A kind of cashmere conveying device

A conveying device, cashmere technology, applied in textile and papermaking, fiber processing, fiber feeding, etc., can solve the problems of high labor intensity, unsafe, low efficiency, etc., and achieve high work efficiency, compact structure, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, technical solution and advantages of the present invention clearer, the invention will be clearly and completely described below in conjunction with specific embodiments.

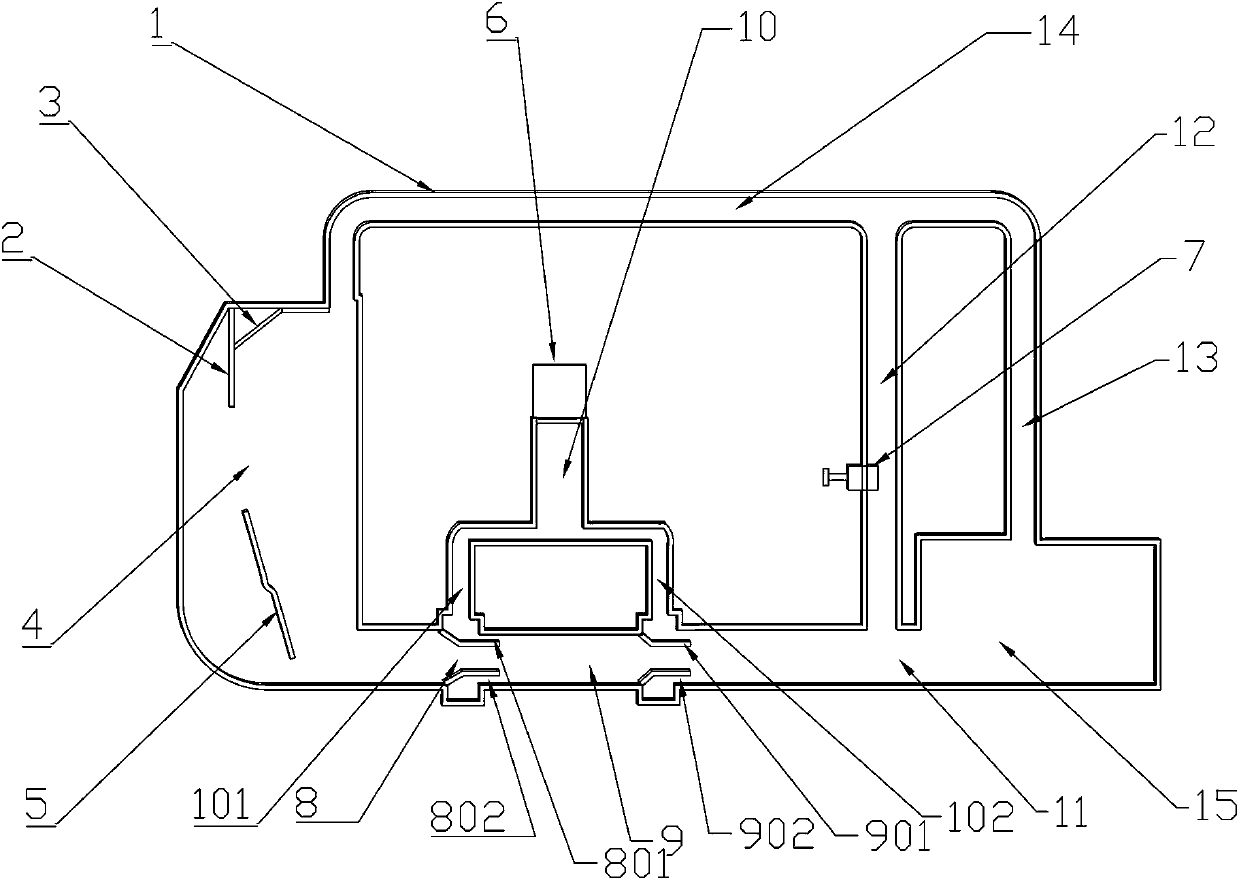

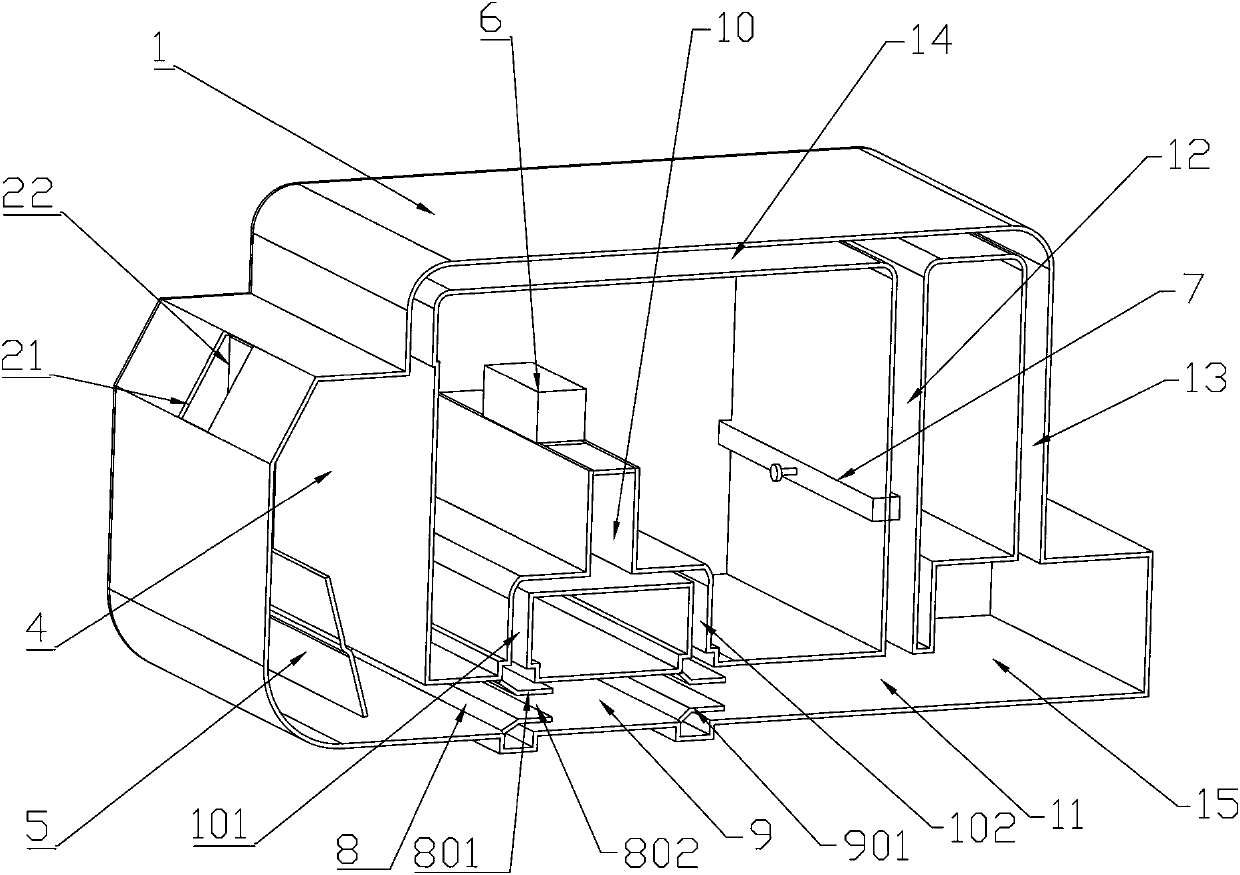

[0019] Such as figure 1 and figure 2 A kind of cashmere conveying device shown, it comprises box body 1, feeding cabin 4, cashmere delivery channel, air blower 6, the blowing air channel that links to each other with described air blower 6, cashmere storage box 15 and return air channel, and described box One side of the body 1 is provided with a feed port 21, the feed port 21 is provided with a feed door 22, the inner side of the feed door 22 is fixedly connected with the box body 1 through the telescopic rod 3, and the other side of the box body 1 The side is provided with cashmere storage box 15, and the bottom of described feed cabin 4 is provided with the stirring wheel 5 that is fixedly connected on the box body, and one side of described cashmere feeding channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com