An electret ultrasonic sputtering liquid charging device and charging method

A technology of a charging device and a charging method, which is applied in the direction of separation methods, combination devices, chemical instruments and methods, etc., can solve the problem of poor adaptability of multi-layer composite electrets, increased cost and complexity of process equipment, non-woven substrates, etc. To avoid problems such as the reduction of material strip power, to achieve a uniform and stable charging effect, a simple electret method, and to improve the uniformity of charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

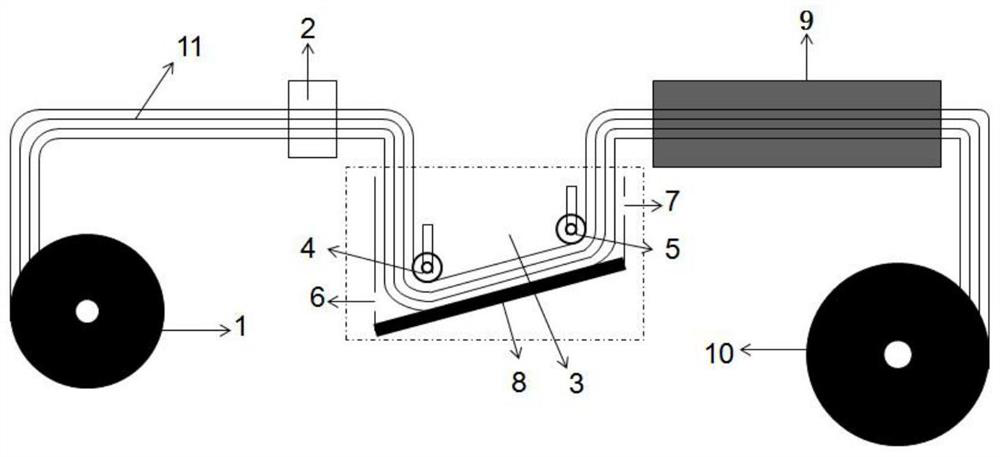

[0026] according to figure 1Schematic diagram of the electret ultrasonic sputtering liquid charging process, 50mm single-layer porous natural fiber sheet material, through the unwinding device at a line speed of 1m / min, first corona treatment through the corona device, tilted from 65° The lower end of the liquid tank tank enters the liquid tank equipped with deionized water. The distance between the first roller made of ceramics and the center line of the second roller made of ceramics is 2m. By adjusting the first roller made of ceramics, the ceramic The vertical distance between the second roller made and the bottom of the liquid tank is 50mm, so that the 50mm single-layer porous natural fiber sheet under the first roller made of ceramics is first passed through the second roller made of ceramics. The material is attached to the bottom of the liquid tank, and at the same time, an ultrasonic wave with a power of 5000w is applied to the bottom of the liquid tank filled with a ...

Embodiment 2

[0028] according to figure 1 It is a schematic diagram of the electret’s ultrasonic sputtering liquid charging process. The 0.5mm multi-layer porous chemical fiber sheet material passes through the unwinding device at a line speed of 10m / min, and first undergoes corona treatment through the corona device. From 20° The lower end of the inclined liquid tank enters the liquid tank equipped with ethanol. The distance between the first roller made of quartz and the center line of the second roller made of quartz is 0.5m. By adjusting the first roller made of quartz, the quartz The vertical distance between the second roller made and the bottom of the liquid tank is 0.5 mm, so that the first roller made of quartz passes through the bottom of the first roller made of quartz, and then the 0.5 mm multi-layer porous chemical layer is passed under the second roller made of quartz. The fiber material is attached to the bottom of the liquid tank, and at the same time, an ultrasonic wave wi...

Embodiment 3

[0030] according to figure 1 It is a schematic diagram of the ultrasonic sputtering liquid charging process of an electret. The polar liquid is a deionized water / ethanol mixture with a mass ratio of deionized water and ethanol of 30:70, and a mixture of 5mm multilayer porous natural fibers and chemical fibers. The sheet material, through the unwinding device at a linear speed of 50m / min, first undergoes corona treatment through the corona device, and enters the liquid tank filled with deionized water / ethanol mixture from the bottom of the 45° inclined liquid tank, quartz The distance between the first roller made of quartz and the center line of the second roller made of quartz is 1m, and the vertical distance between the first roller made of quartz and the second roller made of quartz and the bottom of the liquid tank is 5mm , so that the 5mm multi-layer porous natural fiber and chemical fiber mixed sheet material under the first roller made of quartz and then the second roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com