Si@C lithium-ion battery negative electrode material of core-shell structure and preparation method thereof

A lithium-ion battery, core-shell structure technology, applied in the direction of battery electrodes, secondary batteries, structural parts, etc., can solve the problem that it is difficult to produce a carbon coating layer with a pore structure, it is difficult to achieve large-scale production, and there are few reports on modification, etc. problems, to achieve the effect of being suitable for large-scale production, good product consistency, and improving rate performance and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

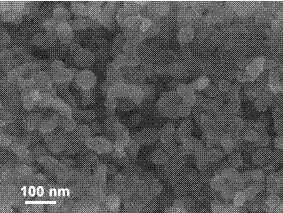

[0032] A. Surface activation of nano-silicon: First, ultrasonically disperse 200 mg of spherical nano-silicon with a diameter of 50-70 nm into 40 ml of 30wt% H 2 o 2 Medium, and the ultrasonic power is 100W, and the time is 20min.

[0033] Then stir at room temperature for 0.5 h to fully activate the spherical nano-silicon.

[0034] After filtering, the filtered product was washed three times with deionized water and absolute ethanol respectively, and then vacuum-dried for 12 hours at a vacuum degree of 0.05 MPa and 55° C. to obtain activated nano-silicon.

[0035]B. Preparation of Si@ZIF-67 precursor: Weigh 20 mg of the above-mentioned activated nano-silicon, ultrasonically disperse it into 60 mL of a mixed solution of methanol and ethanol with a volume ratio of 1:1, add 0.2 g of polyvinylpyrrolidone and 0.07 g of hexahydrate Cobalt nitrate, and continued ultrasonic stirring for 1 h to obtain a suspension.

[0036] Then, because the precursor of Si@ZIF-67 can be generated ...

Embodiment 2

[0041] A. Surface activation of nano-silicon: First, ultrasonically disperse 200mg of spherical nano-silicon with a diameter of 50-70nm into 40 ml of 30wt% H 2 o 2 Medium, and the ultrasonic power is 100W, and the time is 2min.

[0042] Then stir at room temperature for 3 h to fully activate the spherical nano-silicon.

[0043] After filtering, the filtered product was washed three times with deionized water and absolute ethanol respectively, and then vacuum-dried for 10 hours at a vacuum degree of 0.1 MPa and 60° C. to obtain activated nano-silicon.

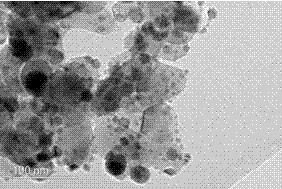

[0044] B. Preparation of Si@ZIF-67 precursor: Weigh 20 mg of the above-mentioned activated nano-silicon, ultrasonically disperse it into 60 mL of a mixed solution of ethanol and methanol mixed at a volume ratio of 1:2, add 0.2 g polyvinylpyrrolidone and 0.5 g Cobalt chloride hexahydrate, continue ultrasonic stirring for 3 h to obtain a suspension.

[0045] Then take by weighing 0.342g 2-methylimidazole and be dissolved in 60m...

Embodiment 3

[0051] A. Surface activation of nano-silicon: first disperse 150mg of spherical nano-silicon with a diameter of 50-70nm into 40ml of 30wt% H 2 o 2 Medium, and the ultrasonic power is 100W, and the time is 10min.

[0052] Then stir at room temperature for 3 h to fully activate the spherical nano-silicon.

[0053] After filtering, the filtered product was washed three times with deionized water and absolute ethanol respectively, and then vacuum-dried for 10 hours at a vacuum degree of 0.1 MPa and 60° C. to obtain activated nano-silicon.

[0054] B. Preparation of Si@MIL-88(Fe) precursor: Weigh 20 mg of the above-mentioned activated nano-silicon, ultrasonically disperse it into 60 mL of a mixed solution of ethanol and dimethylformamide mixed at a volume ratio of 1:1, add 0.025 g ferric nitrate nonahydrate, and continue ultrasonic stirring for 2 h. Then add 0.018g of terephthalic acid, continue to stir for 0.5h, transfer the resulting solution to the reactor, and keep it warm f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com