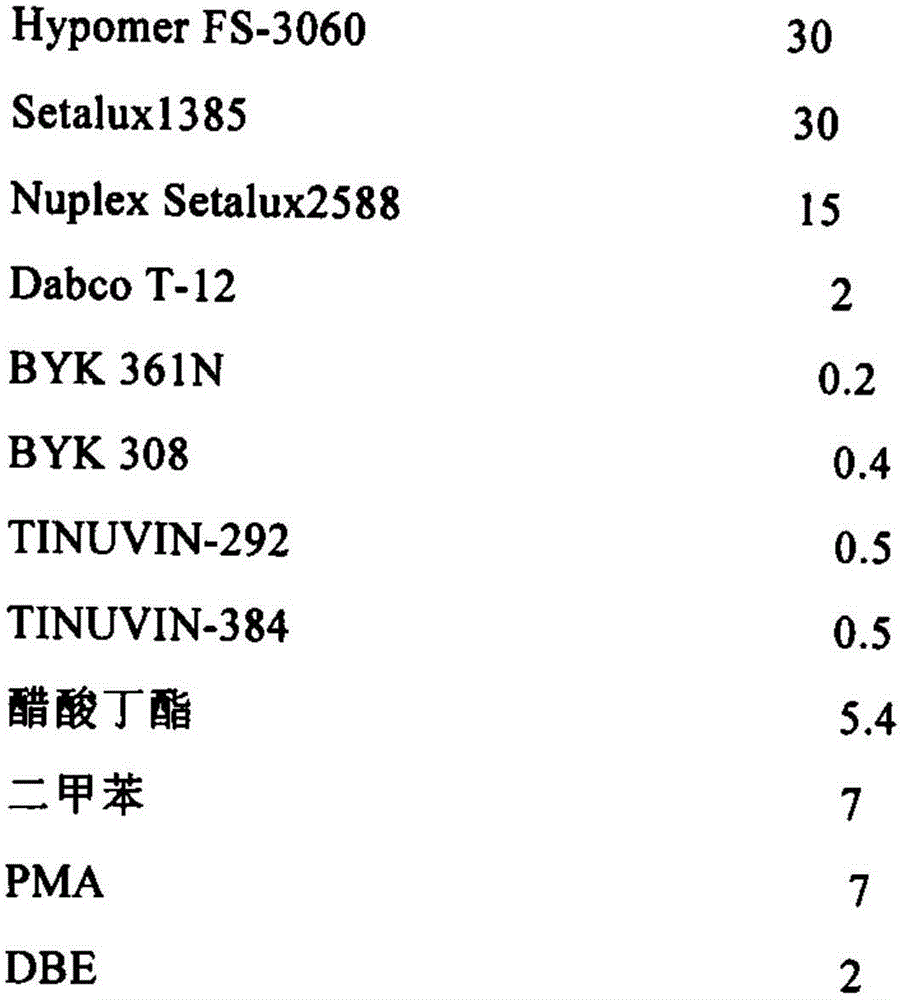

High-temperature-resistant high-metal-effect plastic paint and preparation method thereof

InactiveCN104559556AIncrease polarityGood compatibilityPolyester coatingsAcrylic resinPolyester resin

The invention relates to a high-temperature-resistant high-metal-effect plastic paint and a preparation method thereof. The preparation method comprises the following steps: sequentially adding 20-30 wt% of acrylic resin A, 20-35 wt% of acrylic resin B, 10-20 wt% of polyester resin, 2-3 wt% of catalyst, 0.2-1.0 wt% of acrylic leveling agent, 0.2-0.8 wt% of organic silicon leveling agent, 0.5-1.0 wt% of weather-resistant assistant and 15-25 wt% of mixed solvent, slowly stirring, and stirring at the high speed of 600-800 rpm for 15 minutes to obtain the high-temperature-resistant high-metal-effect plastic paint. Compared with the prior art, the method enhances the high temperature resistance, high metal effect, wear resistance and other properties of the plastic paint.

Owner:DONGLAI COATING TECH SHANGHAI

Filling valve for filing product for filling container

The invention relates to a filling valve for filling a container to be filled with a product to be filled, the valve having a product outlet (5) for injecting the product to be filled into the container to be filled and capable of sealingly holding Valve cone (3) in the first valve seat (7), which is moved into the first valve seat (7) by the valve cone (3) in the direction of the filling product flow towards the product outlet (5) And for shutting off the filling product flow, wherein a second valve seat (8) is provided for sealingly receiving the valve cone (3), which passes through the valve cone (3) in a direction opposite to the filling product flow direction to move into the second valve seat (8) for shutting off the filling product flow.

Owner:KRONES AG

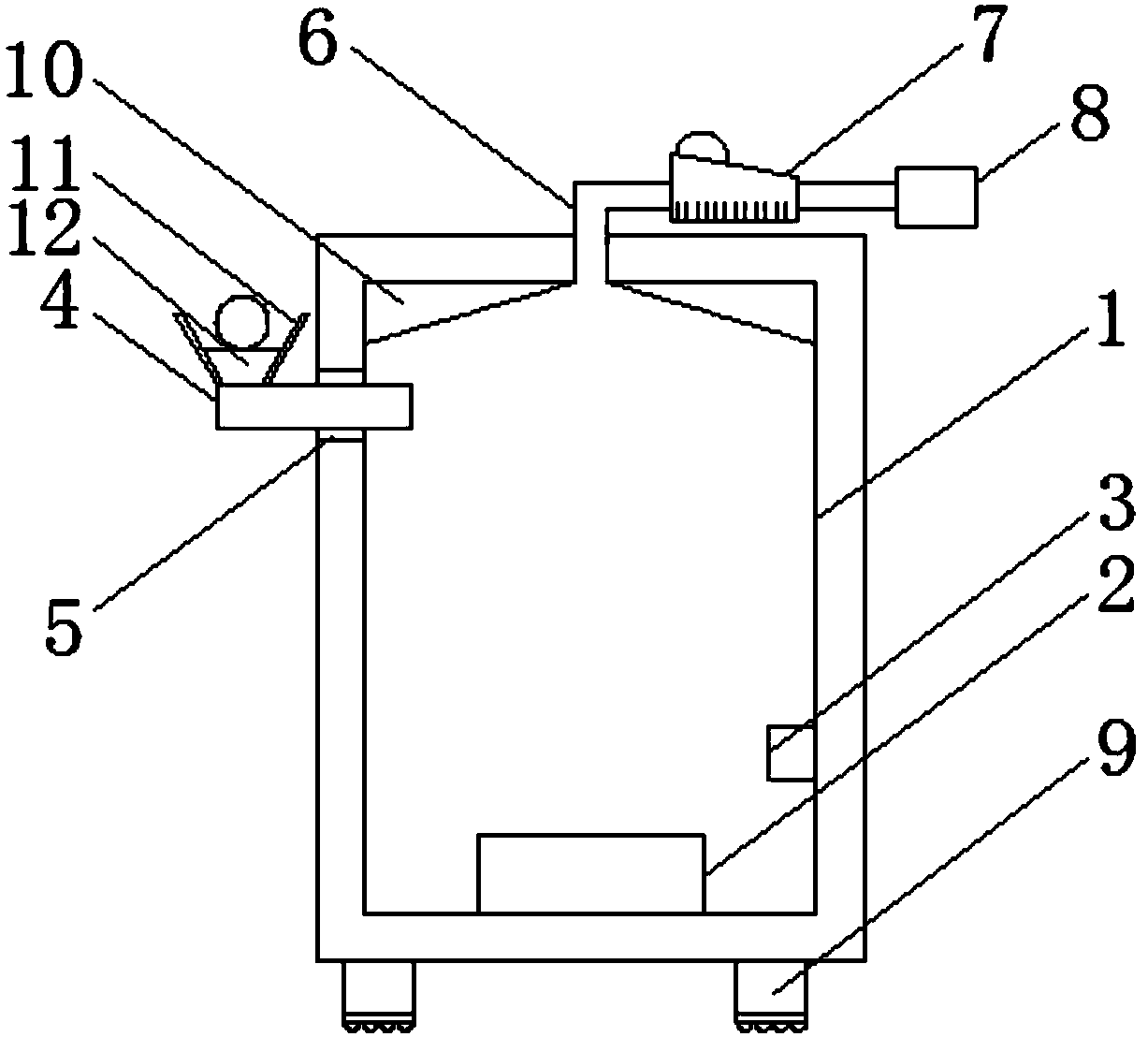

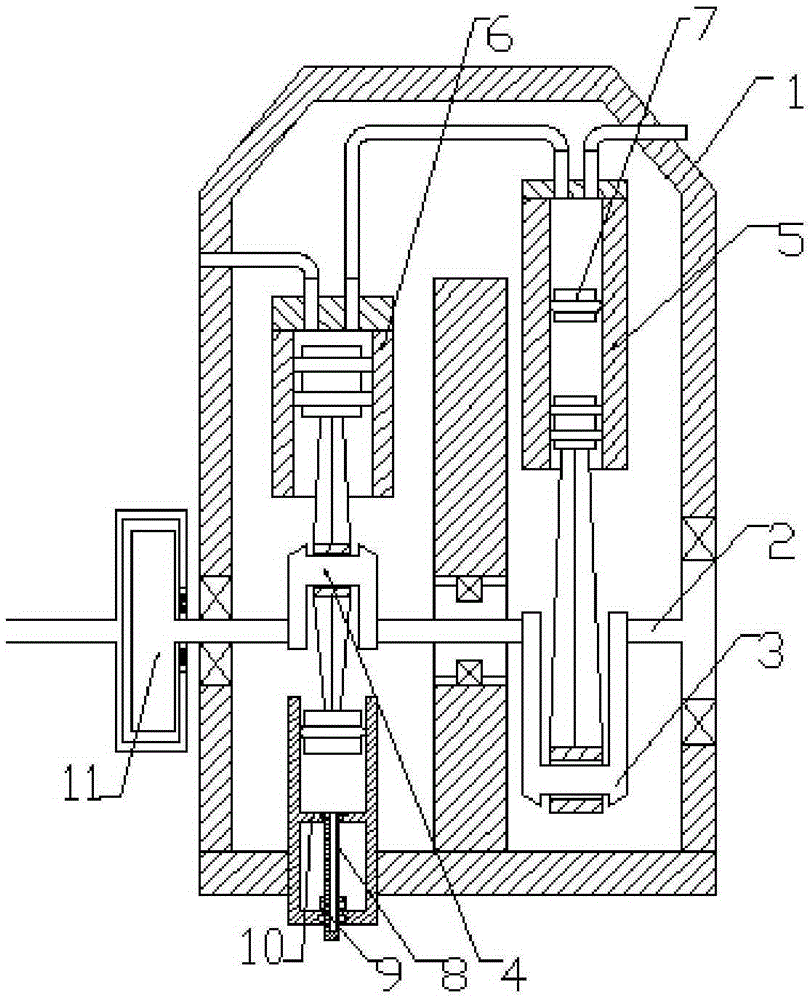

Anesthesia evaporation tank accurately controlling spraying concentration

InactiveCN108543190APrevent fallingChange squeeze strengthRespiratorsMedical devicesEvaporationAgricultural engineering

The invention belongs to the field of medical apparatuses and instruments, and discloses an anesthesia evaporation tank accurately controlling the spraying concentration. The anesthesia evaporation tank comprises a tank body, a heating device is arranged at the bottom of an inner cavity of the tank body, a temperature sensor is arranged at the bottom of the right side of the inner cavity of the tank body, a liquid feeding pipe is movably arranged at the top of the left side of the tank body, an air discharging pipe is arranged at the top of the tank body, and is movably sleeved with an adjusting valve, and a spraying head is connected to the other end of the air discharging pipe; medicine is added into the inner cavity of the tank body from a hopper, a plug body is plugged into after medicine adding is end, the liquid feeding pipe is rotated, a liquid inlet of the hopper is formed downwards, and dust is prevented from entering an inner cavity of the hopper; a rolling wheel moves left and right, extrusion force of the rolling wheel for the air discharging pipe is changed, the flowing speed of steam in the air discharging pipe is adjusted; by rotating a cover, air discharging openings of the cover are in contact with three groups of silica gel rings in sequence, the air discharging openings are plugged through the silica gel rings, the quantity of the air discharging openings capable of discharging air is changed, and the spraying concentration is changed.

Owner:唐在荣

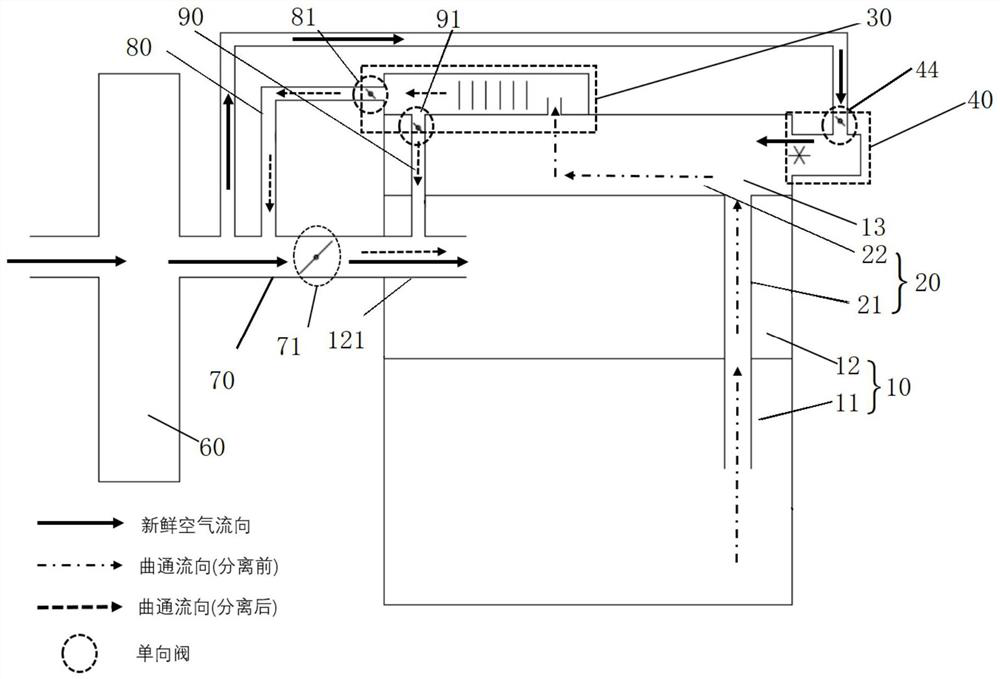

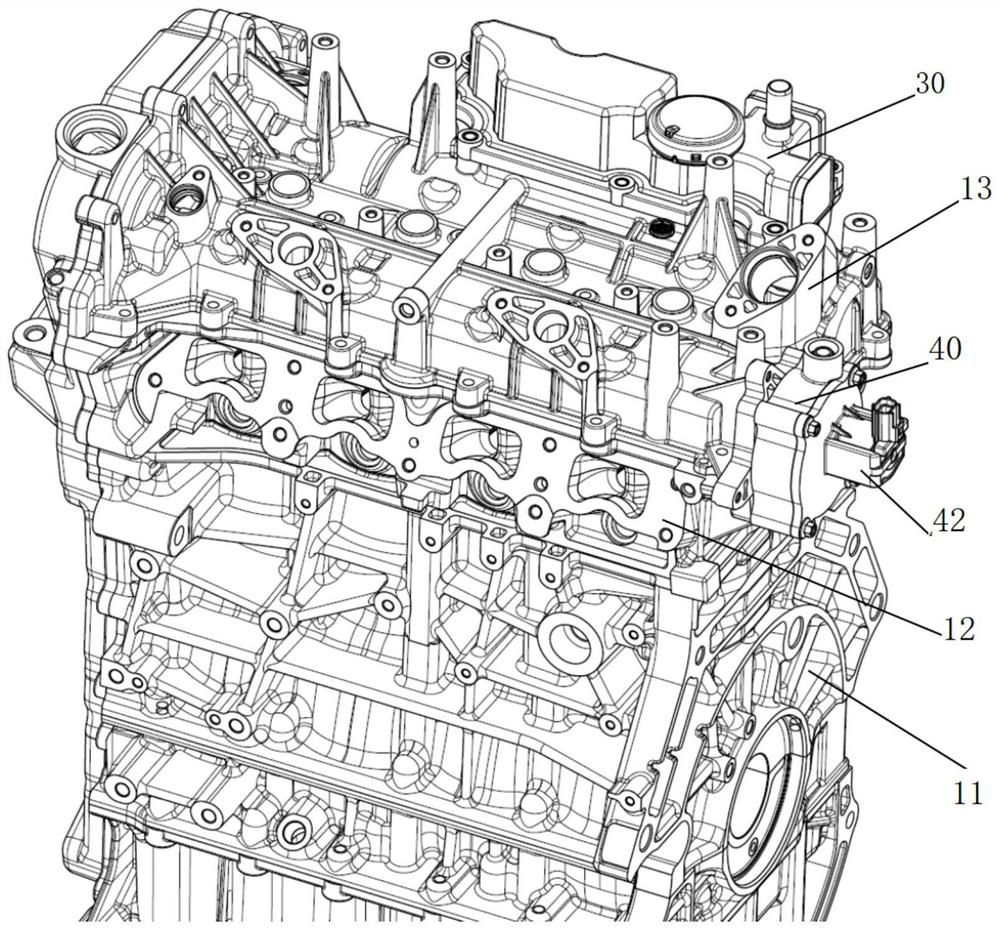

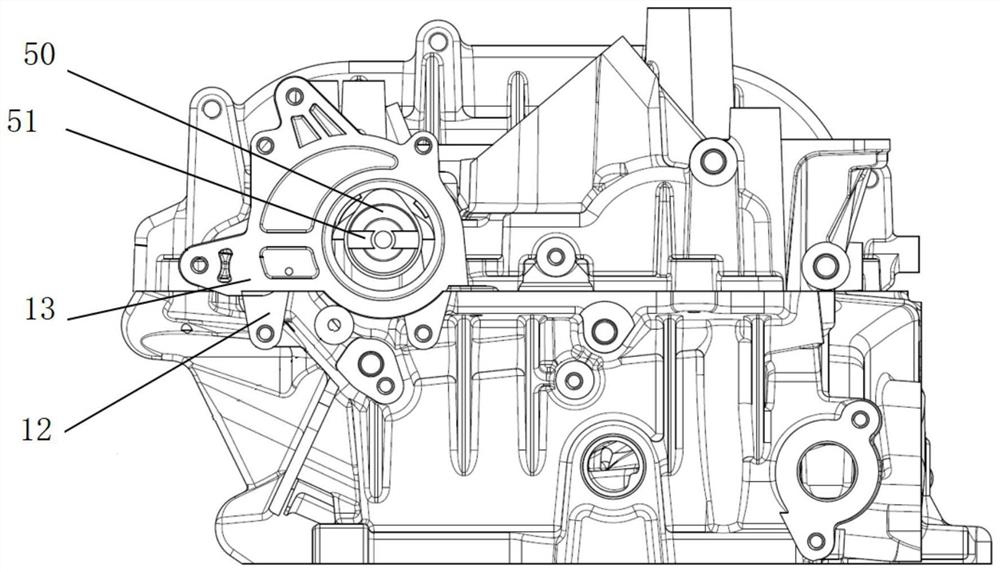

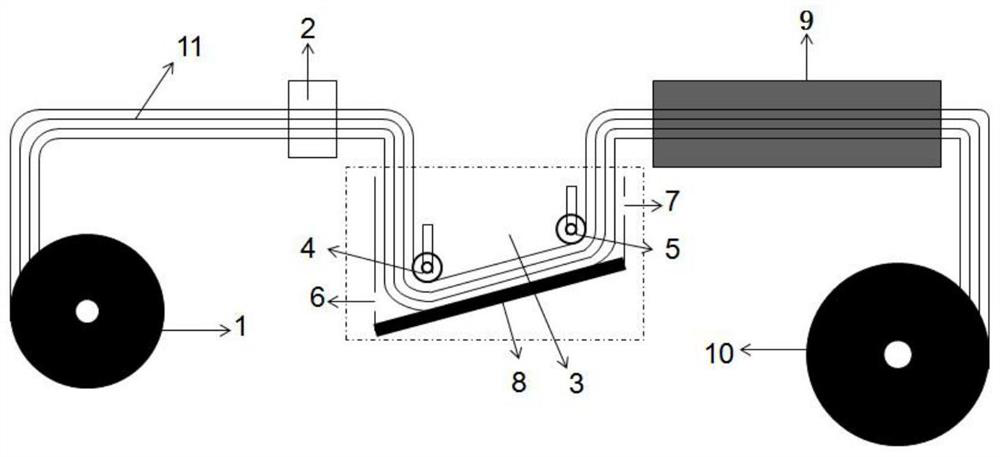

Crankcase ventilation adjusting system and control method of crankcase ventilation adjusting system

The invention discloses a crankcase ventilation adjusting system and a control method. The crankcase ventilation adjusting system comprises a crankcase, a crankcase ventilation gas passage and an oil-gas separator; one end of the crankcase ventilation gas passage is connected with the crankcase, and the other end of the crankcase ventilation gas passage is connected with the oil-gas separator; thecrankcase ventilation adjusting system further comprises a sensor component, a controller and a crankcase ventilation adjuster. the crankcase ventilation adjuster communicates with the crankcase ventilation gas passage; the crankcase ventilation adjuster is provided with an oil passage, an engine oil pressure control valve, an oil pressure cavity, a pressure piece and an adjusting component; andthe oil pressure cavity communicates with the oil passage, the pressure piece is assembled in the oil pressure cavity and connected with the adjusting component, and the engine oil pressure control valve is installed in the oil passage. According to real-time signals measured by the sensor component, the controller controls opening and closing of the engine oil pressure control valve and adjusts the oil quantity of the oil pressure cavity, so that the pressure piece moves along the oil pressure cavity so as to rotate the adjusting component to a standard angle to adjust the speed of crankcaseventilation gas flowing to the oil-gas separator.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

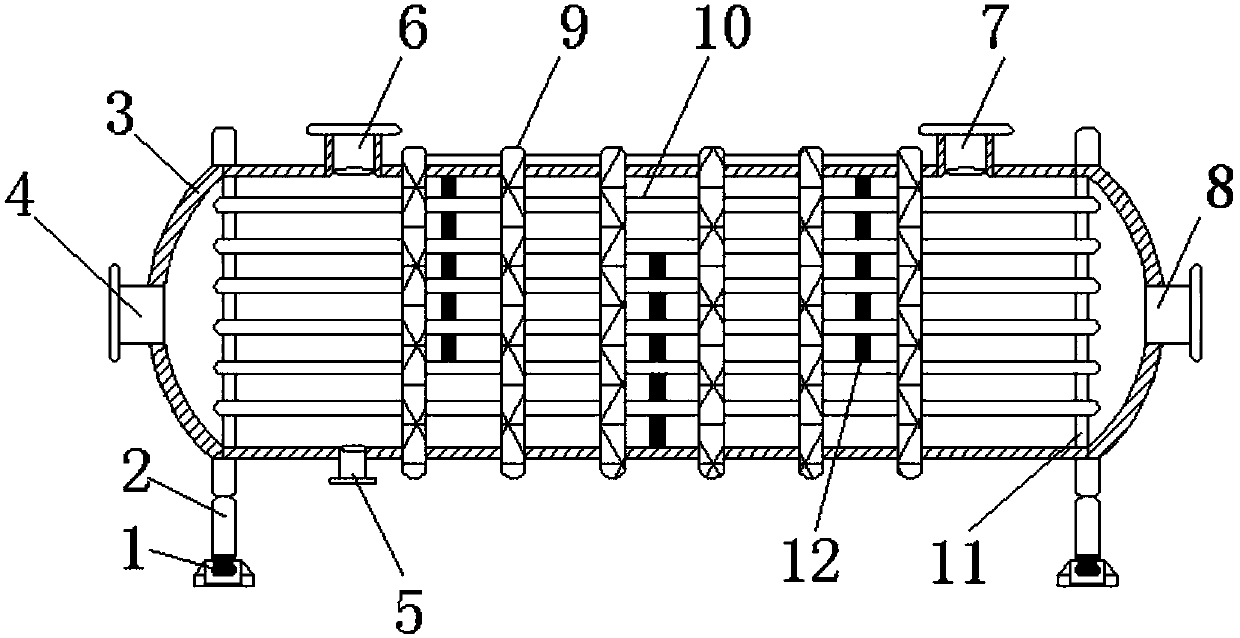

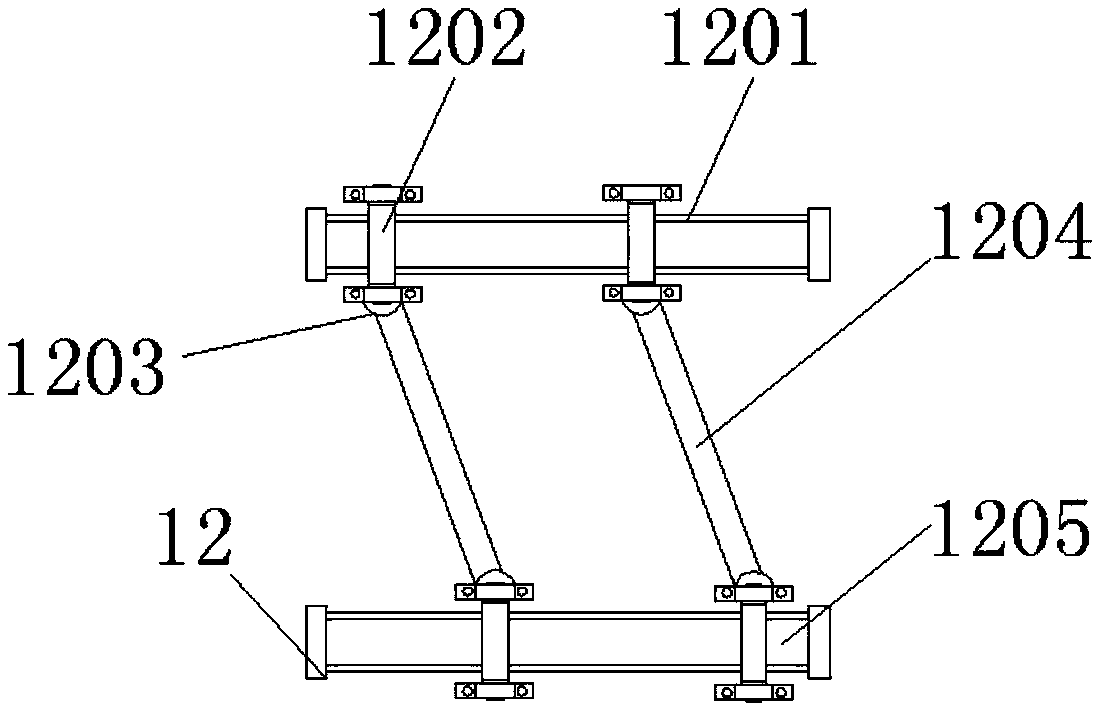

Tubular heat exchanger for chemical production

InactiveCN107677151AAdjust flow directionAdjust flow speedHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerEngineering

The invention discloses a tube-and-tube heat exchanger for chemical production, which includes a support column and a heat exchange tube. A base is installed below the support column, and an outer cylinder is fixed above the support column. The outer cylinder The left side of the outer cylinder is provided with a first medium inlet, and the lower left side of the outer cylinder is provided with a sewage outlet, the upper left side of the outer cylinder is provided with a first medium outlet, and the upper right side of the outer cylinder is provided with a second medium outlet. Two medium inlets, and a second medium outlet is provided on the right side of the outer cylinder, a fixed ring is fixed on the outside of the outer cylinder, spacers are installed at both ends of the heat exchange tubes, and the heat exchange tubes are located outside Inside the cylinder, a baffle device is installed in the middle of the outer cylinder. The tube-and-tube heat exchanger for chemical production has a relatively solid shell, which can flexibly adjust the flow direction of the fluid, thereby flexibly adjusting the flow speed of the fluid and the efficiency of heat exchange.

Owner:陈宏

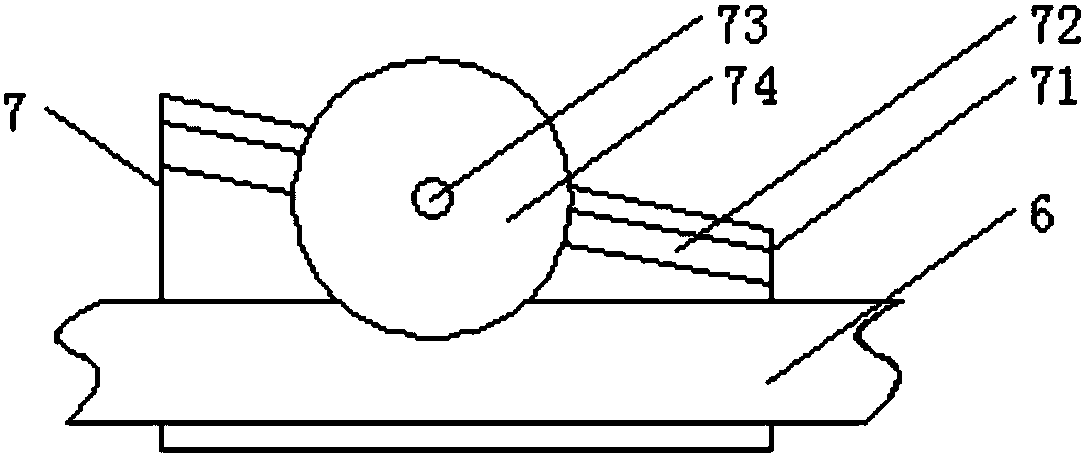

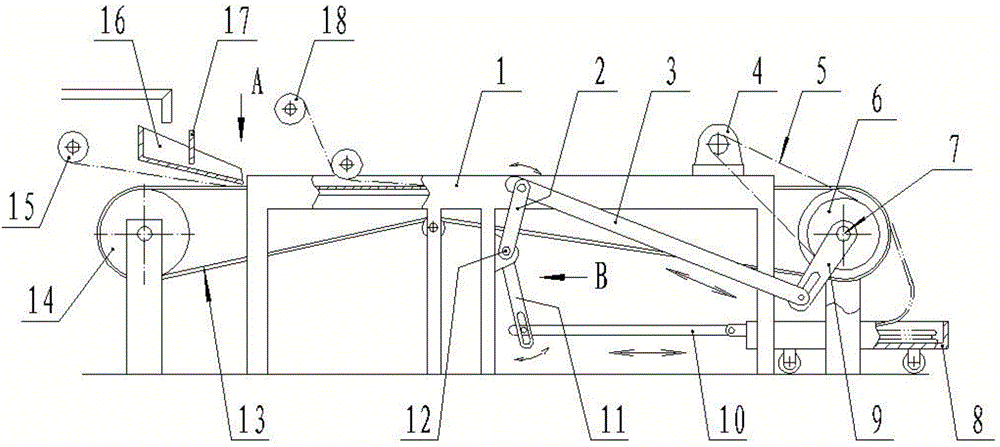

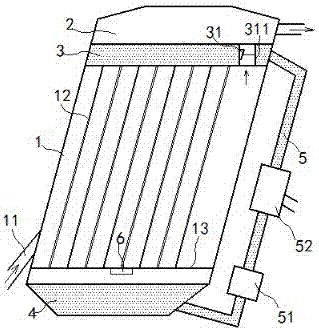

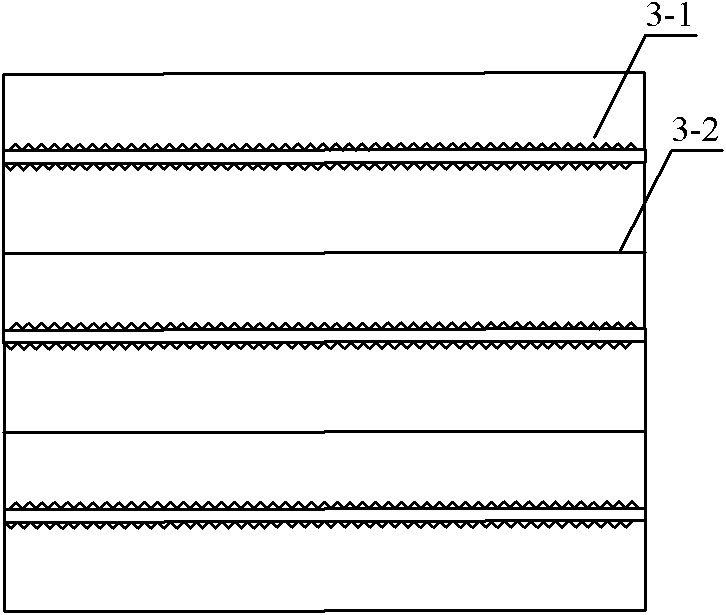

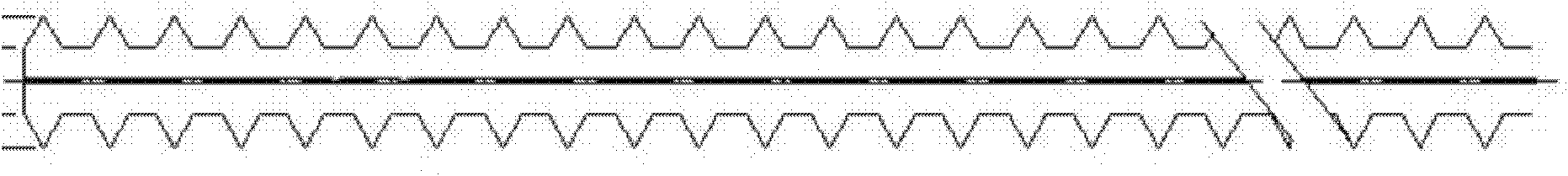

Bean curd sheet preparation equipment

InactiveCN104543021AChange the speed of movementPrevent proliferationCheese manufactureFood scienceProduction rateSurface layer

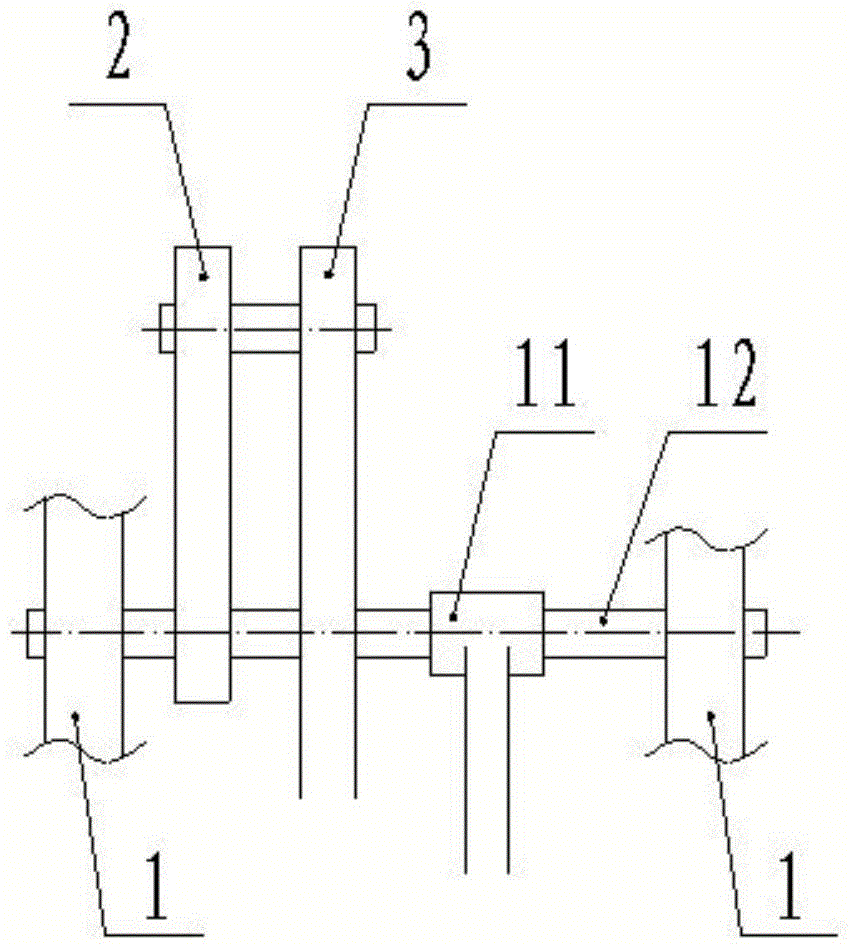

The invention discloses bean curd sheet preparation equipment and aims to provide thin bean curd sheet processing equipment which is consistent in product size, uniform in thickness and high in yield. The bean curd sheet preparation equipment comprises a net-shaped conveyor belt (13) arranged on a rack (1) through a roller shaft (7), wherein the conveyor belt is driven by a motor (4) fixed on the rack (1) through a transmission mechanism; the motor (4) is fixed on the rack (1); the transmission mechanism consists of a small chain wheel fixed on a shaft of the motor, a big chain wheel (6) fixed on the roller shaft (7), and a chain (5) connecting the small chain wheel with the big chain wheel (6); a bottom-layer filter cloth roller (15), a surface-layer filter cloth roller (18) and a slurry slot (16) are arranged above the conveyor belt (13); the slurry slot is positioned between the bottom-layer filter cloth roller (15) and the surface-layer filter cloth roller (18). The bean curd sheet preparation equipment is simple in structure, convenient to operate, and capable of replacing manual operation to realize continuous production, and is bean curd processing equipment.

Owner:贵州龙缘盛豆业有限公司

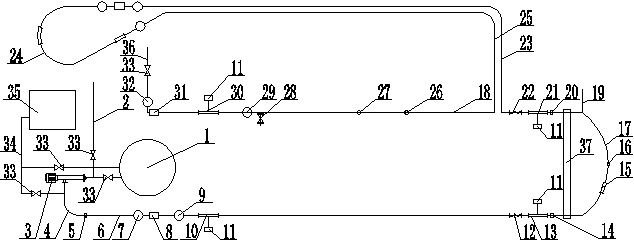

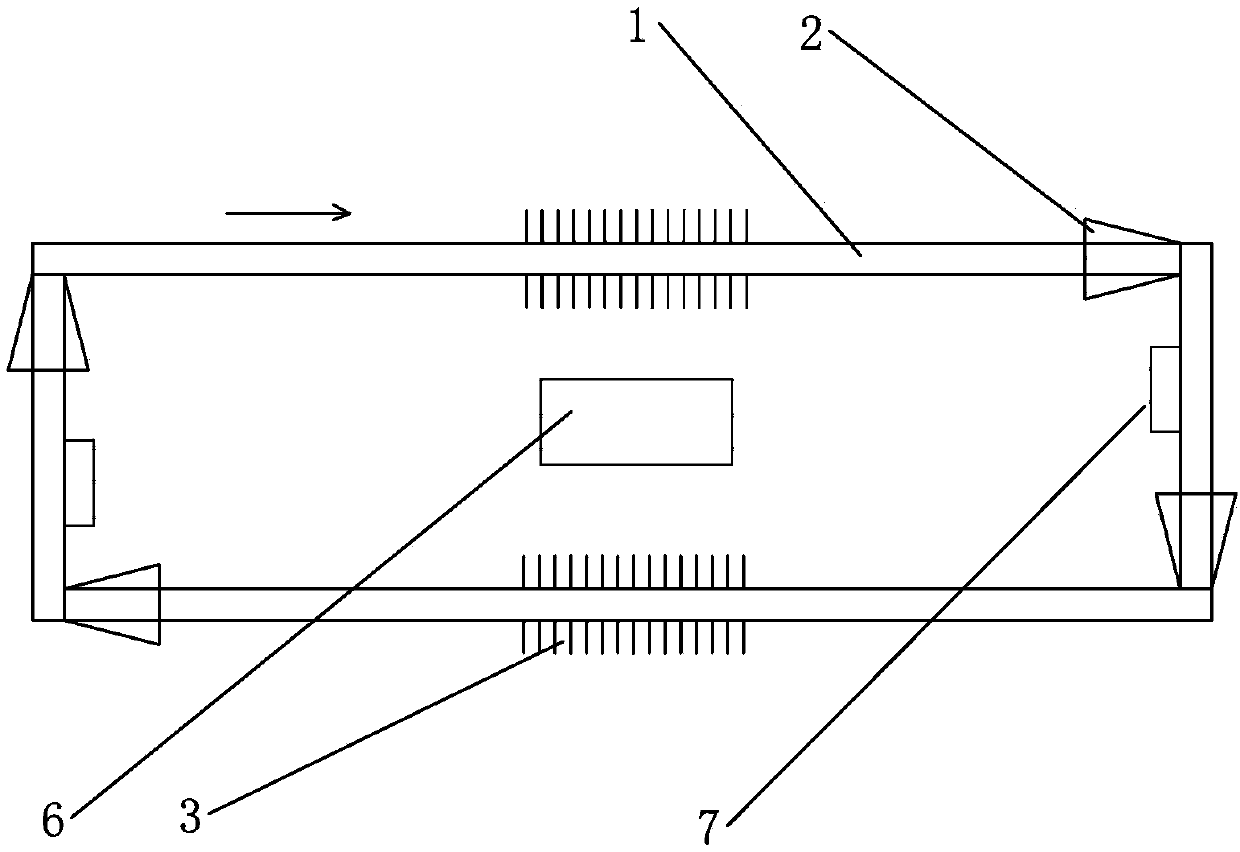

Long distance slurry pipeline safety detection loop system

The invention discloses a long distance slurry pipeline safety detection loop system. According to the long distance slurry pipeline safety detection loop system, the slurry's own characteristics andconveying characteristics is detected before the slurry enters the long-distance conveying pipeline, and data is provided by a large loop feed pipe inlet pressure transmitter, a large loop feed pipe concentration meter, a large loop feed pipe inlet pressure transmitter, a pH meter, a large loop feed pipe inlet observation pipe, an automatic high speed camera, a large loop feed pipe metal hose, a large loop feed pipe outlet observation pipe, a large loop feed pipe outlet pressure transmitter, a pipe bend segment observation pipe, a pipe bend segment pressure transmitter, a pig launcher, a largeloop discharge pipe outlet pressure transmitter, a large loop discharge pipe inlet observation pipe, a large loop discharge pipe metal hose, a density meter, a electromagnetic flowmeter, a sampling discharge port, a thermometer, a large loop discharge pipe outlet observation pipe, a large loop discharge pipe inlet pressure transmitter, and a large loop discharge pipe concentration meter. Therefore, the long distance slurry pipeline safety detection loop system can avoid unqualified slurry entering long-distance pipelines to ensure safety.

Owner:WUHAN DESIGN & RES INST OF CHINA COALTECH & ENG GROUP

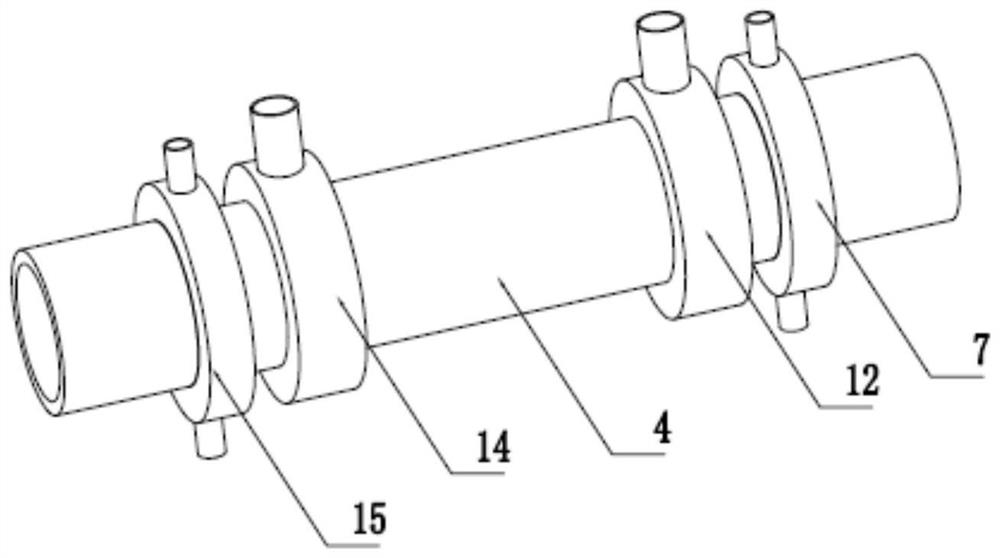

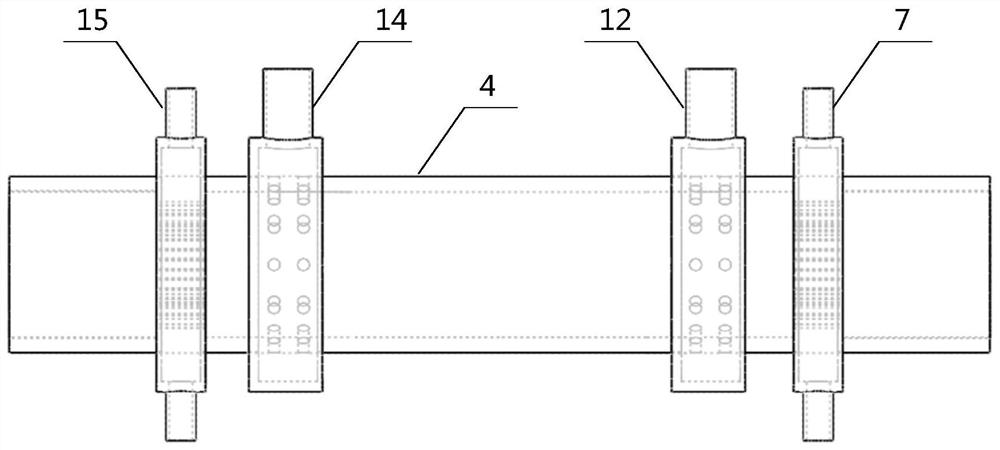

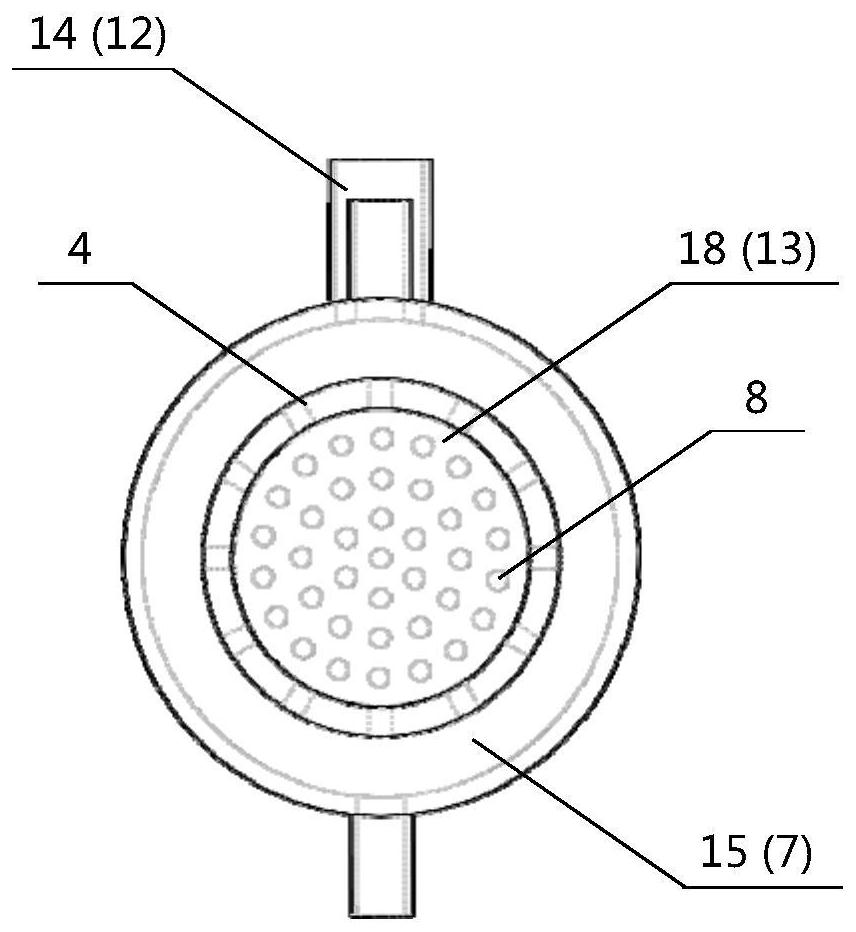

A salt lake lithium extraction device based on ion concentration polarization effect

ActiveCN110004307BReduce ion concentrationAchieve separationProcess efficiency improvementChemical physicsSalt lake

The invention belongs to the field of lithium extraction equipment in salt lakes, and specifically relates to a lithium extraction device in salt lakes based on ion concentration polarization effect, which includes a main channel, on which first buffer pipes are sequentially arranged for feeding into the main channel. The brine tube for extracting the original solution, the lithium-rich solution cavity tube, and the second buffer tube. The two ends of the main channel are respectively provided with a first outlet and a second outlet. The inside of the main channel is provided with a first anion selective block with several channels. and a second anion selective block. The invention utilizes the locally enhanced electric field in the channel caused by the ion concentration polarization effect to realize lithium ion enrichment and lithium-magnesium separation, the solution flow is driven by the pressure at the inlet and outlet, and high-concentration lithium is collected through the openings on the pipeline solution. Different from the direct parallelization of micro-channels, this device realizes the large-scale parallelism of micro-channels by processing a large number of micro-scale channels on ion-selective materials.

Owner:李晓岚

Screening device for producing organic bio-fertilizers

InactiveCN104438039AExtended stayHigh degree of automationSievingScreeningElectric machineryEngineering

The invention discloses a screening device for producing organic bio-fertilizers and belongs to the technical field of agricultural mechanical equipment. The screening device for producing organic bio-fertilizers comprises cylindrical screen cloth, wherein a spiral material guide plate is arranged on the inner wall of the screen cloth and extends in the axial direction of the screen cloth in a precession mode. A feeding port is formed in one end of the screen cloth, a discharging port is formed in the other end of the screen cloth, and a motor is arranged on the screen cloth in a matched mode and drives the screen cloth to rotate around the axis. According to the screening device for producing organic bio-fertilizers, the cylindrical screen cloth can screen organic fertilizer raw materials efficiently during operation to prolong duration of stay of screen efficiently by means of the cylindrical screen cloth and the spiral material guide plate. The screening device for producing organic bio-fertilizers can screen different raw materials or materials of different stages in the production, and has the advantages of being high in automation degree and good in device screen effect.

Owner:SICHUAN KAIERFENG AGRI TECH CO LTD

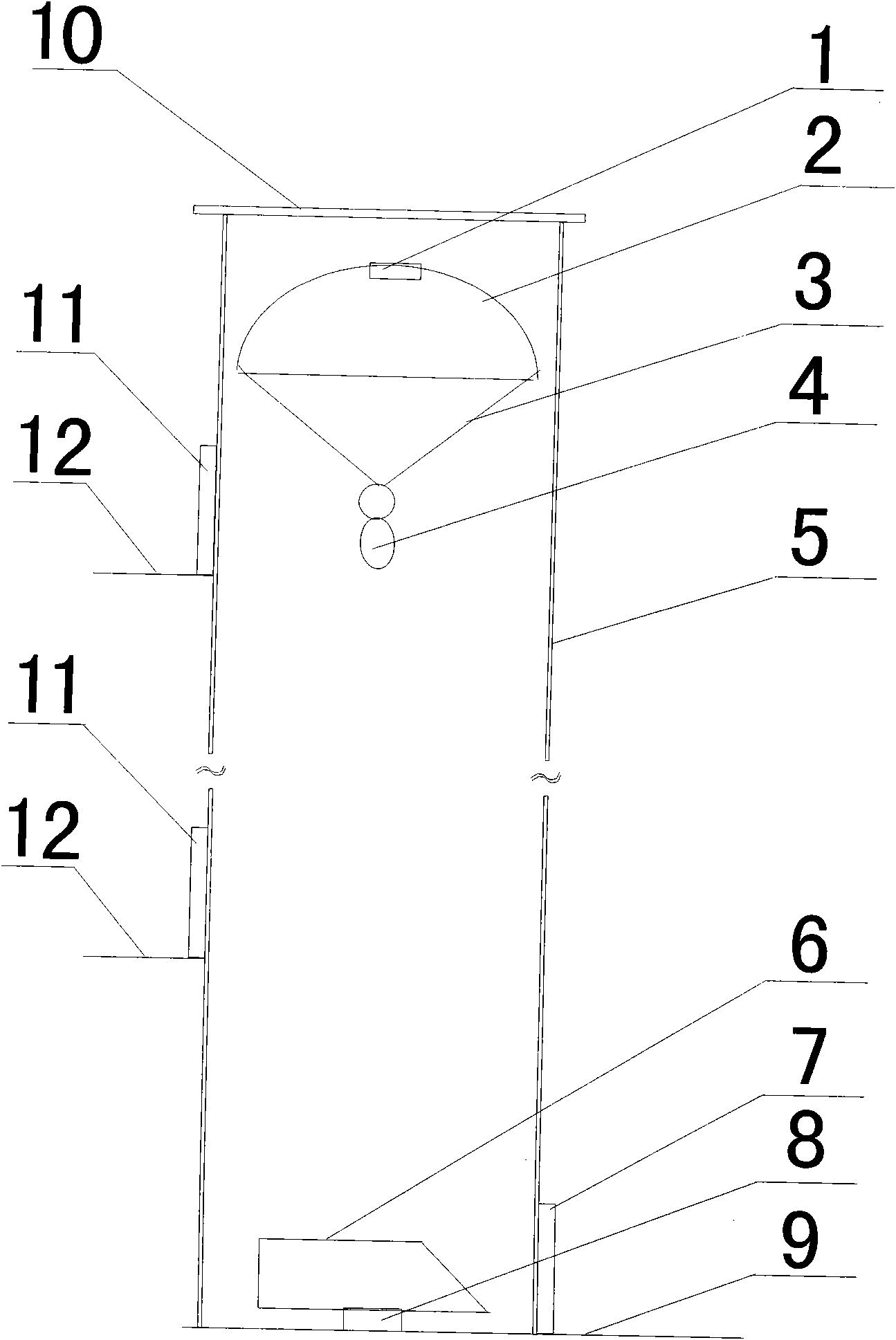

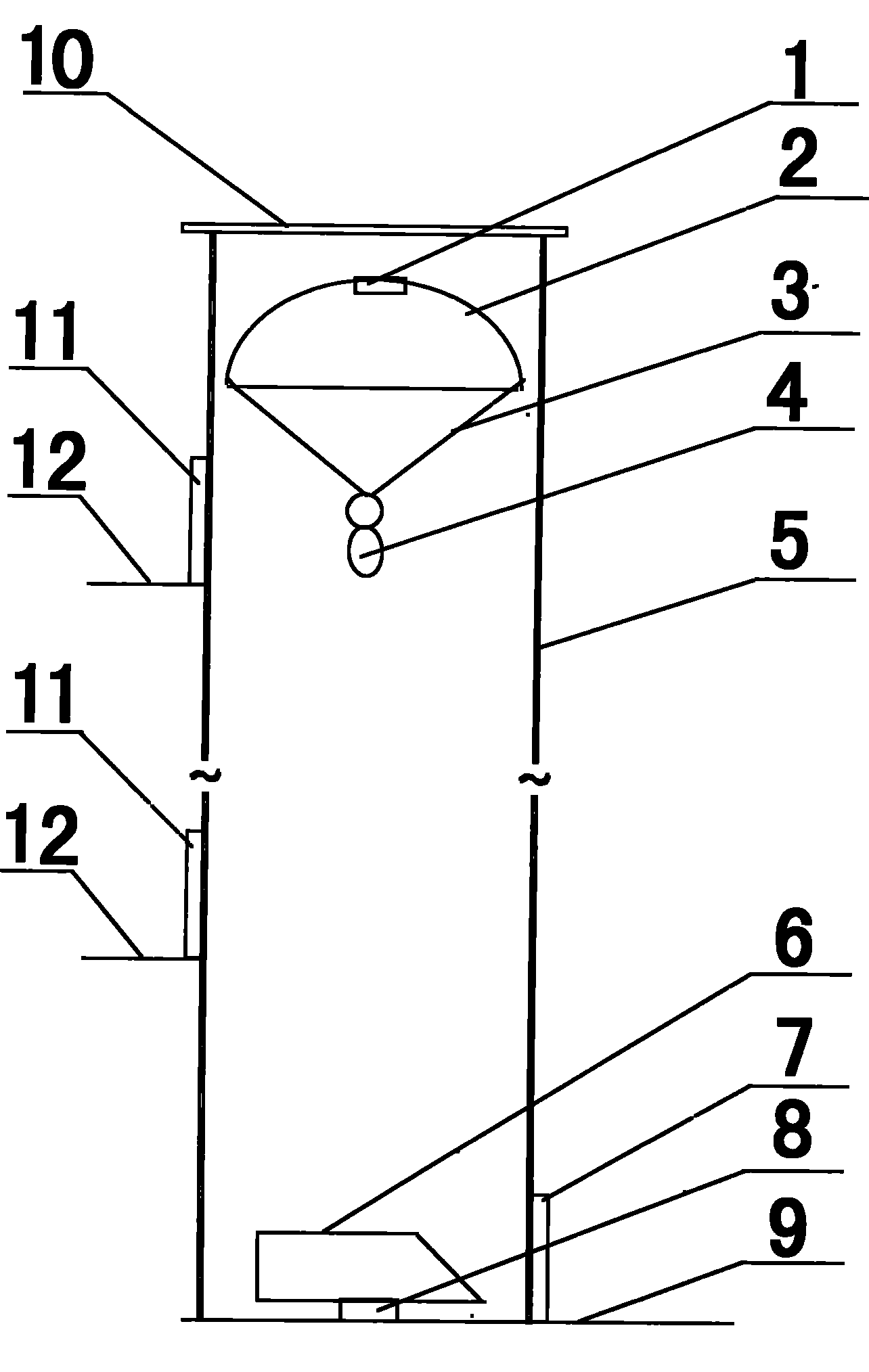

Safety landing device for high building

The invention belongs to high building fire self-rescuing technology, and discloses a safety landing device for high building. Fire self-rescuing escape is realized by sliding down from high altitude through apparatuses and ropes in the prior art, but the prior art has the defects that large space and floor are occupied when the ropes are obliquely arranged and persons with weak physical quality are unsafe during sliding down with the apparatuses. The exteriors of a landing cover (2) and a tied rope (3) are provided with a protective barrel (5), the protective barrel (5) is cylindrical, and the inside diameter of the protective barrel (5) is 6 to 16 millimeters more than the outside diameter of the landing cover (2); the lower part of the cylindrical protective barrel (5) is provided with a rotary table (6), and the lower part of the rotary table (6) is connected with a rotary shaft (8); and the lateral surface of the lower part of the protective barrel (5) is provided with an exit door (7), and the middle part of the protective barrel (5) is provided with an entrance door (11). The safety landing device has simple structure and low cost, can be used with buildings of various different heights, can be used for continuous landing of multiple persons, and has high utilization efficiency and landing safety.

Owner:张明德

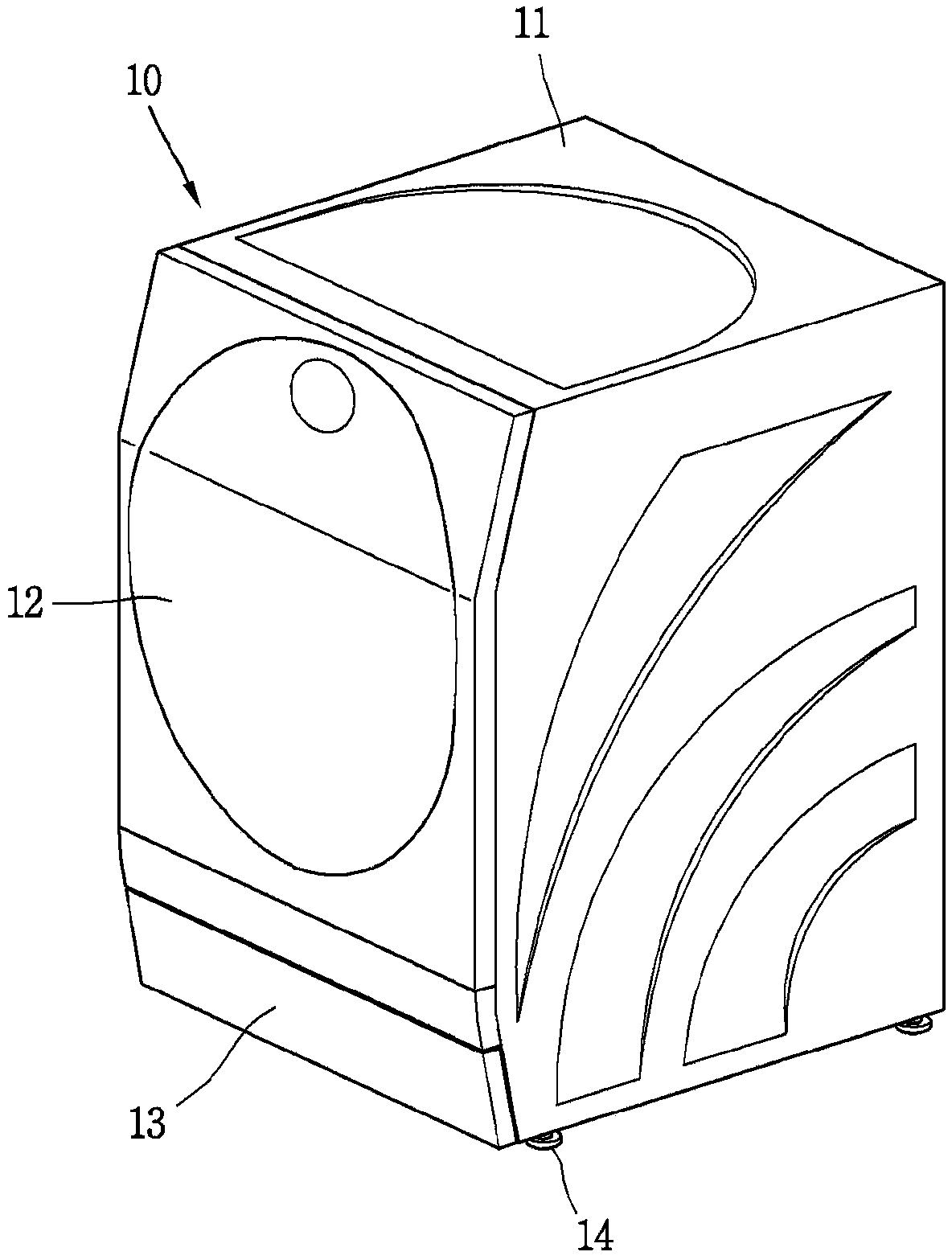

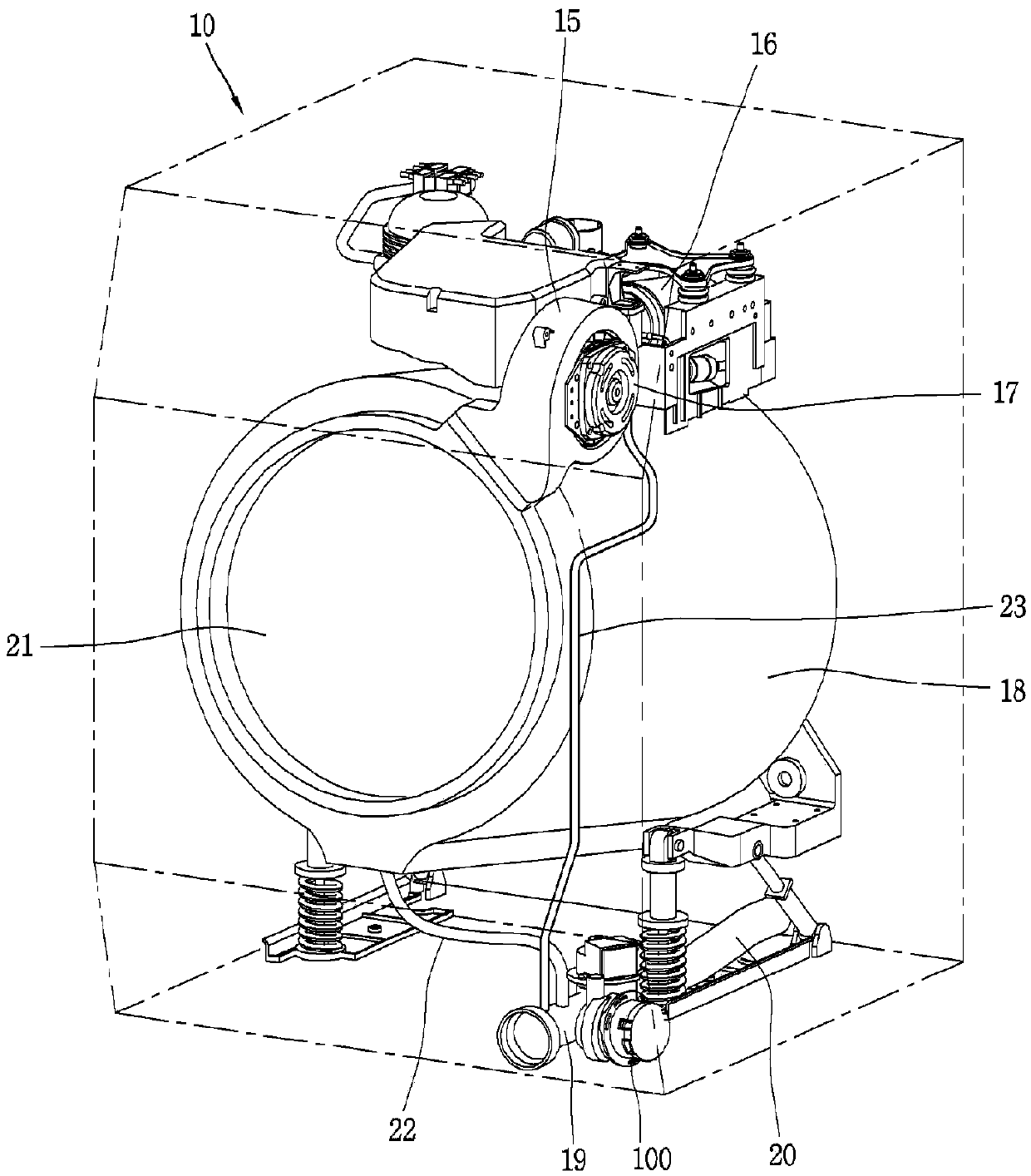

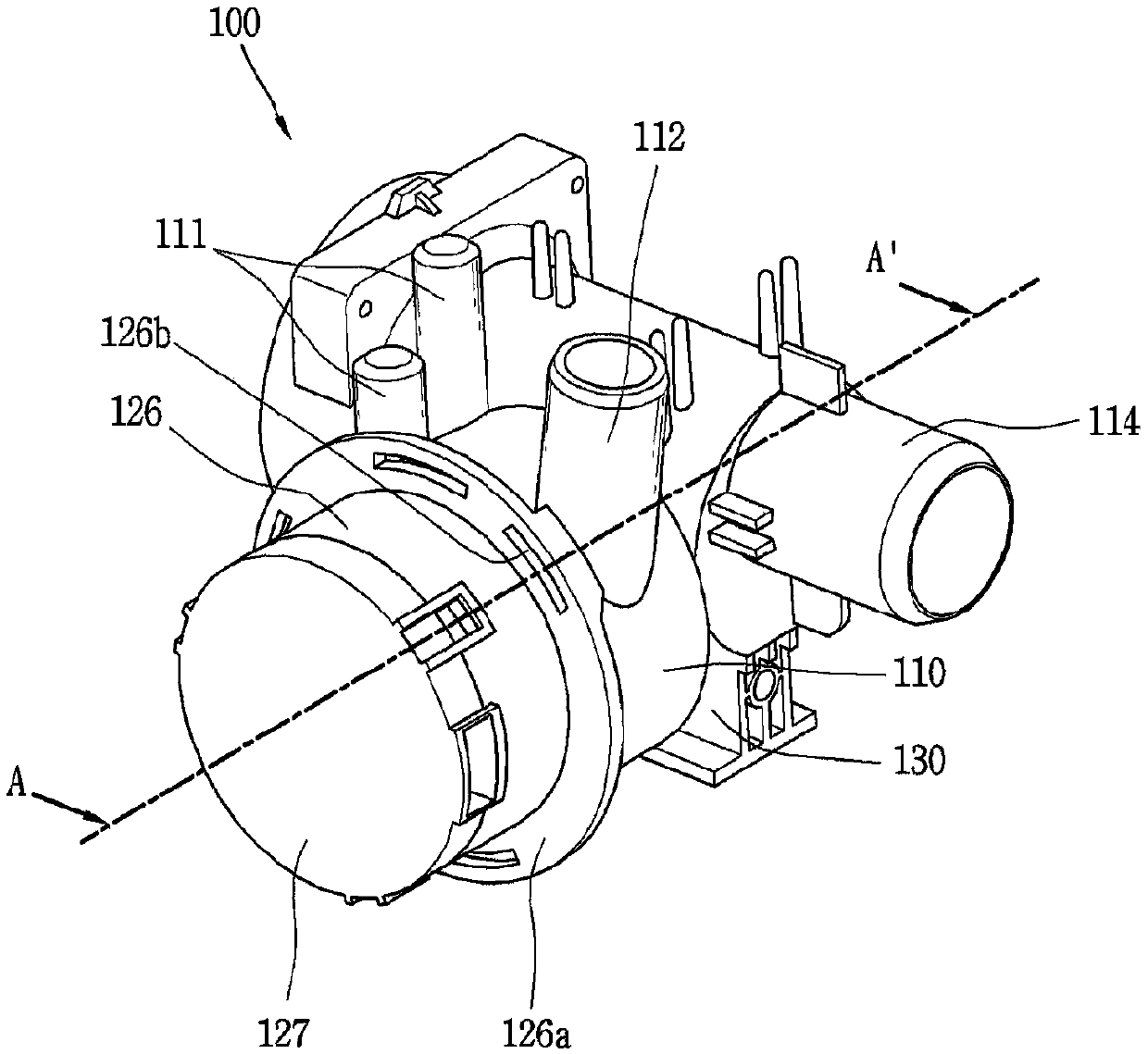

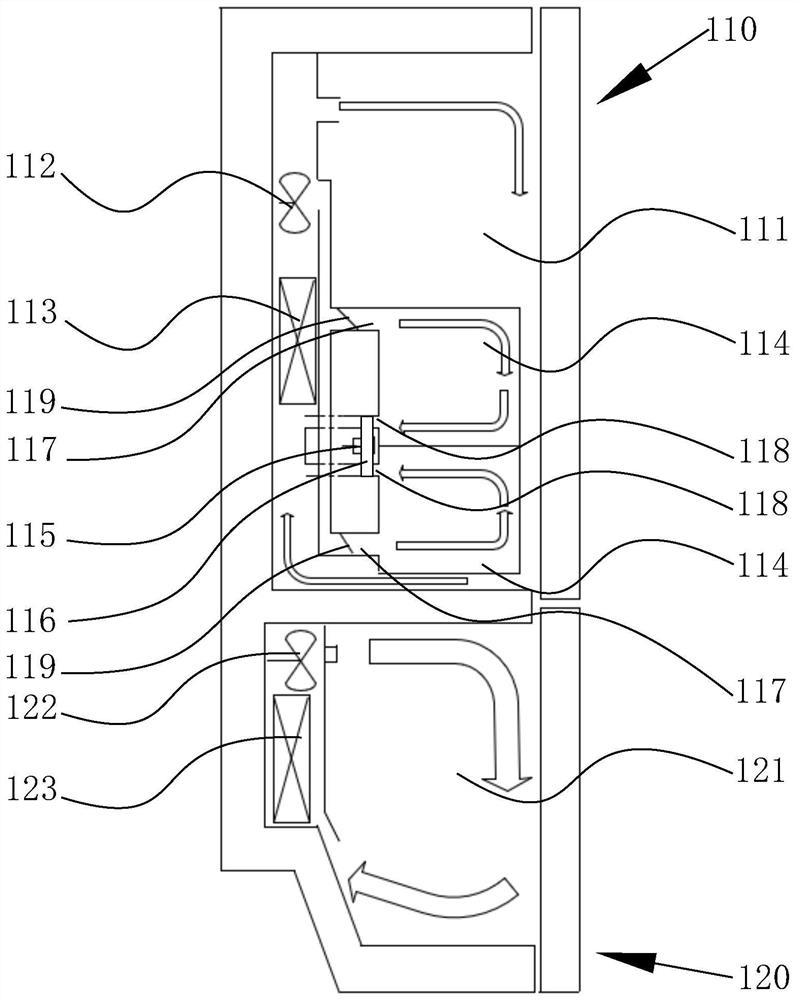

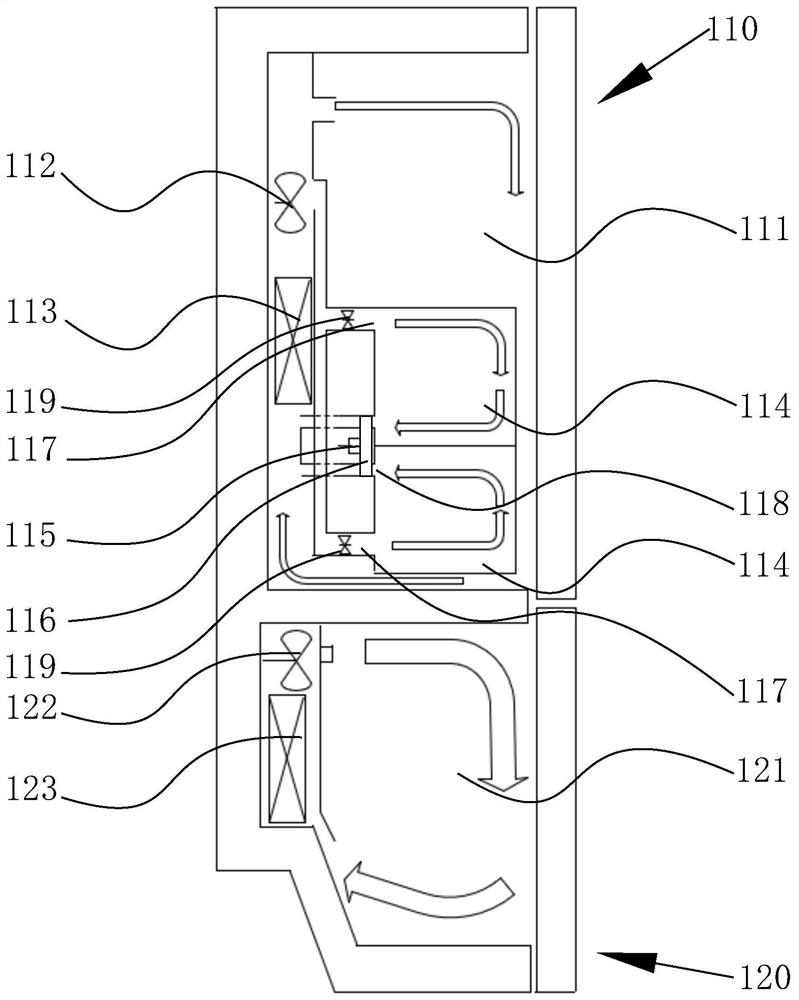

Drain pump

The present invention relates to a drain pump for a clothes-handling apparatus, comprising: a housing for accommodating water; a water flowing part formed on the inner peripheral surface of the housing, and having an impeller for forming a flowing current of water or washing water such that the accommodated water or washing water circulates to a tub or is drained to the outside of a washing machine; a drain pump chamber formed on the inner peripheral surface of the housing so as to receive or store the water or the washing water before the water or the washing water flows into the water flowing part; and an inlet formed between the water flowing part and the drain pump chamber so as to protrude toward the water flowing part.

Owner:LG ELECTRONICS INC

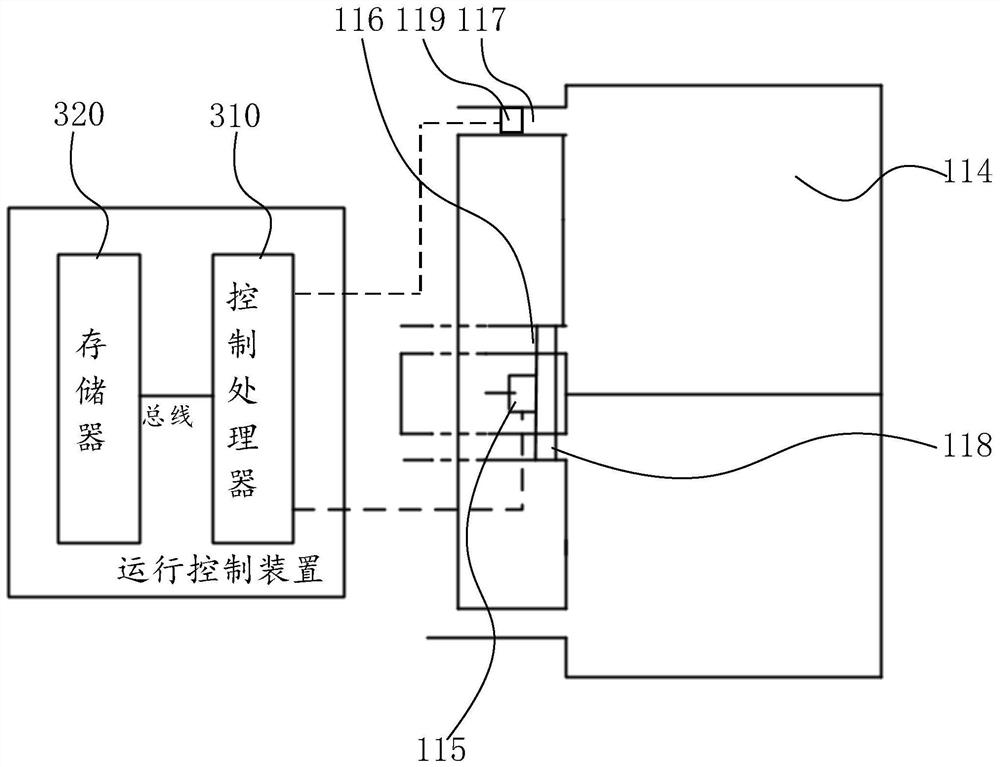

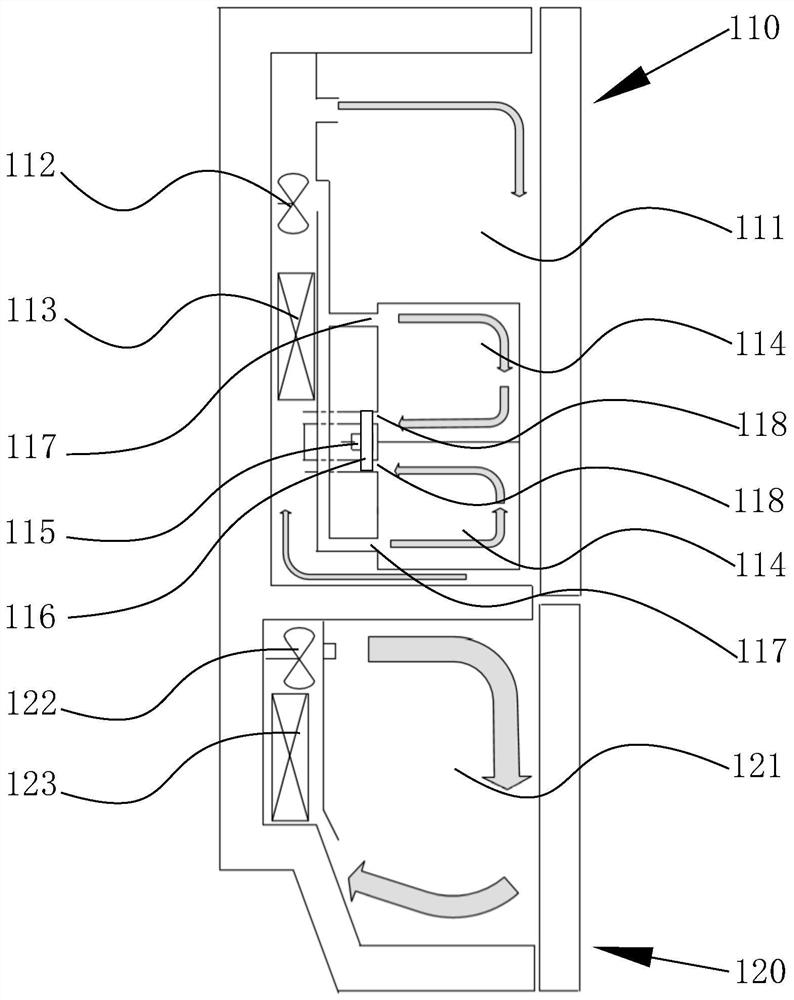

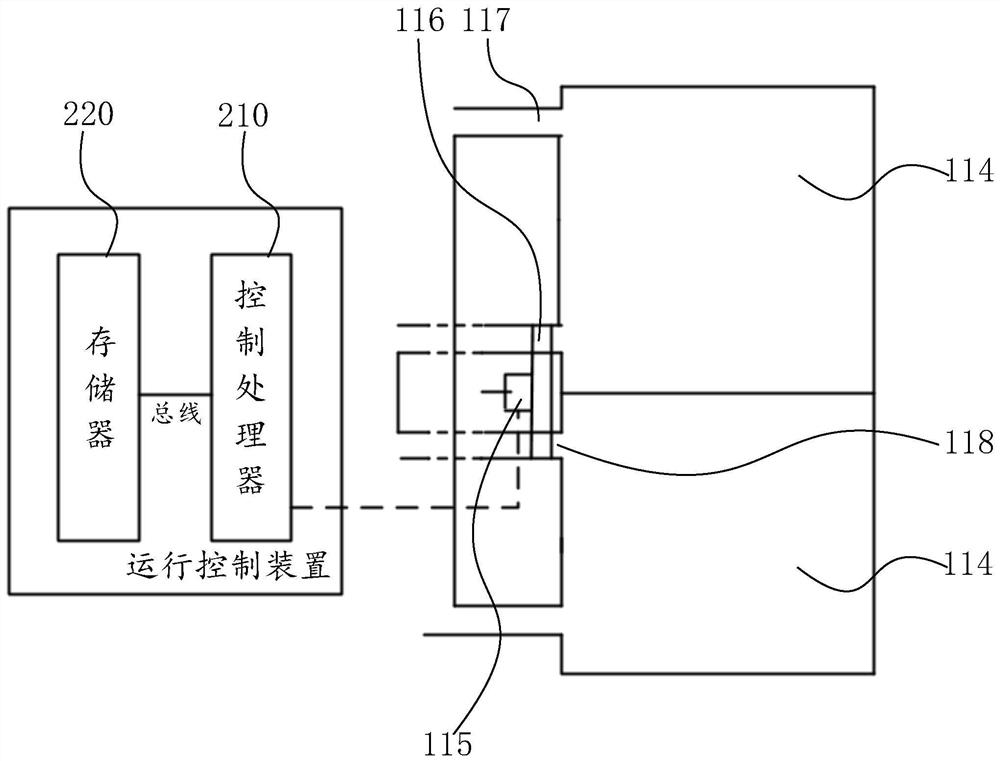

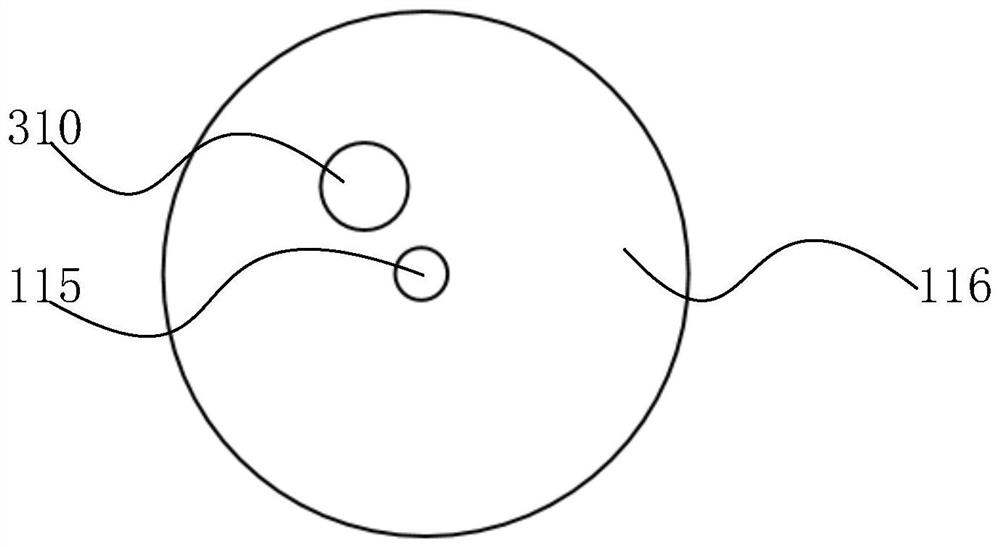

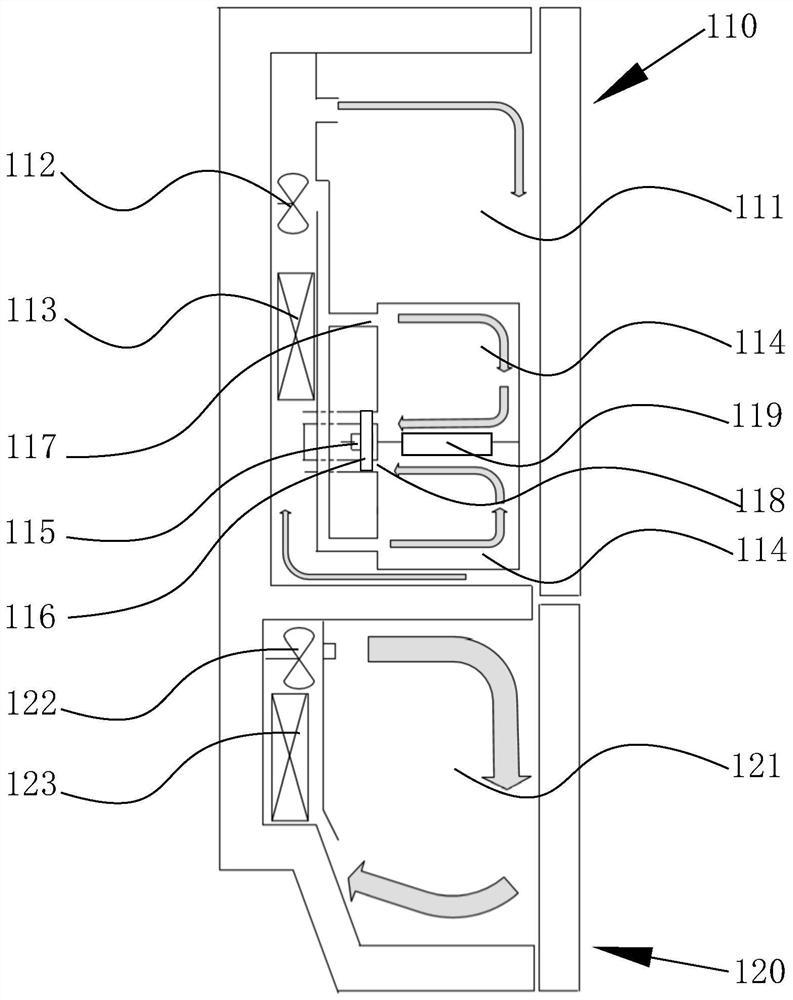

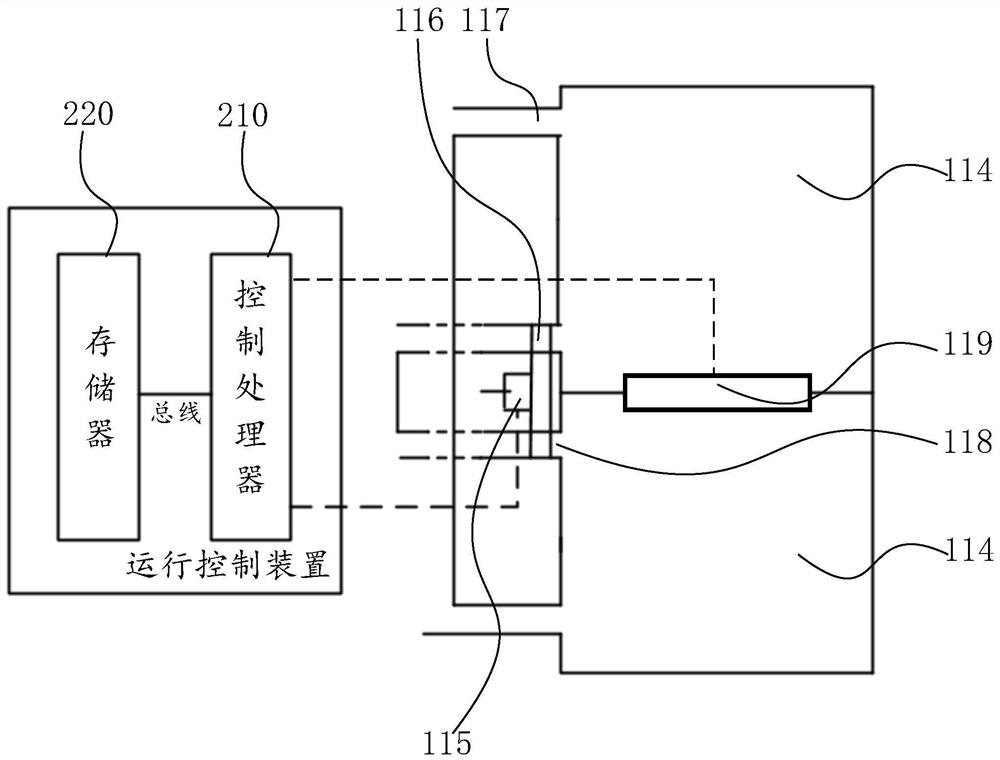

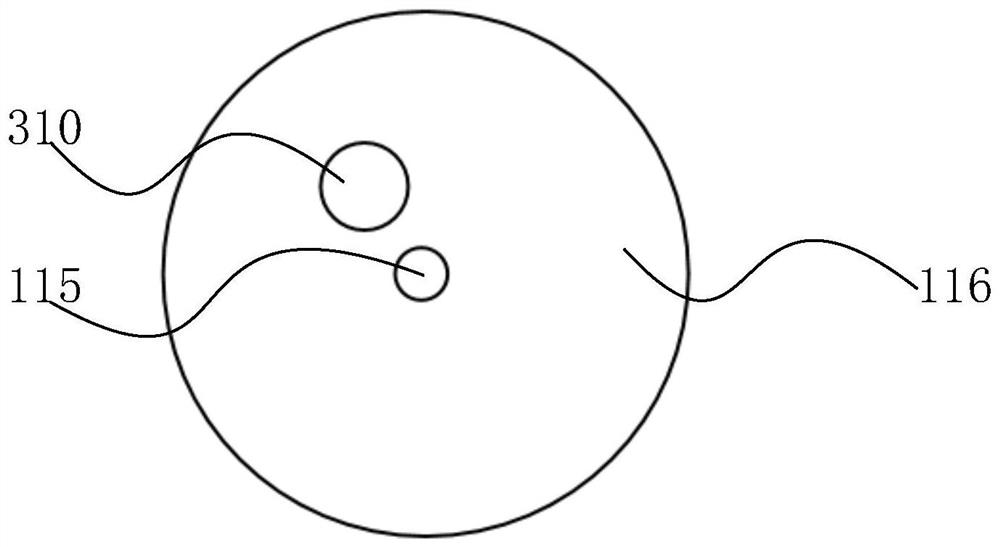

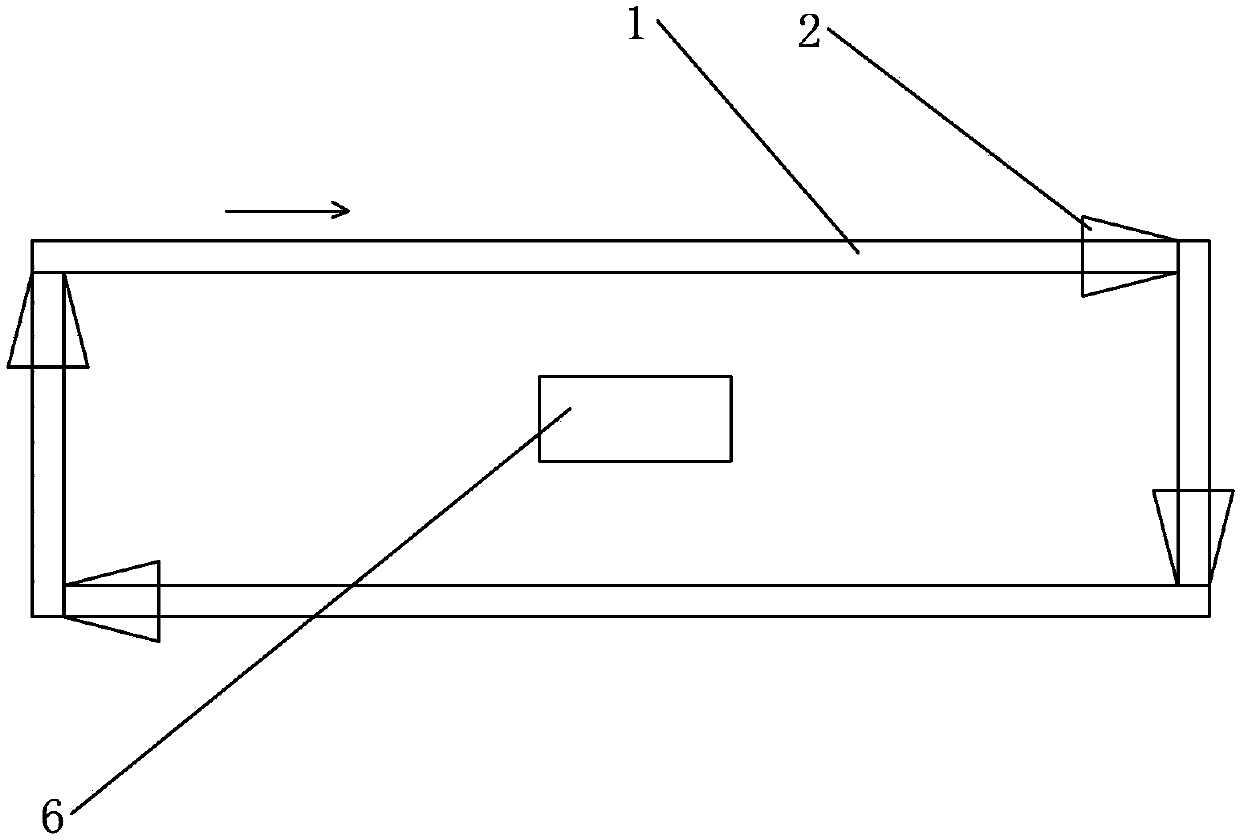

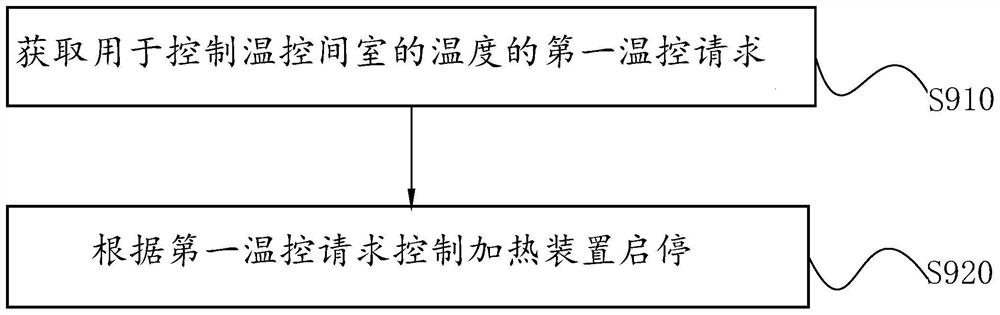

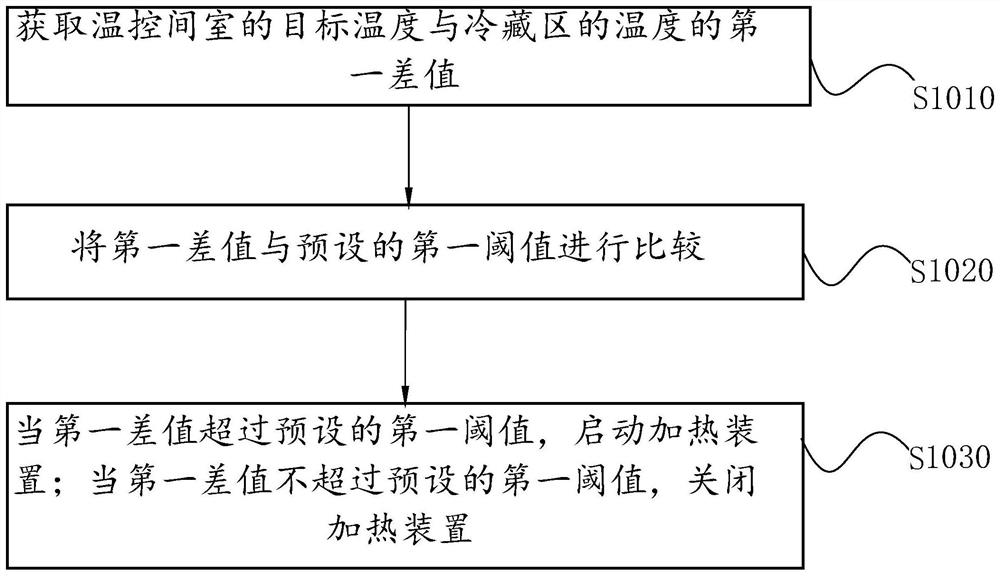

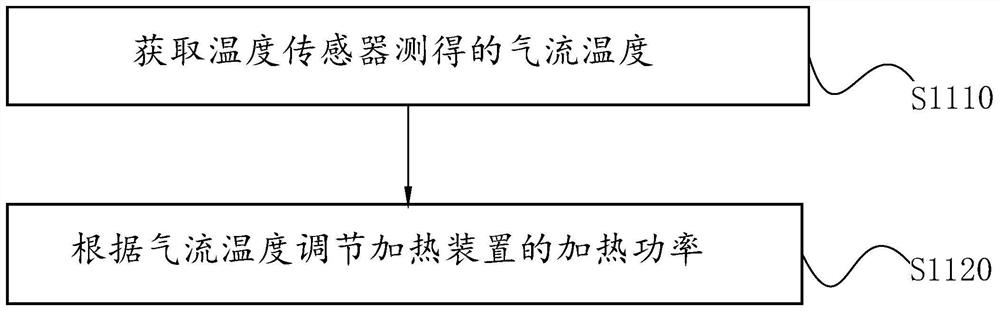

Return air temperature control mechanism, return air temperature control method, operation control device and refrigerator

ActiveCN113375388AAdjust the speed of temperature changeIncrease connection areaLighting and heating apparatusDomestic refrigeratorsTemperature controlIcebox

The invention discloses a return air temperature control mechanism, a return air temperature control method, an operation control device and a refrigerator. The return air temperature control mechanism comprises a rotating disc, a driving device for controlling the rotating disc to rotate and at least two temperature control chambers, each temperature control chamber comprises an air supply opening and an air return opening, and the air supply outlet of at least one temperature control chamber is provided with an air supply control part; and the rotating disc is provided with a communicating opening corresponding to the air return openings, the driving device controls the rotating disc to rotate according to the temperature control request, the communicating opening is made to be communicated with the air return opening of the temperature control chamber corresponding to the temperature control request, the air supply control part acts according to the temperature control request, and the temperature control request is used for controlling the temperature of the corresponding temperature control chamber. Opening and closing of the return air openings of the multiple temperature control chambers are controlled through the rotating disc, and meanwhile, the air supply states of the air supply openings are controlled through the air supply control part, and air circulation channels are formed in the temperature control chambers, so that the temperature control requirements of multiple temperature areas can be met, occupied space is reduced, and cost is reduced.

Owner:HEFEI HUALING CO LTD +2

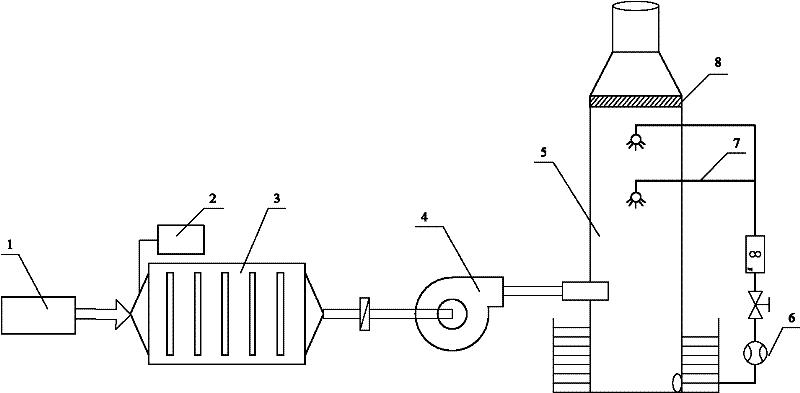

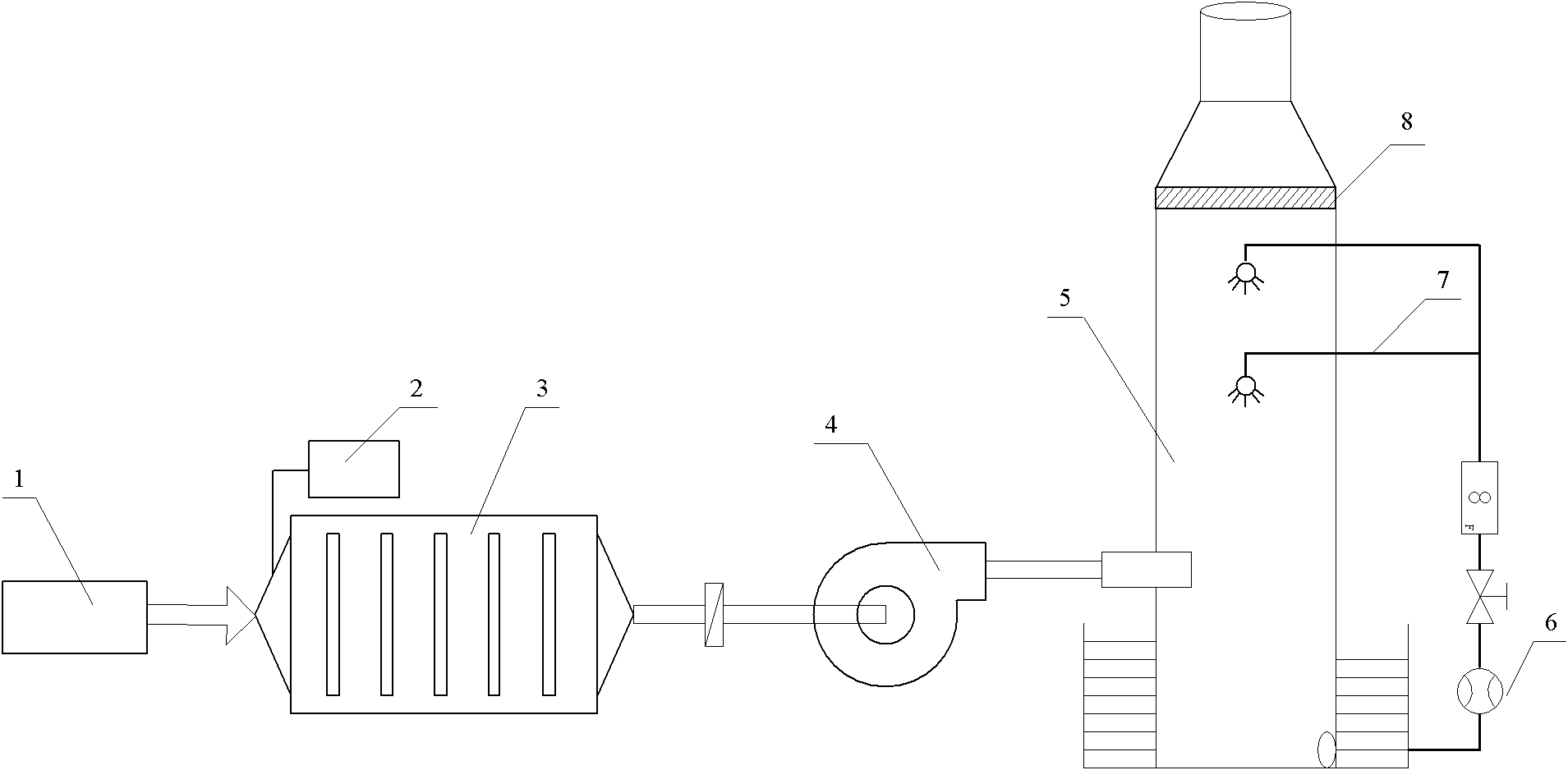

A new type of plasma odor control device

InactiveCN102284079AImprove deodorization efficiencySpeed up the flowDeodrantsProcess engineeringTower

The invention discloses a plasma stink treatment device, which comprises a power supply, a plasma stink removal reactor, a fan and a washing tower, wherein the plasma stink removal reactor is connected with the washing tower. The device is characterized in that: the fan is positioned in a pipeline between the reactor and the washing tower; and an insulating material is connected to the joint of the reactor and the fan. The novel plasma stink treatment device has the characteristics of high efficiency, energy saving, environmental friendliness and the like.

Owner:BEIJING BODXY ENERGY CONSERVATION TECH & RES

Return air temperature control mechanism, return air temperature control method, operation control device and refrigerator

InactiveCN113375409AAdjust the speed of temperature changeIncrease connection areaLighting and heating apparatusDomestic refrigeratorsTemperature controlIcebox

The invention discloses a return air temperature control mechanism, a return air temperature control method, an operation control device and a refrigerator. The return air temperature control mechanism comprises a rotating disc, a driving device for controlling the rotating disc to rotate and at least two temperature control chambers, each temperature control chamber comprises an air supply opening and an air return opening, and the rotating disc is provided with a communicating opening corresponding to the air return openings; and the driving device controls the rotating disc to rotate according to the temperature control request, so that the communicating opening is communicated with the air return opening of the temperature control chamber corresponding to the temperature control request, and the temperature control request is used for controlling the temperature of the temperature control chambers. The rotating disc is used for controlling the opening and closing of the return air openings of the multiple temperature control chambers, so that the temperature control requests of a plurality of temperature zones can be met, and the occupied space and the cost are reduced.

Owner:HEFEI HUALING CO LTD +2

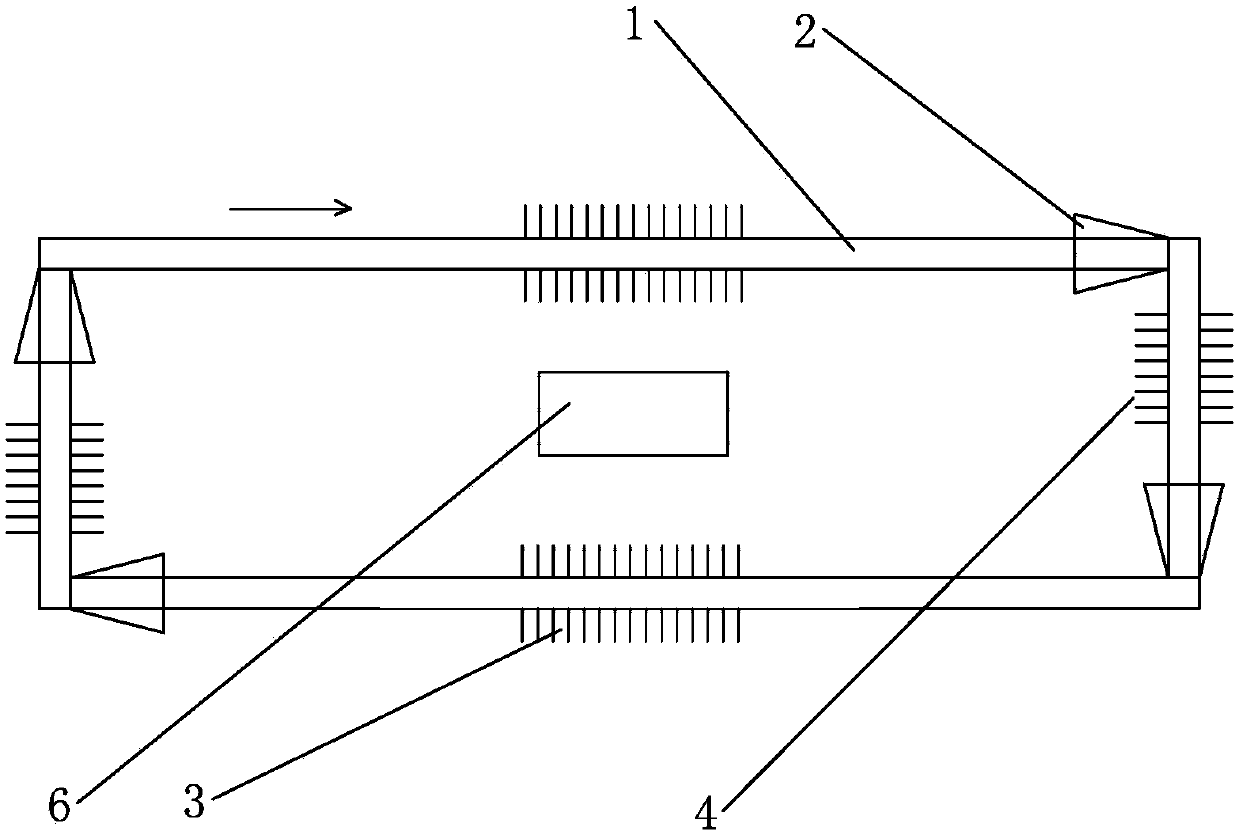

Return air temperature control mechanism, return air temperature control method, operation control device and refrigerator

ActiveCN113375412AAdjust the speed of temperature changeIncrease connection areaLighting and heating apparatusDomestic refrigeratorsTemperature controlIcebox

The invention discloses a return air temperature control mechanism, a return air temperature control method, an operation control device and a refrigerator. The return air temperature control mechanism comprises a rotating disc, a driving device for controlling the rotating disc to rotate and at least one temperature control chamber group; the temperature control chamber group comprises two adjacent temperature control chambers, and the two temperature control chambers are provided with a semiconductor refrigerating assembly in a penetrating manner; the semiconductor refrigerating assembly comprises a hot end and a cold end, the hot end faces one temperature control chamber, and the cold end faces the other temperature control chamber; each temperature control chamber comprises an air supply port and an air return port; and the rotating disc is provided with a communicating port capable of corresponding to the air return ports. The semiconductor refrigerating assembly can control the temperature of the cold end and the hot end according to the temperature requirements of the temperature control chambers, therefore, different temperature control can be carried out on the plurality of different temperature control chambers at the same time, the temperature change range of the temperature control chambers can be expanded, and wide-range temperature adjustment of the temperature control chambers is achieved.

Owner:HEFEI HUALING CO LTD +2

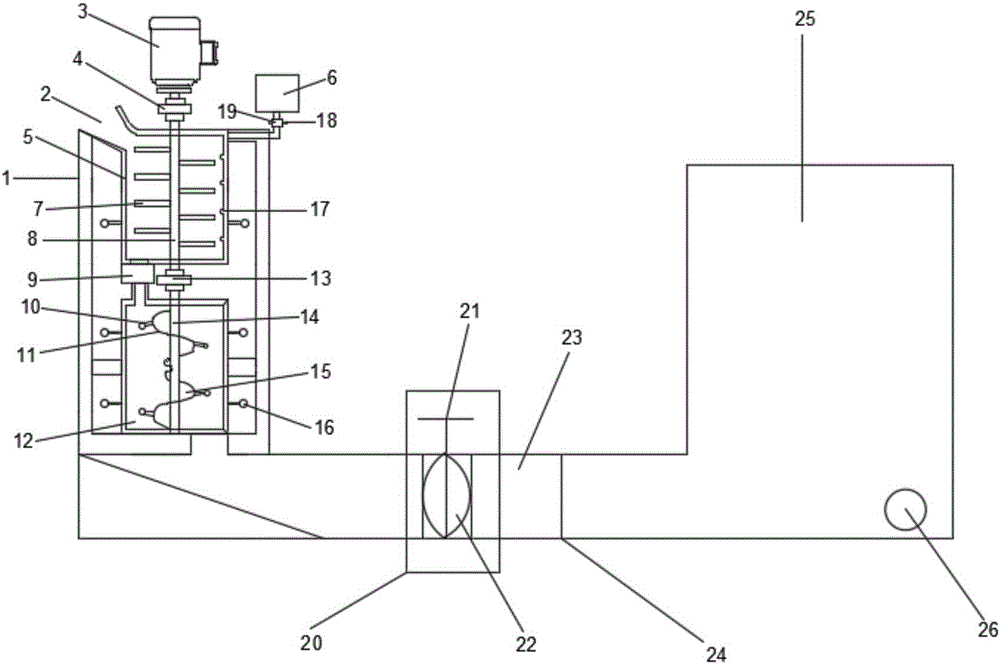

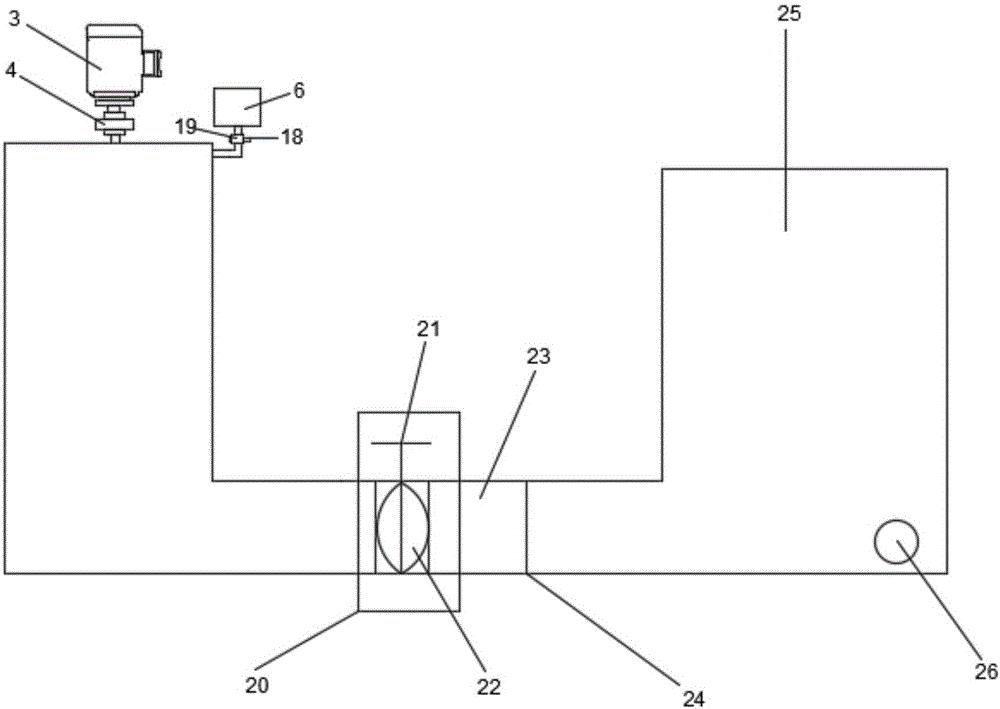

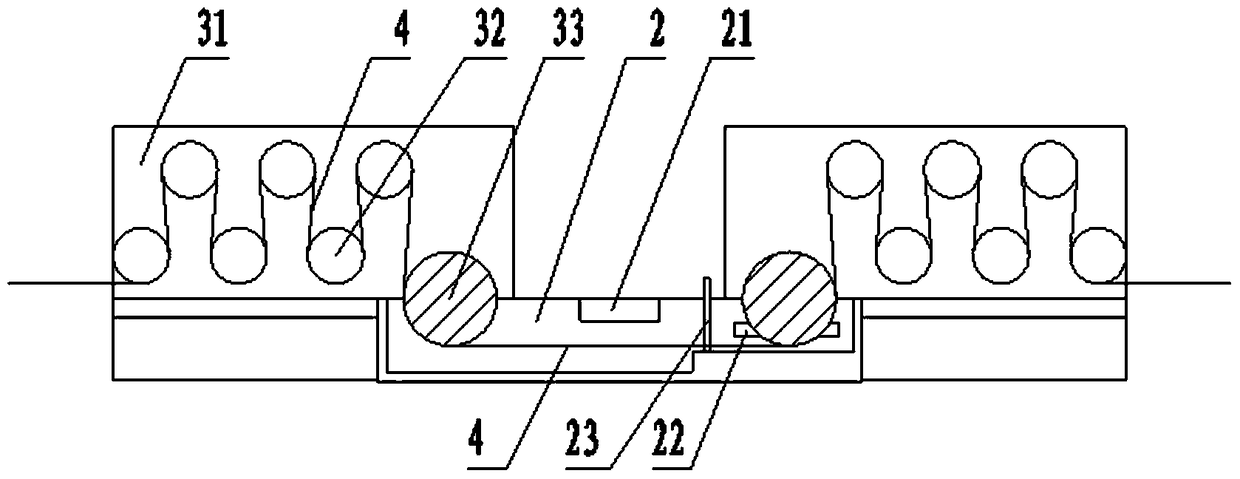

Impulse slow-releasing device

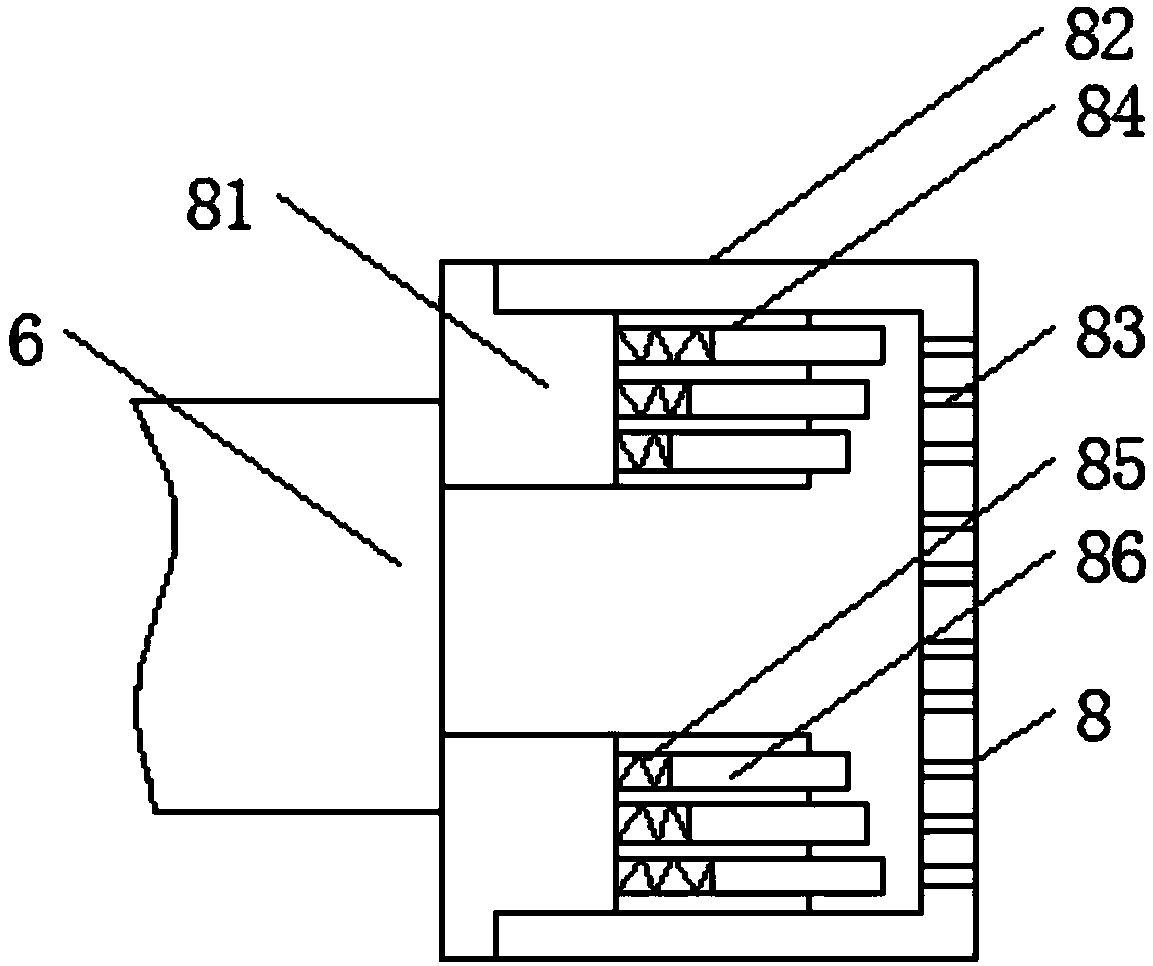

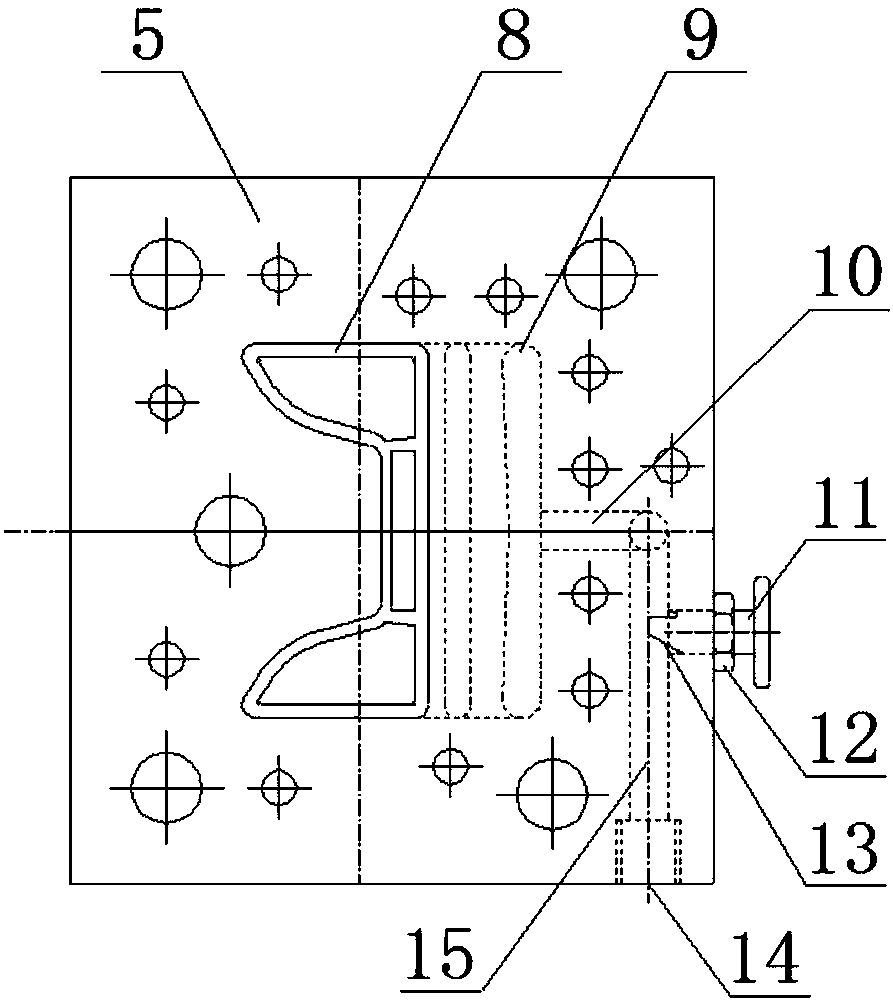

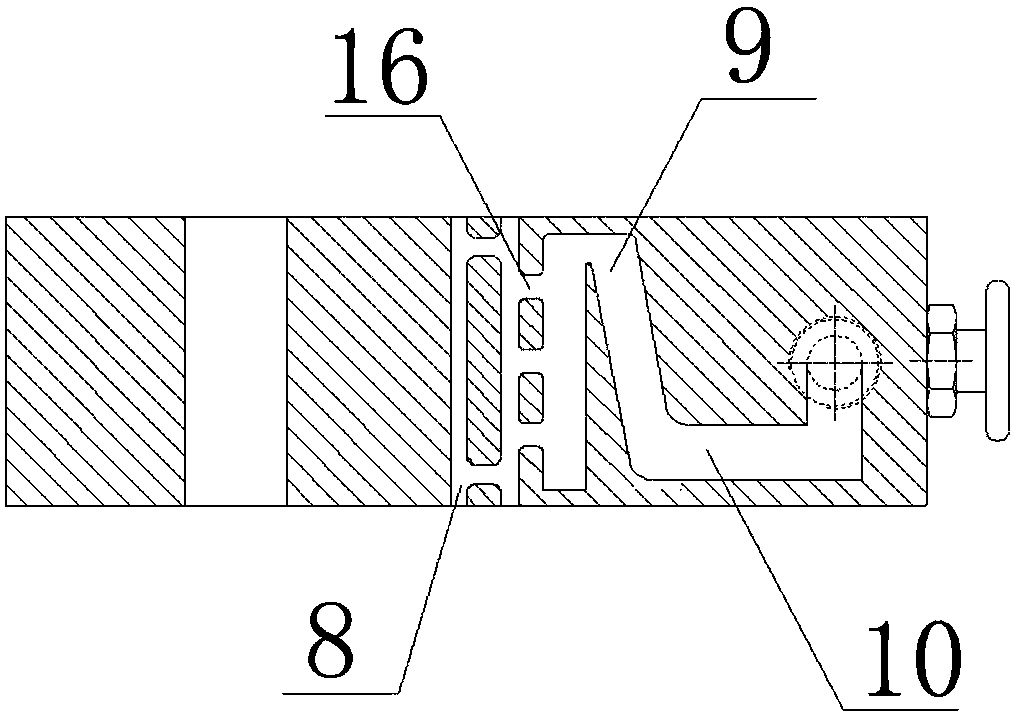

InactiveCN102927189BAdjust flow speedControl speedSpringsLiquid based dampersEngineeringMechanical engineering

The invention relates to an impulse slow-releasing technology and discloses an impulse slow-releasing device. The impulse slow-releasing device comprises a cylinder body provided with an upper cylinder hole and a lower cylinder hole; an upper piston is matched inside the upper cylinder hole in a sealed manner; a piston rod is connected with the upper part of the upper piston; an upper oil cavity is formed by the bottom of the upper piston and the upper cylinder hole; a lower piston is matched inside a lower cylinder hole in the sealed manner; a lower oil cavity is formed by the top of the lower piston and the lower cylinder hole; a lower end cover is threaded connection with the bottom of the lower cylinder hole; a potential storage slow-releasing spring is arranged between the lower piston and the lower end cover; an air vent is formed in the lower end cover; a cylinder base is arranged between the upper cylinder hole and the lower cylinder hole; a step-shaped vertical hole and a step-shaped bending hole, which are communicated with the upper cylinder hole and the lower cylinder hole, are formed in the cylinder base; a one-way valve for guiding oil from the upper oil cavity to the lower oil cavity is arranged inside the step-shaped vertical hole; and a flow adjusting valve for communicating the upper oil cavity and the lower oil cavity are arranged inside the step-shaped bending hole.

Owner:ARCHITECTURAL ENG INST GENERAL LOGISTICS DEPT P L A

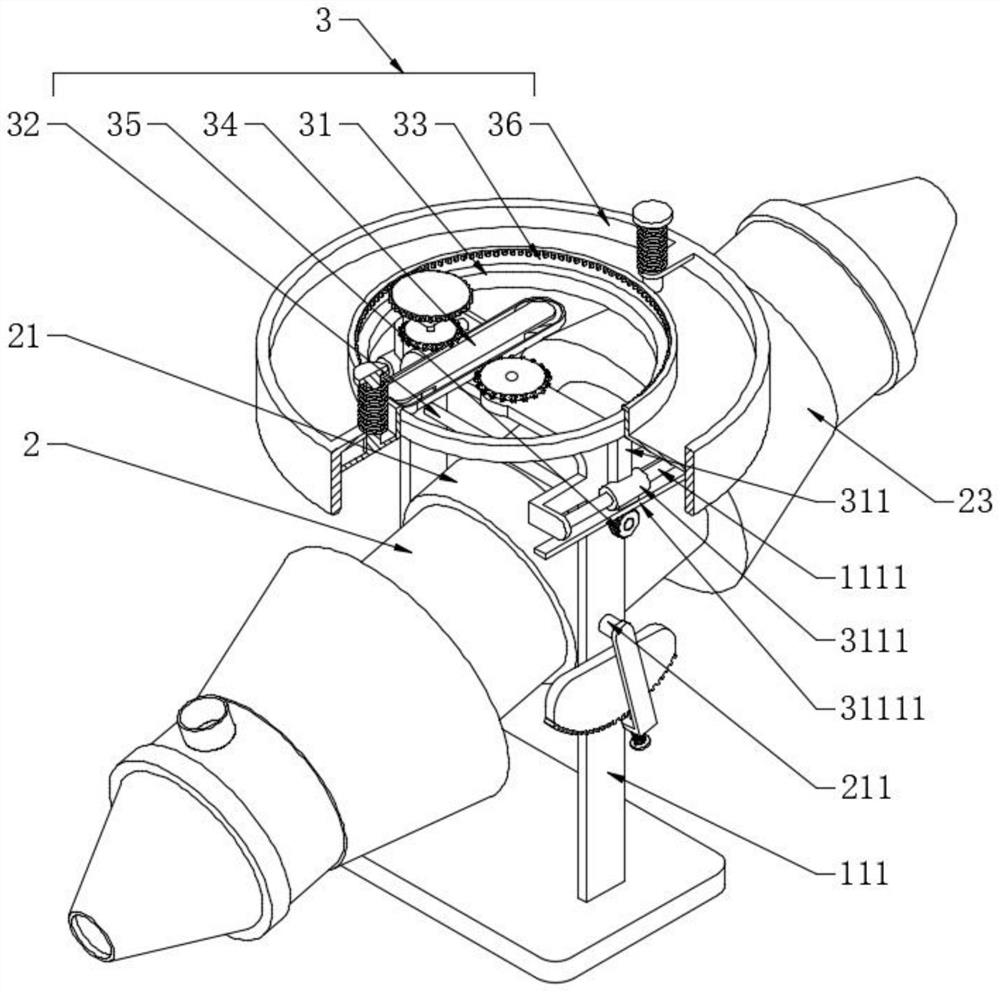

Drum-type chemical raw material screening device with speed regulation function

The invention discloses a drum-type chemical raw material screening device with a speed regulation function. The drum-type chemical raw material screening device comprises a supporting frame, a drum and a speed regulation combination. The supporting frame is arranged, the drum in an inclined state is arranged in the supporting frame, a first filtering plate is arranged at the bottom end of the drum, and the speed regulation combination is arranged at the top of the supporting frame and comprises a supporting annular plate, an adjusting shaft, a driving sleeve, a power combination, a driving gear and a transmission sleeve. The supporting annular plate on the speed regulation combination is in transverse sliding fit on the horizontal plane relative to the supporting frame, the sliding direction and the axis of the drum are located on the same plane, a power output part on the speed regulation combination is the transmission sleeve, the axis of the transmission sleeve is vertically distributed, and the outer wall of the drum is sleeved with a conical sleeve. The bottom of the transmission sleeve is in extrusion contact with the inclined face of the conical sleeve, the transmission sleeve rotates to drive the drum to rotate, internal materials are screened in a rolling manner, when the supporting annular plate slides, the rotating speed of the drum can be changed, the flowing speed of the raw materials can be adjusted, and the device is suitable for screening of the raw materials with different flowability.

Owner:TAIXING SMELTING PLANT

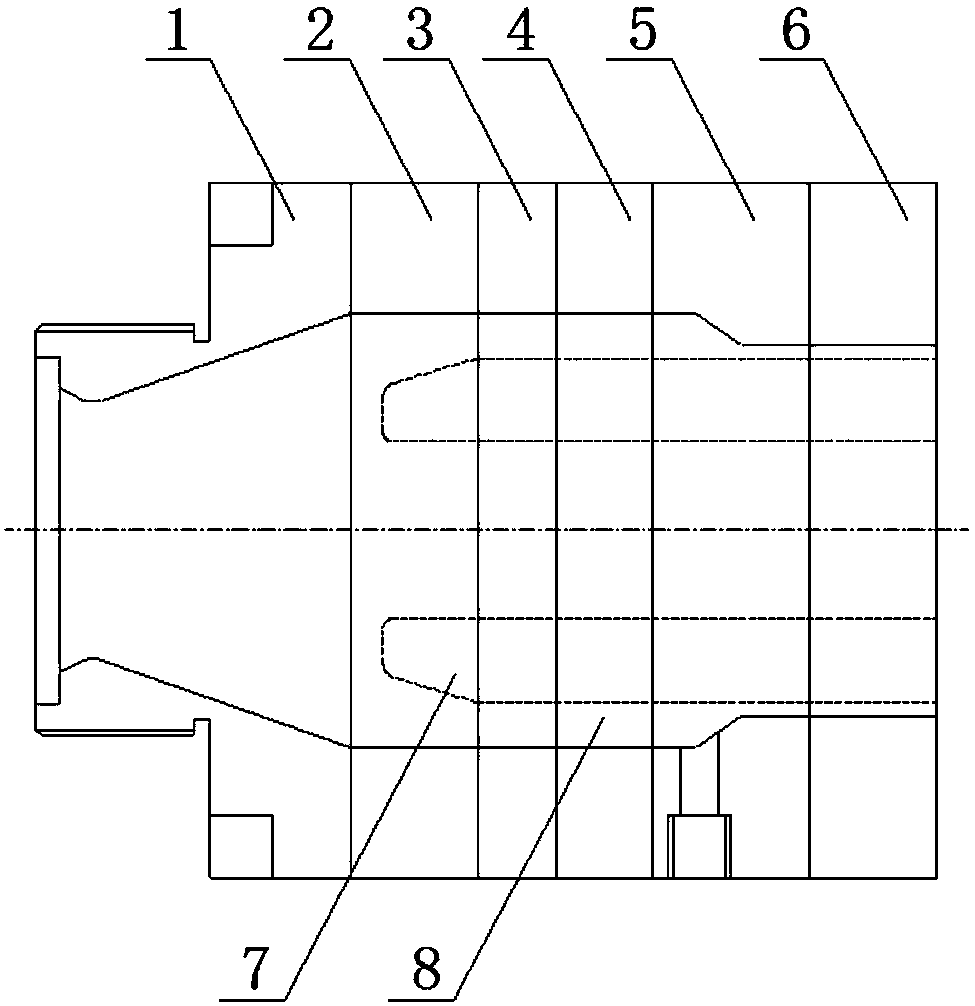

Double-colored coextruded hollow pipeline mold

InactiveCN107696449AIncrease the lengthAdjust flow speedTubular articlesMechanical engineeringEngineering

The invention discloses a double-colored coextruded hollow pipeline mold which comprises a mold body. A transitional plate, a bracket plate, a converging plate, a co-extruding plate and an opening mold plate are successively arranged at one end of the mold body; a mold core and a cavity are formed through the transitional plate, the bracket plate, the converging plate, the co-extruding plate and the opening mold plate; a co-extruding port is formed in one side of the co-extruding plate; a first co-extruding runner, a second co-extruding runner and a third co-extruding runner successively communicating are arranged in the co-extruding plate; the co-extruding port communicates to the first co-extruding runner; the third co-extruding runner communicates to the cavity; and an adjusting baffleplate is arranged on the other side of the co-extruding plate. When the mold is used, a co-extruded material melt flows into the cavity successively from the co-extruding port, the first co-extrudingrunner, the second co-extruding runner and the third co-extruding runner to form double-colored coextrusion. By means of a simple structure, the product quality is improved, the input cost is low andthe mold is conveniently used.

Owner:HUANGSHI HAOSEN IND DEV

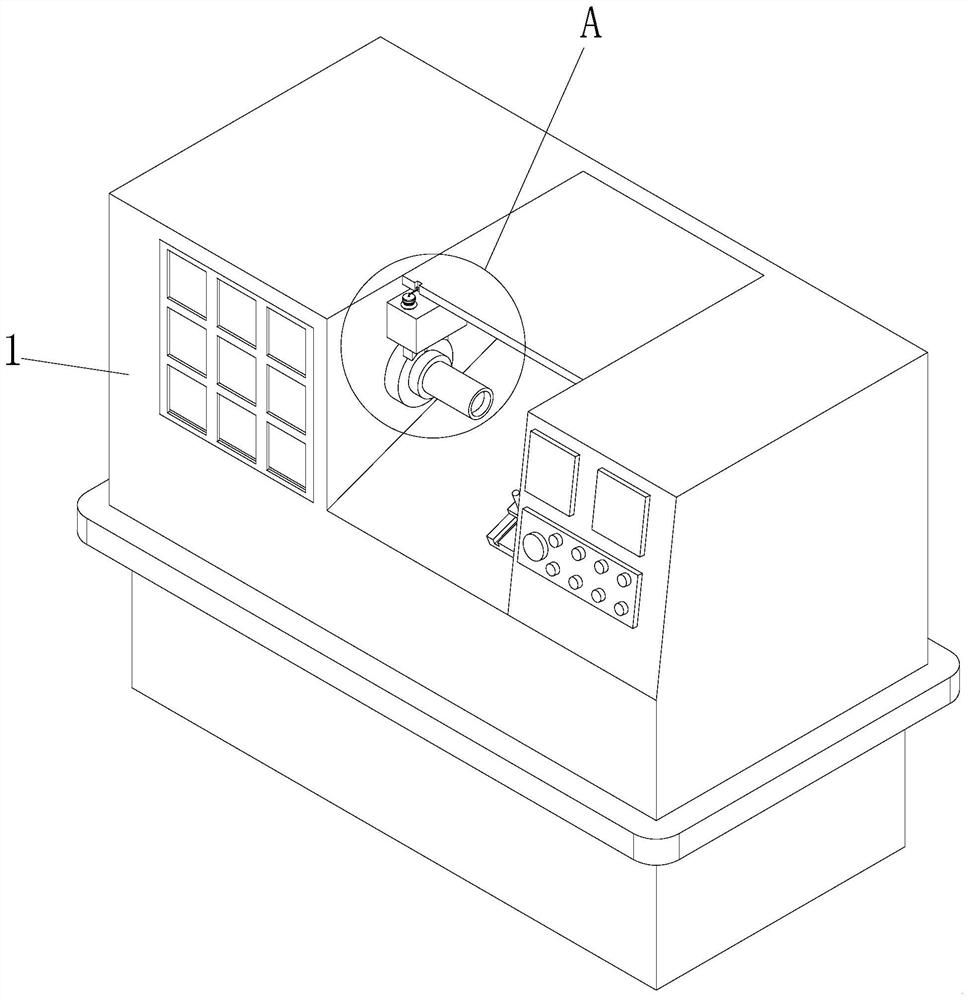

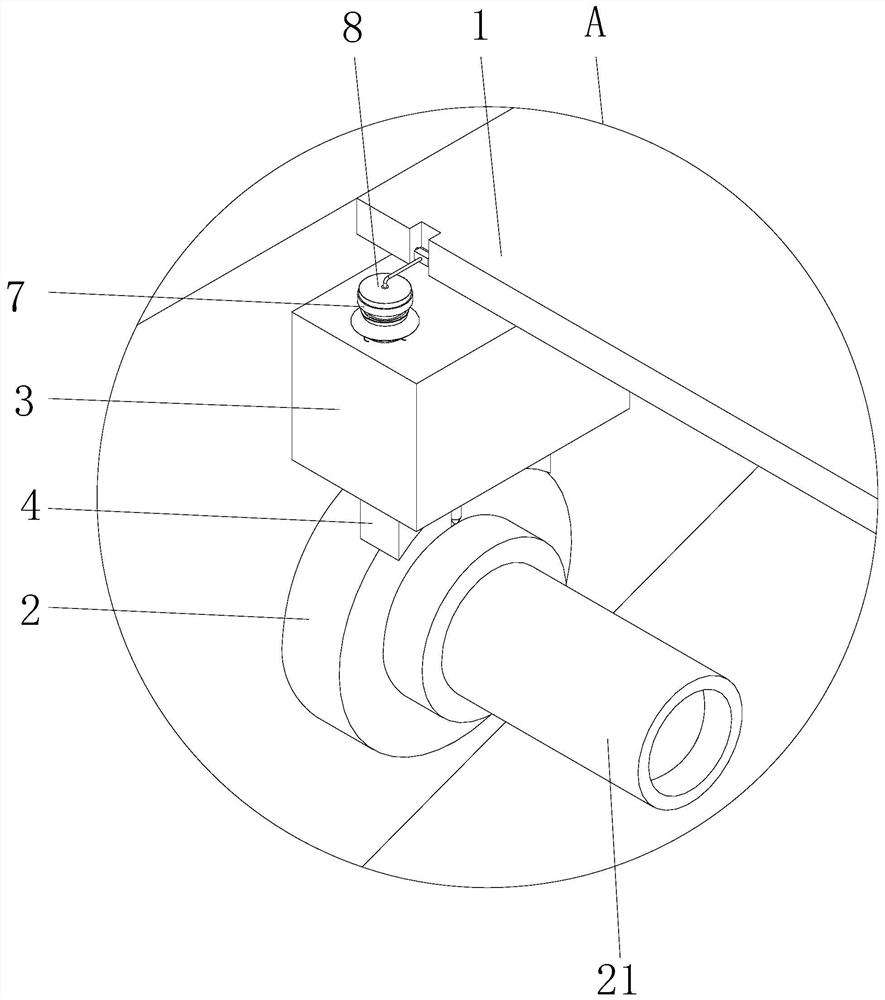

Numerical control lathe with automatic oil supply function

InactiveCN113732815AAdjust flow speedControl flow speedMaintainance and safety accessoriesNumerical controlOil can

The invention discloses a numerical control lathe with an automatic oil supply function, and relates to the technical field of numerical control lathes. The numerical control lathe with the automatic oil supply function comprises a lathe body, a machining area is formed in the center of the front side of the lathe body, the bottom of the machining area is inclined and provided with a clamp, a driving device is embedded and fixed to the left side, an output shaft on the right side of the driving device is fixed to a rotating shaft, and an oil storage tank is arranged at the top of the driving device. According to the numerical control lathe with the automatic oil supply function, lubricating oil can be stored by arranging the oil storage tank, automatic oil supply operation can be conducted between the driving device and the output shaft of the driving device by arranging a self-adaptive oil supply device, so that resistance between the driving device and the output shaft of the driving device is reduced, and a certain cooling function can be achieved on the output shaft; and meanwhile, a temperature control adjusting mechanism is arranged, so that the oil supply amount can be adaptively adjusted according to the temperature of the driving device, and the oil supply amount is controlled according to the actual temperature.

Owner:张智

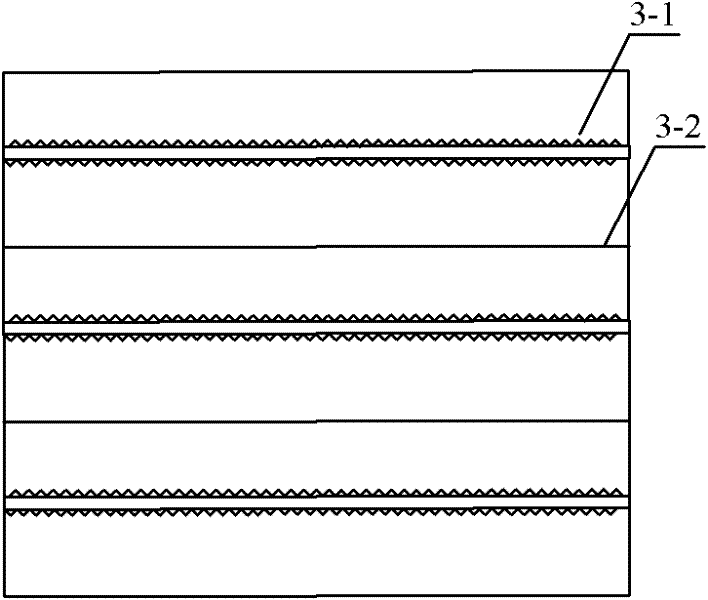

An electret ultrasonic sputtering liquid charging device and charging method

ActiveCN108744713BUniform and stable charging effectWide applicabilityCombination devicesMembrane filtersEngineeringLiquid tank

The invention discloses an electret ultrasonic sputtering liquid charging device and a charging method. In the ultrasonic sputtering charging device of the electret, the liquid tank is trapezoidal, the bottom of the liquid tank and the horizontal plane form an angle of 20-65°, and the material that can be electret enters from the bottom of the liquid tank through the unwinding device. The liquid tank, through the first roller shaft and the second roller shaft, the electret material can be attached to the bottom of the liquid tank, and at the same time, ultrasonic waves can be applied to the bottom of the liquid tank filled with polar liquid and materials that can be electret. After the electret material leaves the liquid tank, it is dried by a drying device to obtain a charged electret. This method can adjust the distance between the first roller shaft, the second roller shaft and the bottom of the liquid tank, and change the inclination of the bottom of the liquid tank, so that the electret materials with different thicknesses and different materials can be laminated easily. , Efficient, stable and uniform charging.

Owner:JIANGSU YIMAO FILTER MEDIA CO LTD

Magnetic heat dissipation device

PendingCN110072367AImprove efficiencyAdjust flow speedDynamo-electric machinesModifications by conduction heat transferMagnetic liquidsPower equipment

The invention provides a magnetic heat dissipation device. The heat dissipation device comprises an annular sealing pipeline, wherein magnetic liquid is filled in the annular sealing pipeline; the annular sealing pipeline is provided with at least one horn-shaped electrifying solenoid; the annular sealing pipeline comprises at least one heat absorption section and at least one heat dissipation section, and direct current is introduced into the electrifying solenoid. If there are multiple electrifying solenoids on the annular sealing pipeline, the small end of each electrifying solenoid pointsto the clockwise or counterclockwise direction of the annular sealing pipeline, and the current flowing in all electrifying solenoids is in the same direction. The heat dissipation device adopts the horn-shaped electrifying solenoid as power equipment, and works in an active, efficient and silent heat dissipation mode.

Owner:大连良华科技有限公司

Liquid net dust collector

ActiveCN105597473BEffective adhesionThere will be no poor exhaustCombination devicesEngineeringCirculating pump

The invention relates to a liquid net dust collector, which includes a dust removal chamber and a purification chamber; an air inlet pipe is installed on the side wall of the dust removal chamber, and a liquid storage chamber is installed on the top of the dust removal chamber; The air guide pipe of the liquid storage room is connected to the purification chamber; on the bottom plate of the liquid storage room, there are dedusting wires hanging equidistantly, and the upper end of the dedusting wires runs through the bottom plate of the liquid storage room, and the dedusting wires are made of elastic materials; each of the dedusting wires The lower end of the dust removal screen is fixed on the dust removal screen, and the dust removal screen is movably installed at the bottom of the dust removal chamber. The dust removal screen can slide up and down along the inner wall of the dust removal chamber; a dust collection chamber is also installed at the bottom of the dust removal chamber. The dust collection chamber is connected to the liquid storage chamber through the catheter; the circulation pump and the dust remover are installed in sequence on the catheter; the dust collector has a novel structure and can efficiently remove dust for a long time; the filtered dust is easy to collect and clean , can make the production coherent and effectively improve the operation efficiency.

Owner:徐州天力汽车油箱厂

A kind of cashmere conveying device

The invention discloses a cashmere conveying device which comprises a box body, a feeding cabin, a cashmere sending channel, an air blower, an air blowing channel connected with the air blower, a cashmere storage box and a return air channel, wherein a feeding opening communicated with the feeding cabin is arranged on one side of the box body, the cashmere storage box is arranged on the other sideof the box body, a stirring wheel fixedly connected to the box body is arranged at the bottom of the feeding cabin, one side of the cashmere sending channel is communicated with the feeding cabin, the other side of the cashmere sending channel is communicated with the cashmere storage box, the air blowing channel is communicated with the cashmere sending channel, one side of the return air channel is communicated with the feeding cabin, and the other side of the return air channel is communicated with the cashmere sending channel. By means of the cashmere conveying device, the cashmere is prevented from leaking in a conveying process, and a risk that fine fiber flies and is inhaled in is reduced; the whole device has the advantages of low energy consumption, high efficiency and favorability for resource saving and environmental protection.

Owner:新昌县君达制冷设备有限公司

Return air temperature control mechanism, return air temperature control method, operation control device and refrigerator

ActiveCN113375413AAdjust the speed of temperature changeIncrease connection areaLighting and heating apparatusDomestic refrigeratorsTemperature controlIcebox

The invention discloses a return air temperature control mechanism, a return air temperature control method, an operation control device and a refrigerator. The refrigerator is provided with a refrigeration evaporator and a refrigeration area air inlet, the return air temperature control mechanism comprises at least two temperature control chambers, a heating device and a refrigeration evaporator air duct, and each temperature control chamber comprises an air supply port and an air return port. The air return ports, the air supply ports and the refrigeration area air inlet are sequentially arranged in the air supply direction of the refrigeration evaporator air duct, the heating device is arranged in the refrigeration evaporator air duct, the refrigeration evaporator is located between the air supply ports and the air return ports, and the heating device is located in front of the air supply ports in the direction from the air supply ports to the refrigeration area air inlet. When the temperature of the temperature control chambers is reduced, the temperature of the airflow entering the refrigeration area is increased by the heating device, the temperature of the refrigeration area cannot be too low even if the temperature reduction amplitude of the temperature control chambers is larger, the temperature change range of the temperature control chambers can be effectively expanded, wide-range temperature adjustment of the temperature control chambers is achieved, and different storage requirements are met.

Owner:HEFEI HUALING CO LTD +2

Novel plasma stink treatment device

InactiveCN102284079BImprove deodorization efficiencySpeed up the flowDeodrantsLine tubingProcess engineering

The invention discloses a plasma stink treatment device, which comprises a power supply, a plasma stink removal reactor, a fan and a washing tower, wherein the plasma stink removal reactor is connected with the washing tower. The device is characterized in that: the fan is positioned in a pipeline between the reactor and the washing tower; and an insulating material is connected to the joint of the reactor and the fan. The novel plasma stink treatment device has the characteristics of high efficiency, energy saving, environmental friendliness and the like.

Owner:BEIJING BODXY ENERGY CONSERVATION TECH & RES

Gypsum mortar spraying machine

InactiveCN107520965AAvoid enteringStir wellDischarging apparatusMixing operation control apparatusElectric machineryStructural engineering

The invention discloses a gypsum mortar spraying machine. The gypsum mortar spraying machine comprises a machine frame, a motor, a stirring barrel and a storage barrel. The motor is located above the machine frame. A primary stirring device and a secondary stirring device are correspondingly installed on the upper portion and the lower portion of the machine frame separately. The stirring barrel is connected with the storage barrel through a connecting pipe, a control valve is arranged on the side, close to the stirring barrel, of the connecting pipe, a rotary handle at the top of a one-way valve is rotated, and an output pump is arranged at the bottom of the storage barrel. The stirring barrel is connected with the storage barrel through a filter screen, well stirred mortar is filtered again to avoid impurities entering into the storage barrel, the stirring barrel is set into a secondary stirring barrel to carry out coarse stirring and refined stirring on raw materials, stirring at all levels does not interfere with each other, not only can the raw materials be sufficiently stirred, but also the stirring efficiency and the stirring quality are improved, and the stirring strength can be enhanced.

Owner:ZHENGZHOU UNIV

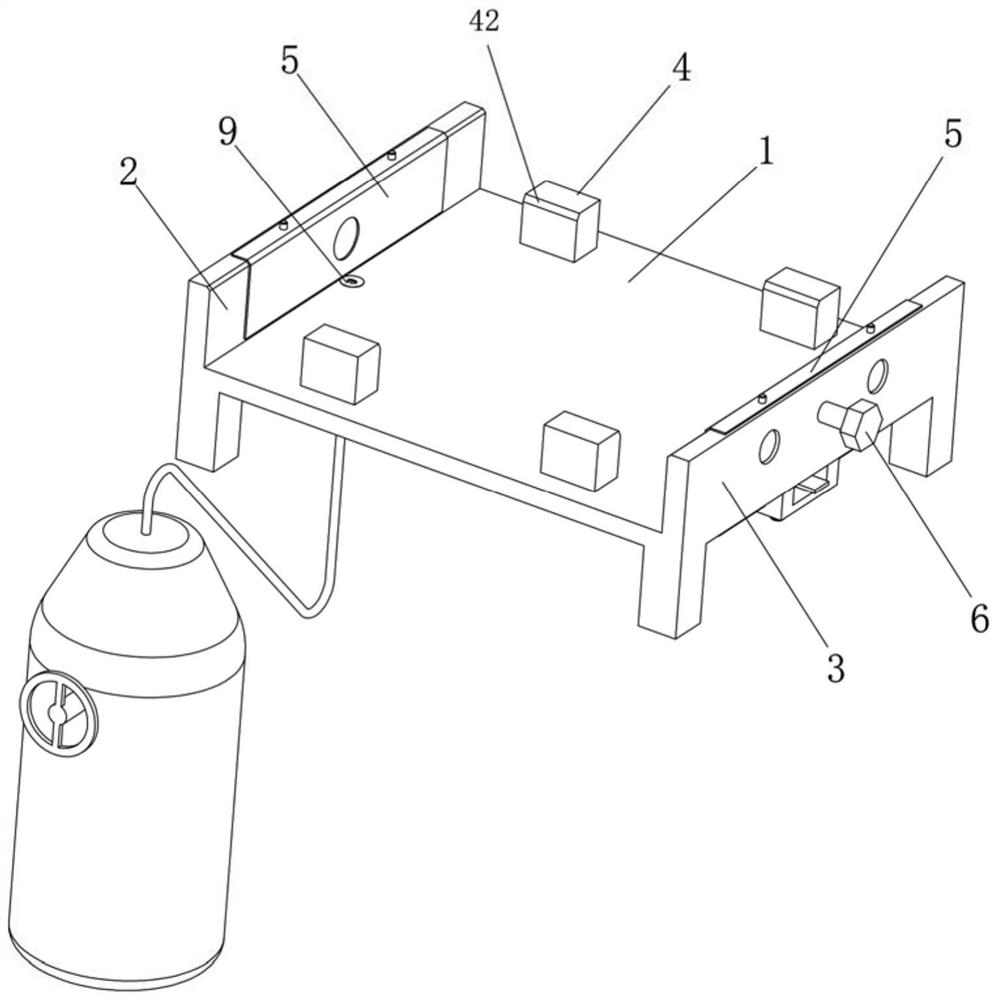

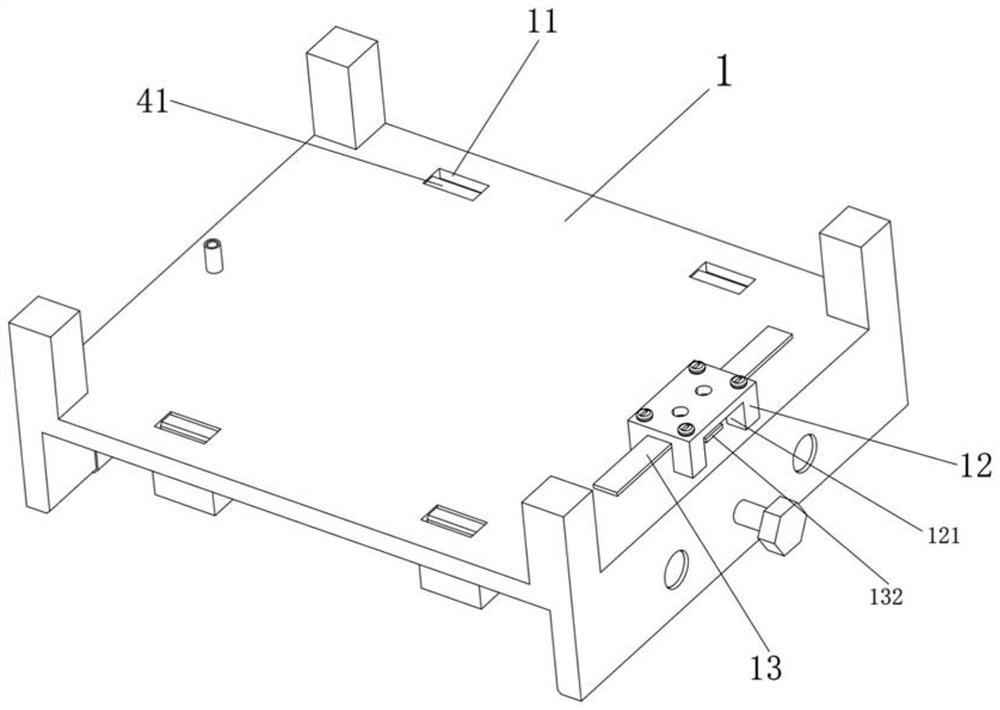

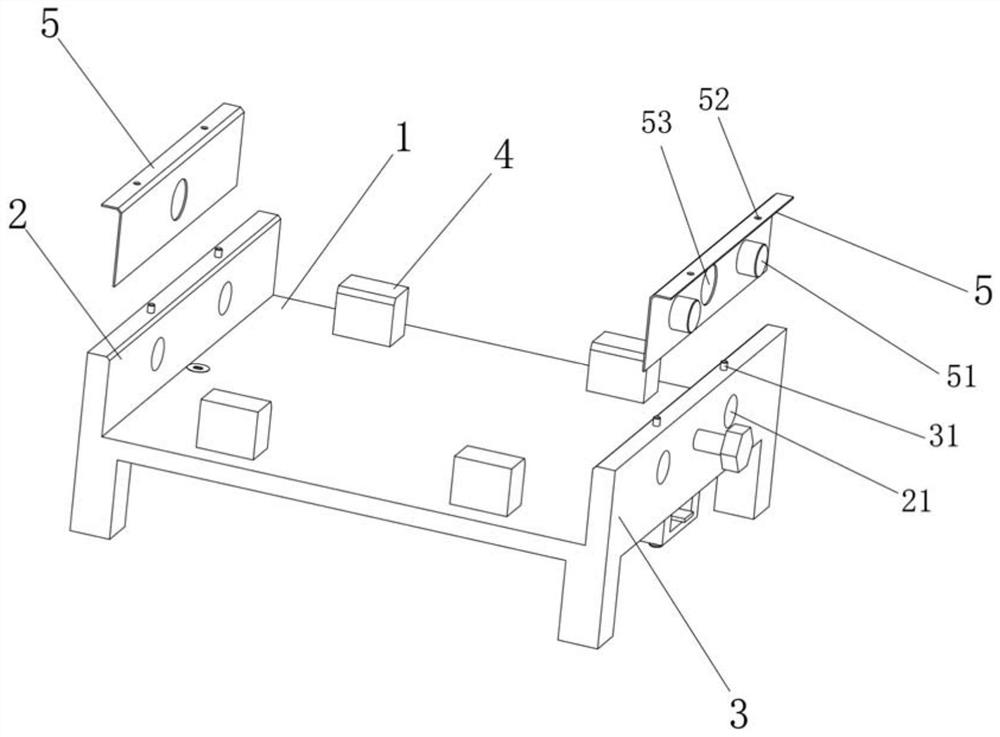

Low-cost and high-efficiency tool structure for battery shell glue filling

ActiveCN113560142AAdjust flow speedImprove consistencyLiquid surface applicatorsFinal product manufactureElectrical batteryInlet valve

The invention relates to a low-cost and high-efficiency tool structure for battery shell glue filling. The low-cost and high-efficiency tool structure comprises a bottom plate, wherein a left side plate and a right side plate are formed on the two sides of the bottom plate correspondingly, a plurality of limiting blocks are arranged on the bottom plate, a side adjusting screw is in threaded connection with the right side plate in the transverse direction, one end of the side adjusting screw penetrates through the right side plate to be connected with a lining pad, and the left side of the bottom plate is connected with a glue inlet valve; the right side of the bottom plate is connected with a glue outlet valve, and a left air outlet hole and a right air outlet hole are formed in the glue outlet valve; and a support is arranged at the bottom of the bottom plate, a sealing pull strip is arranged on the support, the sealing pull strip is attached to the bottom end of the glue outlet valve, a pull strip hole is formed in the sealing pull strip, and the pull strip hole communicates with the left air outlet hole or the right air outlet hole. According to the low-cost and high-efficiency tool structure, through the tool automatic glue filling structure, the glue flowing speed of a glue inlet pipe is effectively adjusted, full filling glue is conveyed to a left glue filling loop and a right glue filling loop of a glue filling shell correspondingly, stable sealing of the glue is completed, and the consistency of glue filling is improved.

Owner:飞毛腿能源科技有限公司

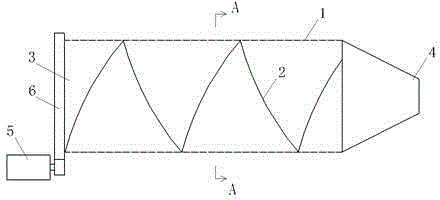

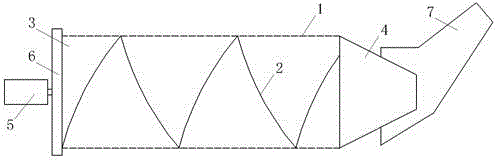

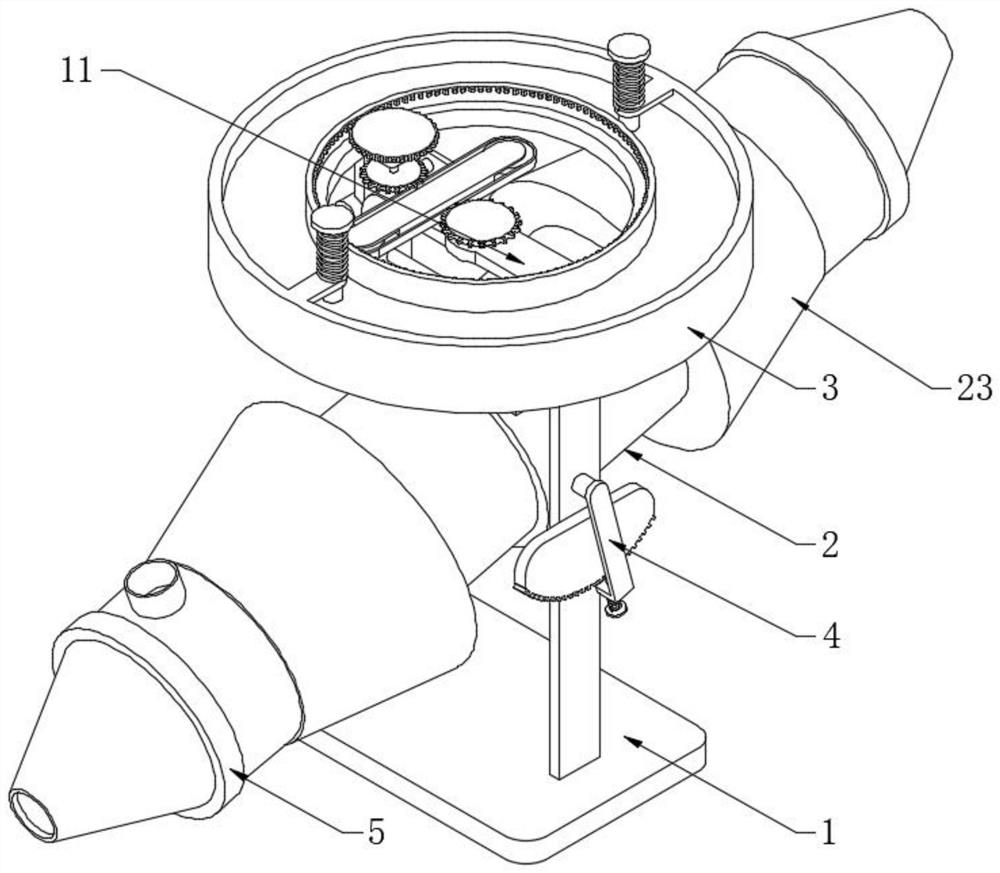

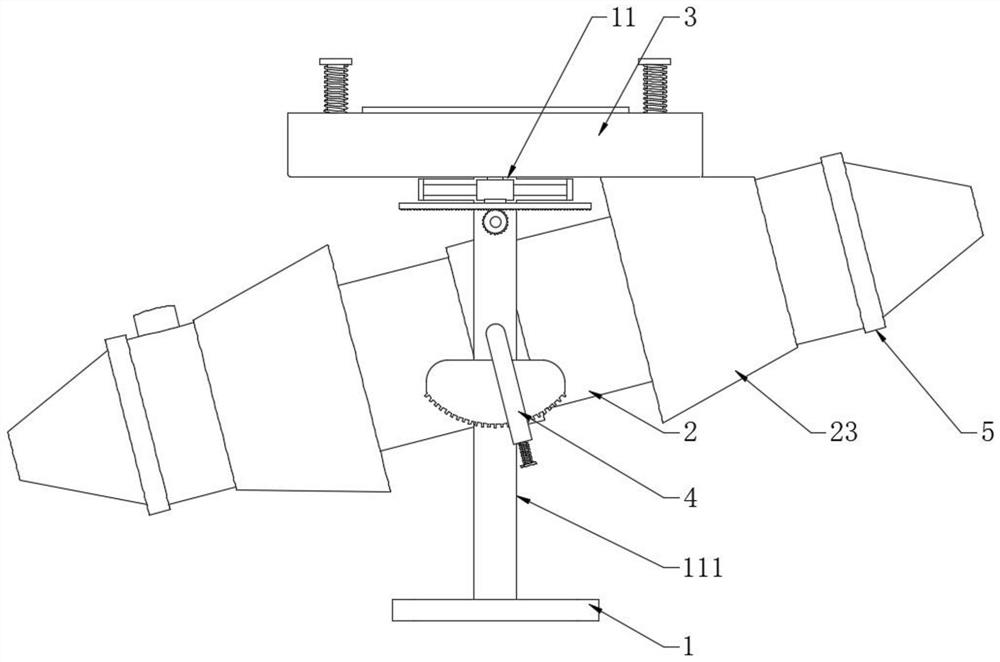

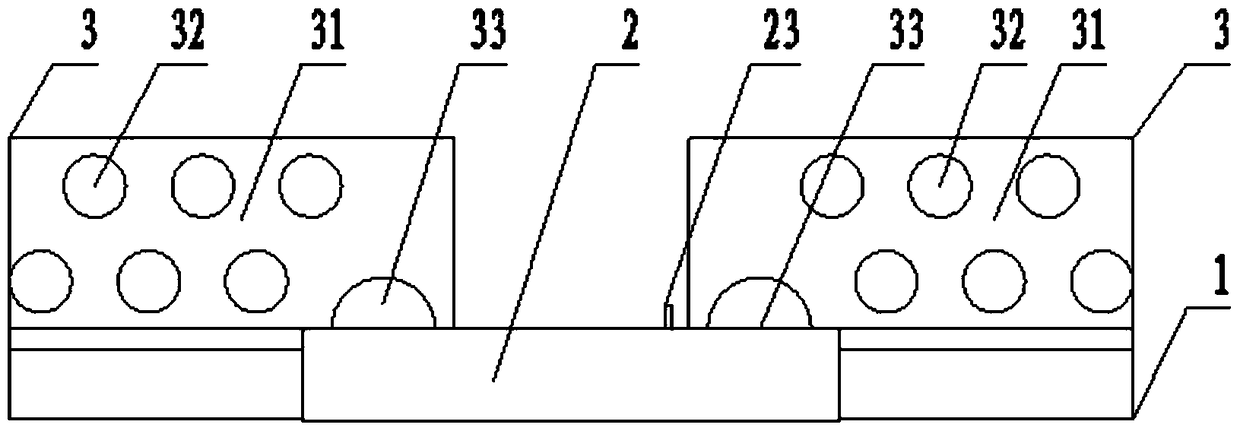

A high-efficiency fiber drawing device

ActiveCN104790088BIncrease walking speedSpeed adjustmentTextiles and paperEngineeringFiber drawing

The invention discloses an efficient stretching device which comprises a rack (1). A plasticizing pool (2) is arranged in the middle of the rack (1), and stretching units (3) are arranged on the two sides of the plasticizing pool (2). A feeding port (21) and an overflowing port (22) are formed in the side wall of the plasticizing pool (2), and a gate (23) is arranged in the plasticizing pool (2) and located between the feeding port (21) and the overflowing port (22). The stretching units comprise installation seats (31) which are provided with a plurality of stretching rolls (32), and the ends, close to the plasticizing tool (2) of the installation seats (31) are provided with limiting rolls (33). The efficient stretching device can improve the plasticizing efficiency and ensure normal work, and has the advantages of the high overall stretching efficiency and the low machining cost.

Owner:湖州旭财高新纤维有限公司

A multi-stage compression air compressor

ActiveCN104047826BReduce wasteQuality improvementPositive displacement pump componentsPump controlExhaust valveEngineering

The invention relates to a multi-stage compression air compressor, which includes a casing, a primary compression cylinder, a secondary compression cylinder, and a crankshaft; the crankshaft is rotatably connected to the casing, and the crankshaft includes two The bending parts are respectively bending part A and bending part B. The piston rod of the first-stage compression cylinder is rotatably connected with the bending part A, and the piston rod of the second-stage compression cylinder is rotatably connected with the bending part B; the first-stage compression cylinder and the second-stage compression cylinder The volumes are equal, the length of the first-stage compression cylinder is half of the second-stage compression cylinder, and the radial length of the bending part B is twice that of the bending part A; the closed end of the first-stage compression cylinder is provided with a The air intake check valve A is connected to the device pipeline, and a discharge check valve A connected to the second-stage compression cylinder is also provided on the first-stage compression cylinder, and an intake air connection connected to the first-stage compression cylinder is provided on the second-stage compression cylinder. The one-way valve B is also provided with an exhaust one-way valve B connected with the expansion valve in the second-stage compression cylinder.

Owner:江苏昊科汽车空调有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com