A SnO2 composite carbon nanotube electrothermal film and a preparation method thereof

A carbon nanotube and electric heating film technology, applied in the field of SnO2 composite carbon nanotube electric heating film and its preparation, can solve the problems of high surface resistance of semiconductor electric heating film, inability to prepare high-temperature conductive film, and high cost of carbon-based electric heating film, and achieves increased The effect of large carrier concentration, strong chemical stability and excellent thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

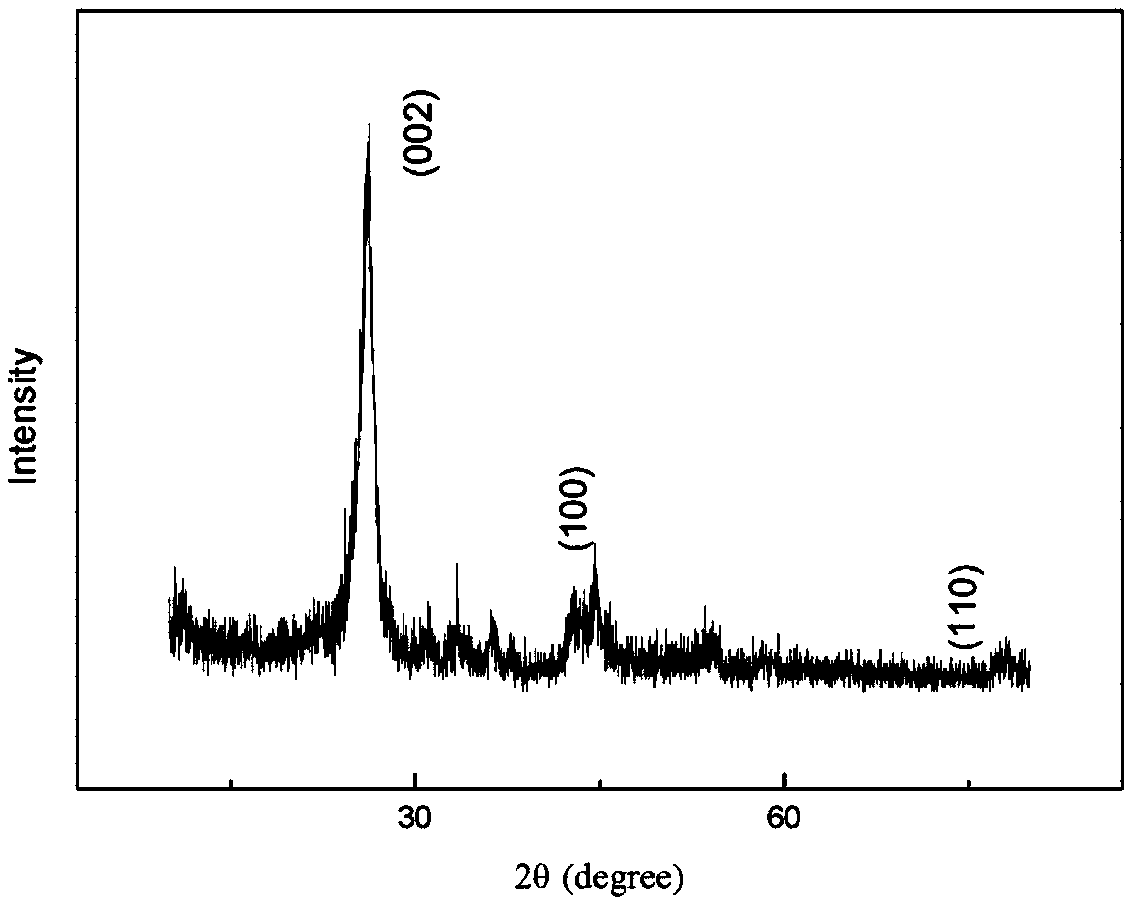

[0030] The present invention prepares SnO 2 The method for composite carbon nanotube electrothermal film comprises the following steps:

[0031] (1) Modified carbon nanotubes: Take 1g of carbon nanotubes, add them to 50ml of a mixture of concentrated nitric acid and concentrated sulfuric acid with a volume ratio of 3:1, mix them evenly, and put them in a constant temperature box. Treat at constant temperature for 1 hour, then continuously add deionized water and centrifuge to pH = 7, and dry in a constant temperature oven at 60°C to obtain modified carbon nanotubes;

[0032] (2) Preparation of electrothermal film precursor solution: weigh 21.0136g of SnCl 4 ·5H 2 O and 0.253 g of SbCl 3 Dissolve in 100ml of ethanol to make a mixed solution, in which SnCl 4 The concentration of the modified carbon nanotubes is 0.6mol / L; weigh 0.0021g of modified carbon nanotubes and add them to the mixed solution, first ultrasonically disperse for 5min, then stir on a magnetic stirrer for 1...

Embodiment 2

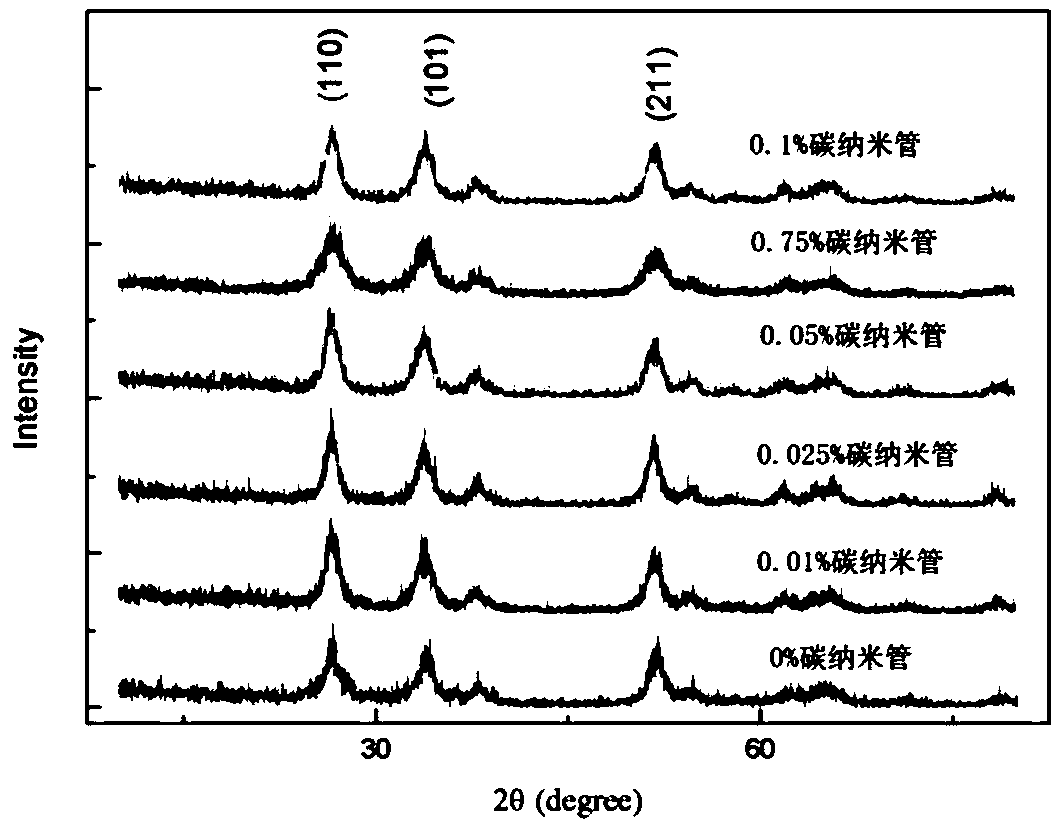

[0043] Design 4 groups of parallel experiments, basic steps are identical with embodiment 1, difference is the addition of carbon nanotube, it and SnCl 4 ·5H 2 The mass ratios of O are 0.00025:1, 0.0005:1, 0.00075:1 and 0.001:1, respectively.

[0044] The electrothermal film prepared in this embodiment was tested for performance, and the obtained results are shown in Table 2 below.

[0045] Table 2 Performance table of the electrothermal film prepared in Example 2

[0046]

[0047] It can be seen from Table 2 that the electrothermal film prepared by the present invention has the advantages of high thermal efficiency and good chemical stability, the sheet resistance is less than 140Ω / □, the emissivity reaches 0.9, and the electrothermal conversion efficiency is >90%, which can replace the traditional heating resistor and heating elements with poor thermal efficiency.

Embodiment 3

[0068] Design group parallel experiments, the basic steps are the same as in Example 1, the difference lies in the concentration of tin element in the electrothermal film precursor solution, respectively 0.1mol / L, 0.2mol / L, 0.4mol / L, 0.8mol / L and 1mol / L.

[0069] The electrothermal film prepared in Example 3 was tested for performance, and the obtained results are described in Table 5 below.

[0070] Table 5 Performance table of the electrothermal film prepared in Example 3

[0071]

[0072] It can be seen from Table 5 that when the concentration of tin element in the electrothermal film precursor solution is 0.2-0.8mol / L, the prepared electrothermal film has the advantages of high thermal efficiency, good chemical stability, etc., and the sheet resistance is less than 140Ω / □, and the emission The rate reaches 0.9, and the electrothermal conversion efficiency is >90%. If the concentration is low, lower than 0.2mol / L, the sample sprayed with the same solution will have les...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com