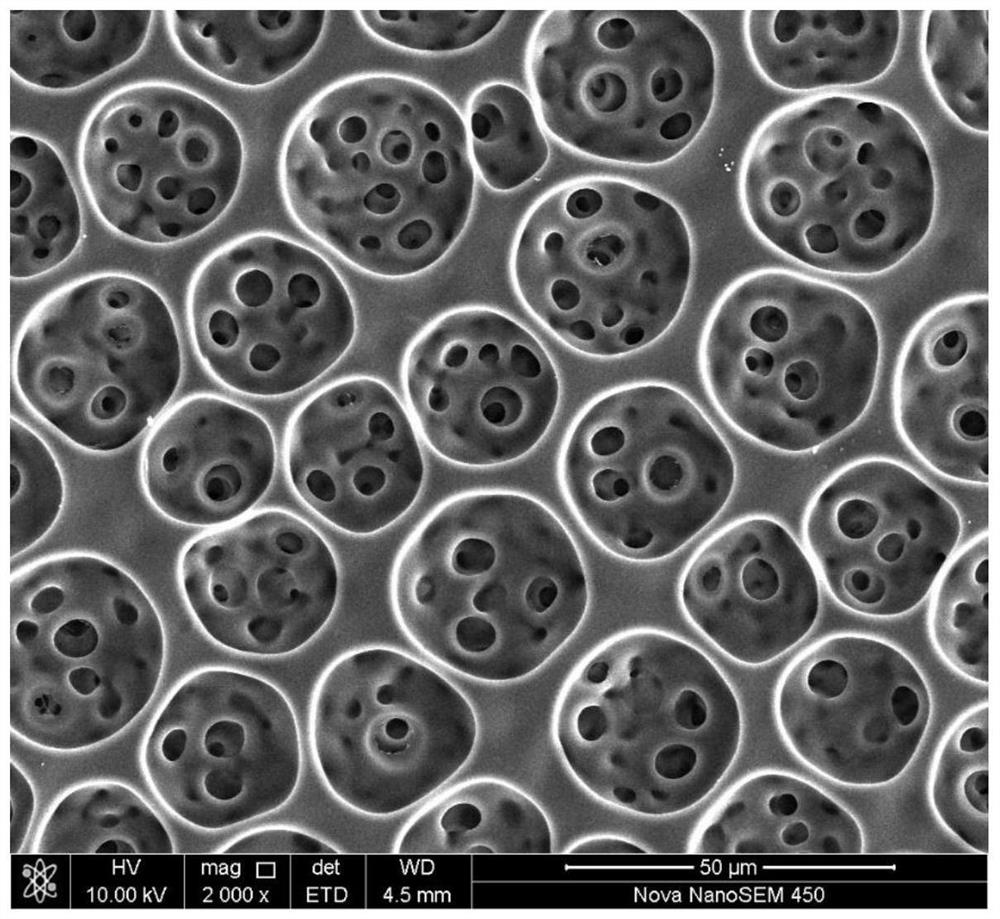

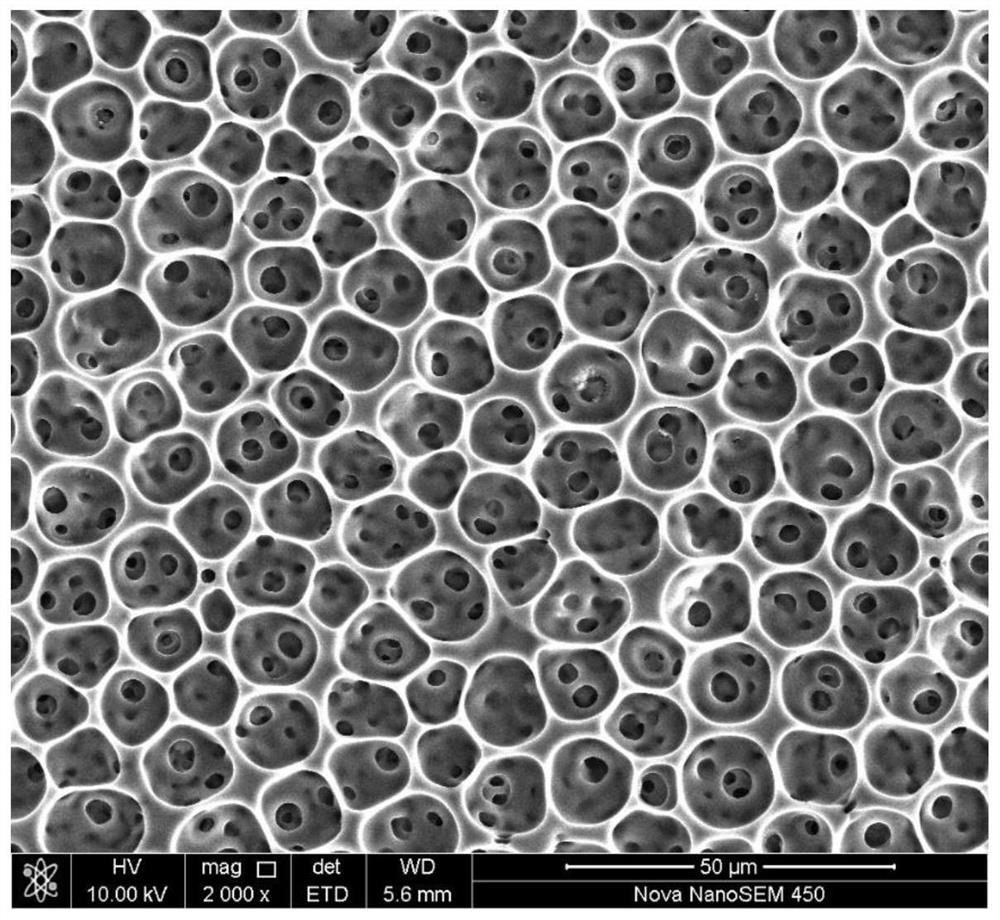

Preparation method for polyurethane nano zinc oxide super-hydrophobic coating

A nano-zinc oxide, super-hydrophobic coating technology, applied in polyurea/polyurethane coatings, coatings, devices for coating liquids on surfaces, etc. Loss of super-hydrophobic properties and other problems, to achieve the effects of uniform and controllable coating thickness, low equipment requirements, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

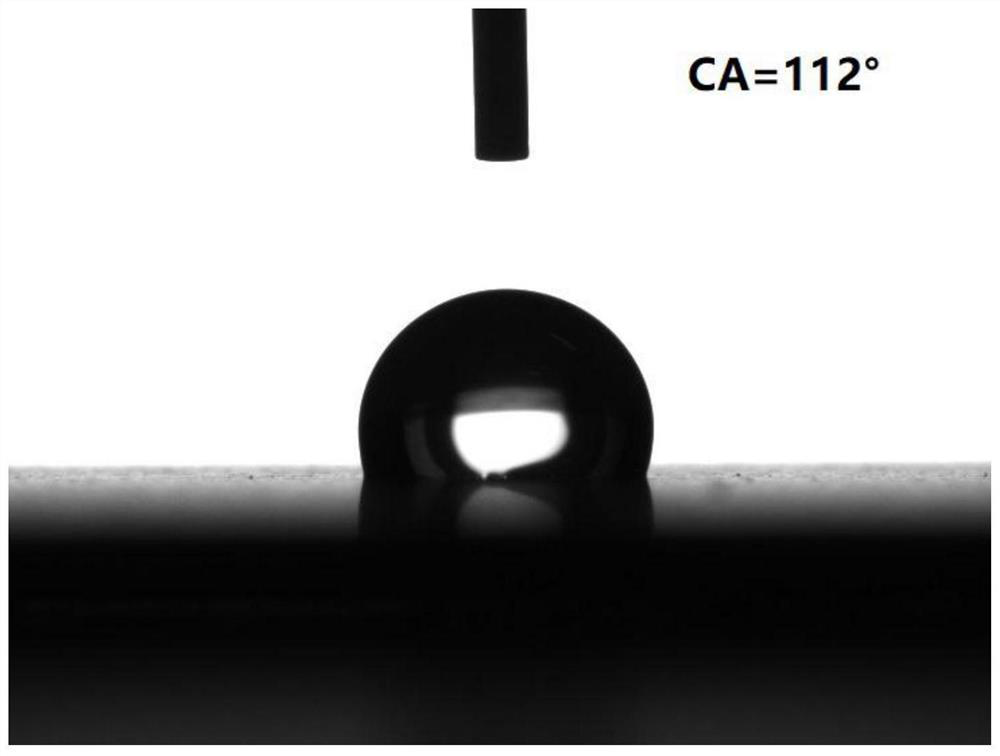

Embodiment 1

[0030] The operation of this example is basically the same as that of the comparative example, except that the mixed solution is mixed with 10wt% nano-zinc oxide mixed solution, so that the obtained coating has a thickness of 150 μm and a static surface contact angle of 160°.

Embodiment 2

[0032] The operation of this example is basically the same as that of Example 1, except that the sandpaper used in the substrate pretreatment is 1500 mesh, and the polyurethane elastomer is dissolved by mechanical stirring in the mixed solution configuration, and the thickness of the coated liquid layer is 300 μm. Dithiol ethanol solution was used for hydrophobic modification, and the thickness of the obtained coating was 100 μm, and the static contact angle of the surface was 162°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com