Low-cost and high-efficiency tool structure for battery shell glue filling

A low-cost technology for battery casings, which is applied to devices and coatings for coating liquid on the surface, which can solve the problems of wasting colloid, increasing the cost of manual wiping, and lacking the consistency and reliability of glue filling and continuous maintenance. Achieve the effects of improving efficiency, reducing processing time, and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

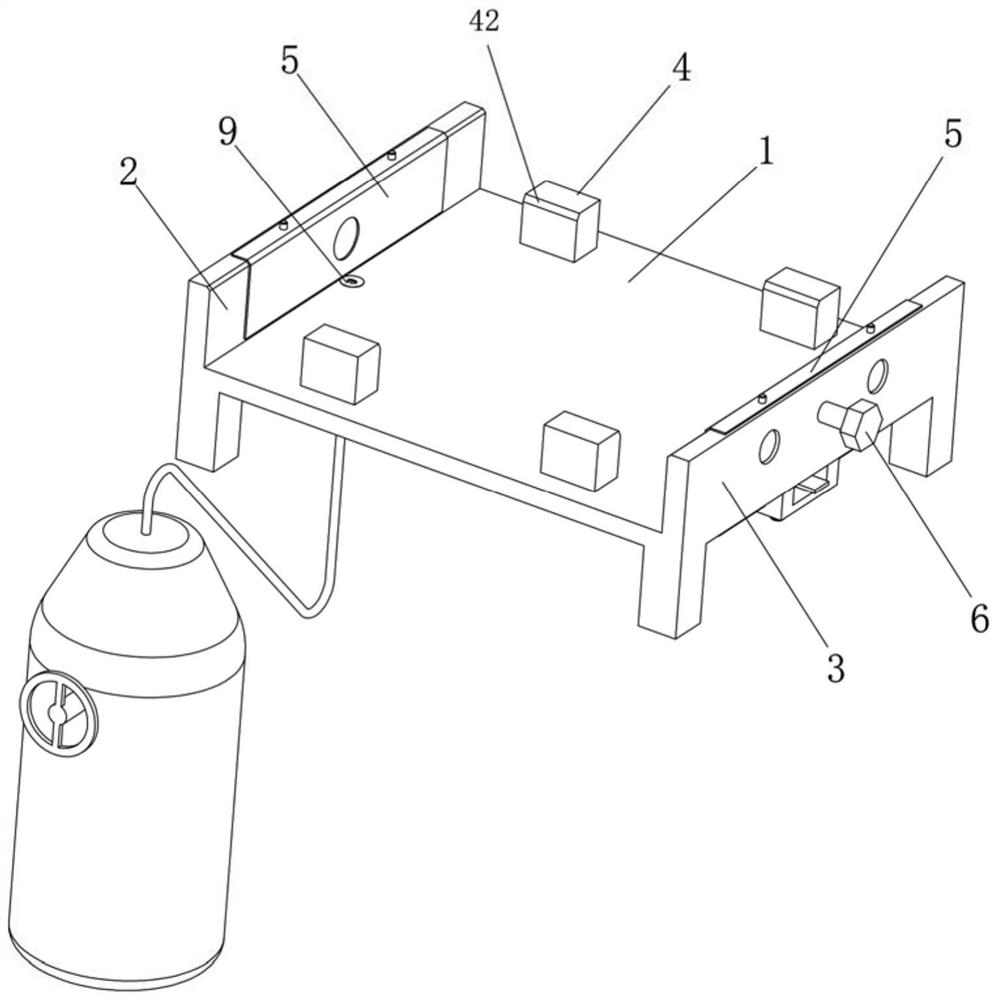

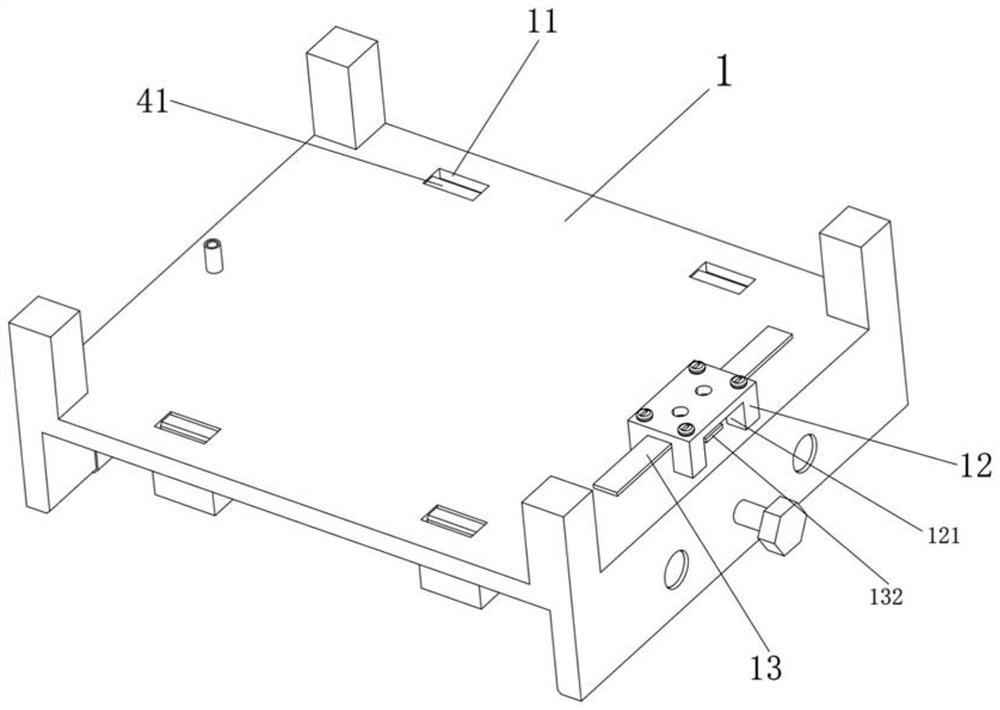

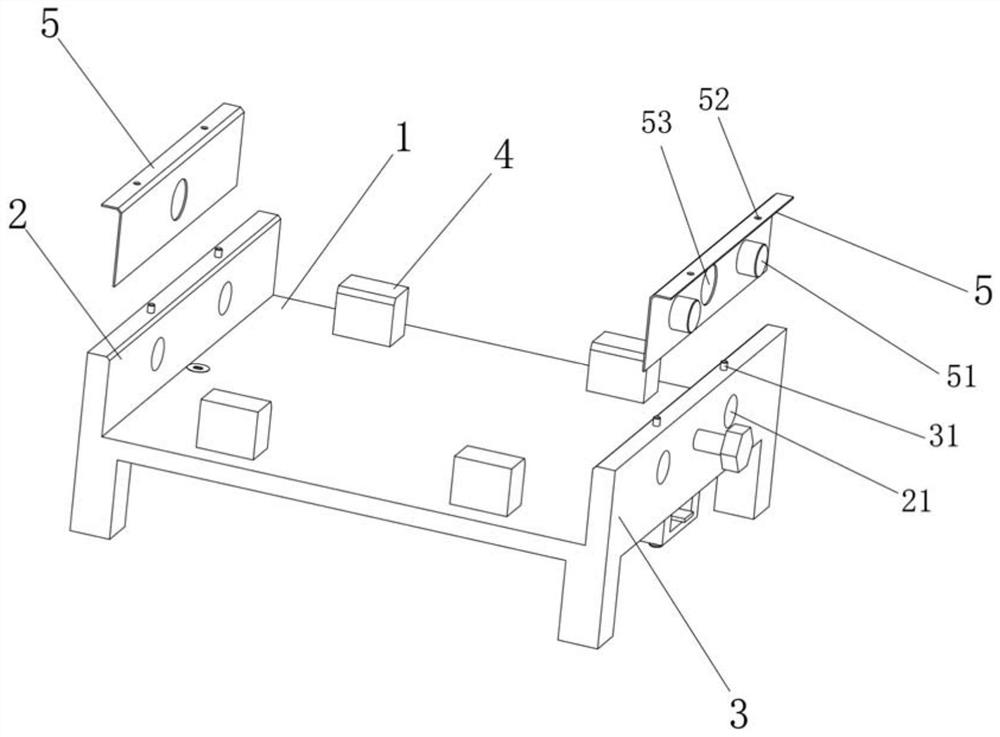

[0031] A low-cost and high-efficiency tooling structure for battery casing glue filling according to an embodiment of the present invention, such as Figure 1-Figure 6 As shown, it includes: a bottom plate 1, a left side plate 2 and a right side plate 3 are respectively formed on both sides of the bottom plate 1, and a number of limit blocks 4 are provided on the bottom plate 1 for limiting the position of the glue filling shell, There are four limit blocks 4, which limit the width direction of the glue filling shell; the bottom plate 1 is provided with an installation groove 11 that matches the limit block 4, and the bottom of the limit block 4 is provided with an installation groove 11 In conjunction with the buckle 41, a guide angle 42 is provided on the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com