Method for in-situ preparation of nano-silver/carboxylated chitosan composite films by using electric deposition technology

A carboxylated chitosan, in-situ preparation technology, applied in the field of materials, can solve the problems of application influence and low solubility, and achieve the effect of simple equipment, low cost and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

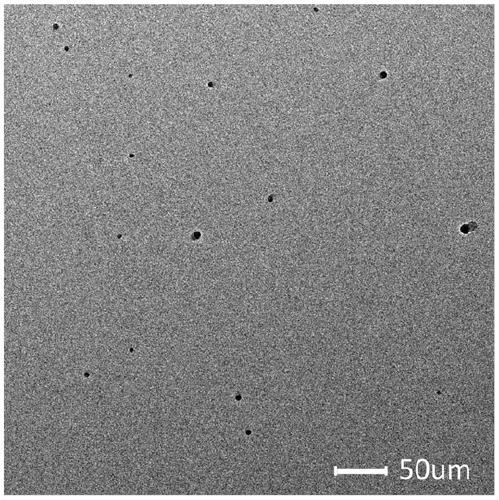

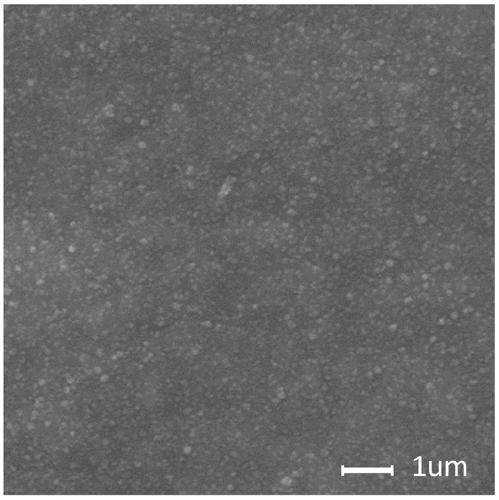

Image

Examples

Embodiment 1

[0029] 1) Preparation of carboxylated chitosan solution: first weigh 1g of carboxylated chitosan solid particle sample, add it to a beaker and then add 100mL of distilled water, stir at room temperature using a magnetic stirrer for 3 hours until carboxylated chitosan The polysaccharide solid particles are fully dissolved, and then the prepared carboxylated chitosan solution is filtered once to obtain a carboxylated chitosan solution with a mass percentage concentration of 1.0%, which is set aside;

[0030] 2) Prepare the metal electrode material: use metal silver sheet as the anode electrode material for electrodeposition, first make the metal silver sheet electrode into the required size and shape, and then repeatedly polish the metal silver sheet with sandpaper until the surface of the silver sheet is smooth and flat, Then silver sheet is immersed in acetone, dehydrated alcohol and distilled water successively, make it ultrasonically clean respectively 3 minutes (ultrasonic p...

Embodiment 2

[0033] 1) Preparation of carboxylated chitosan solution: first weigh 3 g of carboxylated chitosan solid particle samples, add it to a beaker, then add 100 mL of distilled water, and stir for 9 hours at room temperature using a magnetic stirrer until carboxylated chitosan The polysaccharide solid particles are fully dissolved, and then the prepared carboxylated chitosan solution is filtered 3 times to obtain a carboxylated chitosan solution with a mass percentage concentration of 3.0%, which is set aside;

[0034] 2) Prepare the metal electrode material: use metal silver sheet as the anode electrode material for electrodeposition, first make the metal silver sheet electrode into the required size and shape, and then repeatedly polish the metal silver sheet with sandpaper until the surface of the silver sheet is smooth and flat, Then silver sheet is immersed in acetone, dehydrated alcohol and distilled water successively, make it ultrasonically clean respectively 6 minutes (60 wa...

Embodiment 3

[0037] 1) Preparation of carboxylated chitosan solution: first weigh 1.5g of carboxylated chitosan solid particle sample, add it to a beaker and then add 300mL of distilled water, stir with a magnetic stirrer at room temperature for 6 hours until carboxylated The chitosan solid particles are fully dissolved, and then the prepared carboxylated chitosan solution is filtered twice to obtain a carboxylated chitosan solution with a mass percentage concentration of 2.0%, which is set aside;

[0038] 2) Prepare the metal electrode material: use metal silver sheet as the anode electrode material for electrodeposition, first make the metal silver sheet electrode into the required size and shape, and then repeatedly polish the metal silver sheet with sandpaper until the surface of the silver sheet is smooth and flat, Then silver sheet is immersed in acetone, dehydrated alcohol and distilled water successively, make it ultrasonic cleaning 5 minutes respectively (ultrasonic power 50 watts)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com