Honeycomb metal-organic framework nanosheet and preparation method thereof

A technology of metal-organic frameworks and nanosheets, applied in the field of materials, can solve the problems of low activity of active sites, few active sites, and limited ability to capture molecules, and achieve good controllability and repeatability, many surface sites, The effect of improving the ability to capture molecules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

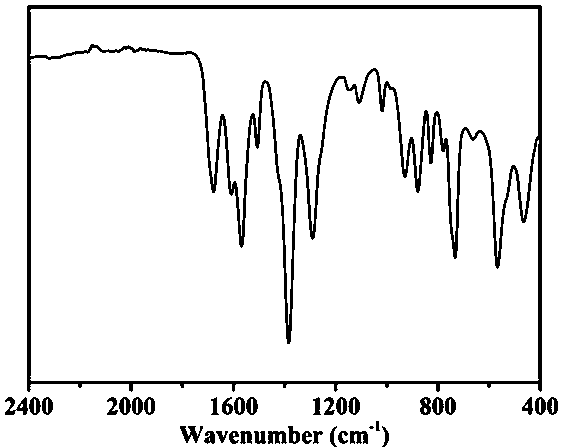

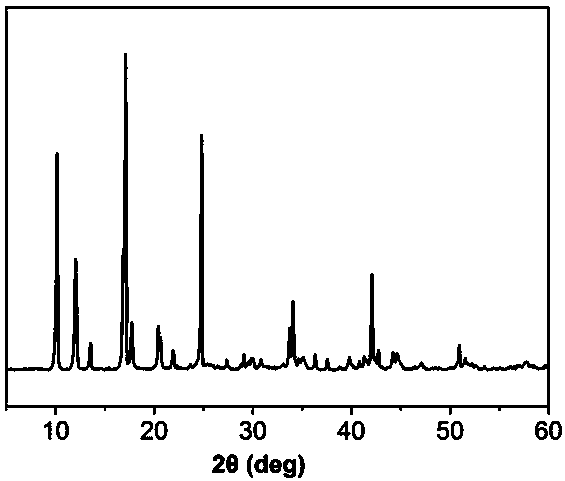

Method used

Image

Examples

Embodiment 1

[0022] First, add 84 μL of ethanolamine to 1L of 0.004mol / L copper nitrate trihydrate solution, heat treatment at 60°C for 0.5h in an oven, and then use a 0.2μm organic filter membrane for suction filtration to generate copper hydroxide crystals on the filter membrane. Then soak the filter membrane with copper hydroxide crystals in 50mL containing 0.4g / L 1,4-terephthalic acid and 10μL H 2 The reaction was carried out in DMF solution of O for 6 h, then the filter membrane was taken out and placed in an oven at 120 °C for vacuum drying for 6 h to obtain honeycomb-like metal-organic framework nanosheets.

Embodiment 2

[0024] First, add 84 μL of ethanolamine to 1L of 0.004mol / L copper nitrate trihydrate solution, heat treatment at 60°C for 0.5h in an oven, and then use a 0.2μm organic filter membrane for suction filtration to generate copper hydroxide crystals on the filter membrane. Then soak the filter membrane with copper hydroxide crystals in 50mL containing 0.4g / L 1,4-terephthalic acid and 20μL H 2 The reaction was carried out in DMF solution of O for 6 h, then the filter membrane was taken out and placed in an oven at 120 °C for vacuum drying for 6 h to obtain honeycomb-like metal-organic framework nanosheets.

Embodiment 3

[0026] First, add 84 μL of ethanolamine to 1L of 0.004mol / L copper nitrate trihydrate solution, heat treatment at 60°C for 0.5h in an oven, and then use a 0.2μm organic filter membrane for suction filtration to generate copper hydroxide crystals on the filter membrane. Then soak the filter membrane with copper hydroxide crystals in 50mL containing 2.0g / L 1,4-terephthalic acid and 10μL H 2 The reaction was carried out in DMF solution of O for 6 h, then the filter membrane was taken out and placed in an oven at 120 °C for vacuum drying for 6 h to obtain honeycomb-like metal-organic framework nanosheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com