Patents

Literature

109results about How to "Be selective" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

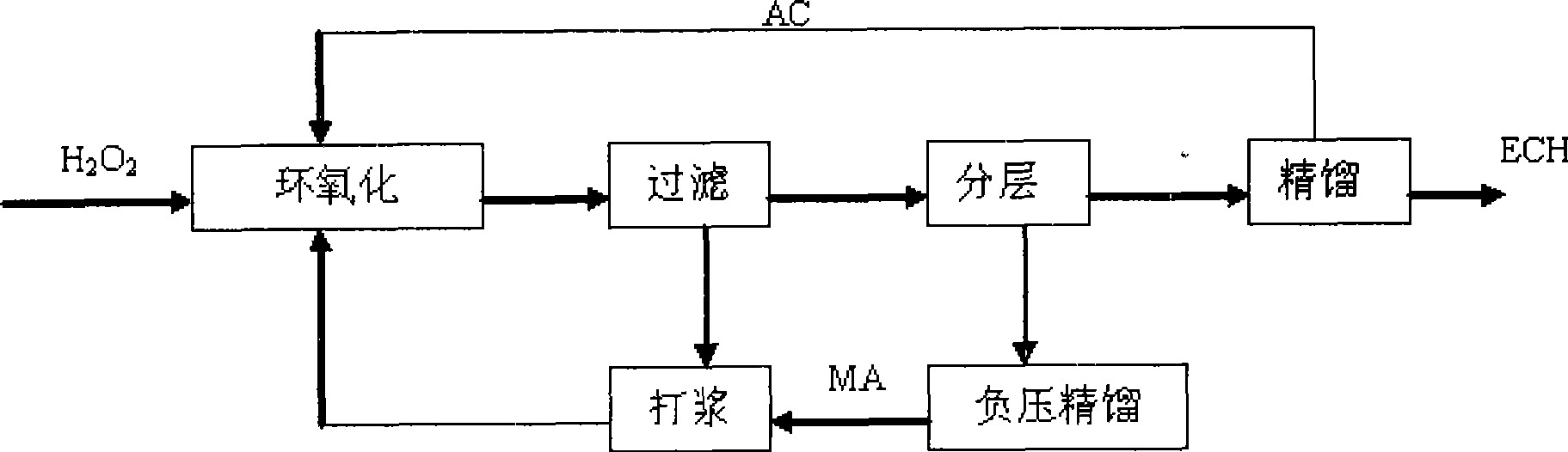

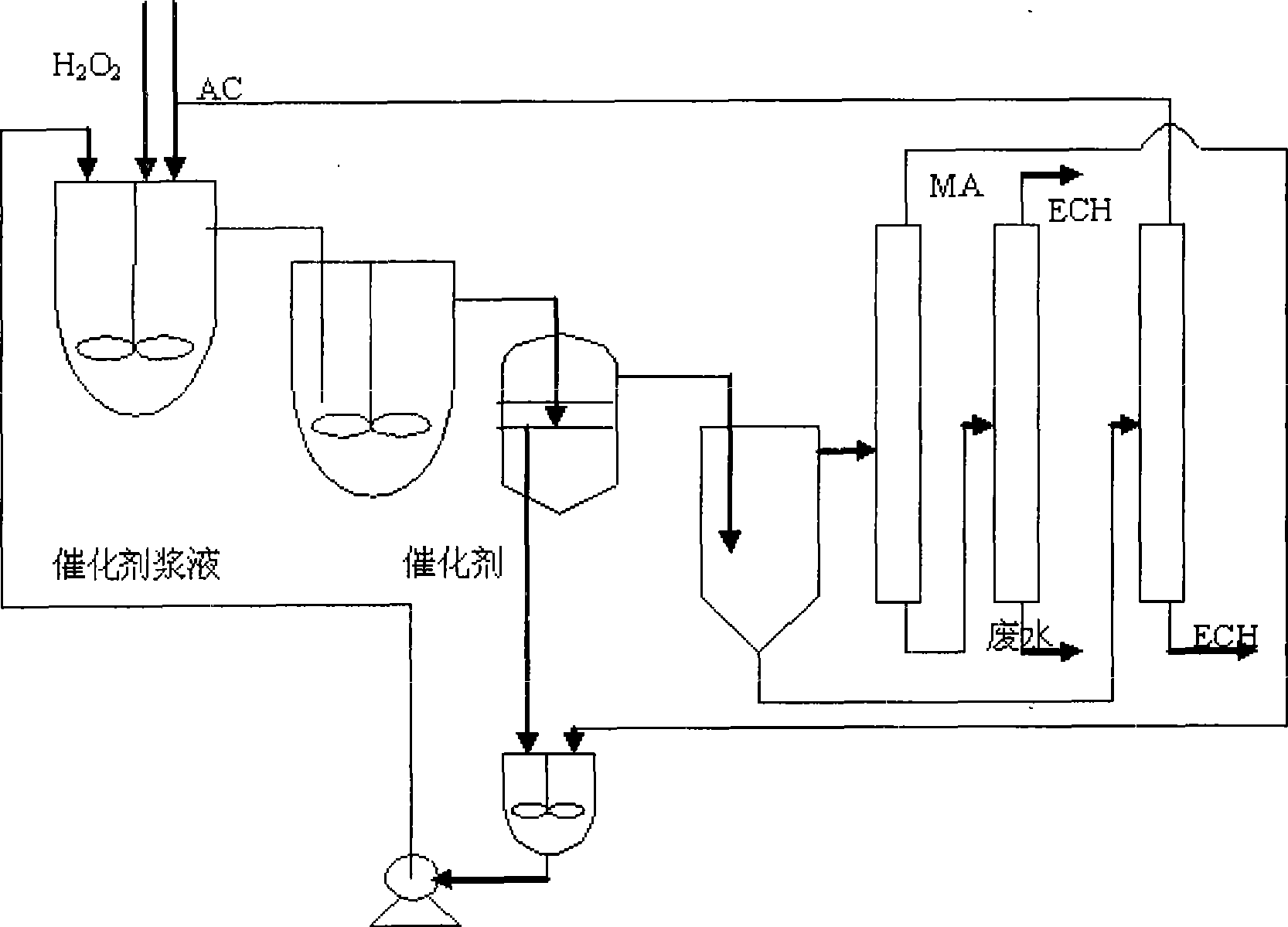

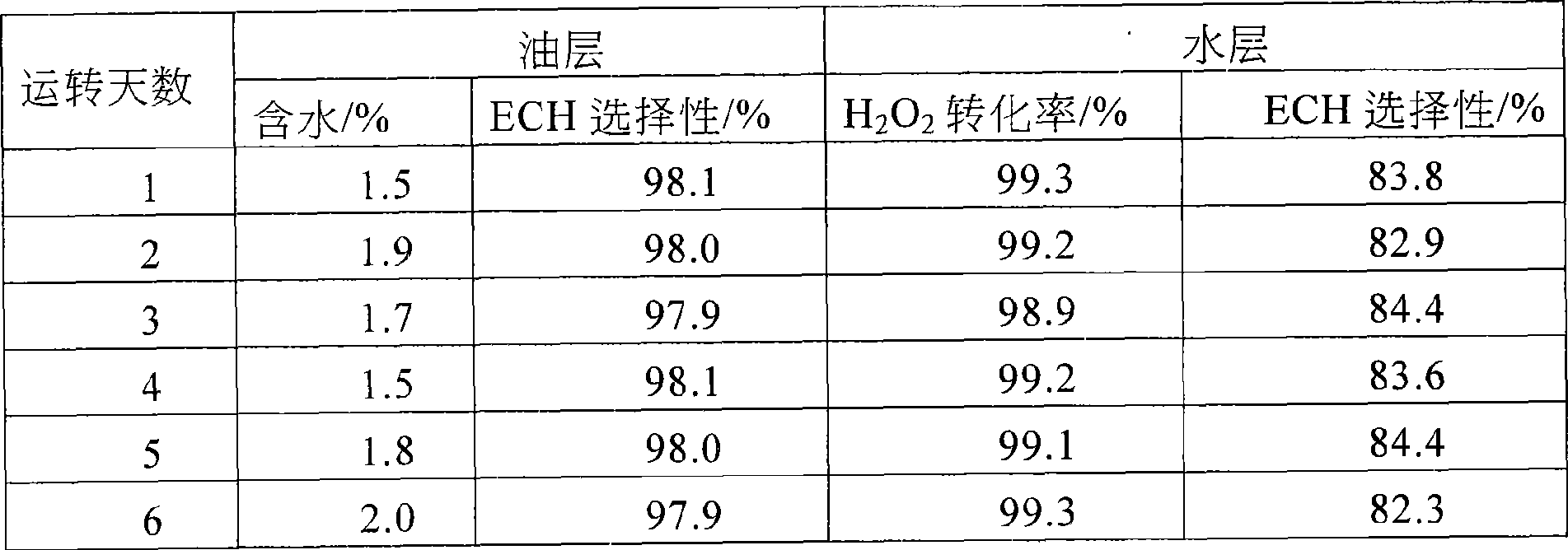

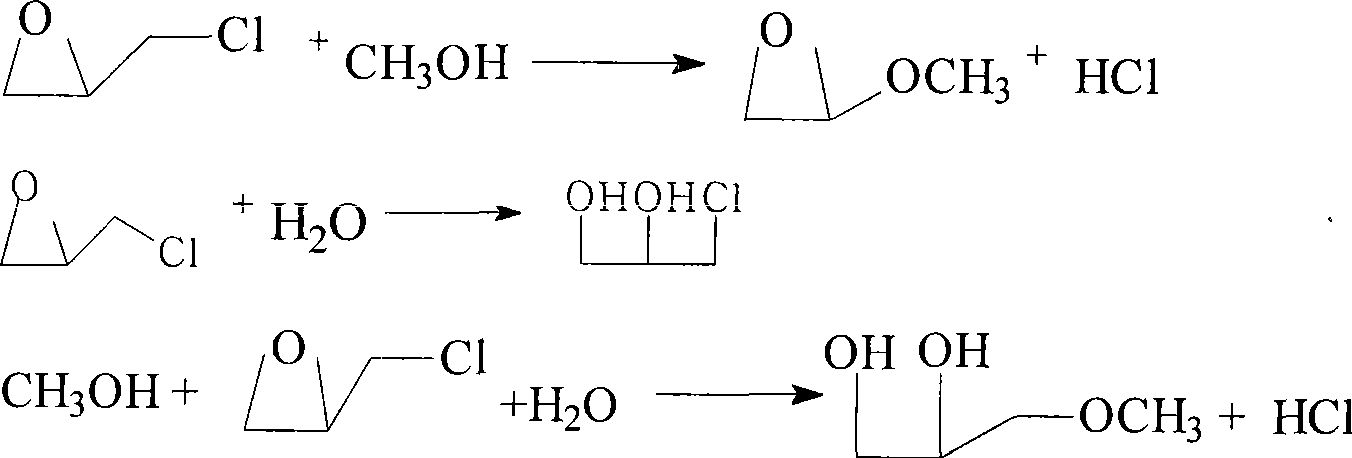

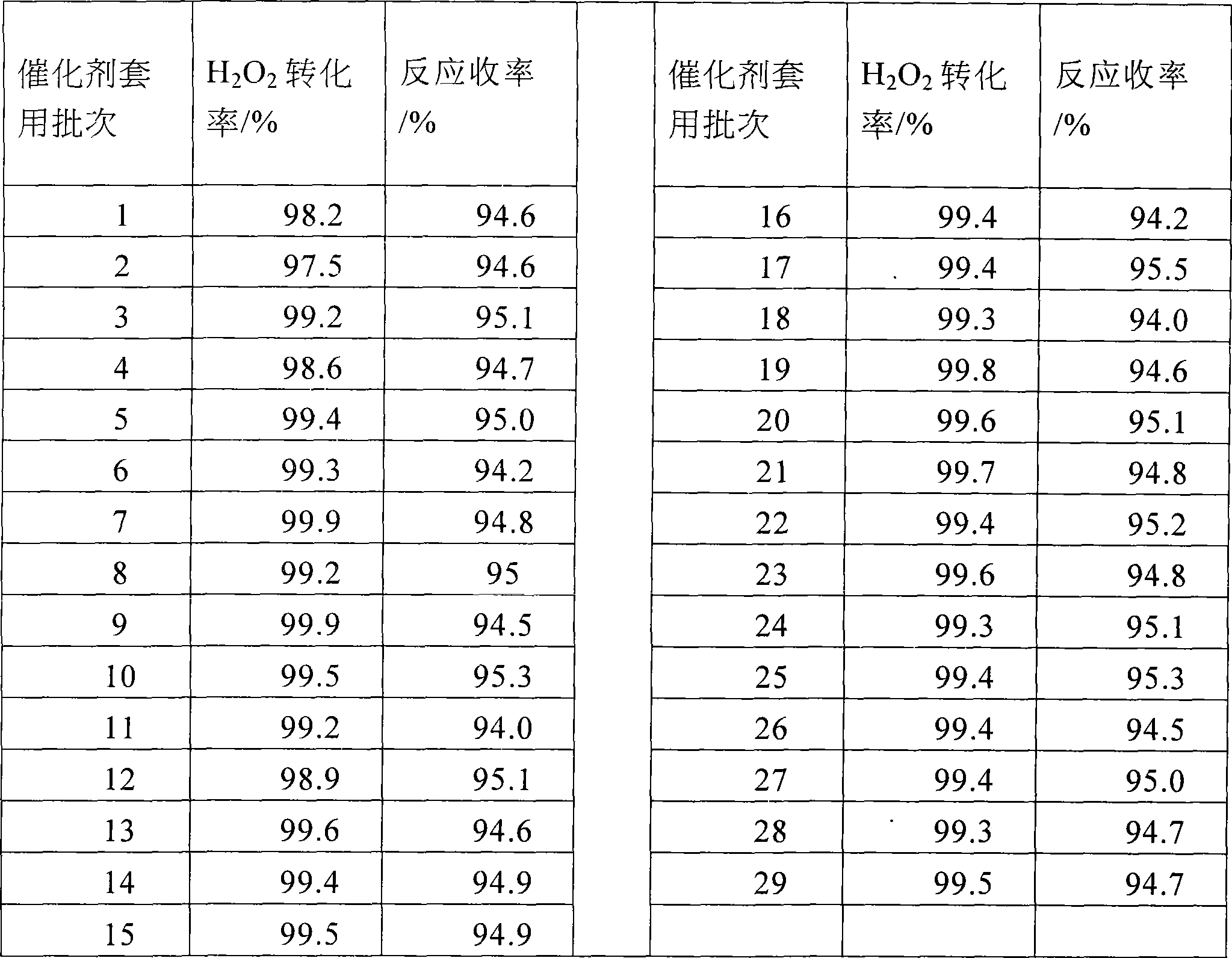

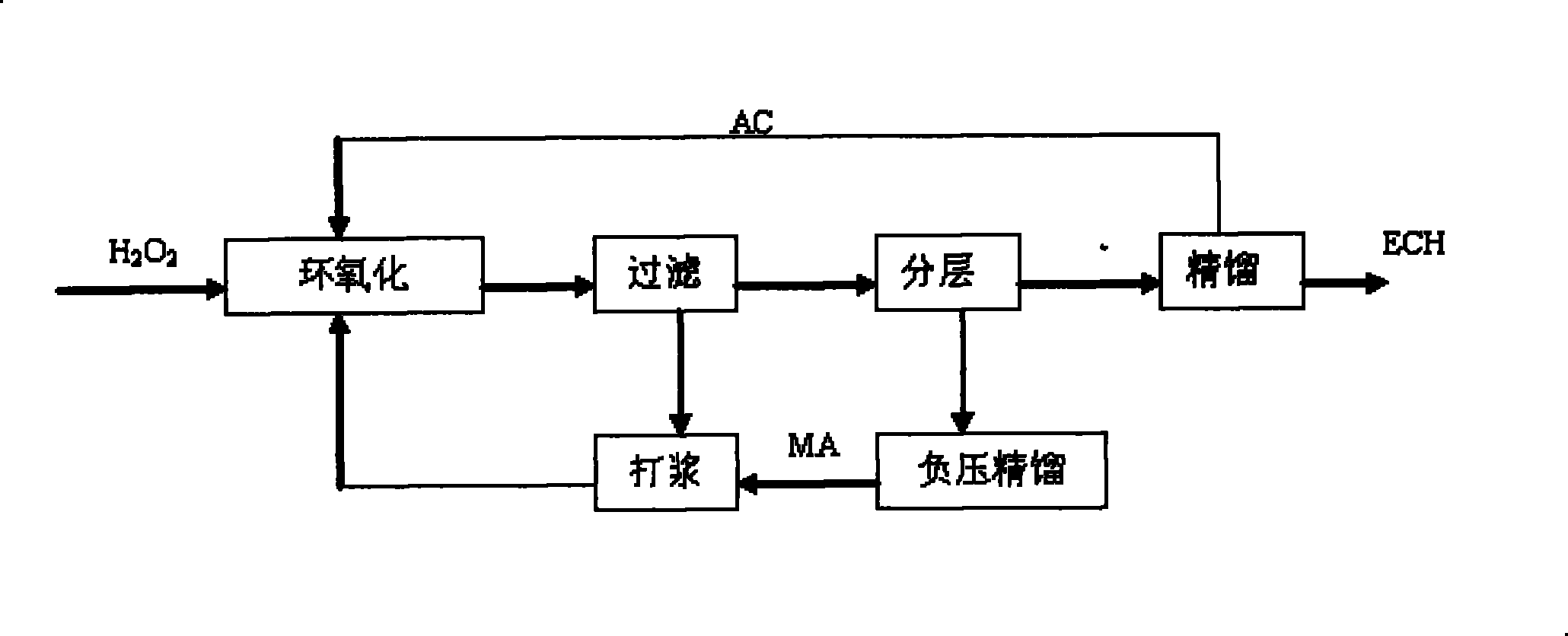

Continuous production method of epoxy chloropropane by hydrogen peroxide process

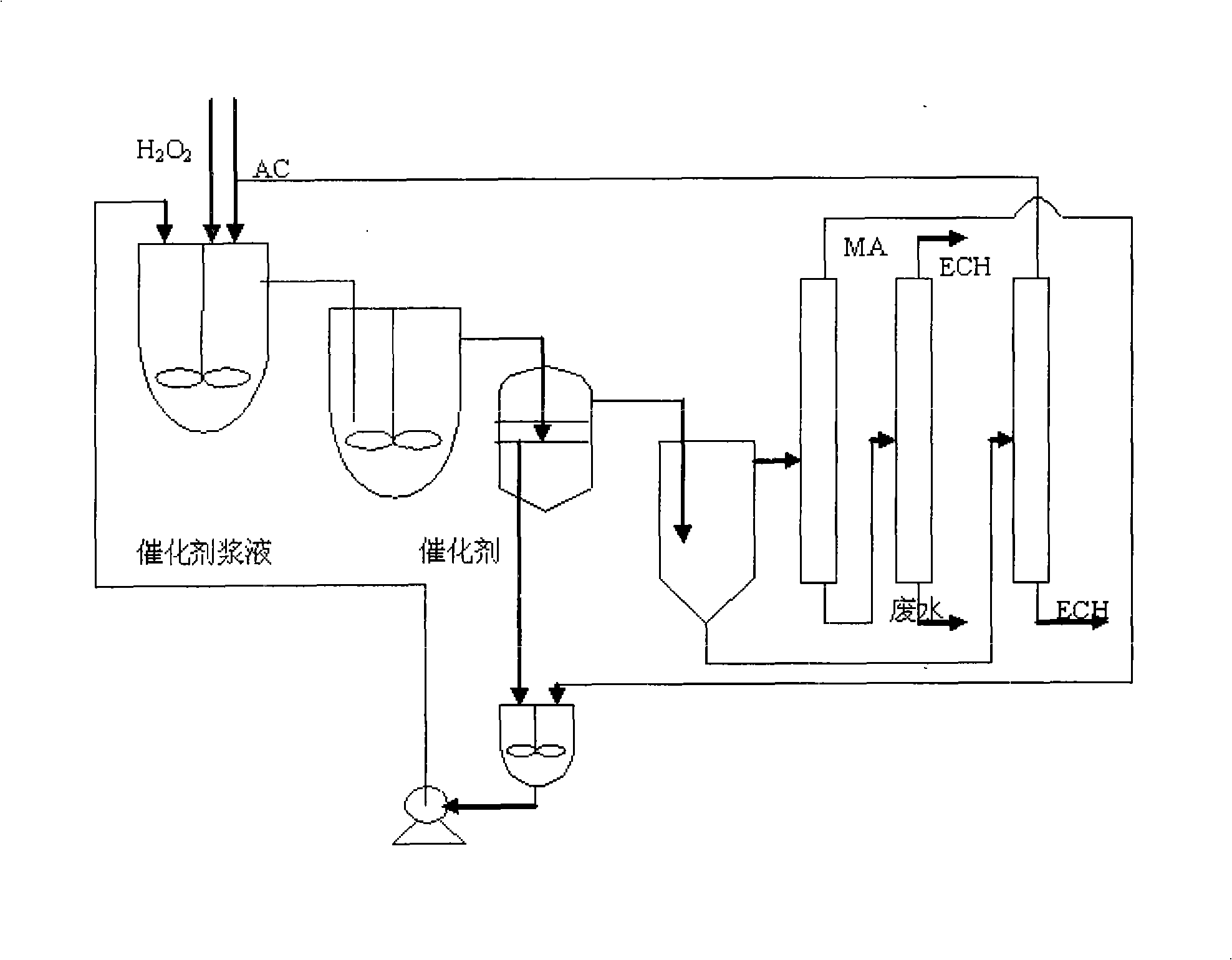

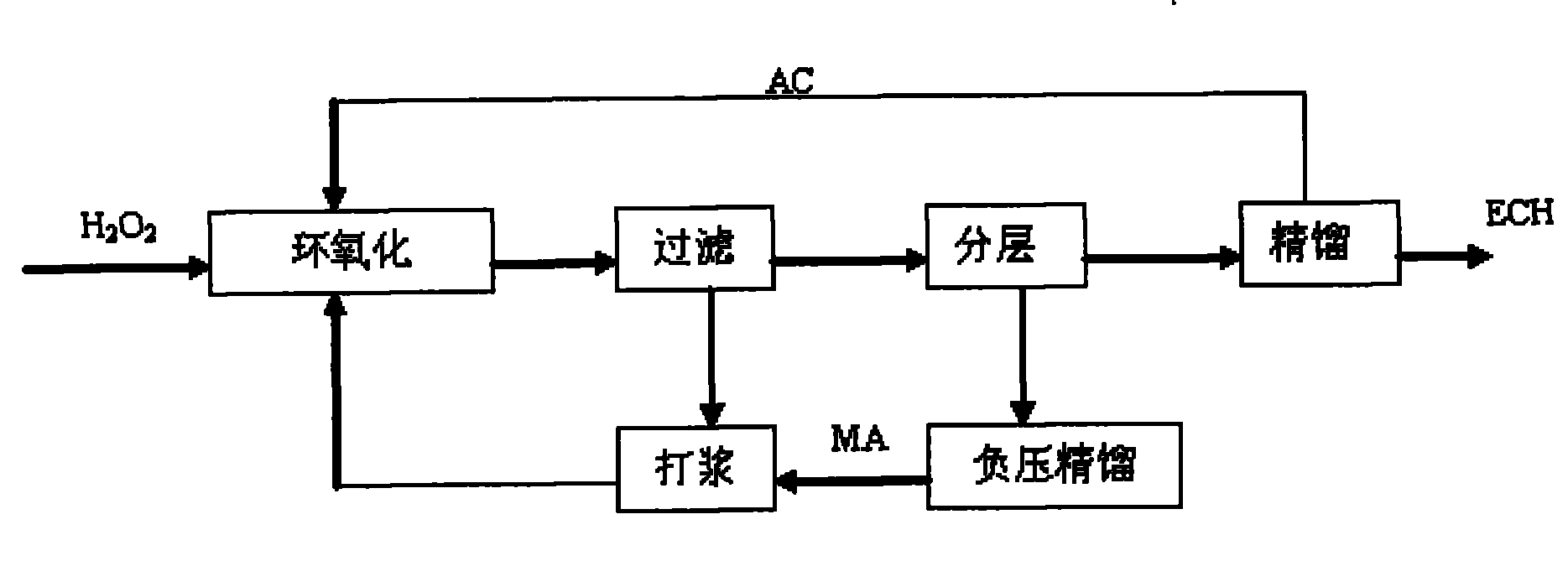

The invention provides a preparation method of chloroepoxy propane by chloropropene epoxidation. Chloropropene, a solvent and titanium silicalite molecular sieve catalyst fine particles are put in a reaction kettle for reaction at the temperature of 10-80 DEG C. The method is characterized in that the reaction kettle is a single kettle or multistage slurry bed reaction kettles with same or different volumes which are connected in series; the reaction solution needs not to be homogeneous phase, slurry particles of the chloropropene, the solvent and the titanium silicalite molecular sieve catalyst are added to a first stage reaction kettle by a metering pump, hydrogen peroxide is dropwise added to the first stage reaction kettle or each stage of the reaction kettles, the reaction occurs in a weakly acidic condition, materials are subject to oil-water delamination after the reaction to be divided into oil-phase slurry and water-phase slurry; the catalyst is suspended in the water phase, and the oil phase is sent to a rectification tower to separate the chloropropene, the epichlorohydrin and trace methanol; the water phase slurry is filtered, a catalyst filter cake or concentrated slurry is directly beaten by the solvent, and pumped to a first stage epoxidation reaction kettle, the water phase slurry contains the methanol, trace epichlorohydrin and the water which is generated by the reaction and the water which is taken by the hydrogen peroxide, the trace methanol and the epichlorohydrin are separated out by negative pressure rectification, and the recovered methanol is used for preparation of the catalyst slurry. The method has the advantages of simple process, little solvent consumption and high product separation yield, and is available for industrialized production.

Owner:JIANGSU YANGNONG CHEM GROUP +2

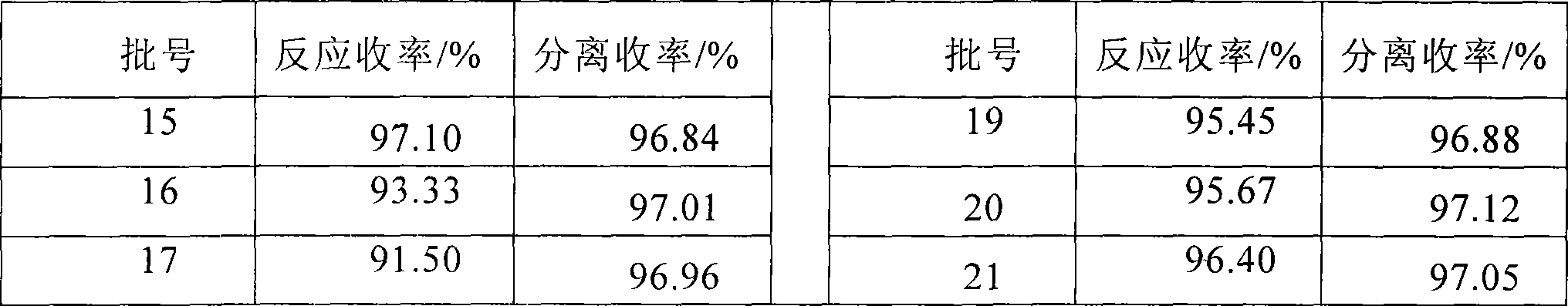

Production method of epoxy chloropropane by hydrogen peroxide method

The invention discloses a method for preparing epoxy chloropropane with the oxidation of chloropropene. The chloropropene, a solvent and fine particles of titanium silicate molecular sieve catalyst are put into a reaction pot and a hydrogen dioxide solution is added at 10 DEG C to 80 DEG C. The method is characterized in that a reaction is carried out under a subacidity condition and after the reaction, materials pass through an intermediate tank for oil-water dissociation to be divided into oil phase and water phase; the oil phase is sent into a rectifying tower for separating the chloropropene and ECH. After the water phase is filtered, a catalyst filter cake is washed by the solvent, regenerated or applied to an epoxidation reaction after being directly beat with the solvent. The ECH is extracted from an aqueous layer after filtration by the chloropropene. An extracted oil layer and an oil layer obtained from the separation of a reaction solution are combined and rectified, or the extracted oil layer is applied to the epoxidation reaction; water left from the extraction is rectified for recycling methanol and applied to the preparation of catalysts; and the method has simple procedures, small consumption amount of solvents, high separation yield of reaction products and easy realization of industrialization.

Owner:JIANGSU YANGNONG CHEM GROUP +2

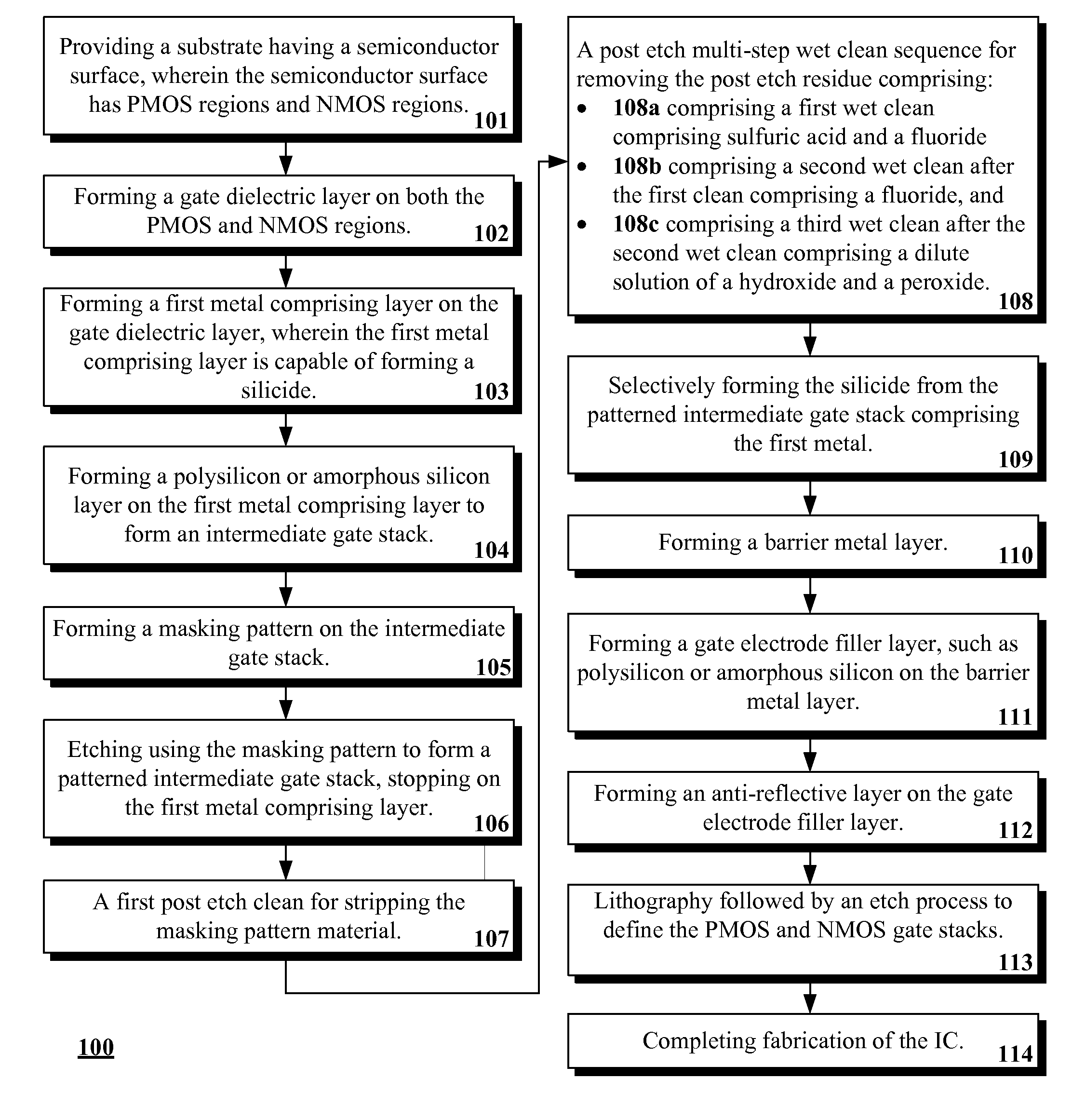

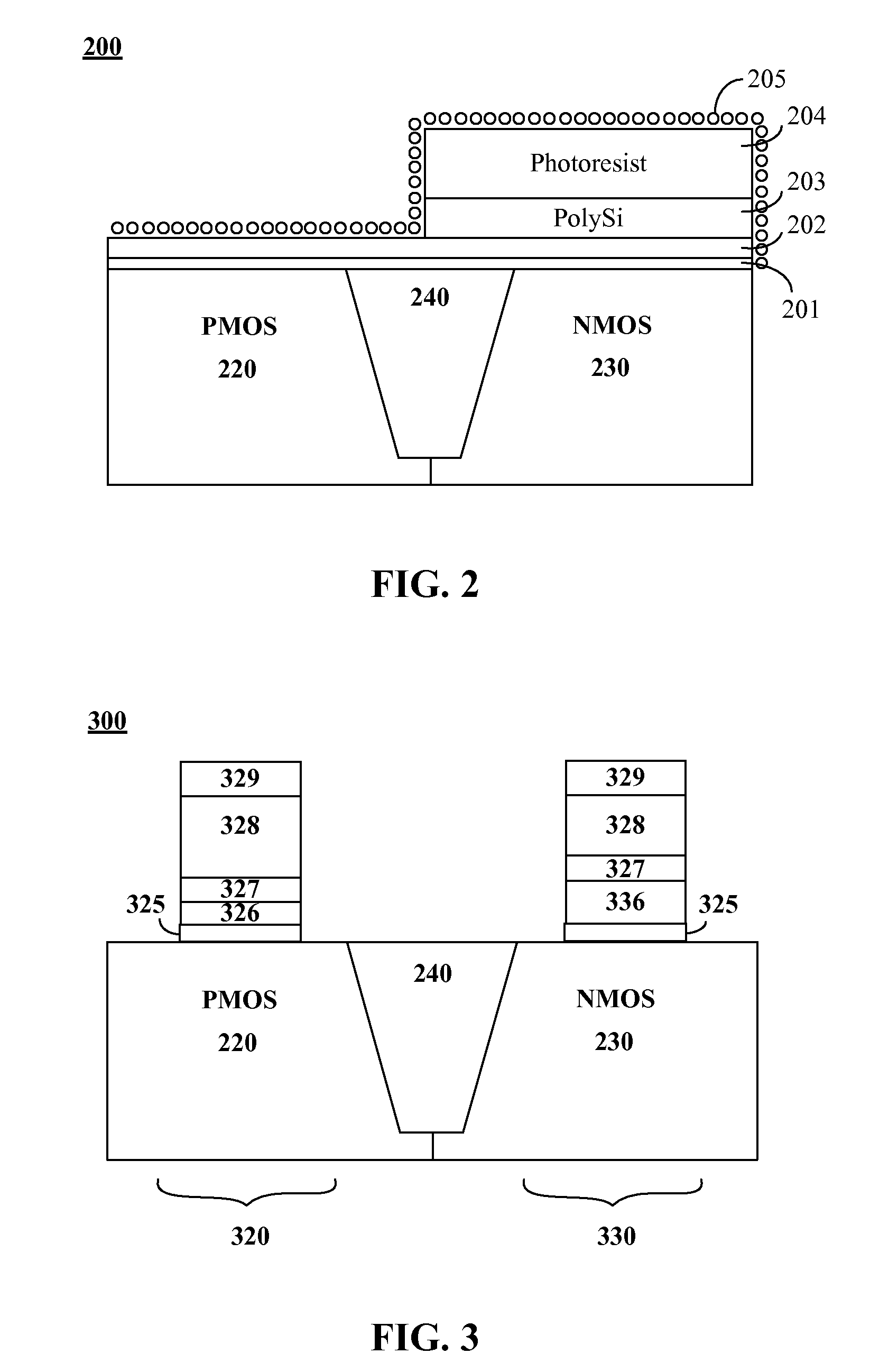

Post metal gate vt adjust etch clean

ActiveUS20100167514A1Reduce residual particleHigh yieldSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricMaterials science

A method for fabricating a CMOS integrated circuit (IC) includes providing a substrate having a semiconductor surface, wherein the semiconductor surface has PMOS regions for PMOS devices and NMOS regions for NMOS devices. A gate dielectric layer is formed on the semiconductor surface followed by forming at least a first metal including layer on the gate dielectric layer. A polysilicon or amorphous silicon layer is formed on the first metal including layer to form an intermediate gate electrode stack. A masking pattern is formed on the intermediate gate electrode stack. The polysilicon or amorphous silicon layer is dry etched using the masking pattern to define a patterned intermediate gate electrode stack over the NMOS or PMOS regions, wherein the dry etching stops on a portion of the first metal comprising layer. The masking pattern is removed using a first post etch clean for stripping the masking pattern. A multi-step solution cleaning sequence is used after the removing step and includes a first wet clean including sulfuric acid and a fluoride, and a second wet clean after the first wet clean including a fluoride. Fabrication of the IC is then completed.

Owner:TEXAS INSTR INC

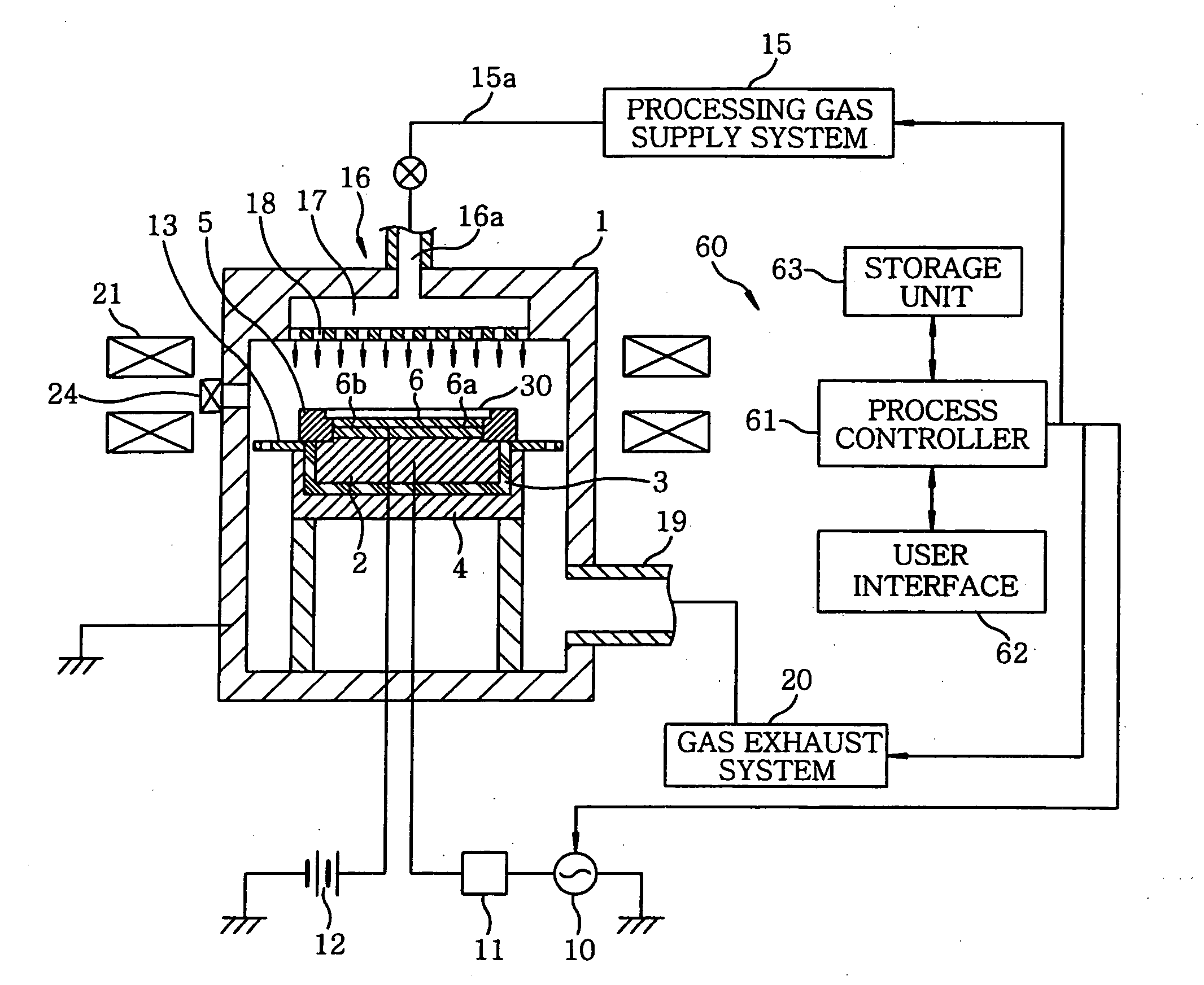

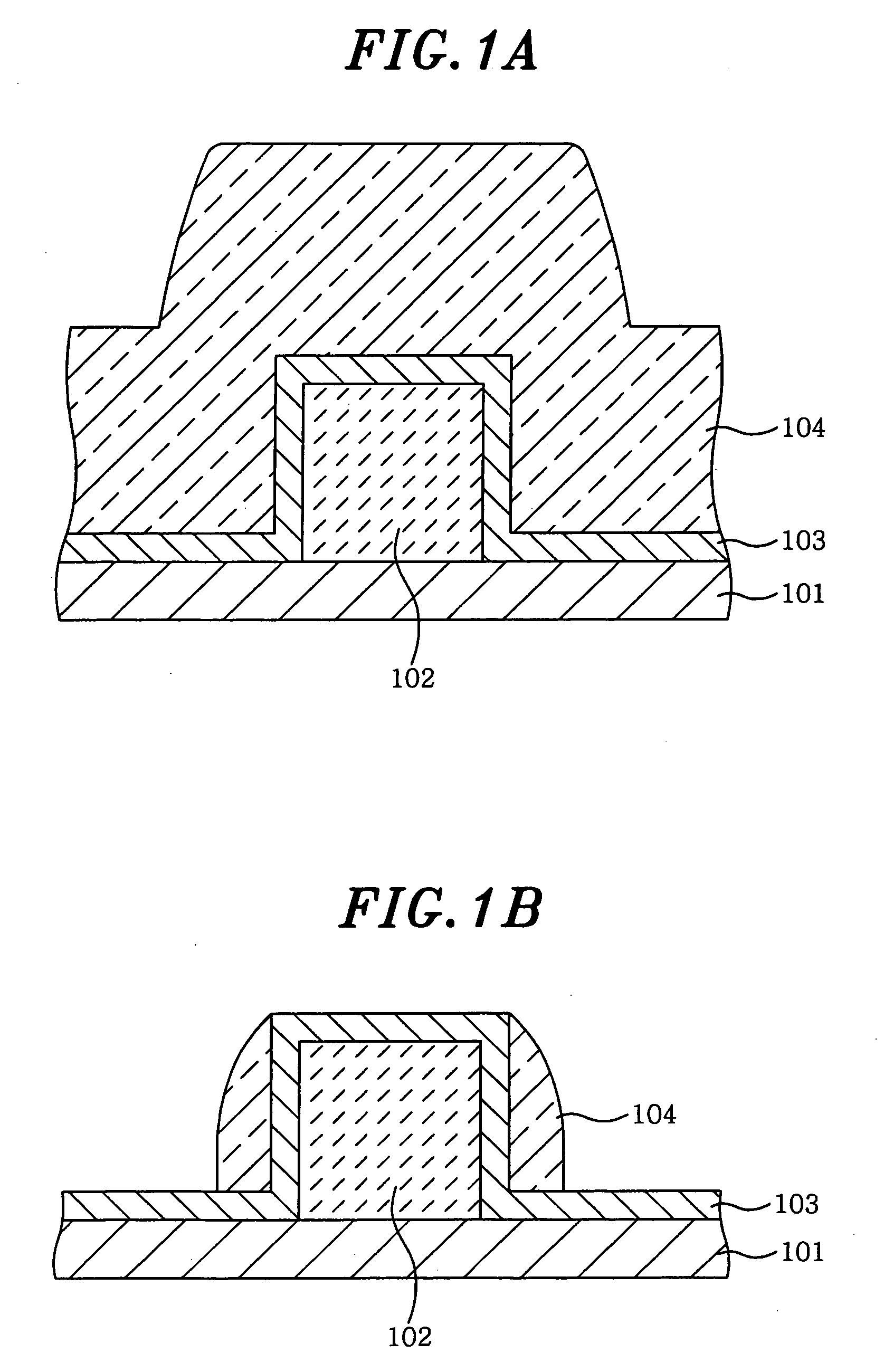

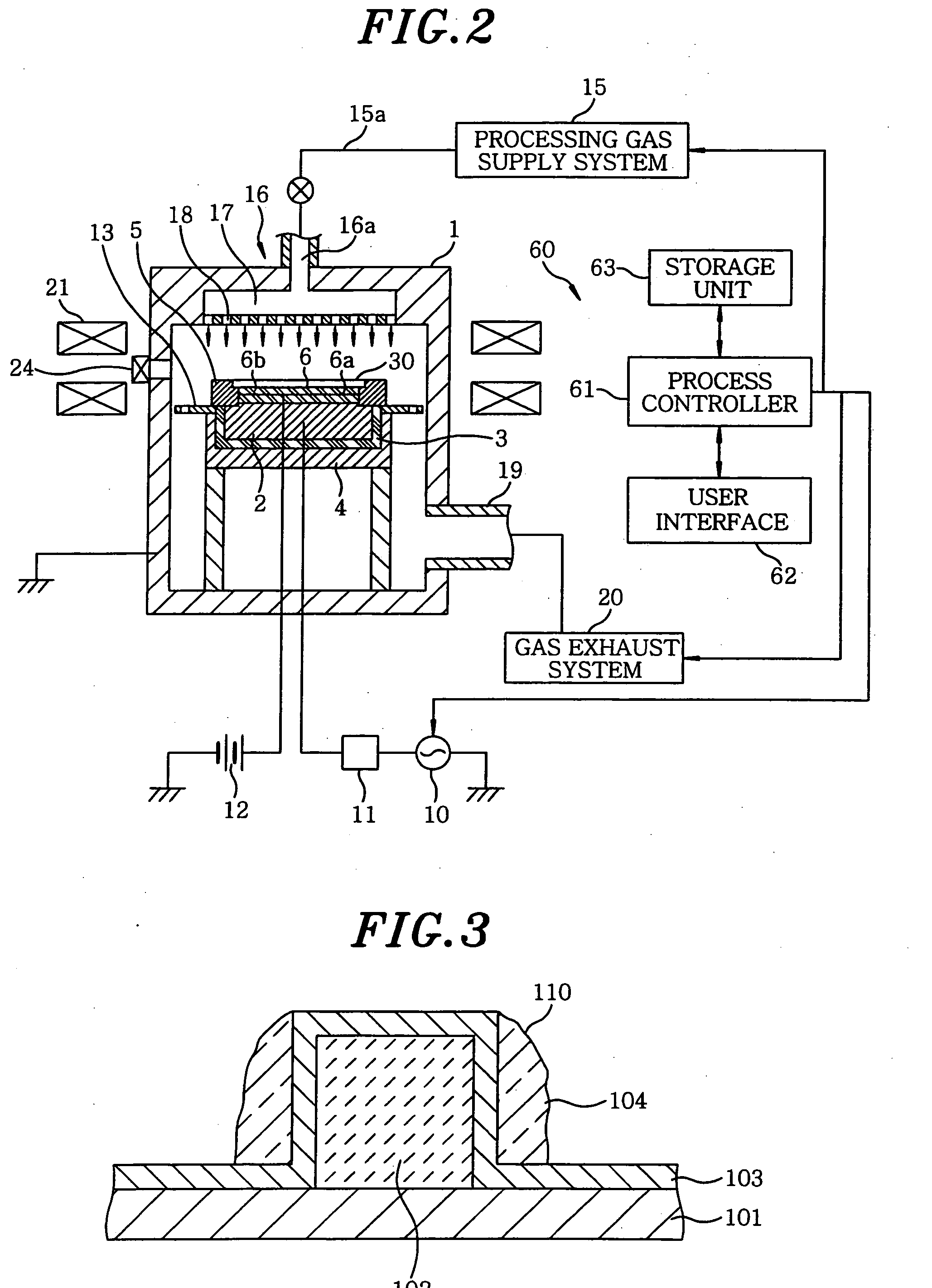

Method and apparatus for manufacturing a semiconductor device, control program thereof and computer-readable storage medium storing the control program

InactiveUS20070105389A1Maintain selectivityAvoid roughnessSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon nitridePlasma etching

A semiconductor device manufacturing method includes a plasma etching process for selectively plasma etching a silicon nitride film against a silicon oxide film formed under the silicon nitride film in a substrate to be processed. The plasma etching process uses an etching gas including a CmFn gas (m, n represent integers of 1 or greater) added to a gaseous mixture of a CHxFy gas (x, y represent integers of 1 or greater) and O2 gas, wherein the flow rate of the CmFn gas is not greater than 10% of that of the O2 gas. The etching gas may further include a rare gas.

Owner:TOKYO ELECTRON LTD

Method for treating aluminium section bar sarface by nano modified powder paint

InactiveCN1458196AWith interface effectSize andLiquid surface applicatorsPowdery paintsNanometreAluminium

The present invention relates to a metal surface treating technology, and is to utilize nano technology and nano material to modify traditional powder paint. Specifically, aluminum section bar surface is treated with nano modified powder paint to raise quality and increase special functions. The nano modified powder paint is prepared through the steps of mixing conventional paint material including resin, curing agent, pigment, assistant and stuffing with nano material, smelting, extruding, cooling, pressing, coarse crushing, grinding, sieving etc. The nano modified powder paint is used to treat aluminum shapes through electrostatic painting.

Owner:ZHONGKE JIEDA TECH INST BEIJING

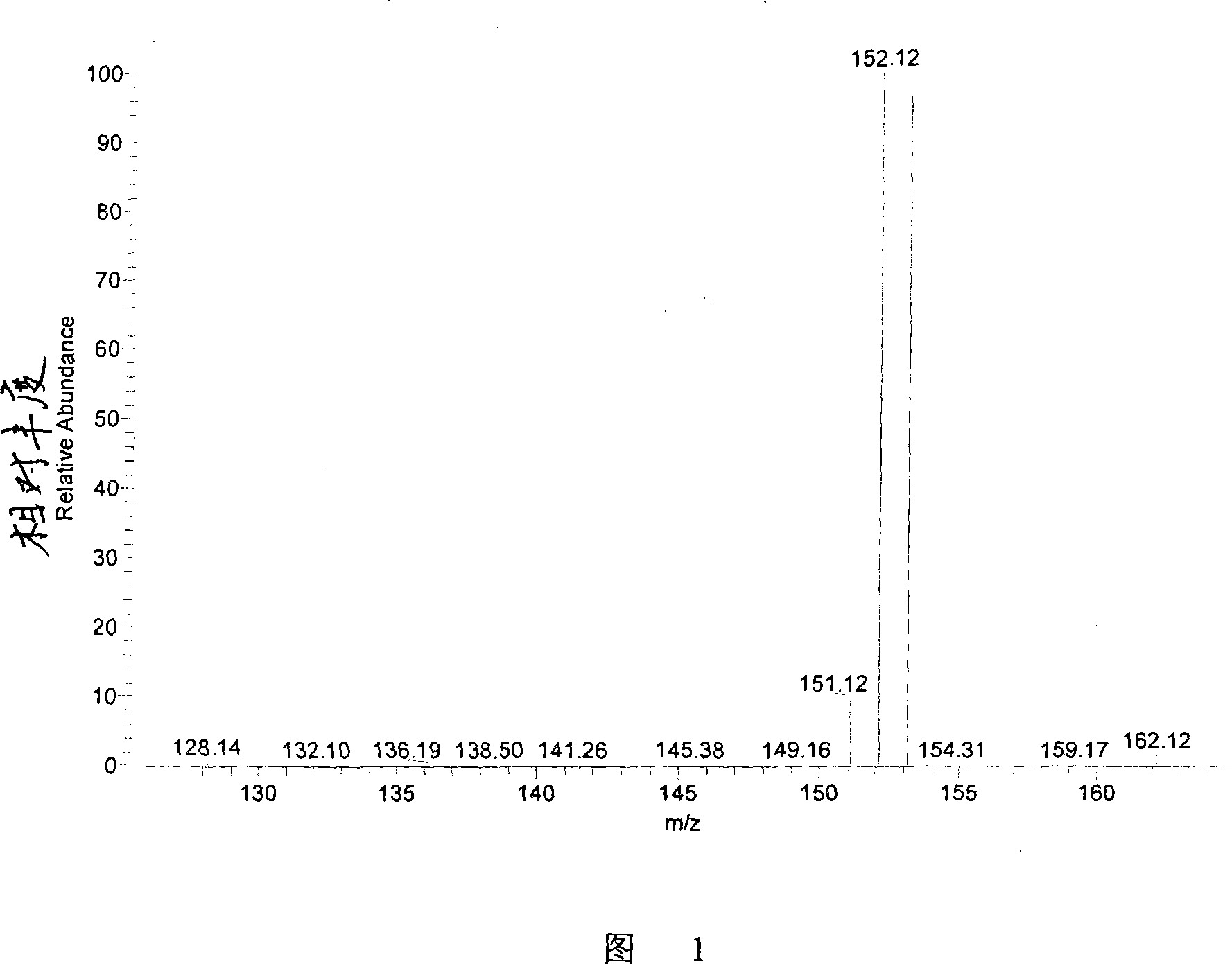

Method for detecting atmosphere granule trace polychlorinated biphenyls by ion trap tandem mass spectrometry

InactiveCN101105477AThe detection method is simpleQuick checkComponent separationWithdrawing sample devicesParticulatesIon trap mass spectrometry

The invention provides a method of detecting the trace polychlorinated biphenyls in atmospheric particulates by ion trap tandem mass spectrometry; the steps of the method comprises sample collection, sample leach, sample concentration and purification and the detection of pilot sample by chromatography-ion trap mass spectrometry; by optimizing the conditional parameters of gas phase chromatography and tandem mass spectrometry, the invention has better selectivity and better sensitivity in the detection of titled compound compared with the conventional detection method; the invention solves the mutual interference between PCBs and multi-chlorine organic compounds in the traditional analysis and detection method by SRM technique of gas phase chromatography / ion trap tandem mass spectrometry (GC / ITMS), and greatly simplifies the fussy steps of purification and separation in sample pretreatment; SRM technique has the advantages of sensitivity, selectivity, low detecting expense and reliable and accurate determination of the nature; therefore, the invention has remarkable advantage compared with the traditional detecting instrument such as GC / ECD,GC / LRMS,GC / HRMS.

Owner:NANJING UNIV

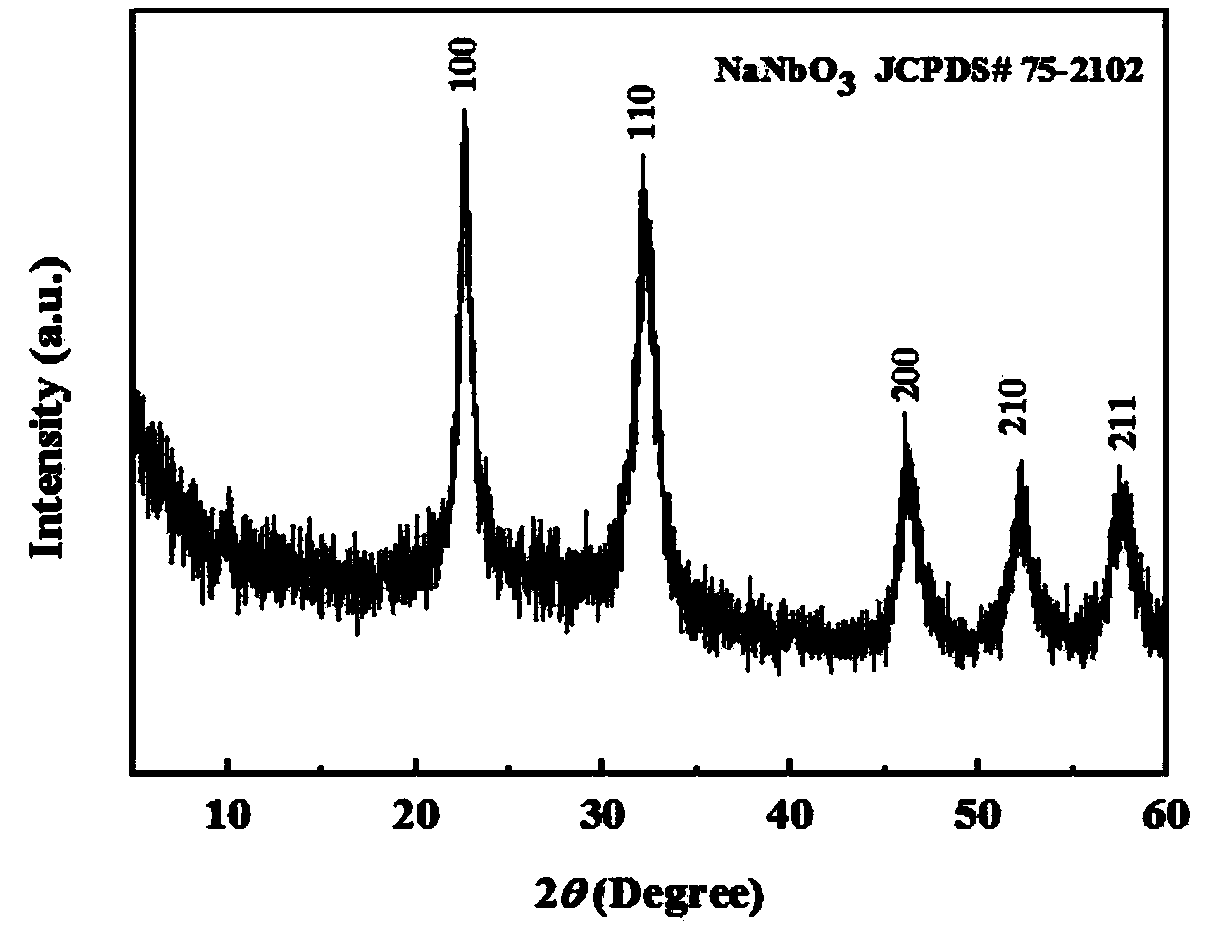

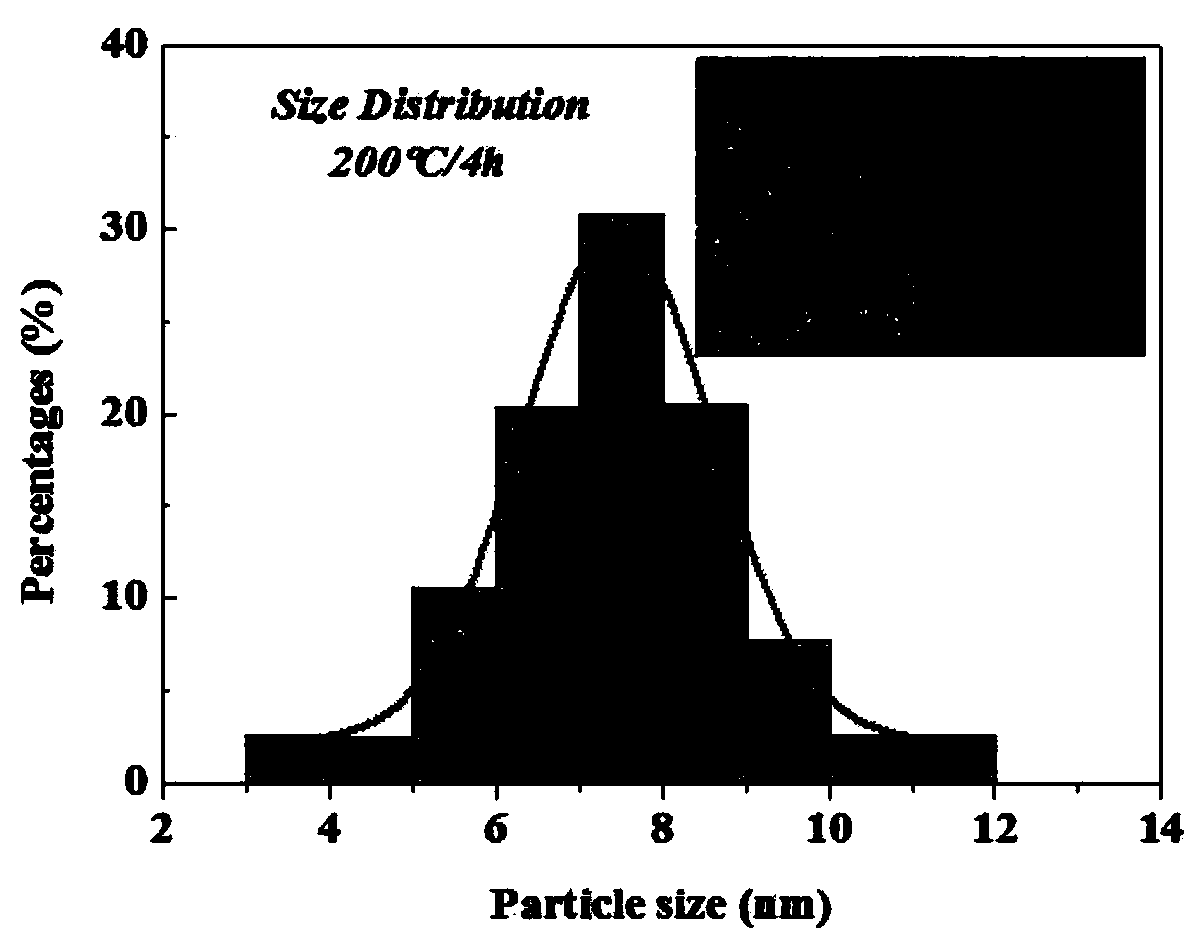

Synthetic method of sodium niobate nanowire

ActiveCN104016408ALow priceSimple processMaterial nanotechnologyNiobium compoundsOrganic solventActive agent

The invention discloses a synthetic method of a sodium niobate nanowire. The synthetic method comprises the following steps: mixing NaOH and an organic solvent, carrying out hydro-thermal reaction, washing, centrifugally separating and drying. According to the synthetic method, used equipment is simple, reaction conditions are mild, the preparation of an intermediate phase precursor and the later annealing treatment are not needed, reaction raw materials are low in price, and expensive surface active agents are not need to be used as templates. The synthetic method has the main characteristics of simple technological process, capability of saving energy sources, low cost, easy control and operation, good repeatability and the like and can be put into industrial production easily, is capable of effectively shortening synthetic time and improving production efficiency and is an ideal environment-friendly synthetic technology.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

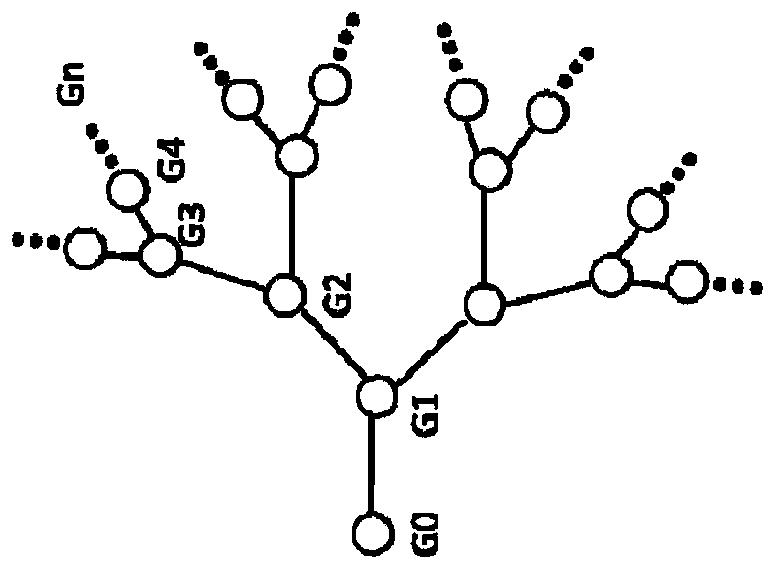

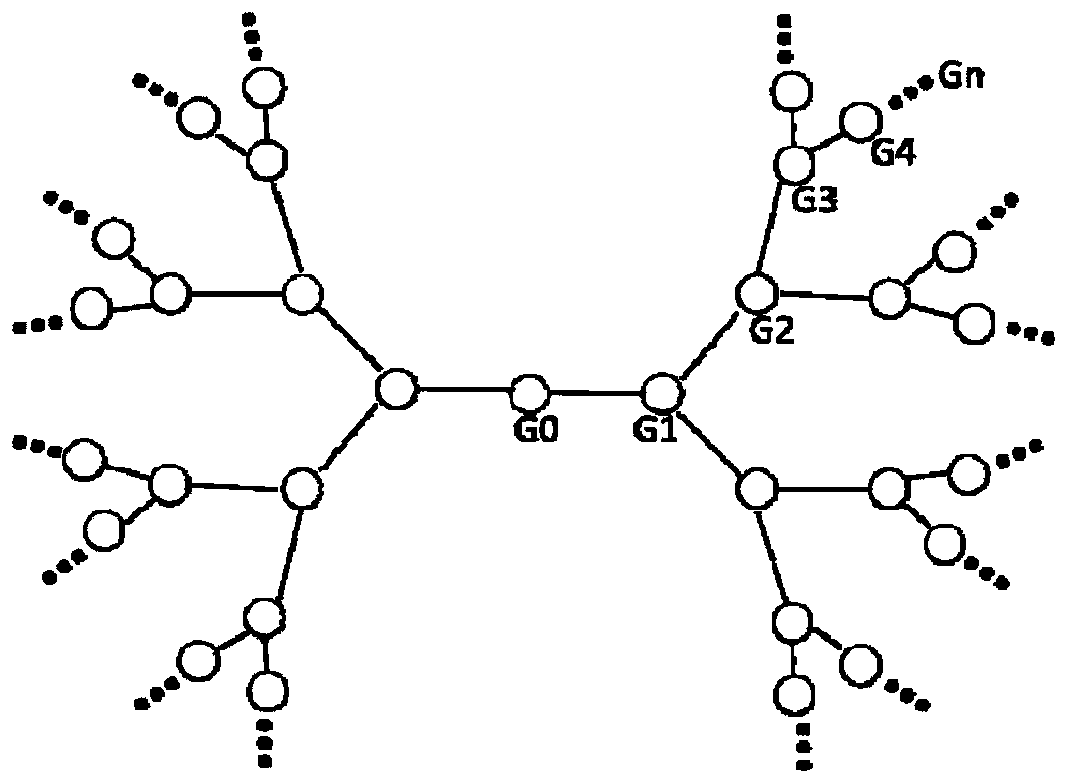

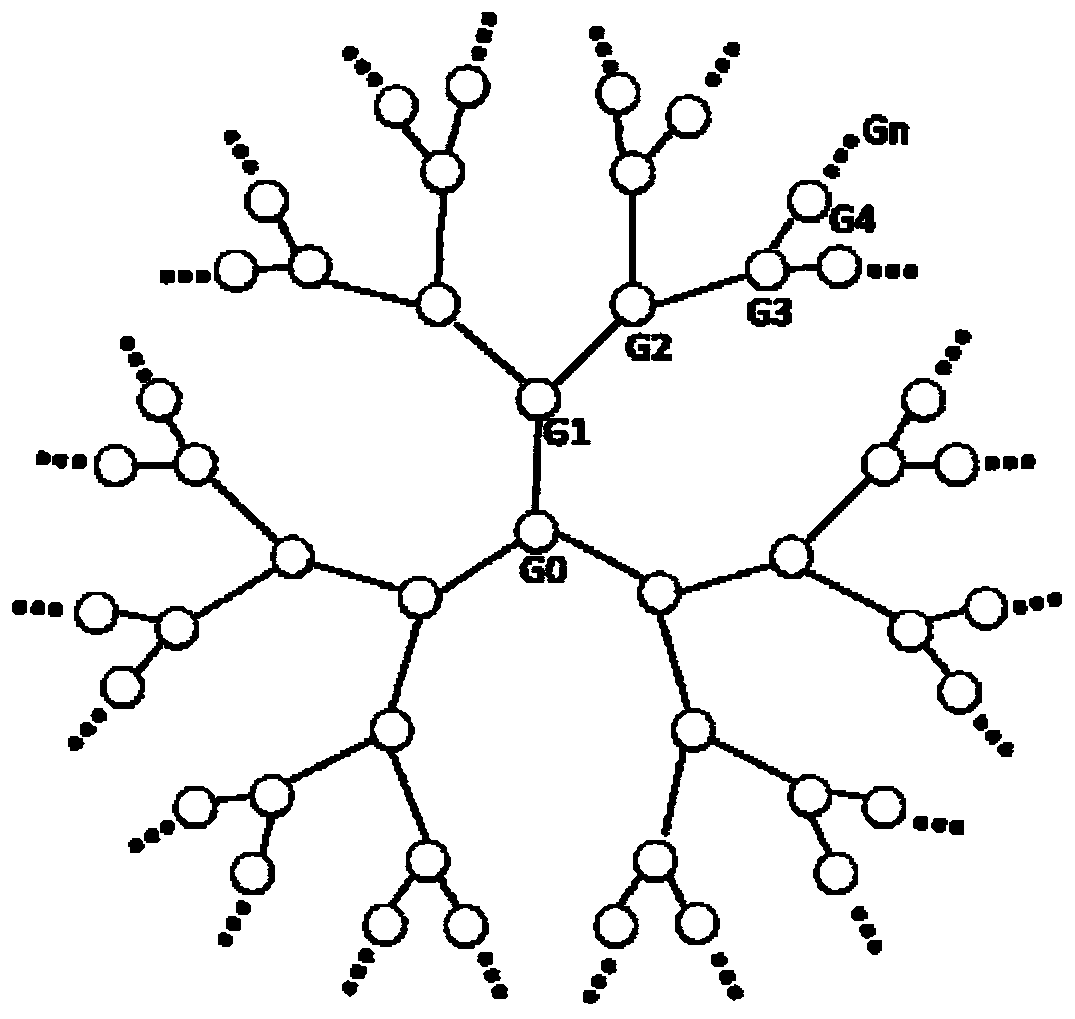

Dendritic branched molecular modified separation membrane and preparation method thereof, composite separation membrane and application of dendritic branched molecular modified separation membrane and composite separation membrane

ActiveCN110314562AHigh permeate fluxSimple processSemi-permeable membranesMembranesSurface structureSeparation technology

The invention provides a dendritic branched molecular modified separation membrane and a preparation method thereof, a composite separation membrane and application of the dendritic branched molecularmodified separation membrane and composite separation membrane, and relates to the technical field of fluid separation. The dendritic branched molecular modified separation membrane comprises separation membranes, wherein modified membranes are formed on the membrane surfaces and / or hole walls of inner holes of the separation membranes, and the modified membranes are mainly prepared from dendritic branched molecules. The provided dendritic branched molecular modified separation membrane has the advantages that the modified membranes mainly composed of the dendritic branched molecules are formed on the membrane surfaces and / or hole walls of inner holes of the separation membranes to effectively regulate the surface structures and / or inner structures of the separation membranes, be conductive to maximizing the balance between the permeability and the selectivity, and increase the permeation flux.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Continuous production method of epoxy chloropropane by hydrogen peroxide process

The invention provides a preparation method of chloroepoxy propane by chloropropene epoxidation. Chloropropene, a solvent and titanium silicalite molecular sieve catalyst fine particles are put in a reaction kettle for reaction at the temperature of 10-80 DEG C. The method is characterized in that the reaction kettle is a single kettle or multistage slurry bed reaction kettles with same or different volumes which are connected in series; the reaction solution needs not to be homogeneous phase, slurry particles of the chloropropene, the solvent and the titanium silicalite molecular sieve catalyst are added to a first stage reaction kettle by a metering pump, hydrogen peroxide is dropwise added to the first stage reaction kettle or each stage of the reaction kettles, the reaction occurs in a weakly acidic condition, materials are subject to oil-water delamination after the reaction to be divided into oil-phase slurry and water-phase slurry; the catalyst is suspended in the water phase, and the oil phase is sent to a rectification tower to separate the chloropropene, the epichlorohydrin and trace methanol; the water phase slurry is filtered, a catalyst filter cake or concentrated slurry is directly beaten by the solvent, and pumped to a first stage epoxidation reaction kettle, the water phase slurry contains the methanol, trace epichlorohydrin and the water which is generated by the reaction and the water which is taken by the hydrogen peroxide, the trace methanol and the epichlorohydrin are separated out by negative pressure rectification, and the recovered methanol is used for preparation of the catalyst slurry. The method has the advantages of simple process, little solvent consumption and high product separation yield, and is available for industrialized production.

Owner:JIANGSU YANGNONG CHEM GROUP +2

Process for producing organic carboxylic acid amides

ActiveUS20110004020A1Easy to produceImprove stabilityOrganic compound preparationCarboxylic acid amides preparationCarboxylic acidHydrolysis

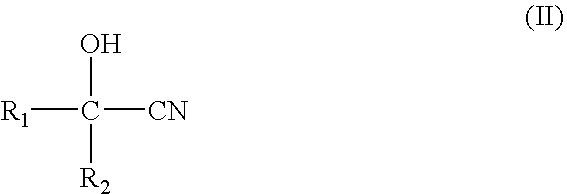

The present invention relates to a process for producing organic carboxylic acid amides by nitrile hydrolysis of a nitrile compound at certain temperature and pressure in the presence of a catalyst to produce an organic carboxylic acid amide.

Owner:CHINA PETROCHEM DEVMENT

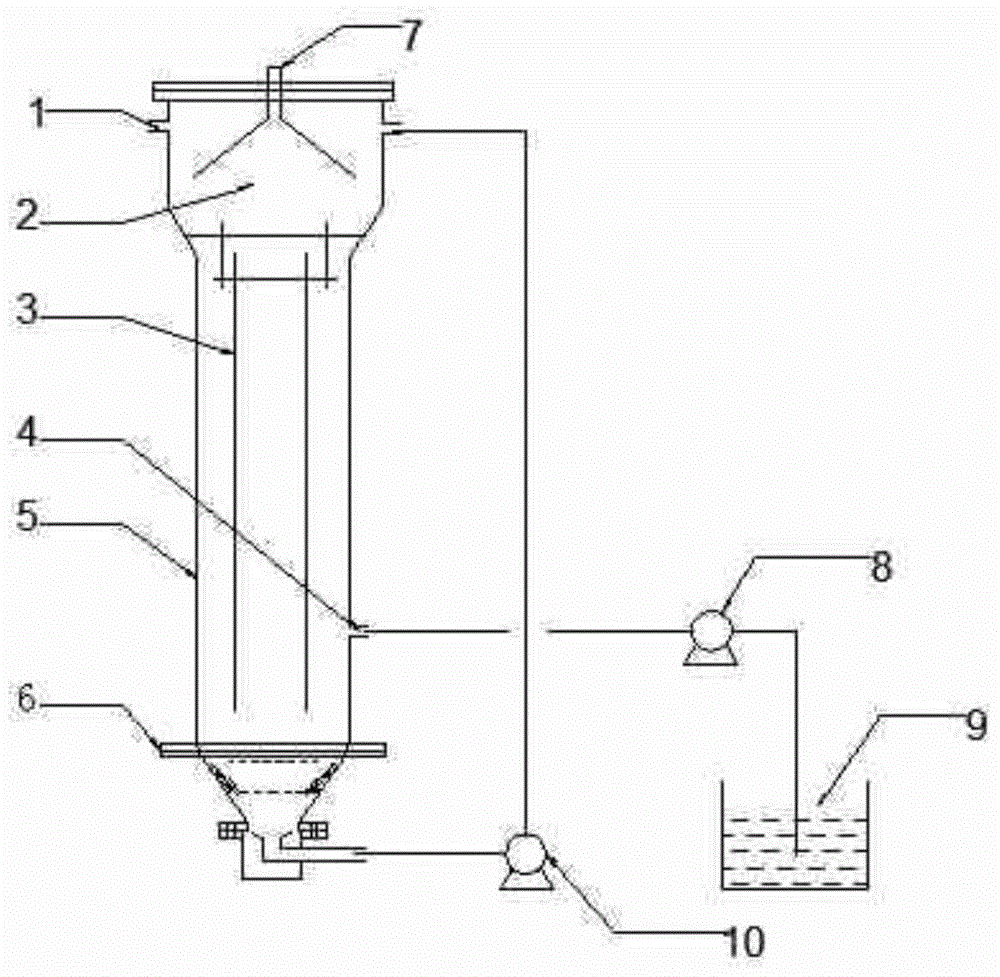

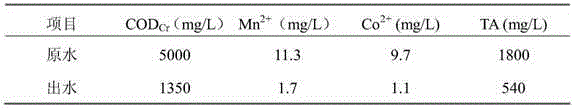

Anaerobic organism fluidized bed mixed carrier for treating industrial waste water and application of anaerobic organism fluidized bed mixed carrier

ActiveCN104437423AImprove the growing environmentRemove inhibitionOther chemical processesWater treatment compoundsChemical oxygen demandIndustrial waste water

The invention discloses an anaerobic organism fluidized bed mixed carrier for treating industrial waste water and application of the anaerobic organism fluidized bed mixed carrier. The anaerobic organism fluidized bed mixed carrier is characterized by consisting of modified active carbon, modified kieselguhr and modified resin, wherein the volume of the modified active carbon is 55%-62% of that of the mixed carrier; the volume of the modified resin is 31%-42% of that of the mixed carrier; the volume of the modified kieselguhr is 3%-7% of that of the mixed carrier. In the application, the total volume of the mixed carrier is 9%-11% of the total volume of the anaerobic organism fluidized bed. By the application of the mixed carrier in the organism fluidized bed, the mass transfer efficiency can be improved, the energy consumption can be reduced, the sludge yield is can be reduced, the HRT(hydraulic retention time) can be shortened, and the impact load endurance of the anaerobic organism fluidized bed is relatively high, so that when industrial waste water is treated by utilizing the mixed carrier anaerobic organism fluidized bed, the chemical oxygen demand removing effect is far higher than the effect of the traditional anaerobic organism treatment method.

Owner:NANJING UNIV OF TECH

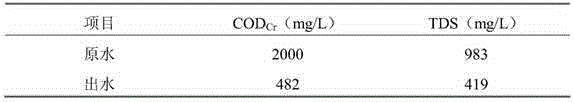

Method for preparing fatty aldehyde by means of a hydroformylation reaction

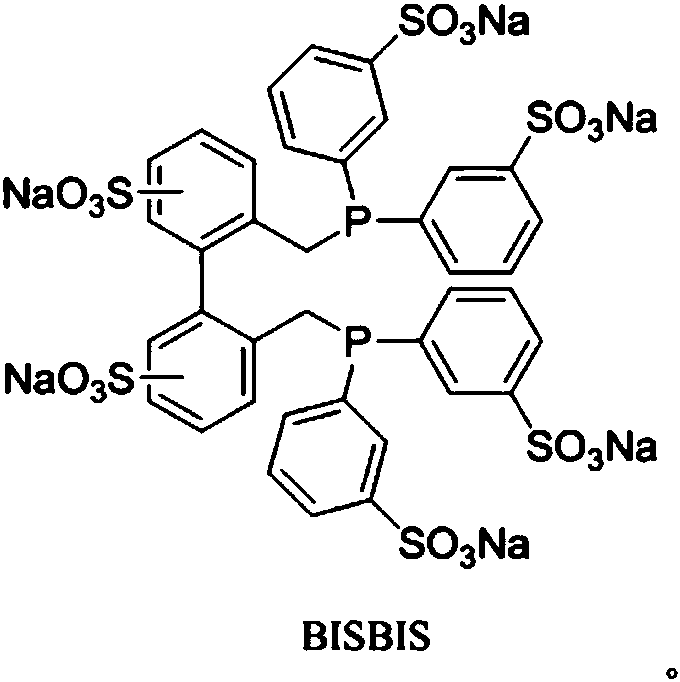

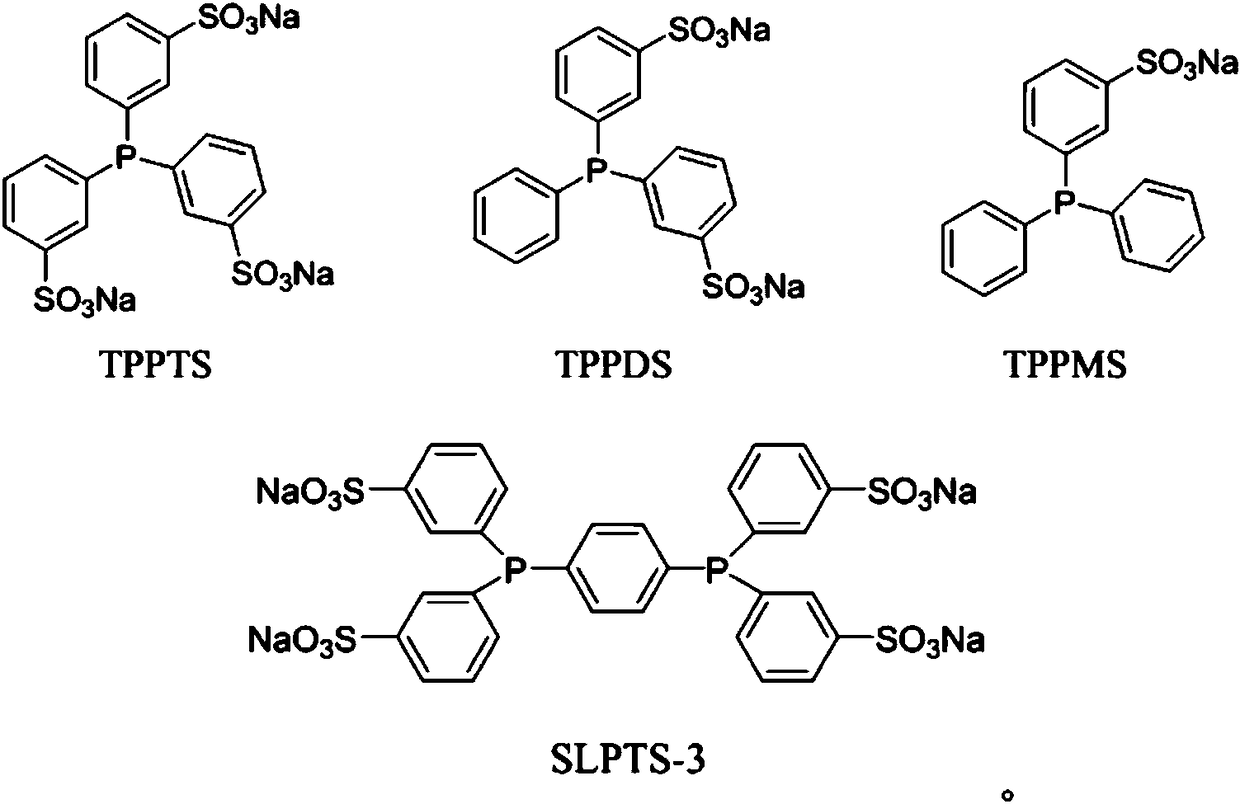

InactiveCN109456154ATake advantage ofGood choiceOrganic compound preparationPreparation by carbon monoxide reactionFormylation reactionDiphosphines

The invention discloses a method for preparing fatty aldehyde by means of a hydroformylation reaction. A catalyst system consisting of a water-soluble rhodium phosphine complex and a diphosphine ligand is used in water / organic two phases for catalyzing 1-butene, 2-butene and a mixture of the 1-butene to be subjected to the hydroformylation reaction so as to prepare n-valeraldehyde; due to the combination of the water-soluble bisphosphine ligand BISBIS and organic additives, the hydroformylation reaction of the butene is accelerated, and the molar ratio of the produced n-valeraldehyde / isovaleraldehyde is greater than 93 to 7. A catalyst aqueous solution is simple and convenient to separate from the product; furthermore, the catalytic performance is stable, the reaction conditions are mild,the service life of a catalyst is long, and the production cost of the n-valeraldehyde is remarkably lowered.

Owner:成都欣华源科技有限责任公司

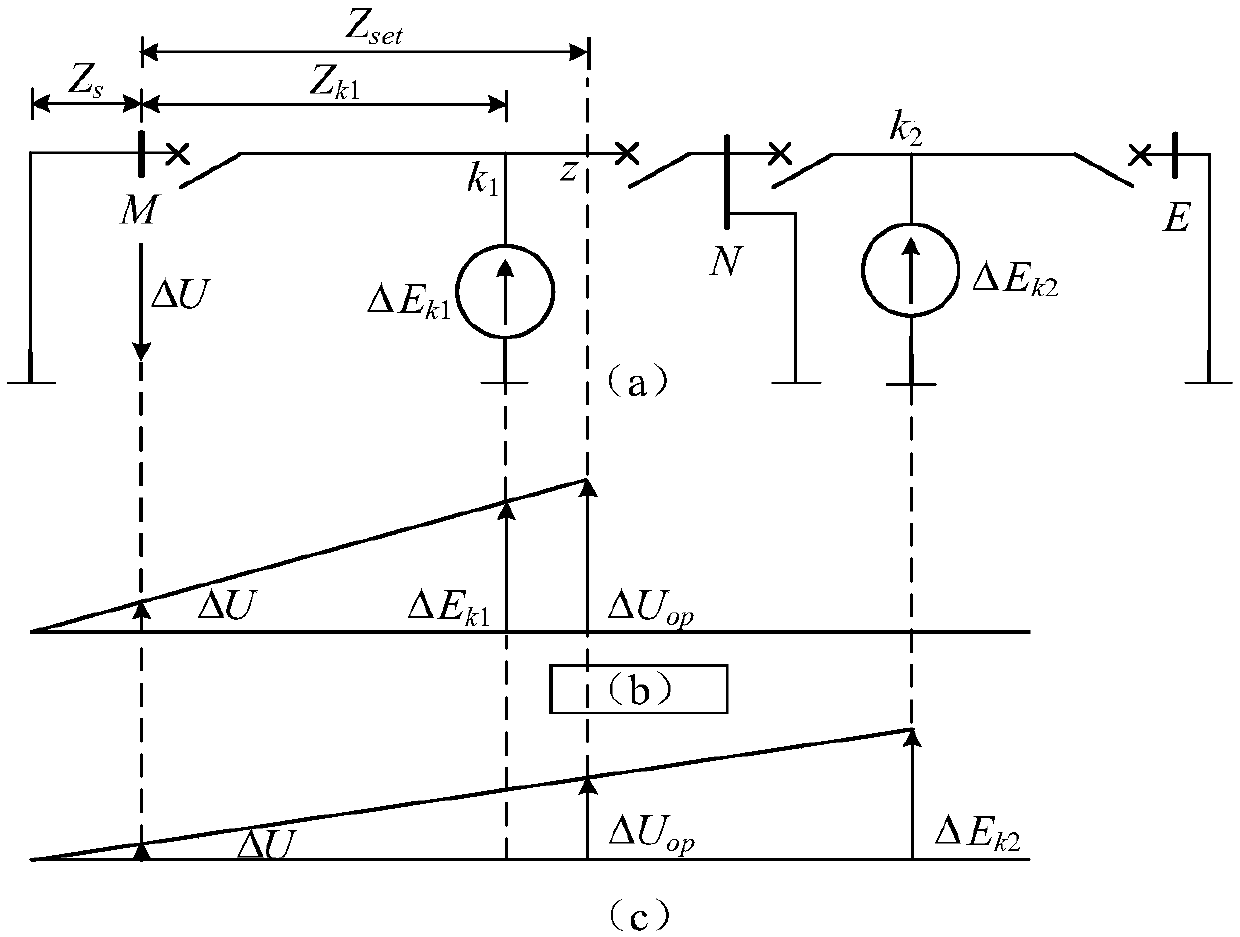

High-frequency break variable distance protection method of flexible DC power distribution system

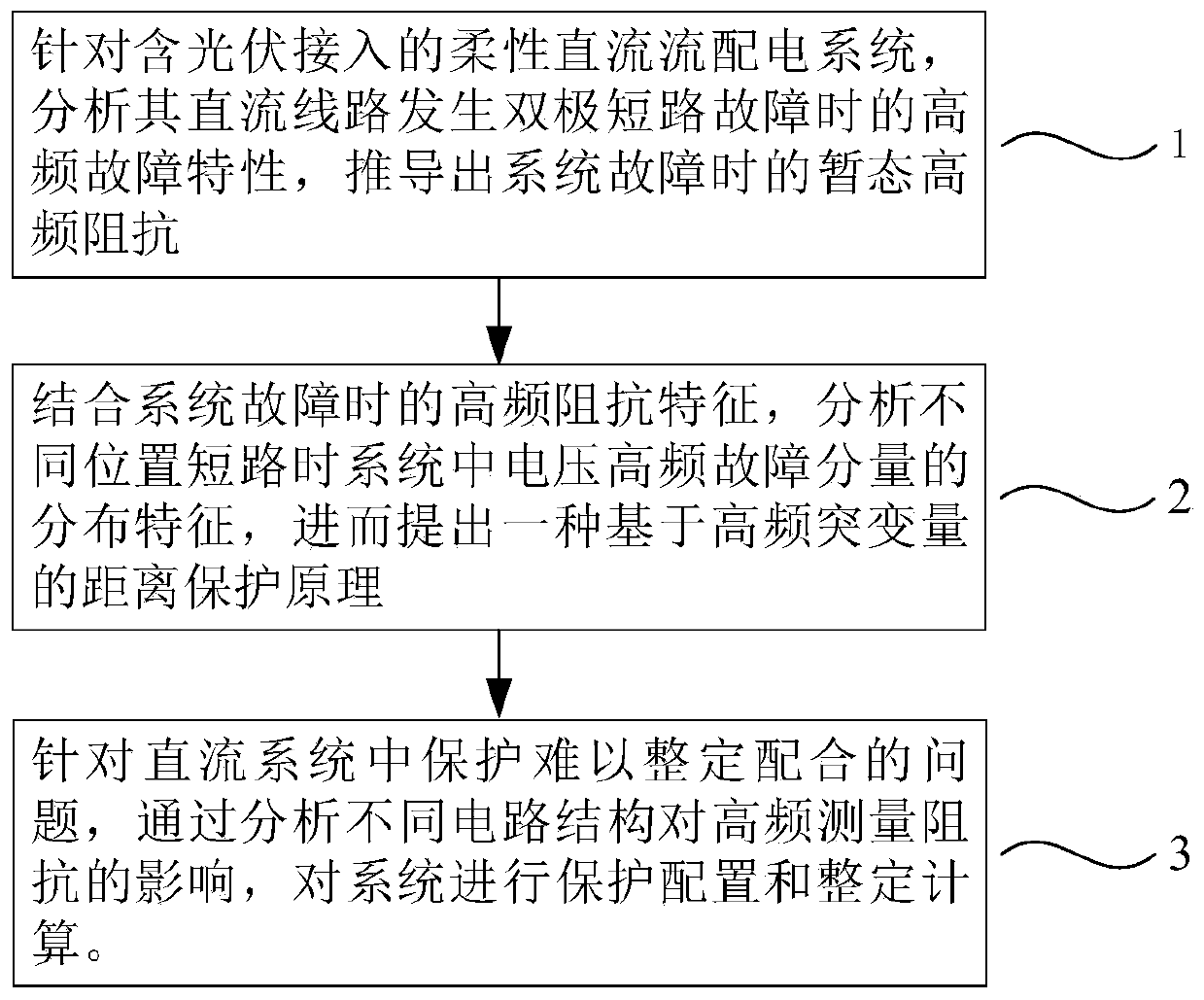

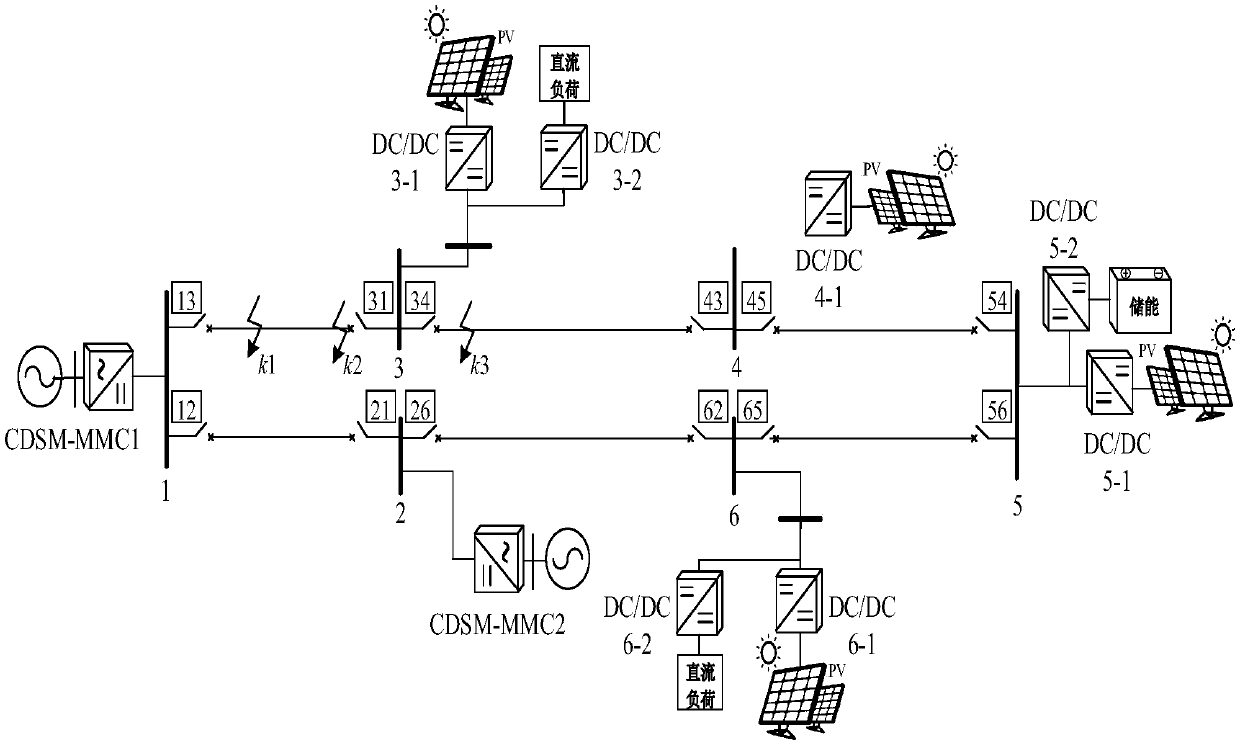

ActiveCN109617027AFastBe selectiveEmergency protective circuit arrangementsTransient stateDistribution characteristic

The invention discloses a high-frequency break variable distance protection method of a flexible DC power distribution system. The protection method comprises the following steps of 1, analyzing high-frequency fault characteristic when a bipolar short-circuit fault occurs in a photovoltaic access-containing flexible DC circuit with regard to the photovoltaic access-containing flexible DC circuit,and deriving transient high-frequency impedance of the system during a fault; 2, analyzing distribution characteristic of a voltage high-frequency fault component in the system during short circuit atdifferent positions, thereby obtaining a high-frequency break variable distance protection principle; and 3, analyzing influence of different circuit structures on high-frequency measurement impedance with regard to the problem of difficult in setting and matching of protection in the DC system, and performing protection configuration and setting calculation on the system.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

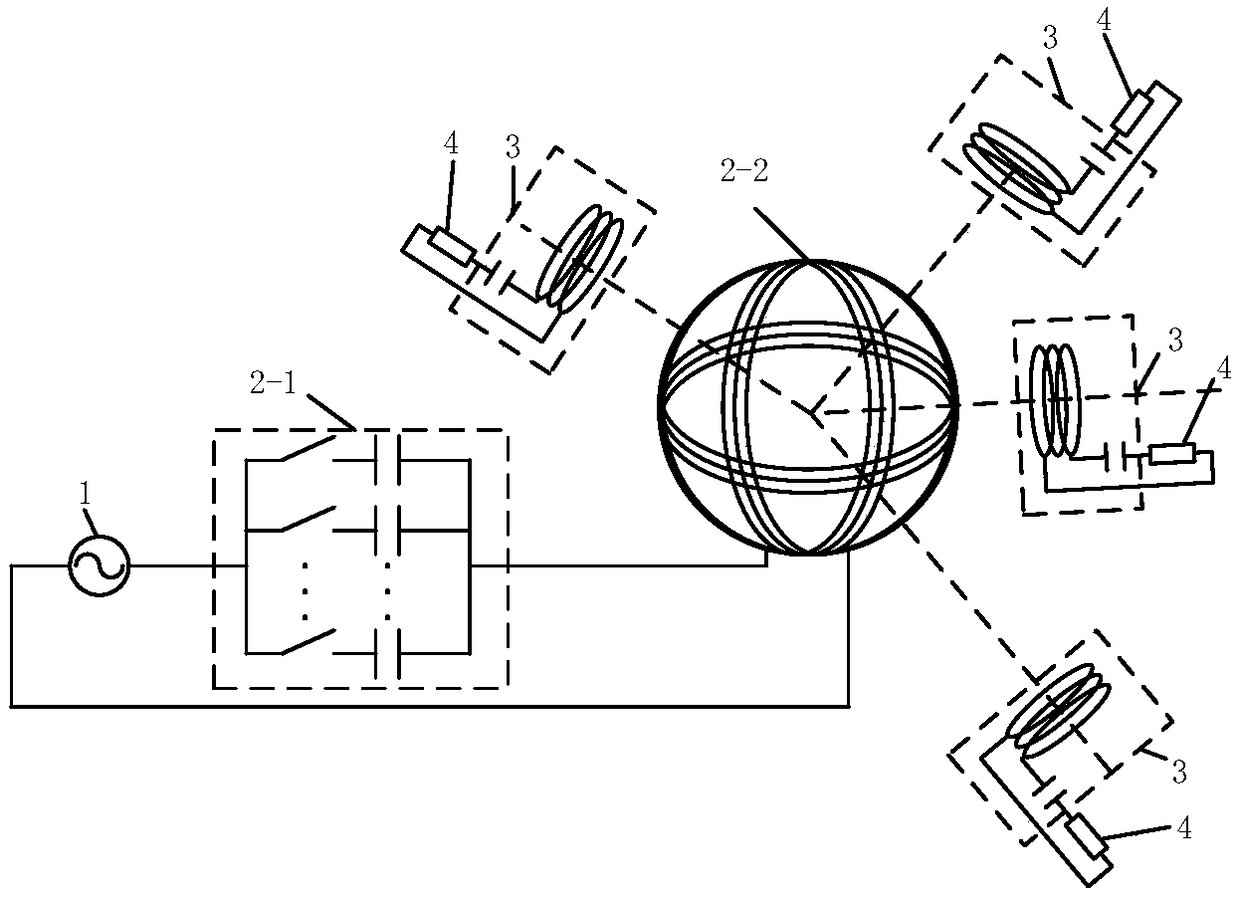

Omnidirectional selectivity radio energy transmission system

InactiveCN108400657AImprove energy utilizationSmall device sizeCircuit arrangementsSpecific timeSupply energy

The invention relates to the technology of the radio energy transmission, and specifically relates to an omni-directional selectivity radio energy transmission system. The system comprises a transmitting end connected with a power supply module, and a load module connected with multiple receiving ends; the frequency of the transmitting end is adjustable and is matched with the resonant frequency of each receiving end. The transmission system can satisfy the energy supply to multiple receiving ends at any location of the space by only needing one transmitting end, and the transmission system has the selectivity function at the same time, the energy is only supplied to the receiving end needing the energy in the specific time slot, the energy utilization efficiency is improved, and the loadservice life is prolonged.

Owner:WUHAN UNIV

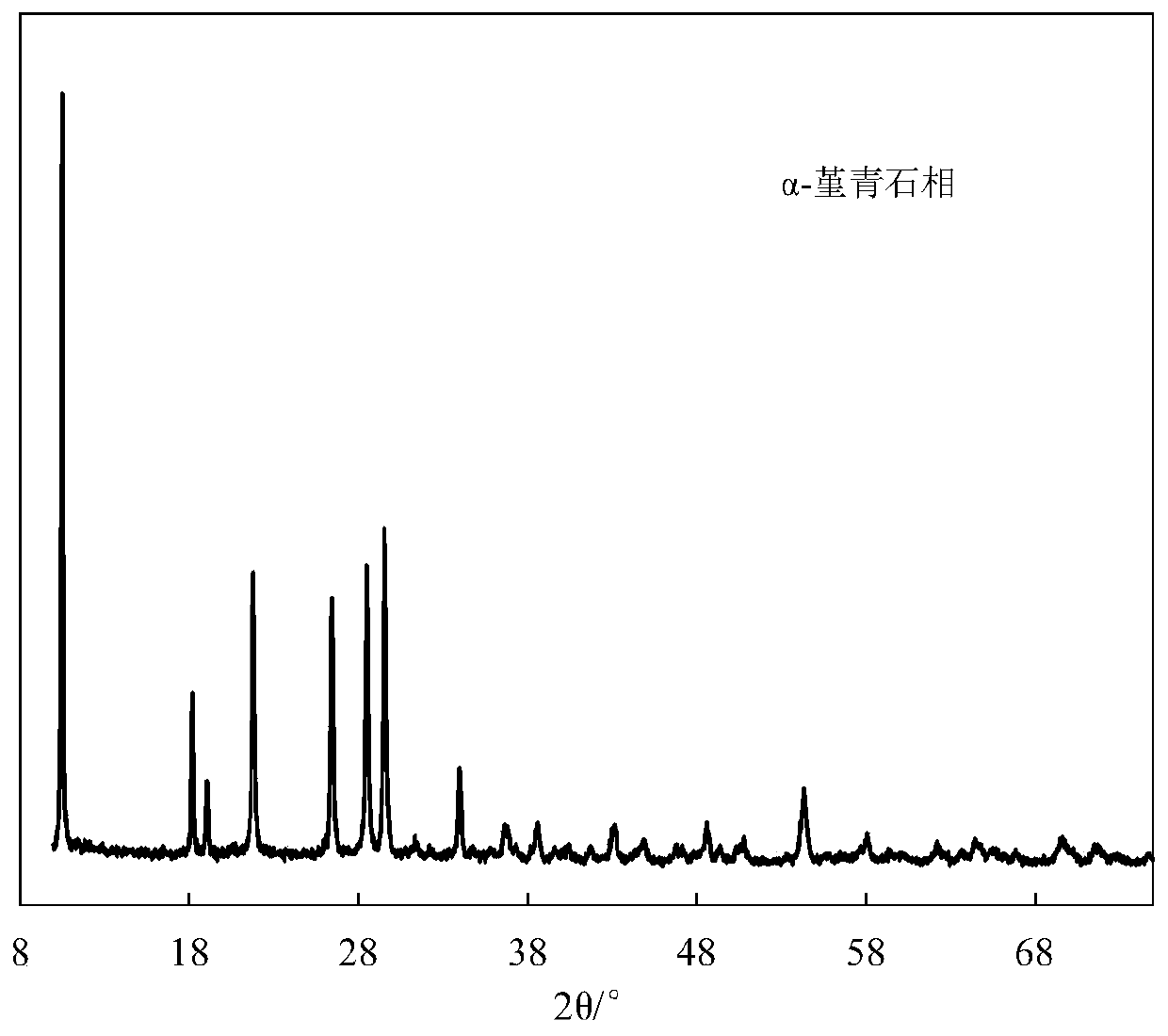

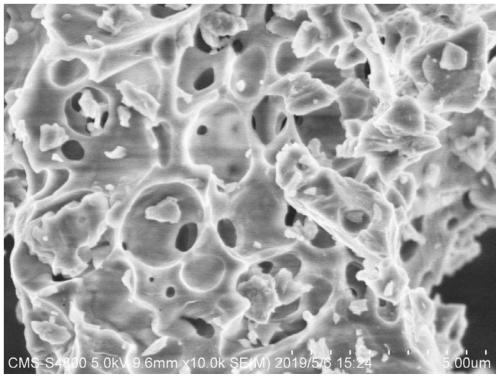

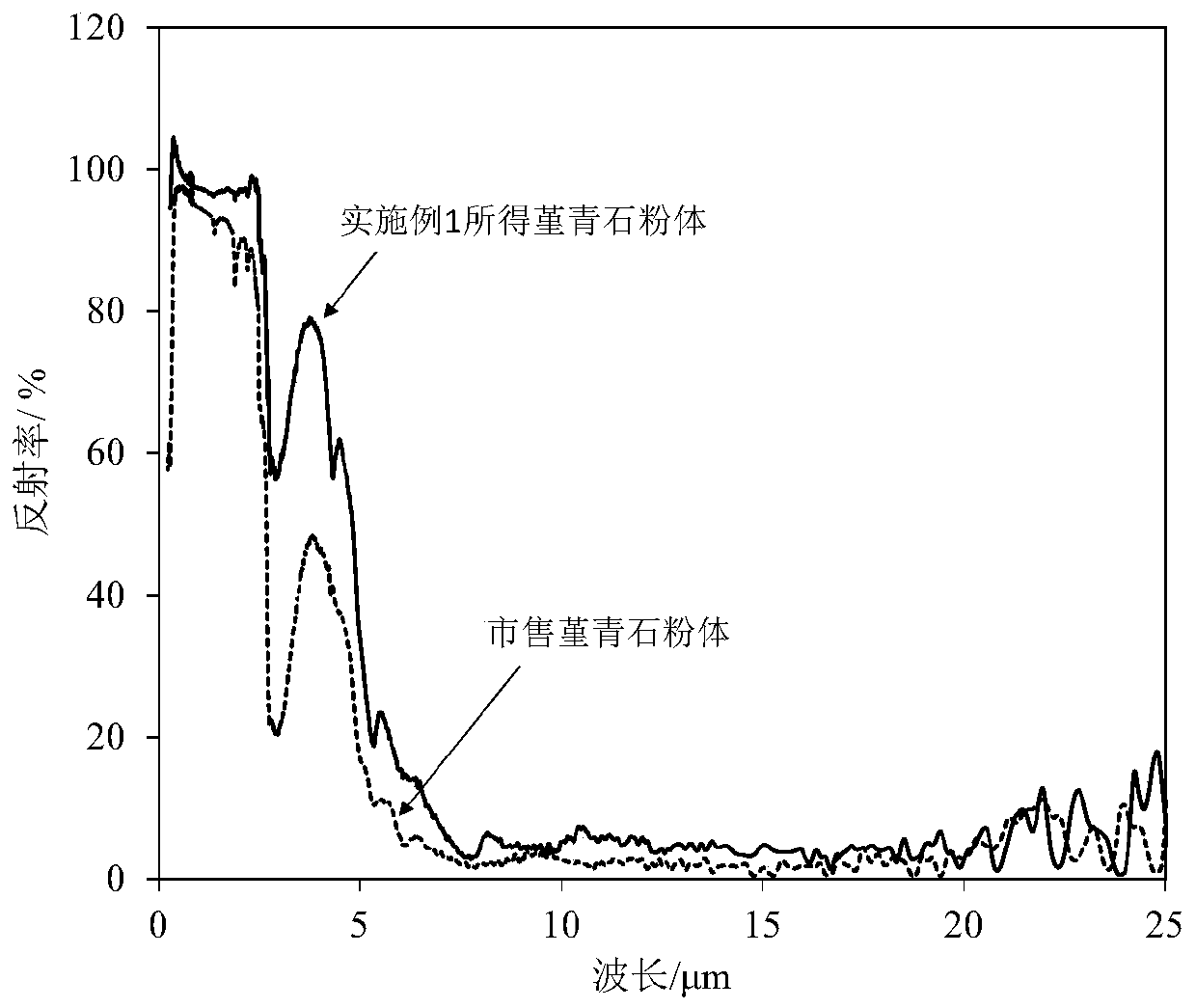

Radiation refrigeration coating and preparation method and application thereof

ActiveCN111303709AIncrease surface tensionReduce surface tensionAluminium silicatesReflecting/signal paintsAcrylic resinEthylic acid

The invention discloses a radiation refrigeration coating as well as a preparation method and application thereof. The radiation refrigeration coating is prepared from the following raw material components in percentage by mass: 4%-8% of porous cordierite, 10%-18% of titanium dioxide, 22%-35% of acrylic resin, 0.5%-1.5% of a silane coupling agent, 0.1%-1% of a coalescing agent, 0.1%-1% of a leveling agent, 0.1%-1% of a dispersing agent, 0.2%-1% of an antifoaming agent, 0.1%-2% of a thickener, 0.1%-2% of an anti-flash rust agent and the balance of dipropylene glycol methyl ether acetate, and the radiation refrigeration coating is prepared by mixing the raw materials. The radiation refrigeration coating disclosed by the invention has high sunlight reflectivity and high selectivity and radiance in an atmospheric window, the preparation method has the advantages of simplicity, feasibility, low cost and the like, and meanwhile, a radiation refrigeration coating layer prepared from the coating can realize all-weather refrigeration, has a good refrigeration effect, and has very high use value and application prospect.

Owner:NAT UNIV OF DEFENSE TECH

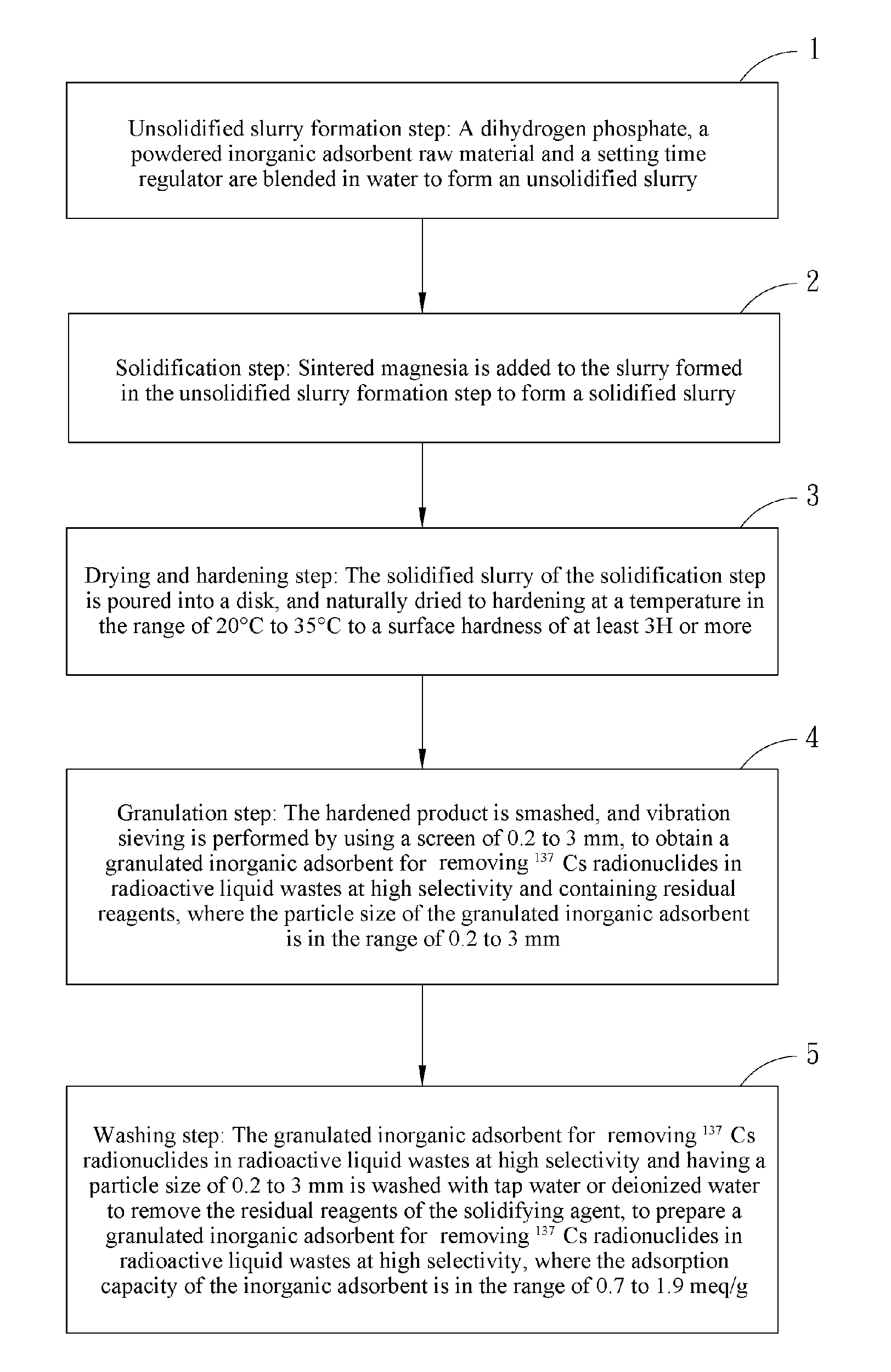

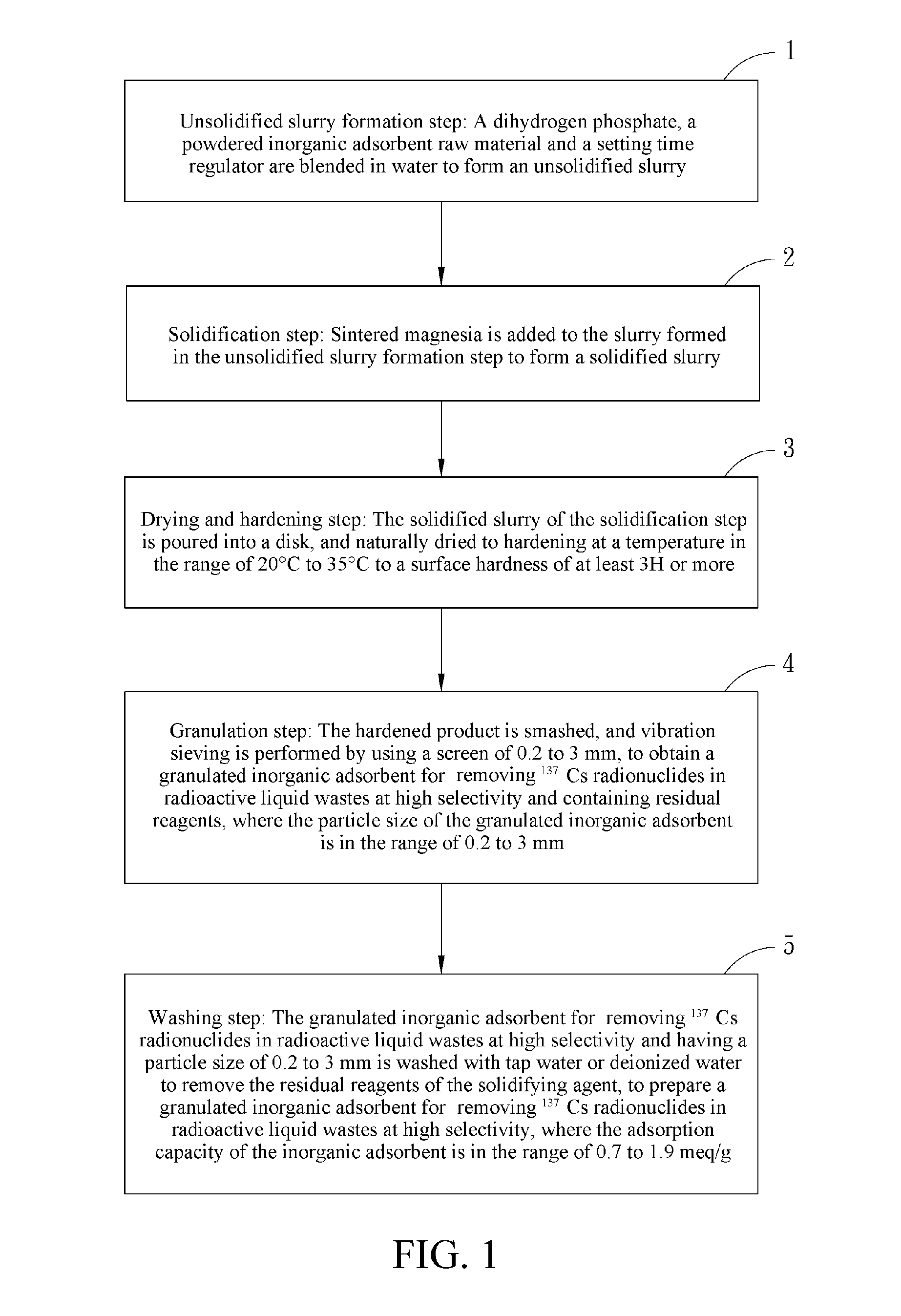

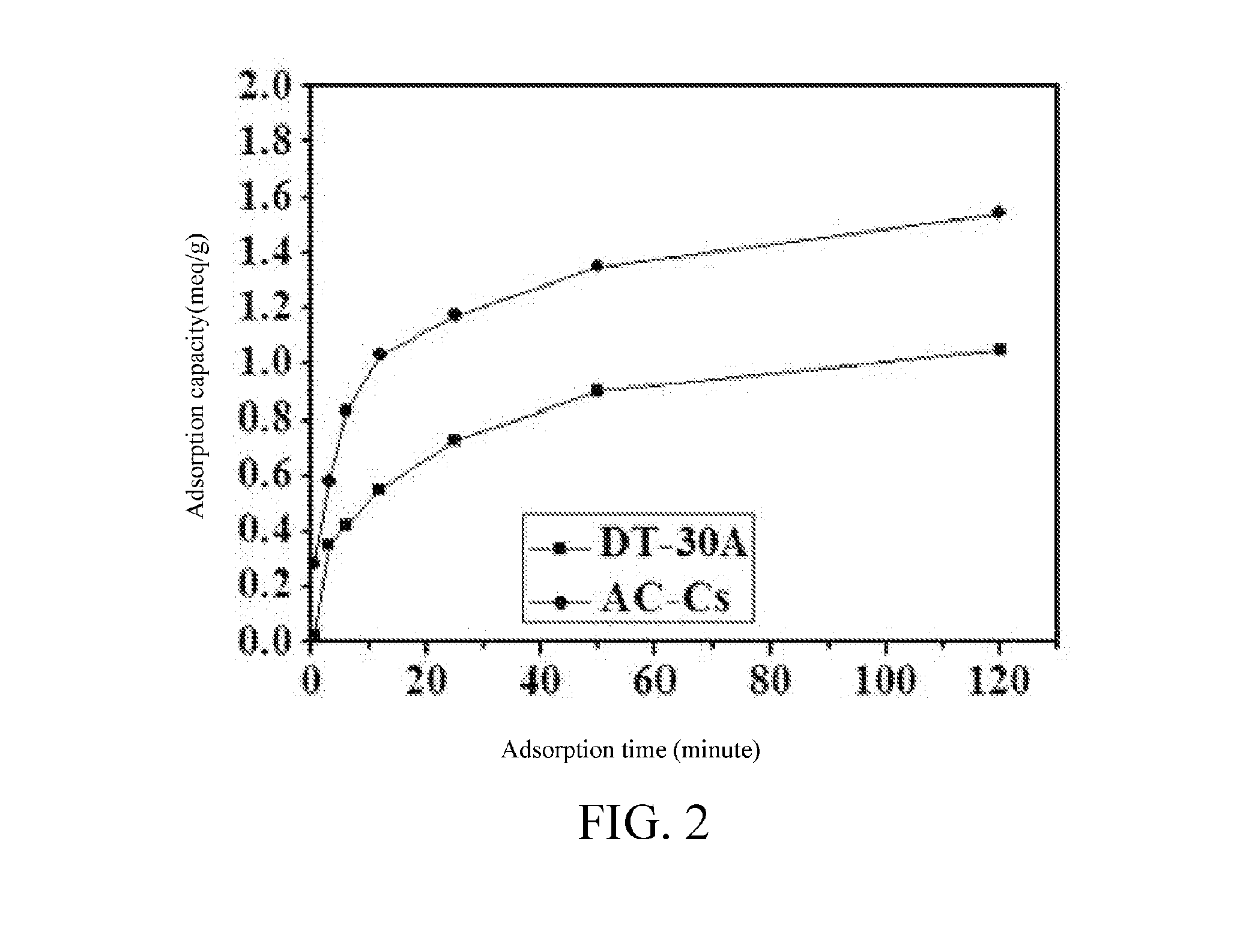

Method for preparing granulated inorganic adsorbent for radionuclides

ActiveUS20160067672A1High selectivityImprove adsorption capacityMolecular sieve catalystsOther chemical processesPhosphateSorbent

Disclosed is a method for preparing a granulated inorganic adsorbent for radionuclides including slurry forming, solidification, drying and hardening, granulation, and washing steps: blending a dihydrogen phosphate, a powdered inorganic adsorbent raw material and a setting time regulator in water to form a slurry; adding sintered magnesia into the slurry, and blending the mixture to form a solidified slurry; setting the solidified slurry on a disk member, and naturally drying to hardening in a specific temperature range to form a hardened solid material; smashing the hardened solid material and performing vibration sieving by using a screen to obtain a granulated inorganic adsorbent for radionuclides containing residual reagents; washing the granulated inorganic adsorbent for radionuclides containing residual reagents with water, to remove the residual reagents to complete preparation, where the adsorption capacity of the granulated inorganic adsorbent for radionuclides thus prepared is in the range of 0.7 to 1.9 meq / g.

Owner:INST NUCLEAR ENERGY RES ROCAEC

Process for the direct synthesis of trialkoxysilane

ActiveUS20070060764A1Lower Level RequirementsSpeed up reactionSilicon organic compoundsAlcoholInorganic compound

The Direct Synthesis of trialkoxysilane is carried out by conducting the Direct Synthesis reaction of silicon and alcohol, optionally in solvent, in the presence of a catalytically effective amount of Direct Synthesis catalyst and an effective catalyst-promoting amount of Direct Synthesis catalyst promoter, said promoter being an organic or inorganic compound possessing at least one phosphorus-oxygen bond.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

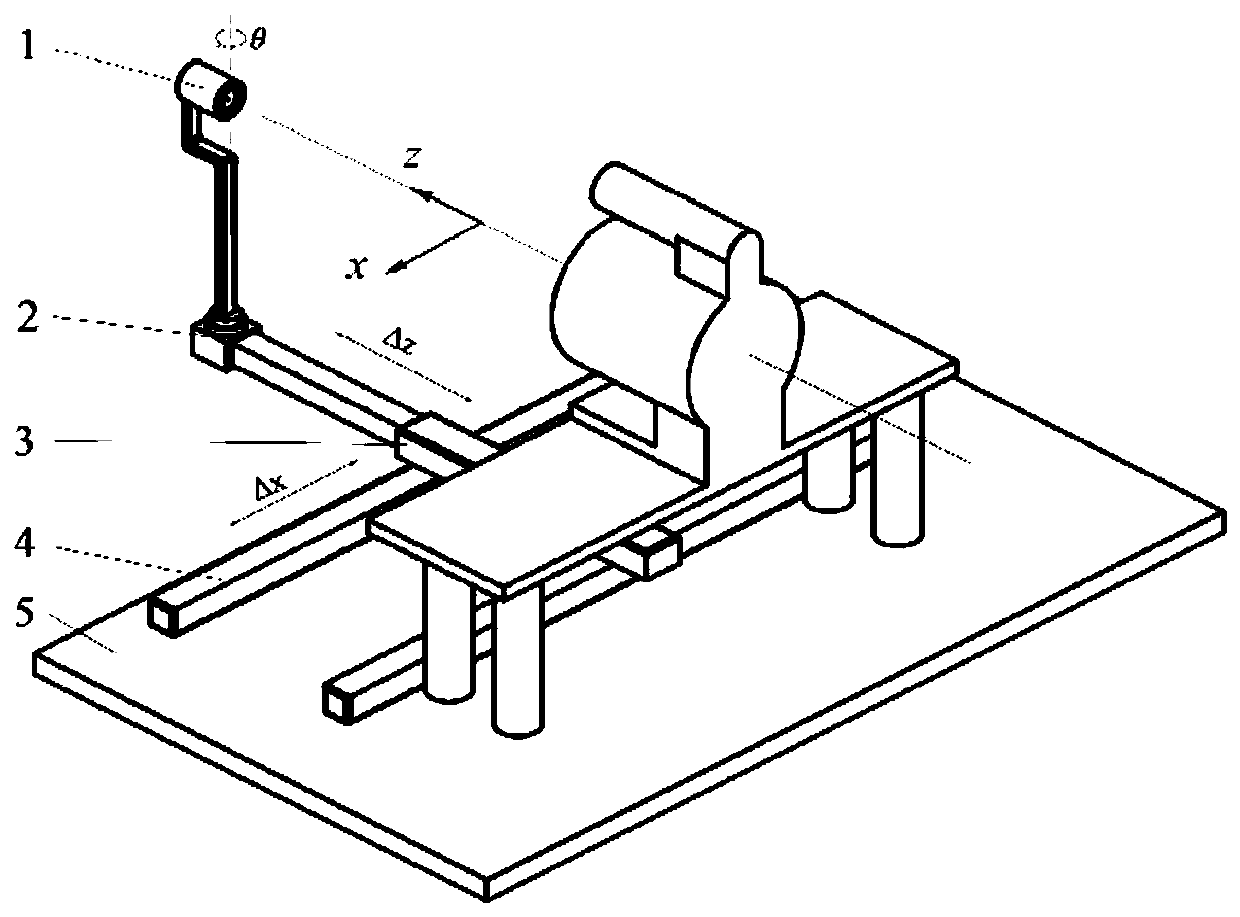

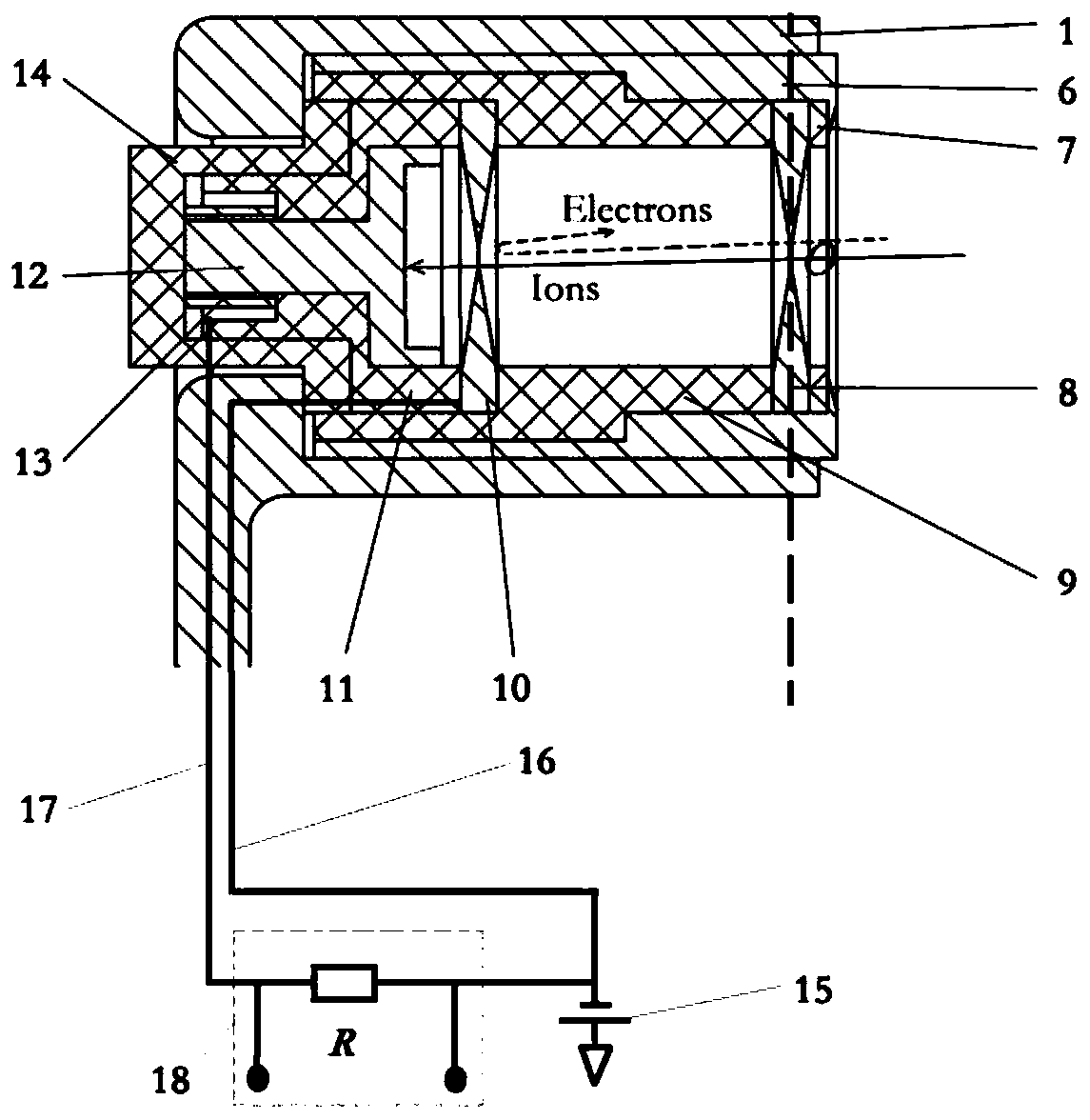

Plasma thruster steady-state ion flow field measurement device and measurement method

ActiveCN110618443ABe selectiveAddressing measurement deficienciesX/gamma/cosmic radiation measurmentMeasurement deviceMeasurement point

The embodiment of the invention provides a plasma thruster steady-state ion flow field measurement device and a measurement method and belongs to the technical field of steady-state ion flow field measurement. The device comprises a measurement module, a power supply module and a probe assembly, the probe assembly comprises a probe, a probe support and an electric rotary table, the probe comprisesan insulation shell, an ion receiving pole, an incident gate and an emergent gate, one end of the insulation shell is open, the incident gate is located at the opening of the insulation shell, the emergent gate is located at the middle part of the inner cavity of the insulation shell, the ion receiving pole is located at one section, far away from the incident gate, in the inner cavity of the insulation shell, an incident hole of the incident gate and an emergent hole of the emergent gate are coaxial, the ion receiving pole, the incident gate and the emergent gate are mutually insulated, theinsulation shell is fixed on the probe support, and the electric rotary table is used for driving the probe support to rotate around the incident hole of the incident gate. The device provided by theembodiment of the invention can obtain an ion current density distribution function on each azimuth angle of a measurement point by enabling the probe to rotate around the measurement point, and a vector angle of an ion velocity is obtained at the same time.

Owner:BEIJING INST OF CONTROL ENG

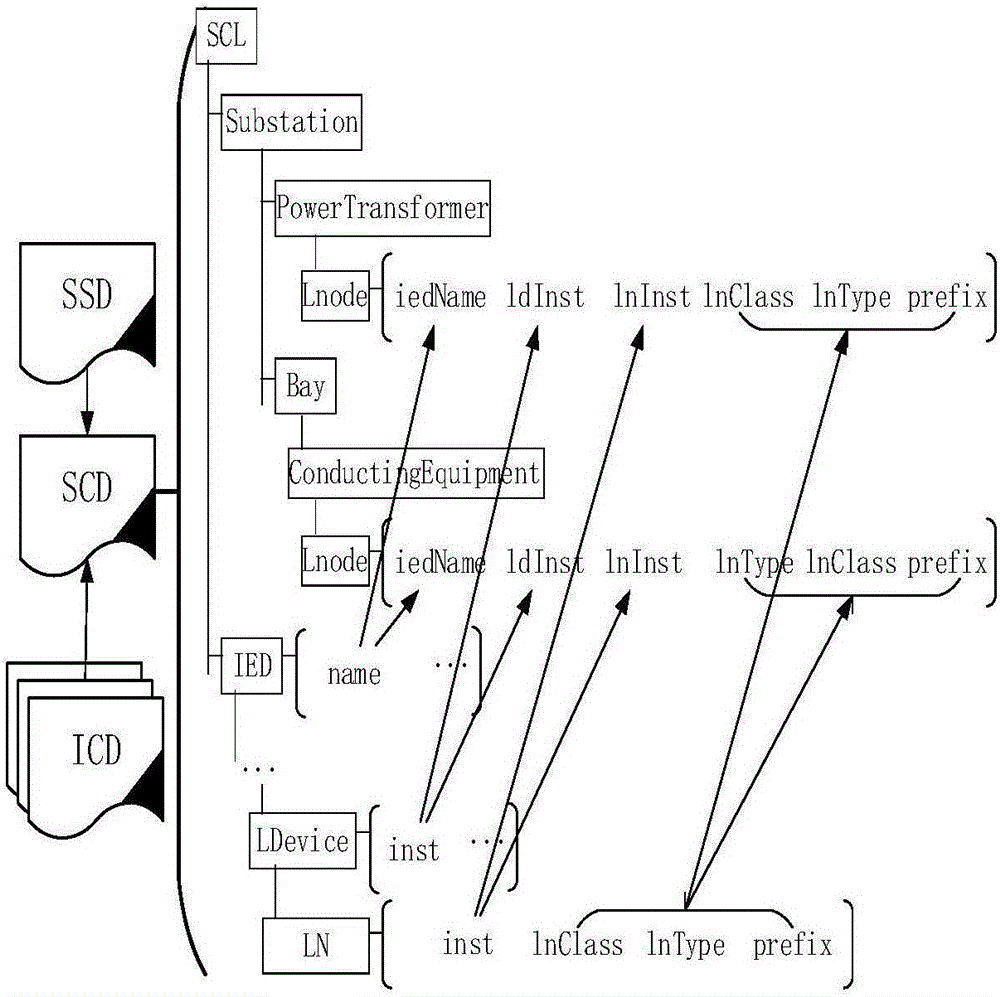

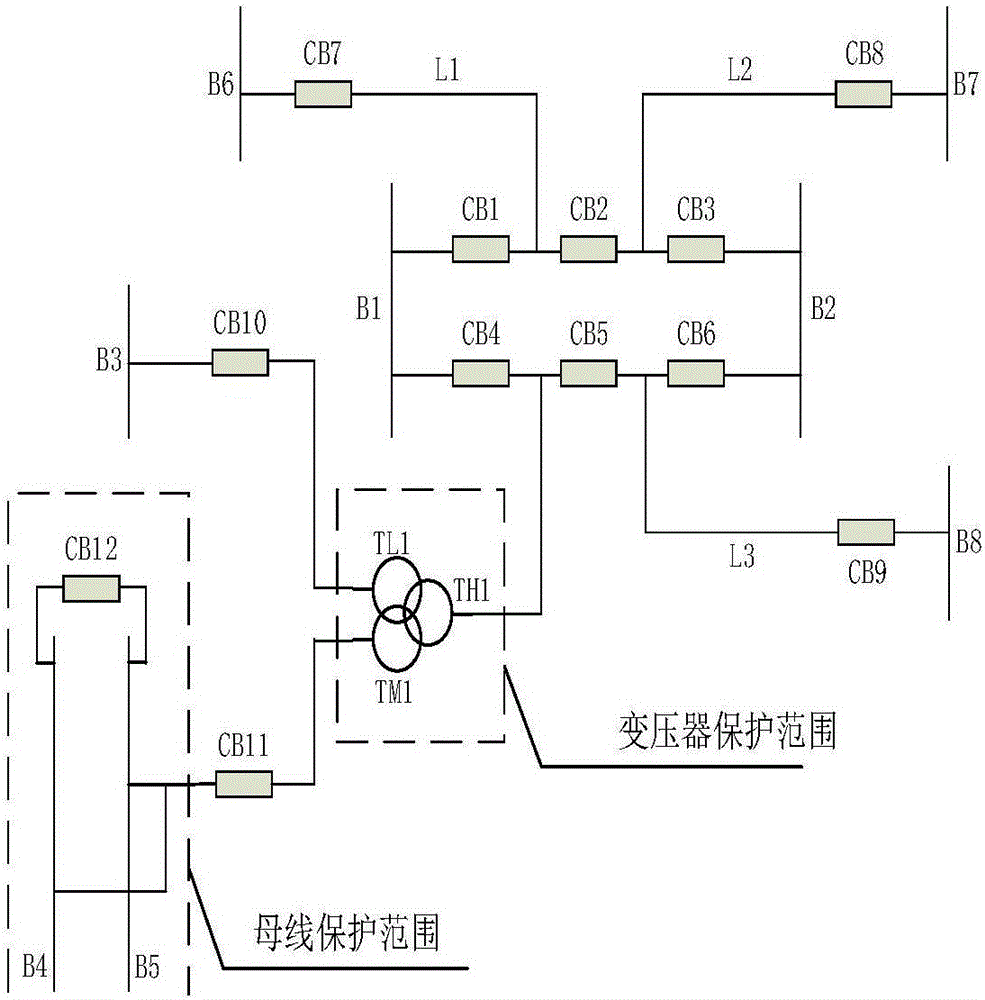

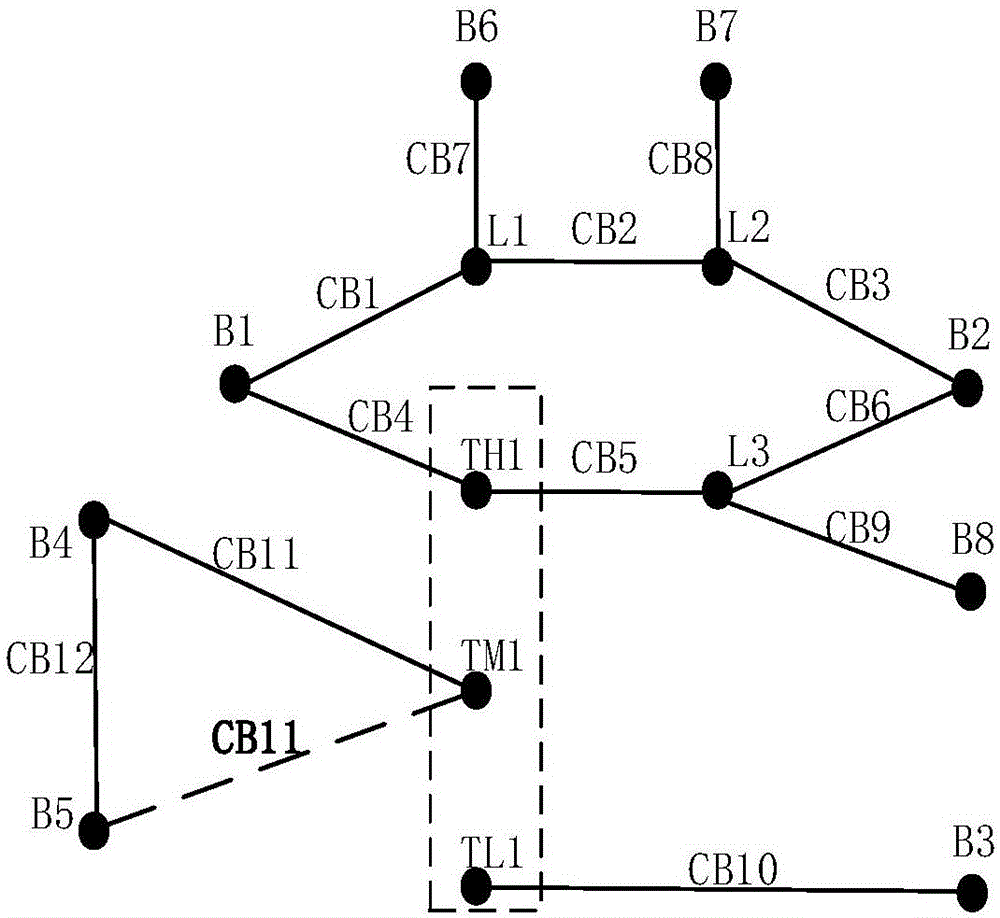

Method and system for modeling associated information topology analysis in power distribution network

InactiveCN106169749ASensitiveBe selectiveAc network circuit arrangementsTransformerElectric power system

The invention relates to a method and a system for modeling associated information topology analysis in a power distribution network. The method comprises the following steps: 1) obtaining primary equipment information and secondary system information in the power distribution network; 2) according to the primary equipment information, establishing a power grid topology network model, wherein the node elements of the network model comprise a generator, a busbar, a circuit and a transformer, and the branch element of the network model is switch equipment; and 3) according to the secondary system information, combining the primary equipment information to establish an associated information topology network model, wherein the node element of the network model is secondary system logic equipment, and the branch element of the network model is the relation between primary equipment and the secondary system logic equipment. According to the method disclosed by the invention, the complicated system information of the power distribution network can be simplified, fault information is quickly and effectively analyzed according to the associated information topology network, and stable operation of an electric power system is guaranteed.

Owner:XUJI GRP +3

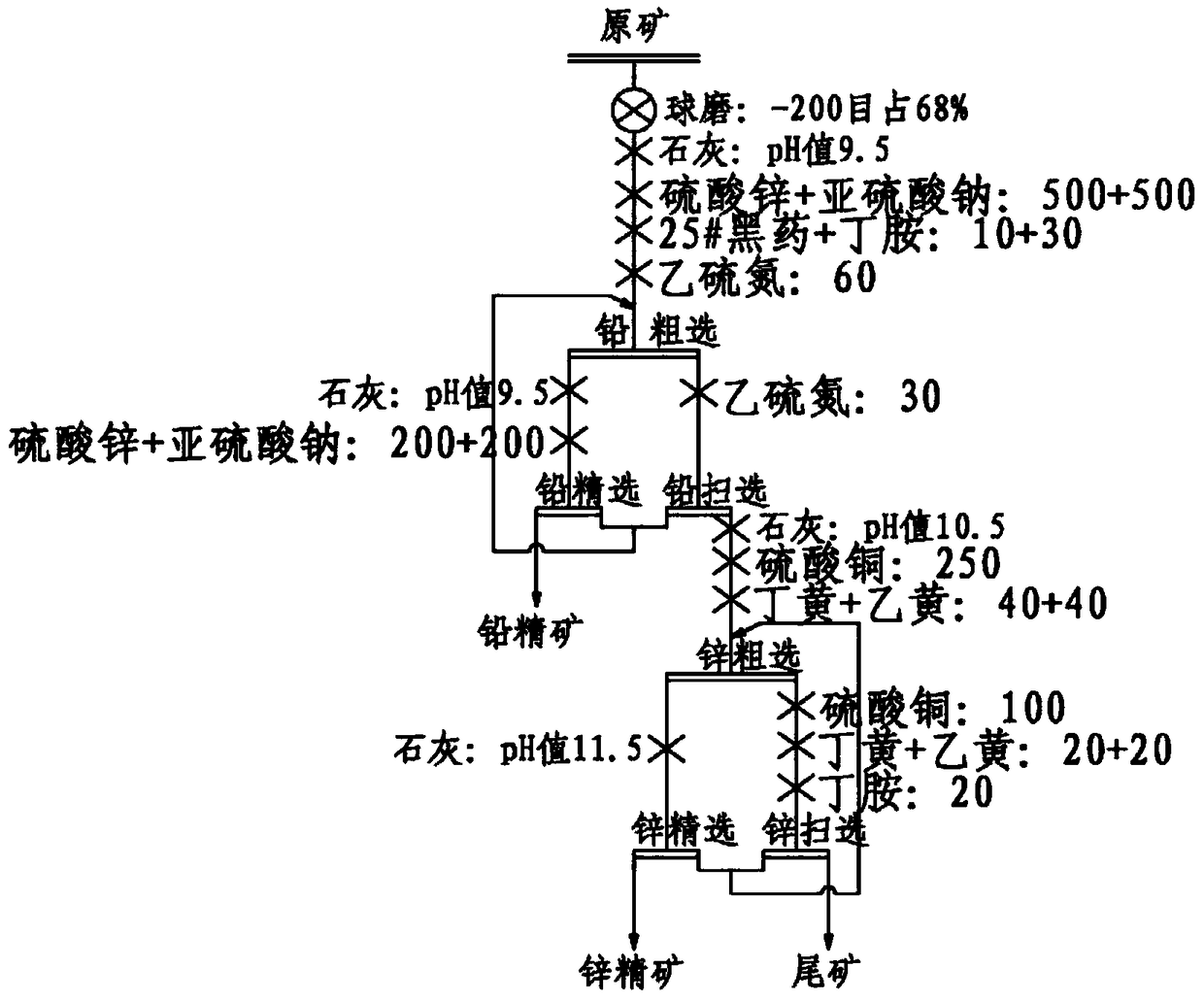

Method for improving beneficiation indexes of low-grade lead-zinc-silver polymetallic ores by combining collecting agent

The invention belongs to the technical field of beneficiation, particularly relates to a method for improving beneficiation indexes of low-grade lead-zinc-silver polymetallic ores by combining a collecting agent. According to the method, ethanethiol is adopted as a main collecting agent in the lead process, a butylamine black medicine, the 25 # black medicine is an auxiliary collecting agent, thezinc flow ethyl xanthate and the butyl xanthate are added according to a ratio of 1:1 to serve as a main collecting agent, and the butyl amine black medicine is used as an auxiliary collecting agent.By utilizing the use of the combined collecting agent, the concentrate grade is stable and even the small amplitude is improved, the recovery rate of the three kinds of metal of the lead and zinc silver is greatly improved, the content of the silver in the lead concentrate is improved, and the economic benefit is obviously improved.

Owner:云南中金共和资源有限公司

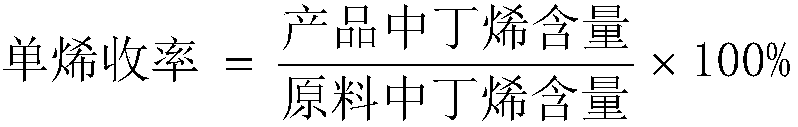

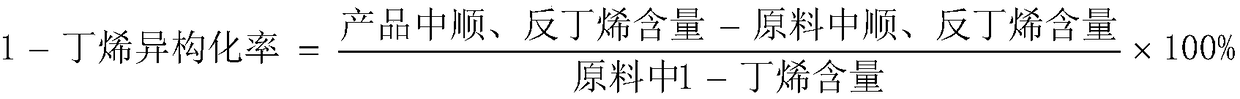

Prehydrogenation treatment method for carbon-4 alkylation raw material

ActiveCN108865243AImprove thermal stabilityAperture ConcentrationHeterogenous catalyst chemical elementsCatalyst activation/preparationChemistryAlkyl transfer

The invention relates to a prehydrogenation treatment for a carbon-4 alkylation raw material. According to the prehydrogenation treatment method, a palladium-molybdenum series catalyst and a fixed bedreactor are utilized; hydrogenation process conditions are that a reaction temperature is 30 to 75 DEG C, reaction pressure is 1 to 3MPa, a liquid space velocity is 2 to 10h<-1>, and a molar ratio ofhydrogen to butadiene is 1 to 10; the palladium-molybdenum series catalyst is prepared from an aluminum oxide carrier containing nickel with a specific crystal form, so that the catalyst has appropriate acidity and a higher reactive metal utilization rate, and butadiene hydrogenation activity and selectivity of the catalyst are remarkably improved. By means of the hydrogenation treatment method disclosed by the invention, a carbon-4 alkylation raw material pretreatment device can effectively remove impurity butadiene at a higher feeding space velocity under the situation that monoolefine in ahydrogenation product is fundamentally not lost; thus, very obvious and good effects of improving environmental benefits and economic benefits of a follow-up alkylation device are achieved.

Owner:PETROCHINA CO LTD

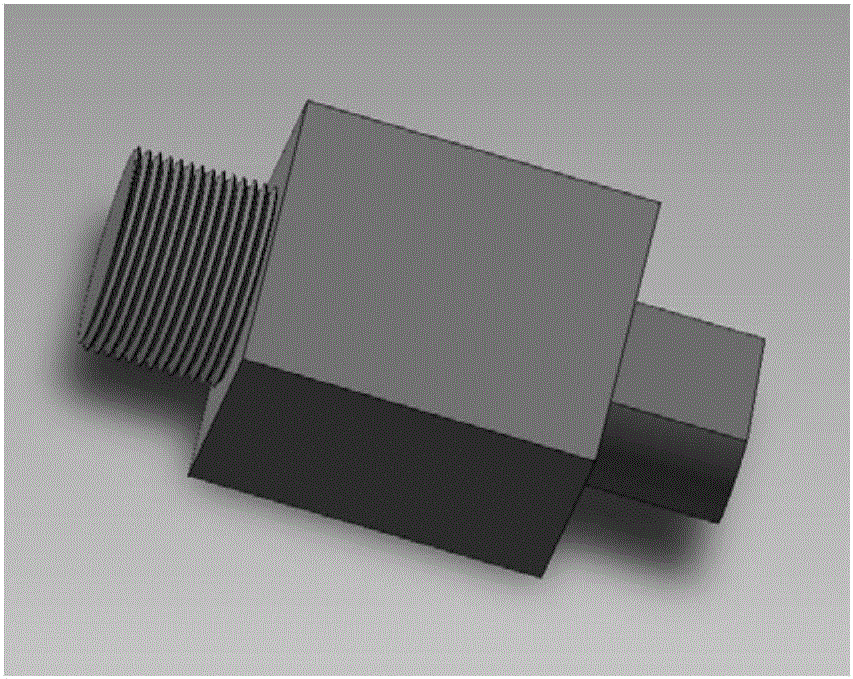

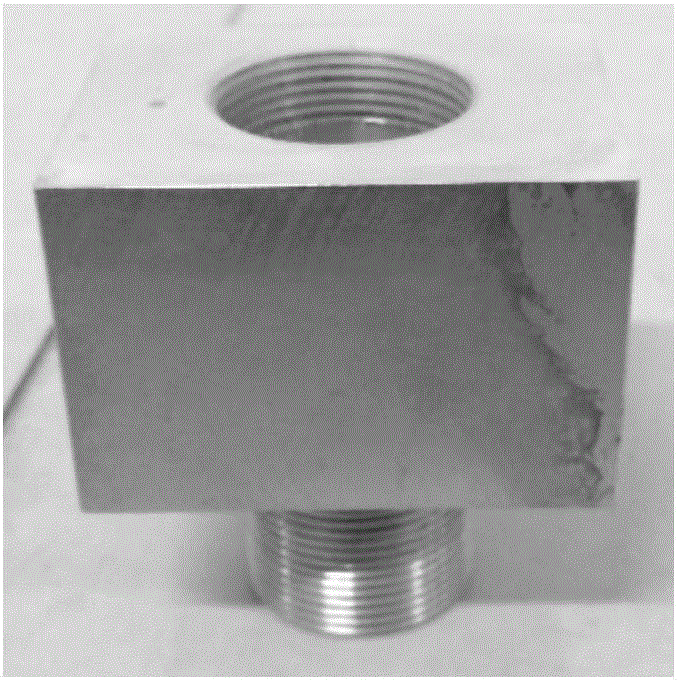

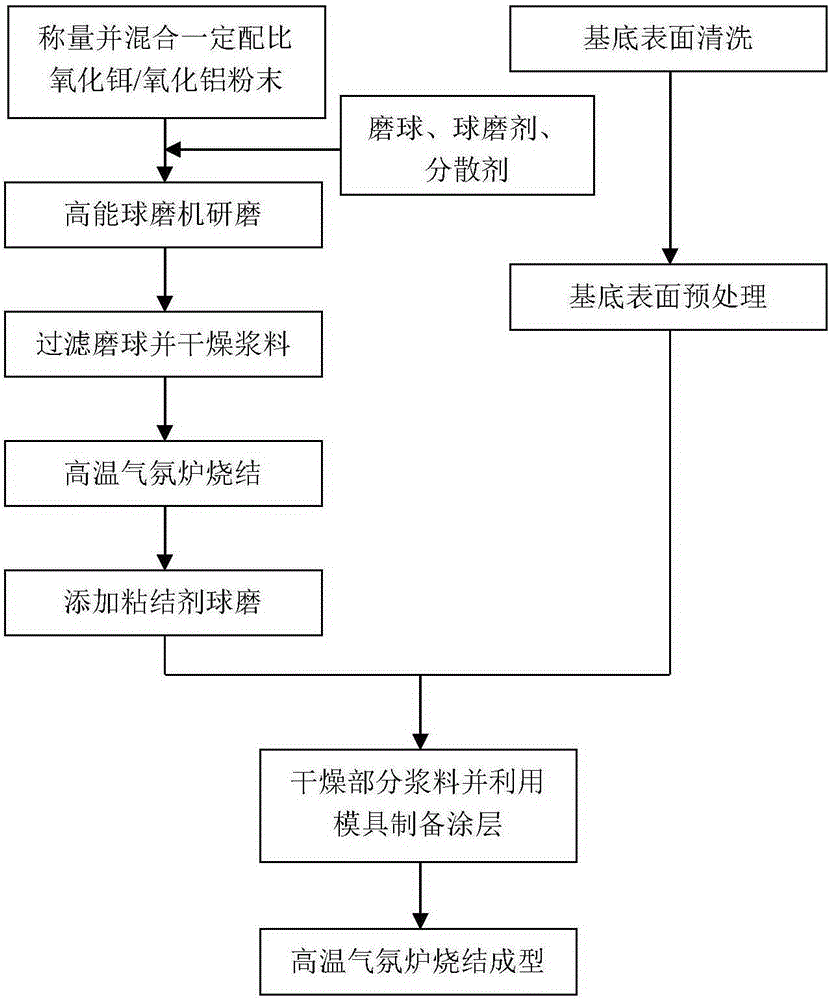

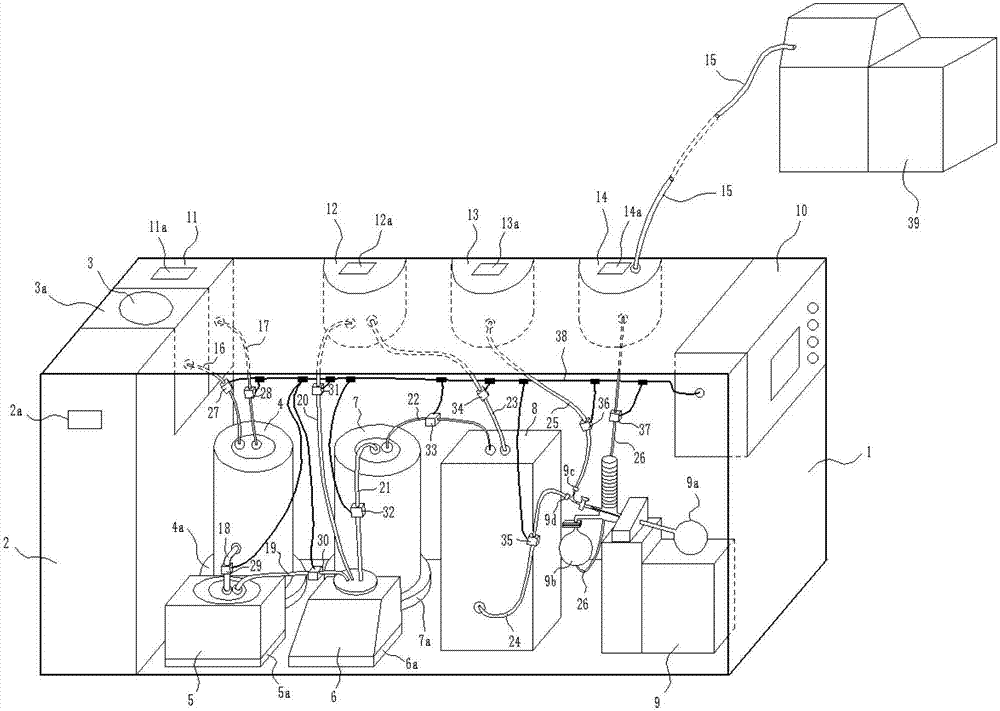

Wavelength selective radiator coating applied to thermophotovoltaic power generation device and preparation method

The invention discloses a wavelength selective radiator coating applied to a thermophotovoltaic power generation device and a preparation method of the wavelength selective radiator coating. Firstly, erbium oxide powder and aluminum oxide powder are uniformly mixed, then mixed powder is obtained, grinding balls, a ball-milling liquid, the mixed powder and a dispersing agent are added to a ball-milling tank for ball milling, and uniformly dispersed slurry is obtained; the grinding balls in the slurry are filtered out, the ball-milling liquid in the slurry is dried, and dry powder is obtained; the dry powder is put in a high-temperature atmosphere furnace and heated, so that the erbium oxide powder and the aluminum oxide powder in the dry powder are sintered to form composite powder, the grinding balls, a binding agent and a diluent are added to the composite powder, the mixture is subjected to ball milling, the uniformly mixed slurry after ball-milling is dried, and then a die can be used for coating a substrate material; after the coated substrate material is dried and sintered at a high temperature, the wavelength selective radiator coating is formed and obtained. The mechanical performance and the surface strength of the coating are improved, the thermal stability of a coating radiator is improved, and the defect that the coating cannot be bonded to a ceramic substrate easily is overcome.

Owner:NANJING UNIV OF SCI & TECH +1

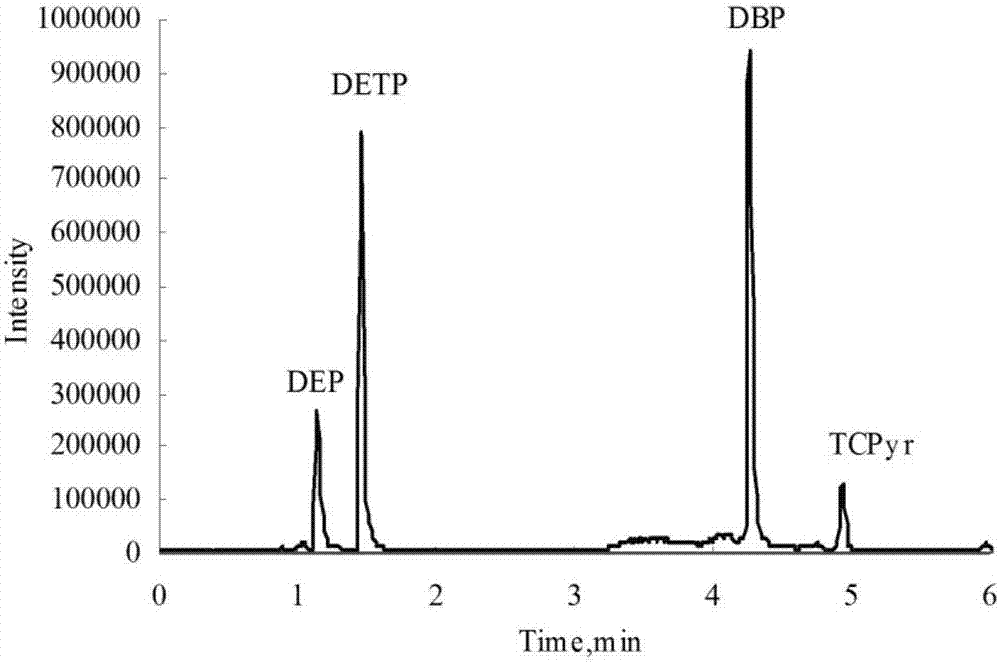

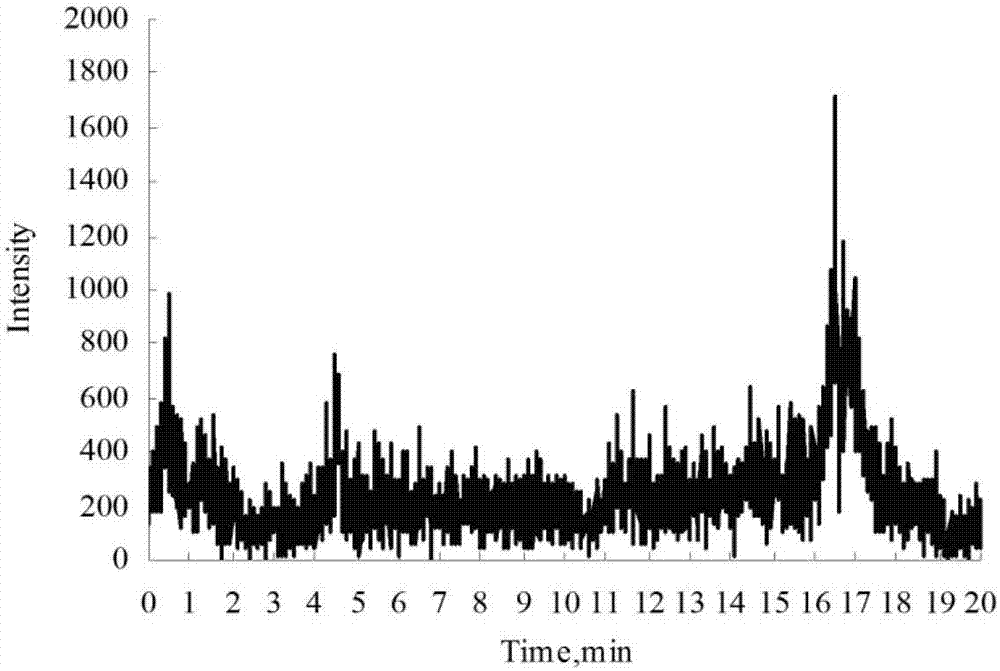

Method and device for simultaneously detecting three metabolic products of chlorpyrifos in urine

ActiveCN107389829ASimplify preprocessing stepsImprove Qualitative AccuracyComponent separationDiethyl thiophosphateDiethyl phosphate

The invention discloses a method and a device for simultaneously detecting three metabolic products of chlorpyrifos in urine. The method comprises the following steps: (A) target compounds selection: selecting 3,5,6-trichloro-2-pyridoxol, triethyl phosphate and diethyl thiophosphate; (B) sample enzymolysis; (C) sample extraction; (D) sample purification and concentration; (E) instrumental analysis. The device mainly comprises a main body and a chromatography-ion tandem mass spectrum detector, wherein the main body comprises a power supply unit, a thawing unit, a centrifugal device I, a water bath device, a turbine mixing device, a centrifugal device II, a purification device, a rotary evaporation device and a PLC (programmable logic controller). According to the method disclosed by the invention, the detection effectiveness and the detection reliability are greatly improved, and the detection time and the detection cost are saved.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

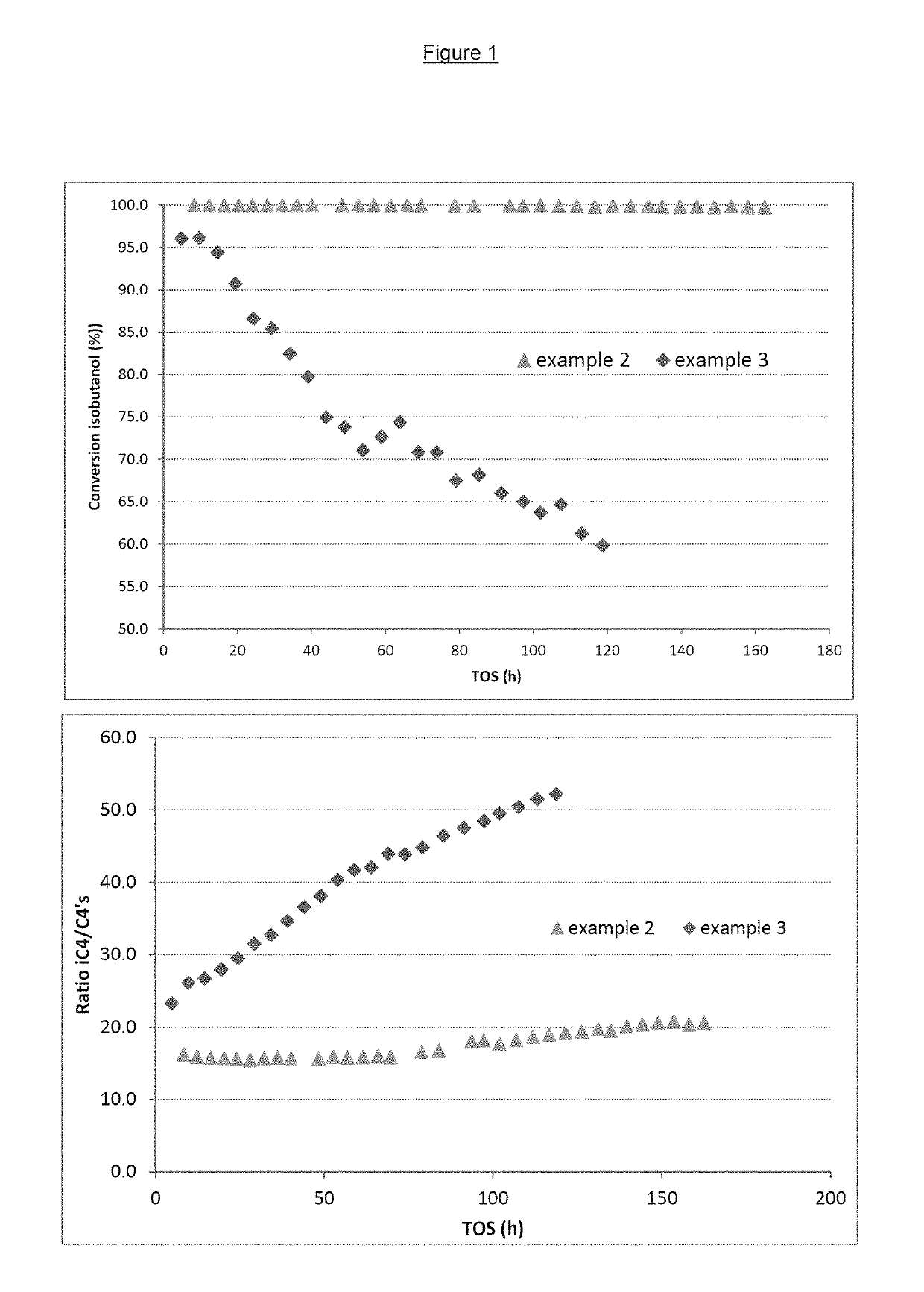

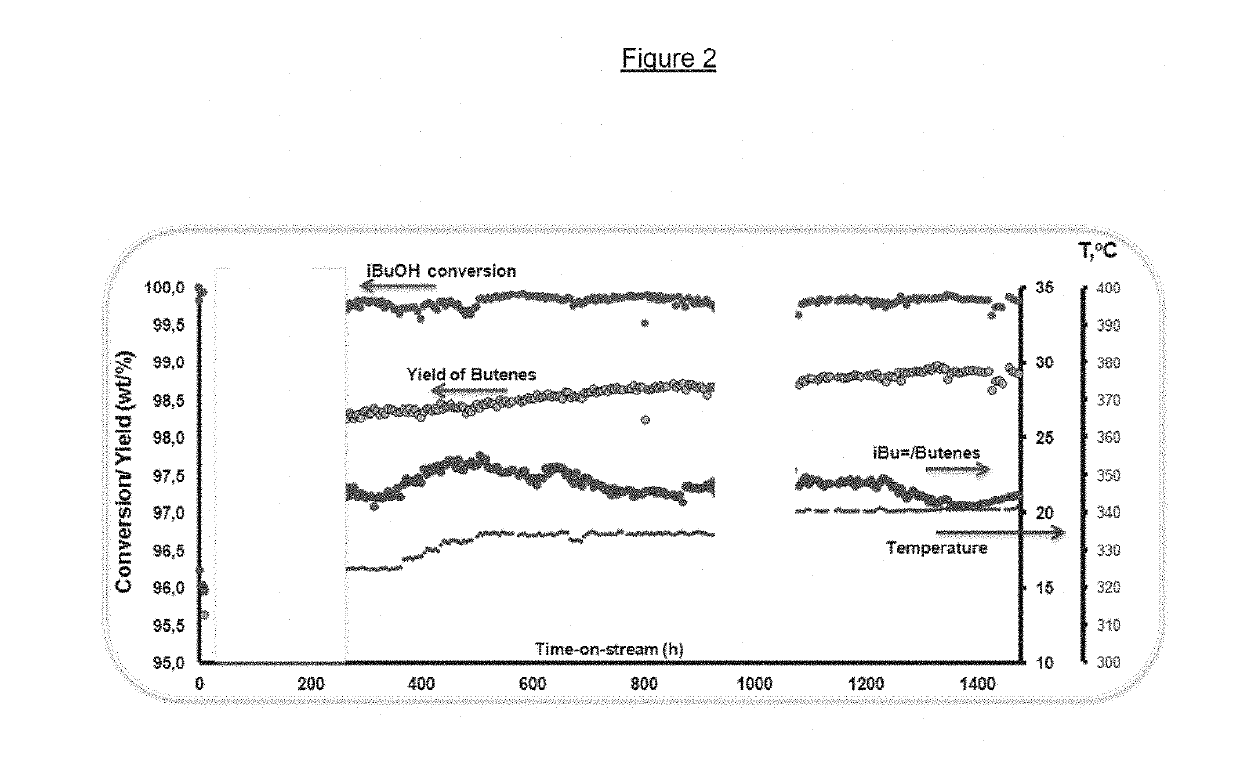

Method for the isomerizing dehydration of a non-linear primary alcohol feedstock in the presence of water injection and a catalyst comprising a fer or mfs zeolite

ActiveUS20190270687A1Speed up the conversion processHigh selectivityHydrocarbon by isomerisationMolecular sieve catalystsGas phaseOrganic chemistry

A process for the isomerizing dehydration of a feedstock including a primary monoalcohol, alone or as a mixture, of formula R—CH2—OH, wherein R is a nonlinear alkyl radical of general formula CnH2n+1 where n is an integer between 3 and 20, the process taking placein the gas phase at a weighted average temperature between 275° C. and 400° C., at a pressure between 0.3 MPa and 1 MPa and at a WWH (weight per weight per hour) between 5 and 10 h−1,in the presence of a catalyst containing at least one silicic binder and at least one zeolite having at least one series of channels, the opening of which is defined by a ring of 8 oxygen atoms (8MR),process wherein vaporized feedstock entering the reactor has a weight content of water of from 4% to 35%.

Owner:TOTAL RES & TECH FELUY +1

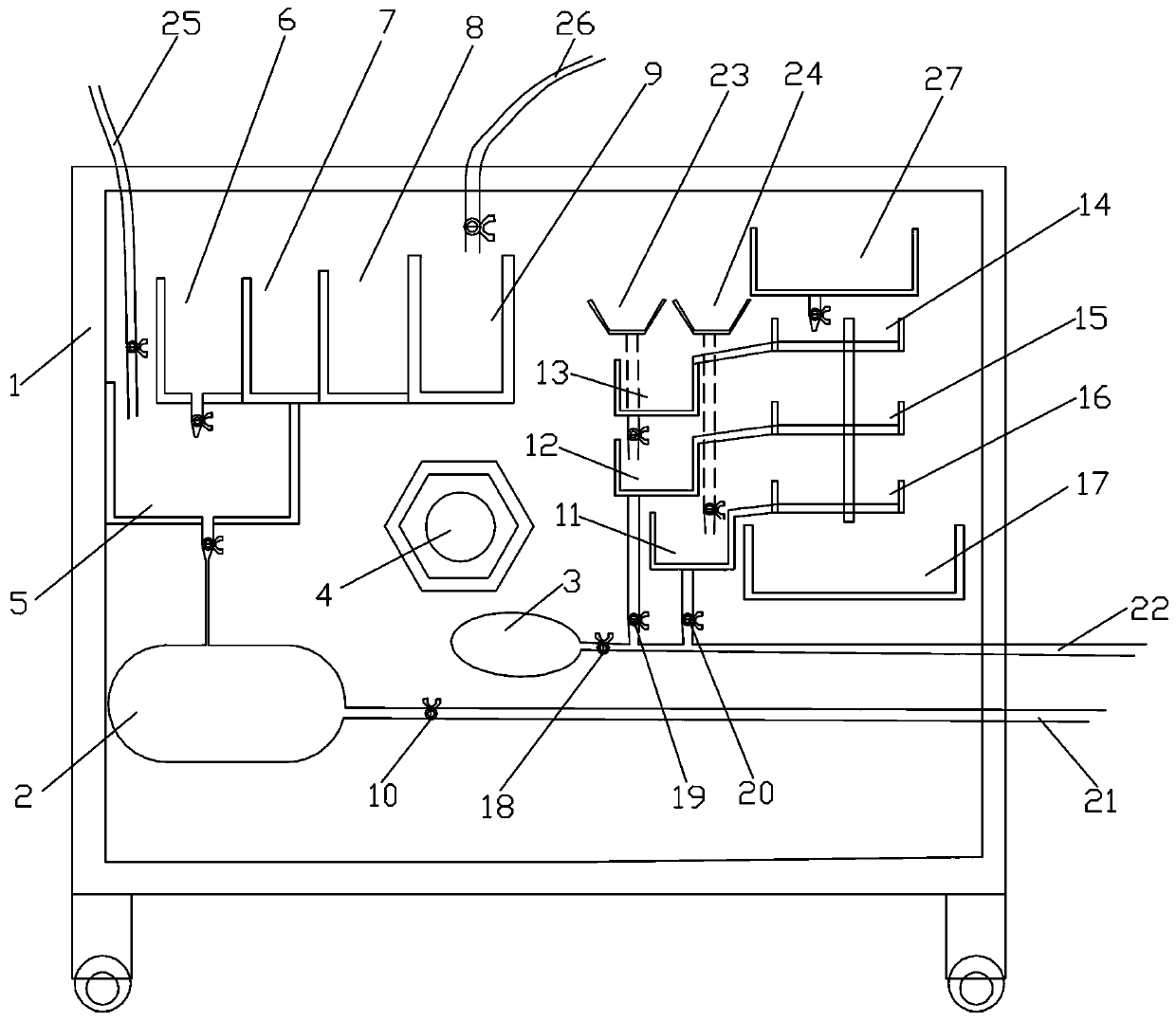

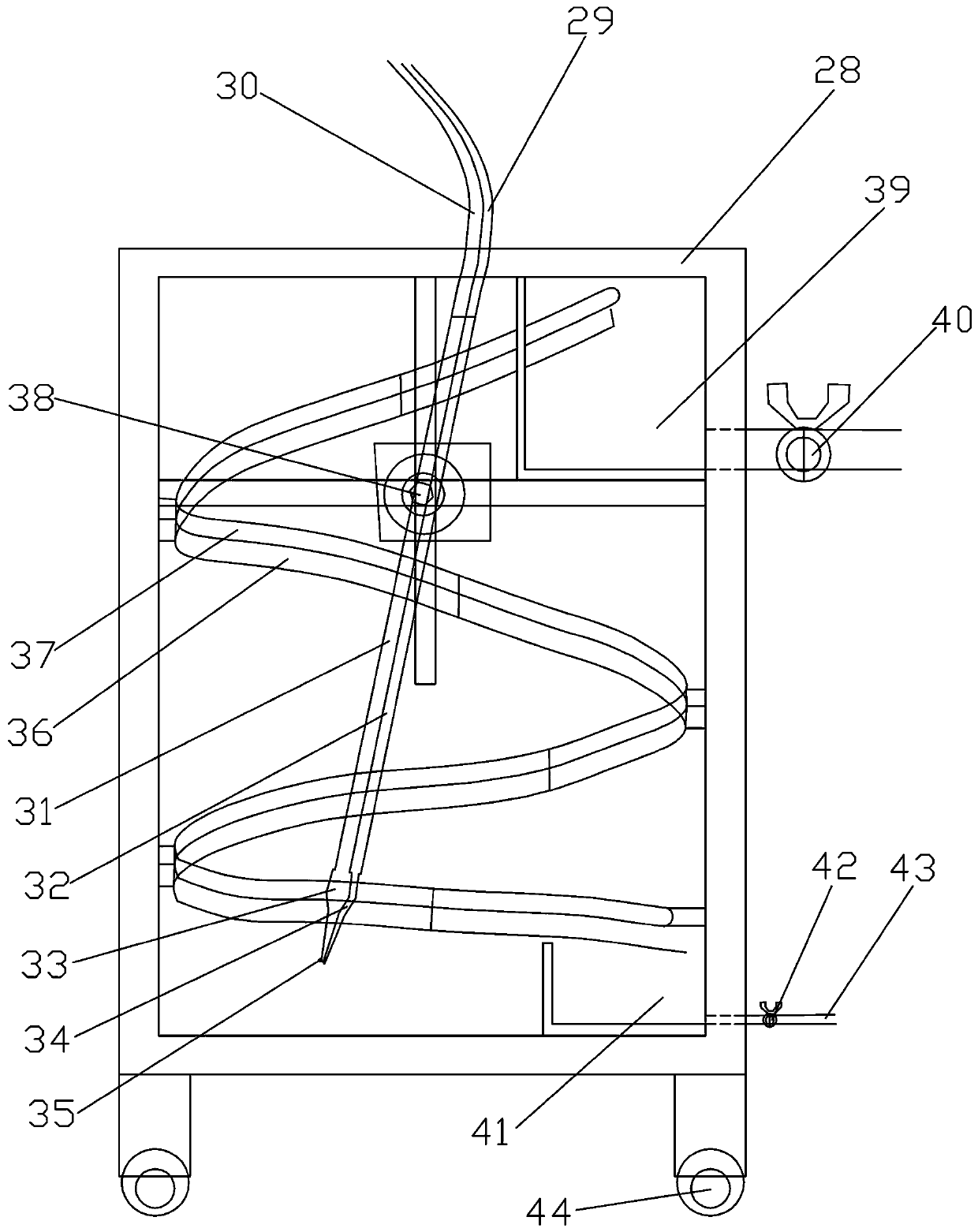

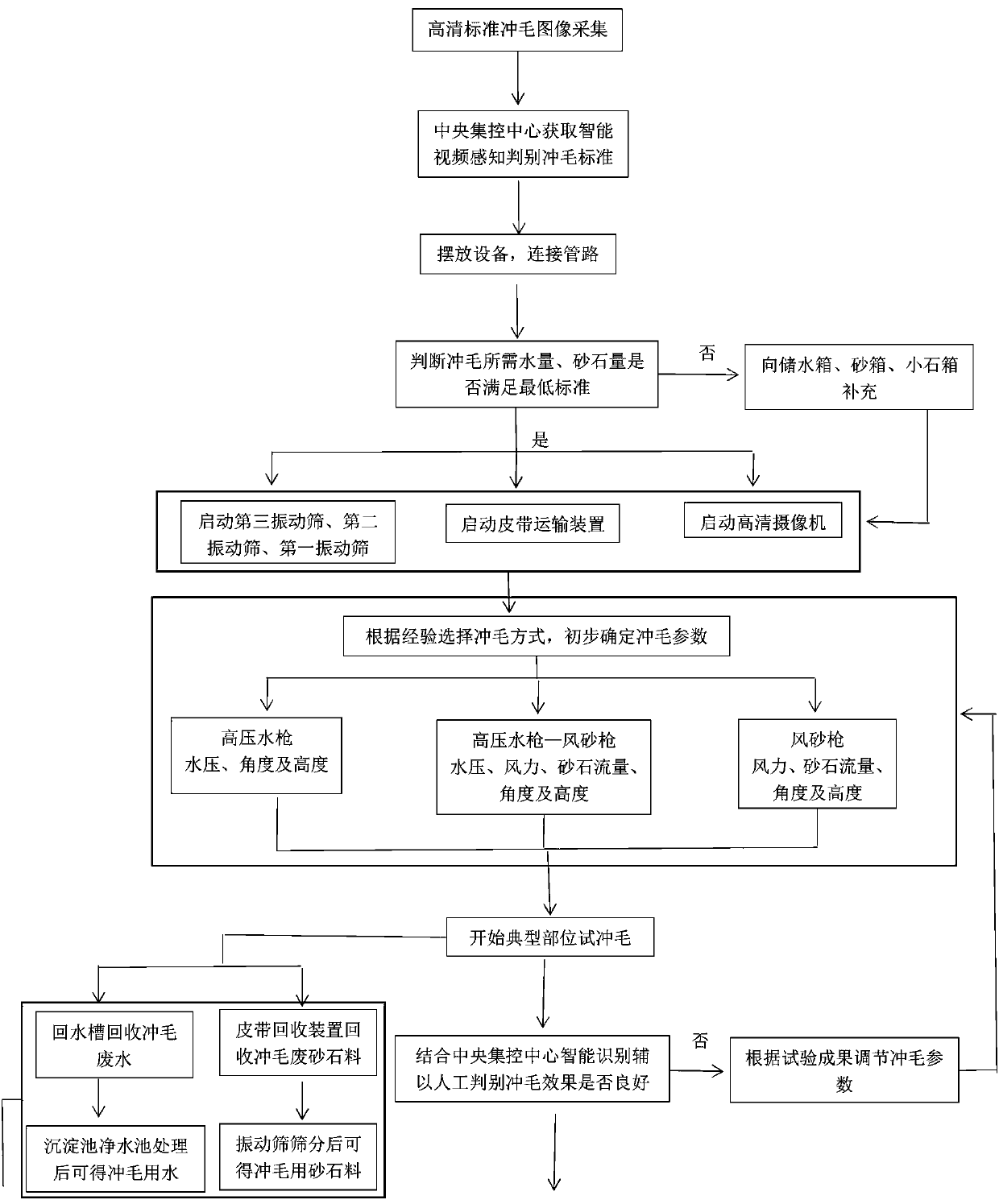

Dam bin surface green cutting device and construction method thereof

PendingCN109972591AReduce manual interventionReduce resource requirementsBarrages/weirsFoundation engineeringAir compressionWater storage tank

The invention discloses a dam bin surface green cutting device and a construction method thereof. The dam bin surface green cutting device comprises a preparation device and an operation device, wherein the preparation device comprises a high-pressure water pump, an air compression device and a central centralized control center, a water inlet of the high-pressure water pump is connected with a water storage tank, a water outlet of the high-pressure water pump is connected with a high-pressure water outlet pipe, an air outlet of the air compression device is connected with an air sand outlet pipe, and the air sand outlet pipe is simultaneously connected with a sand box for providing sand materials and a small stone box for providing stone materials; and the operation device comprises a high-pressure water gun and an air sand gun which are connected side by side. According to the intermittent time and strength of concrete on the dam bin surface, single or double effects of the high-pressure water gun and the air sand gun are selected to perform green cutting on the concrete on the dam bin surface to achieve the best green cutting effect.

Owner:CHINA THREE GORGES PROJECTS DEV CO LTD

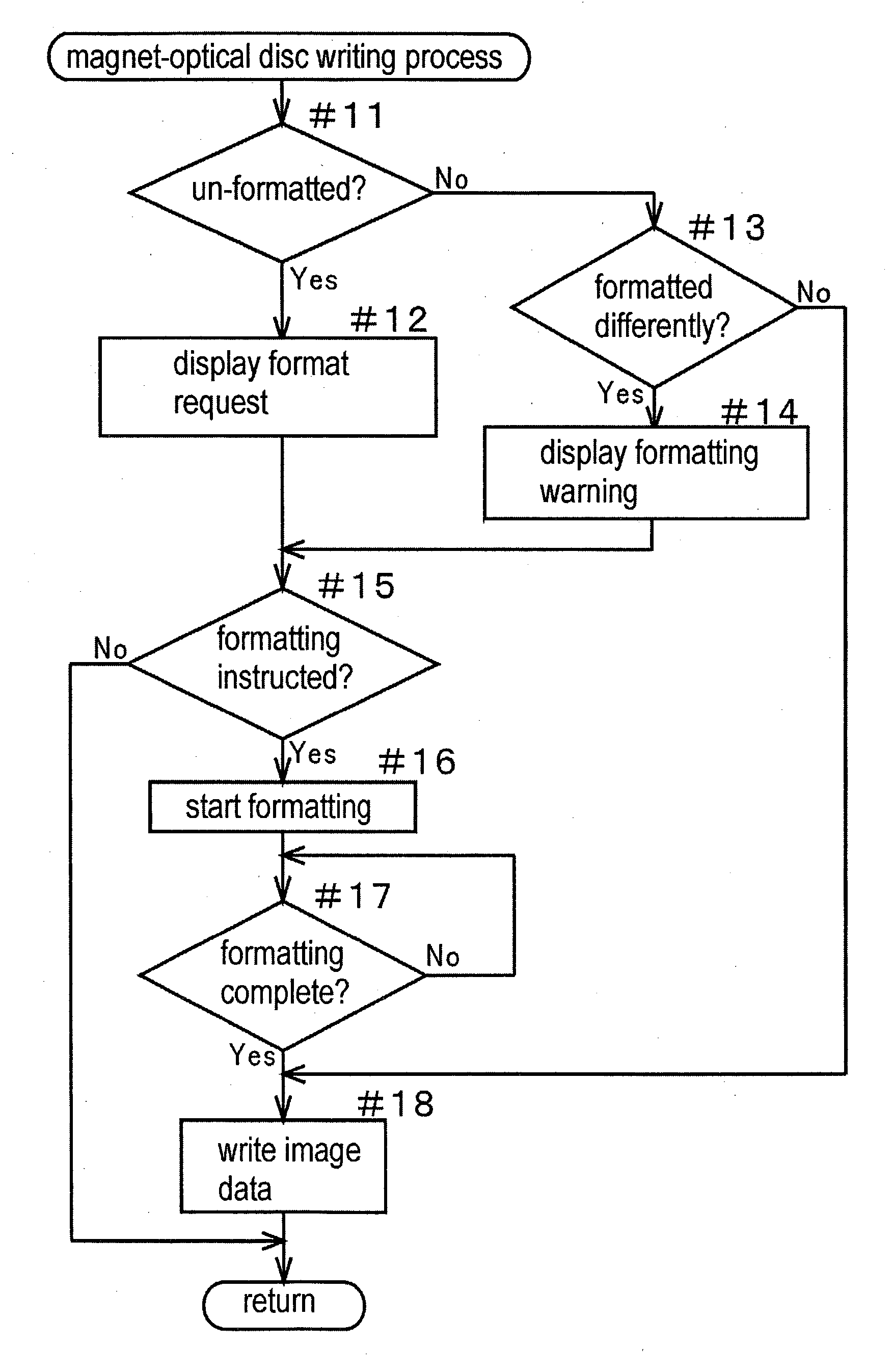

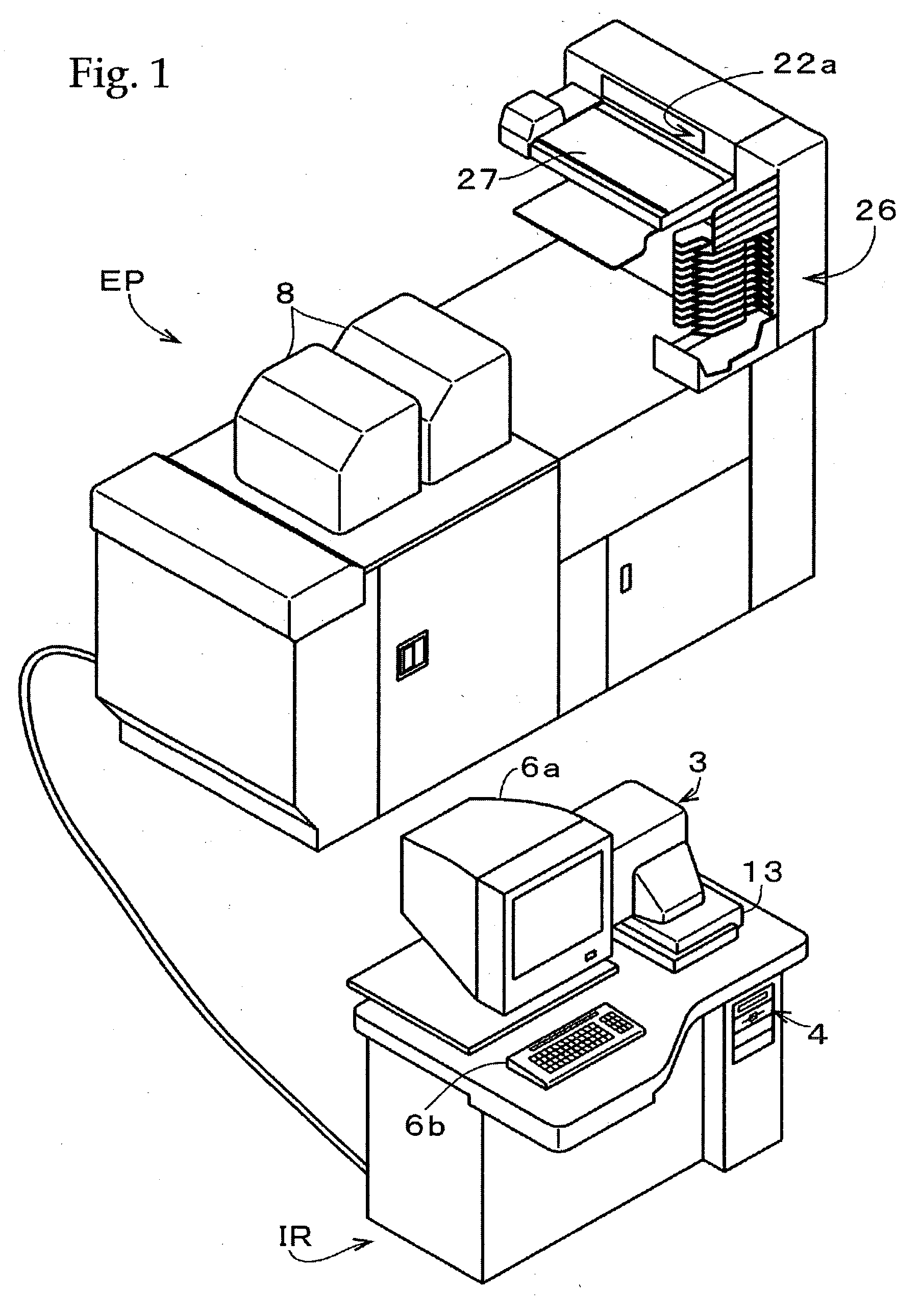

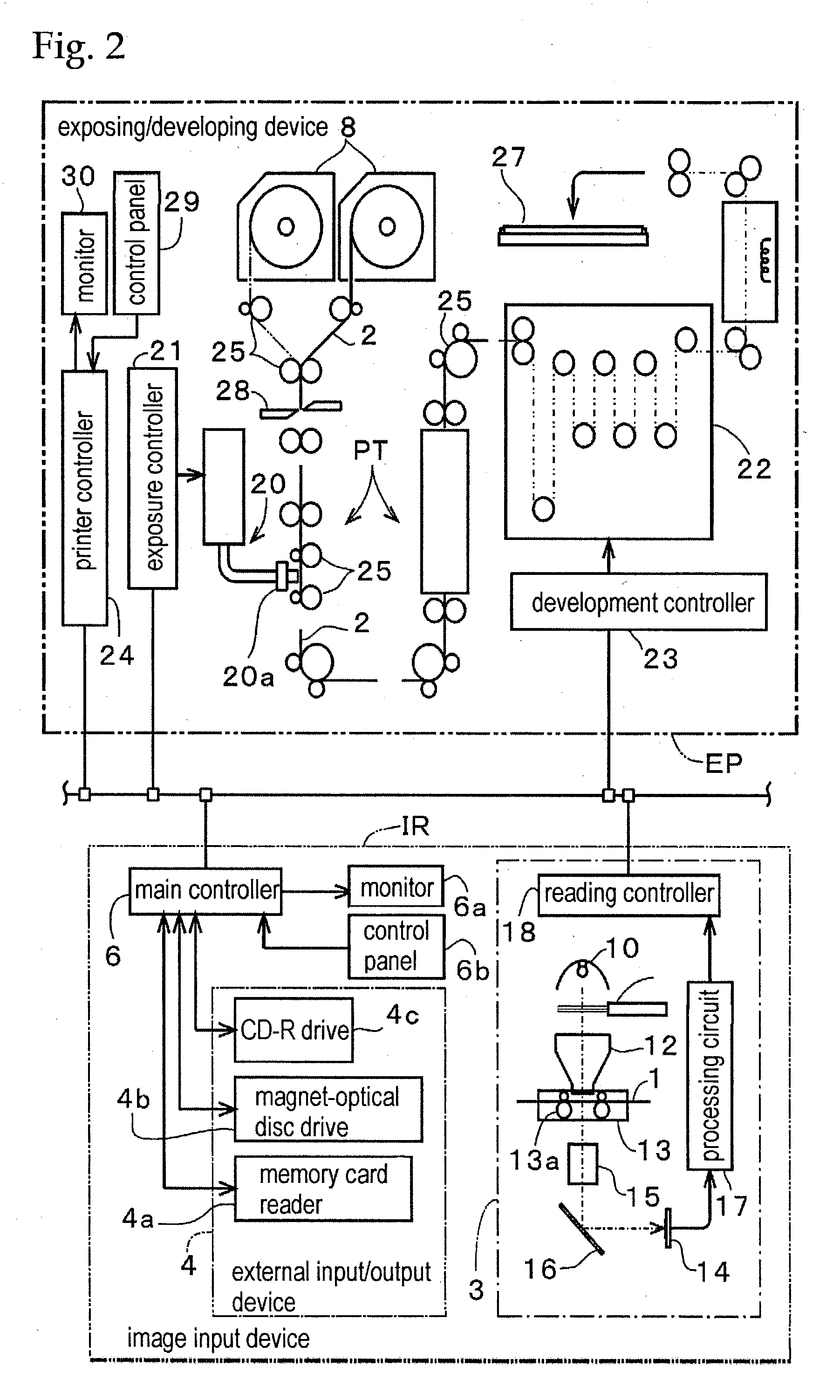

Photographic printing system

InactiveUS20060050322A1Facilitate handlingBe selectiveCombination recordingTelevision system detailsDisplay processingFilm (photographic)

A photographic printing system includes a film reader for reading photographic image of a photographic film, a printer for printing the photographic image on an image recording medium based on photographic image data obtained through the film reader, a writer for writing at least the photographic image data in a loaded optical disc of the WORM (Write Once Read Many) type, and a controller for controlling the writing process of the writer. The controller allows writing, in the optical disc, of both the image data and a display processing program for displaying the image data written in the optical disc on a monitor when the optical disc has no data pre-written therein and allows writing, in the optical disc, of the image data when the optical disc has such display processing program pre-written therein.

Owner:NK WORKS CO LTD

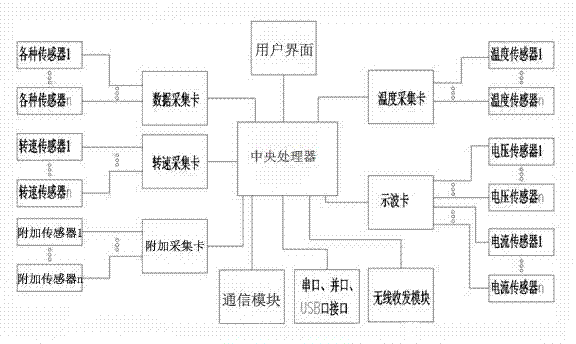

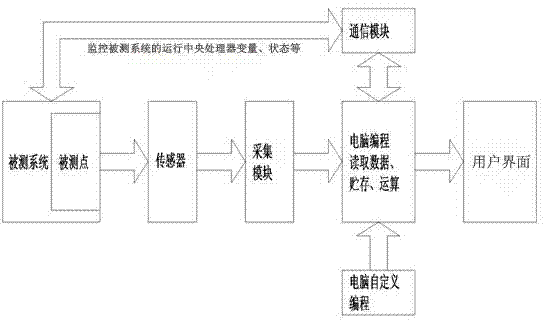

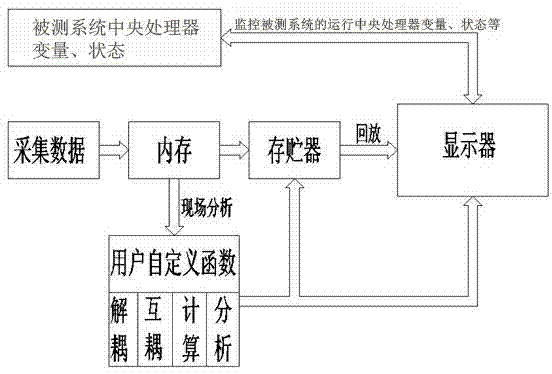

Comprehensive testing system

InactiveCN103115646AAccelerated settlementDirect monitoring of operating statusMeasurement devicesData displayCombined test

The invention relates to the technical field of measurement and test, in particular to a comprehensive testing system. The comprehensive testing system comprises a central processing unit, an acquisition module, a communication module and a user interface. The central processing unit is used for storing and operating information of the acquisition module. The acquisition module is connected with the central processing unit, and the central processing unit receives data acquired by the acquisition module. One end of the communication module is connected with the central processing unit, and the other end of the communication module is connected with a tested system or tested point and monitors central processing unit variables of the tested system or variation states of the tested point. The user interface is connected with the central processing unit and used for receiving and displaying signals of the central processing unit. The central processing unit comprehensively solves the technical problems of measurement and test according to display, storage and operation of the acquired data.

Owner:HISENSE HOME APPLIANCES GRP CO LTD +1

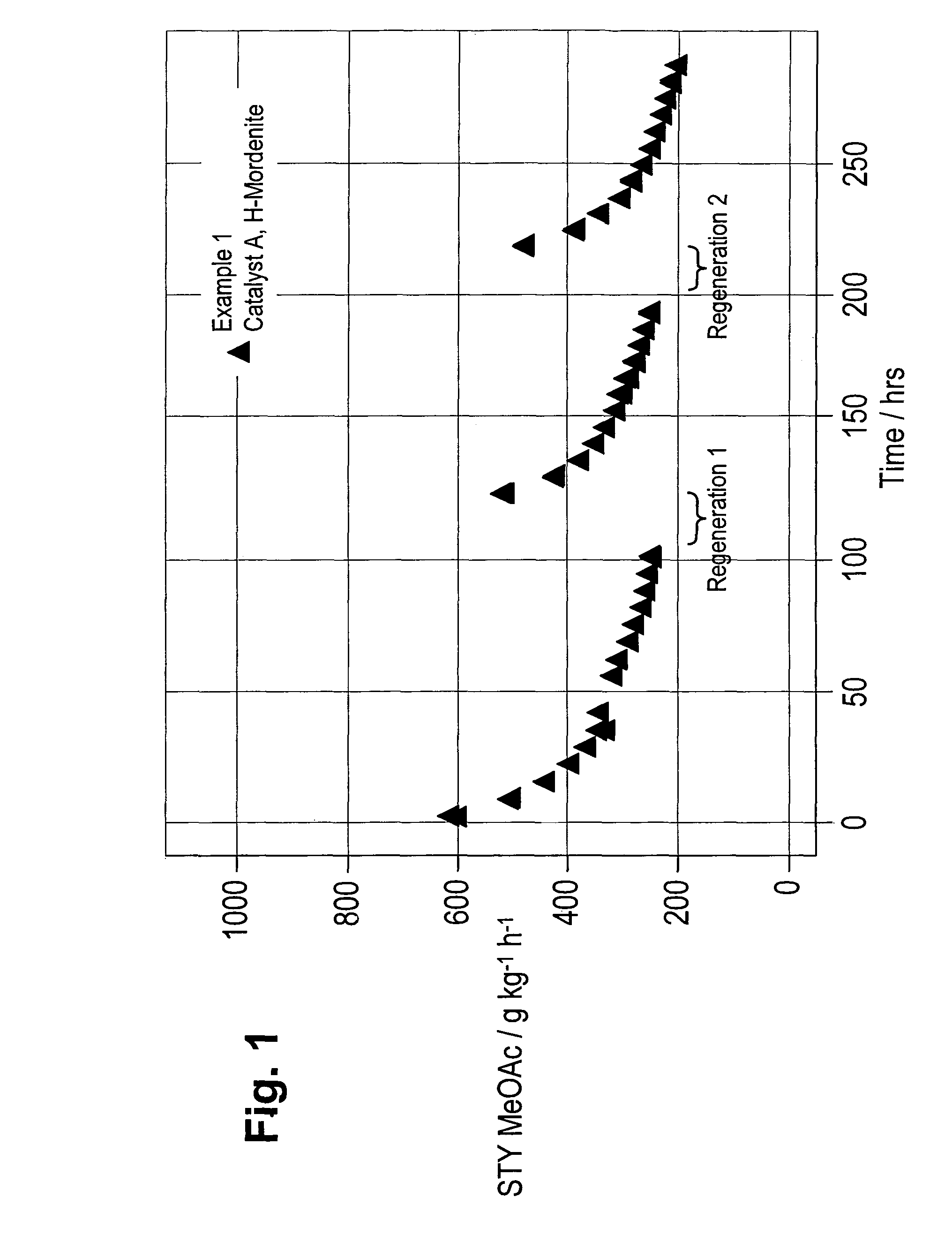

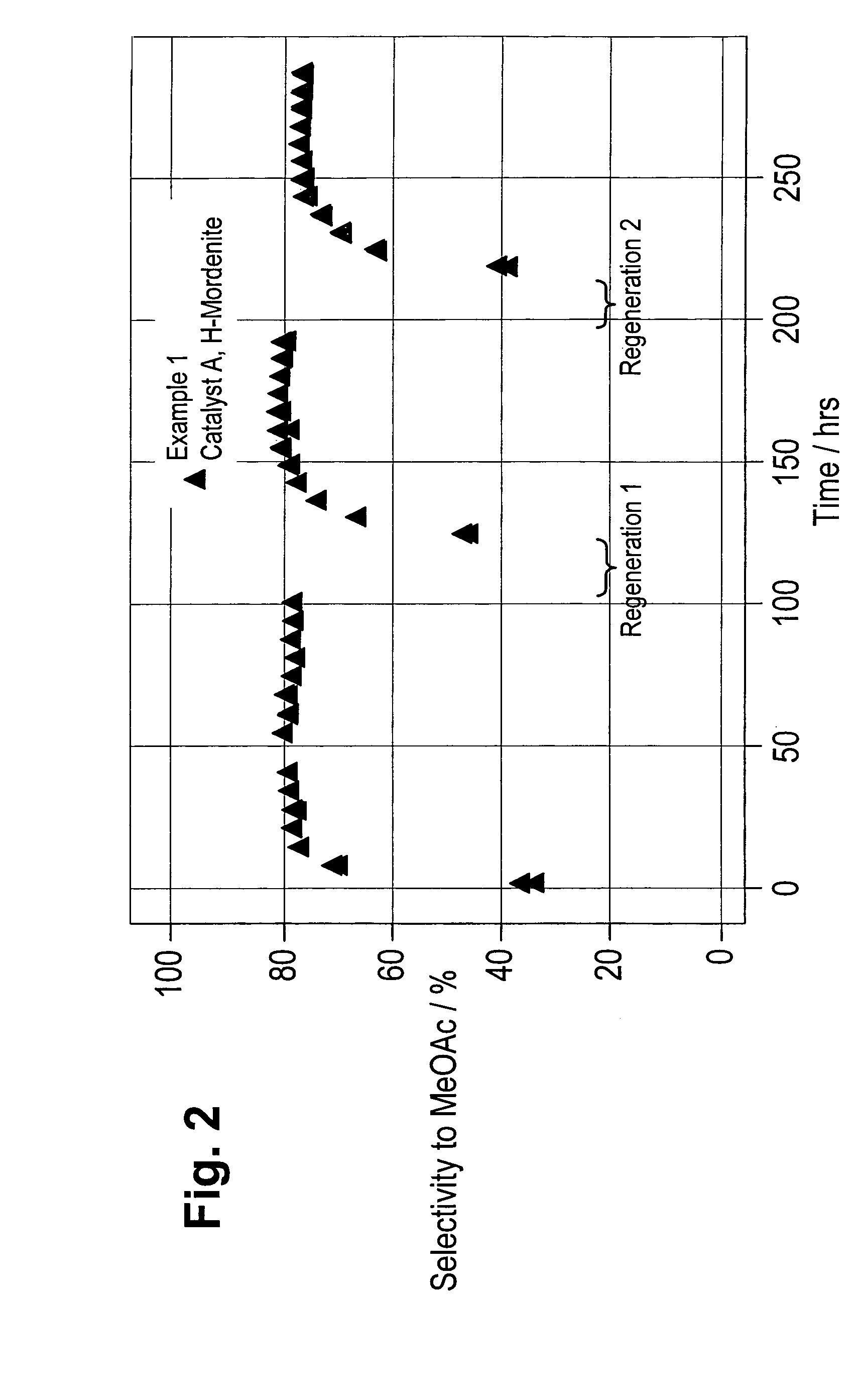

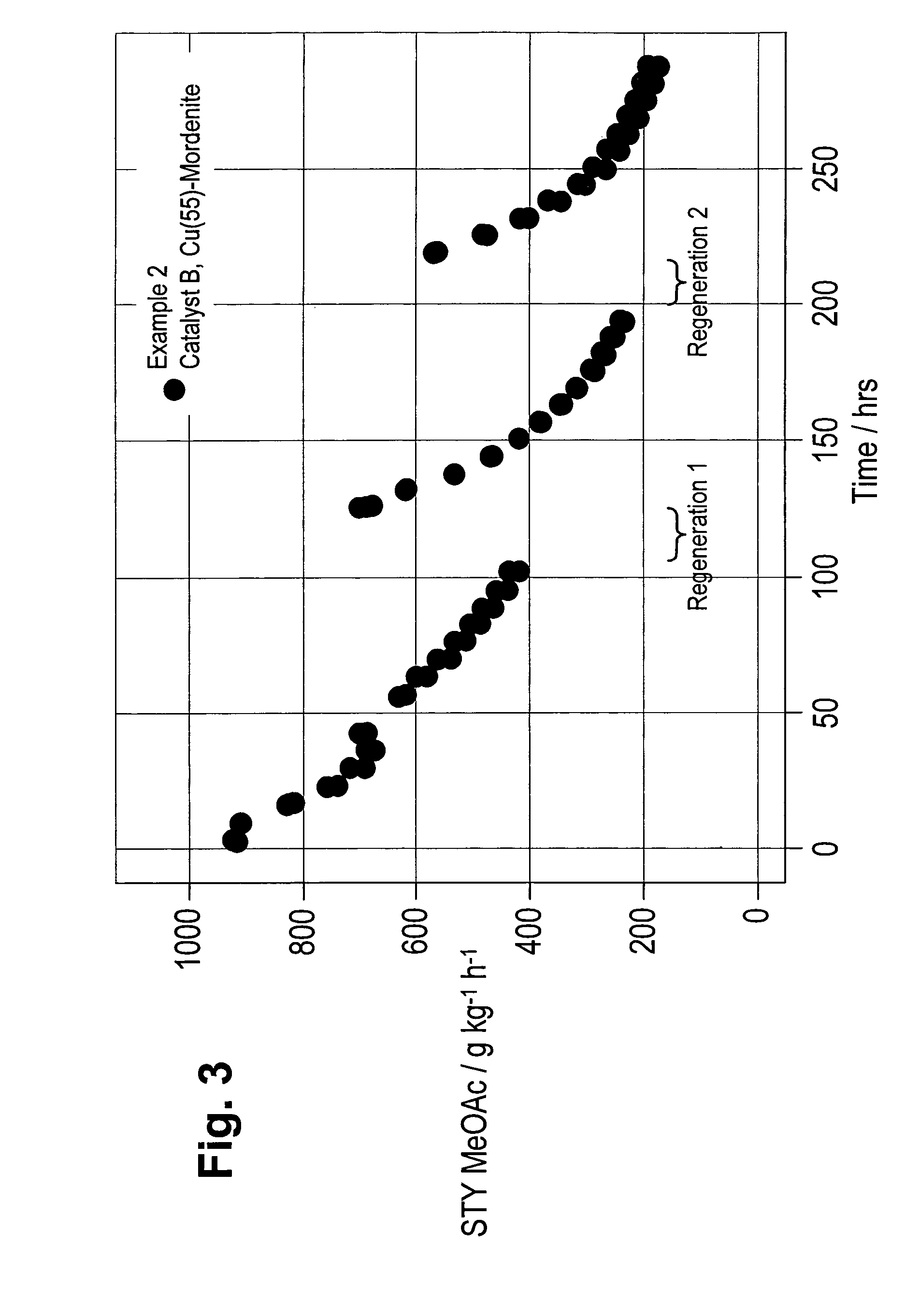

Regeneration of zeolite carbonylation catalysts

ActiveUS8329606B2Restore catalyst activityMaintain selectivityMolecular sieve catalystsOrganic compound preparationCarbonylationDimethyl ether

Process for the in-situ regeneration of a zeolite catalyst in a carbonylation process for the production of at least one of methyl acetate and acetic acid. The process is carried out by (a) contacting a carbonylatable reactant selected from methanol, dimethyl ether and dimethyl carbonate and carbon monoxide in a reactor with a zeolite catalyst and recovering a product stream containing at least one of methyl acetate and acetic acid from the reactor, (b) ceasing contact of the catalyst with the carbonylatable reactant, (c) regenerating the catalyst with a regenerating gas selected from hydrogen or a mixture of hydrogen and carbon monoxide at a temperature in the range 250 to 600 C, and (d) terminating the hydrogen regenerating step and resuming contact of the catalyst with the carbonylatable reactant and carbon monoxide.

Owner:THE BRITISH PETROLEUM CO LTD

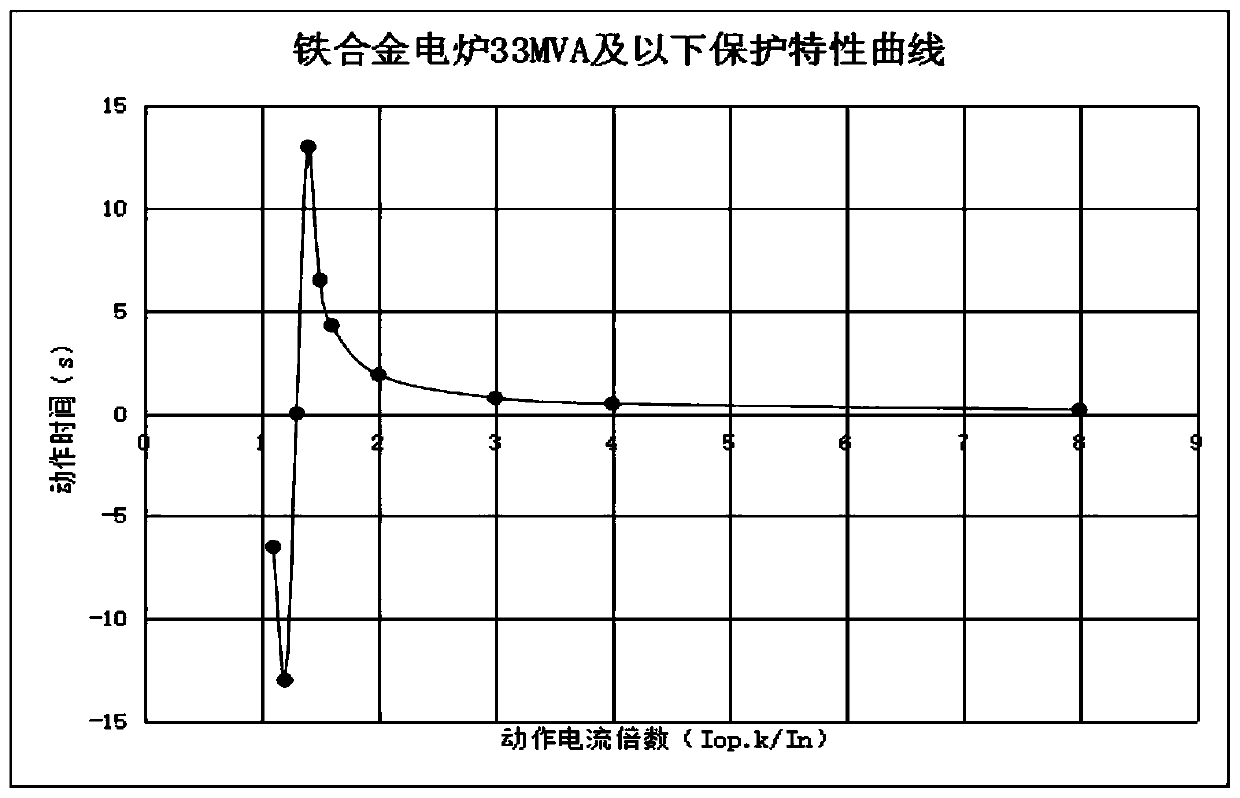

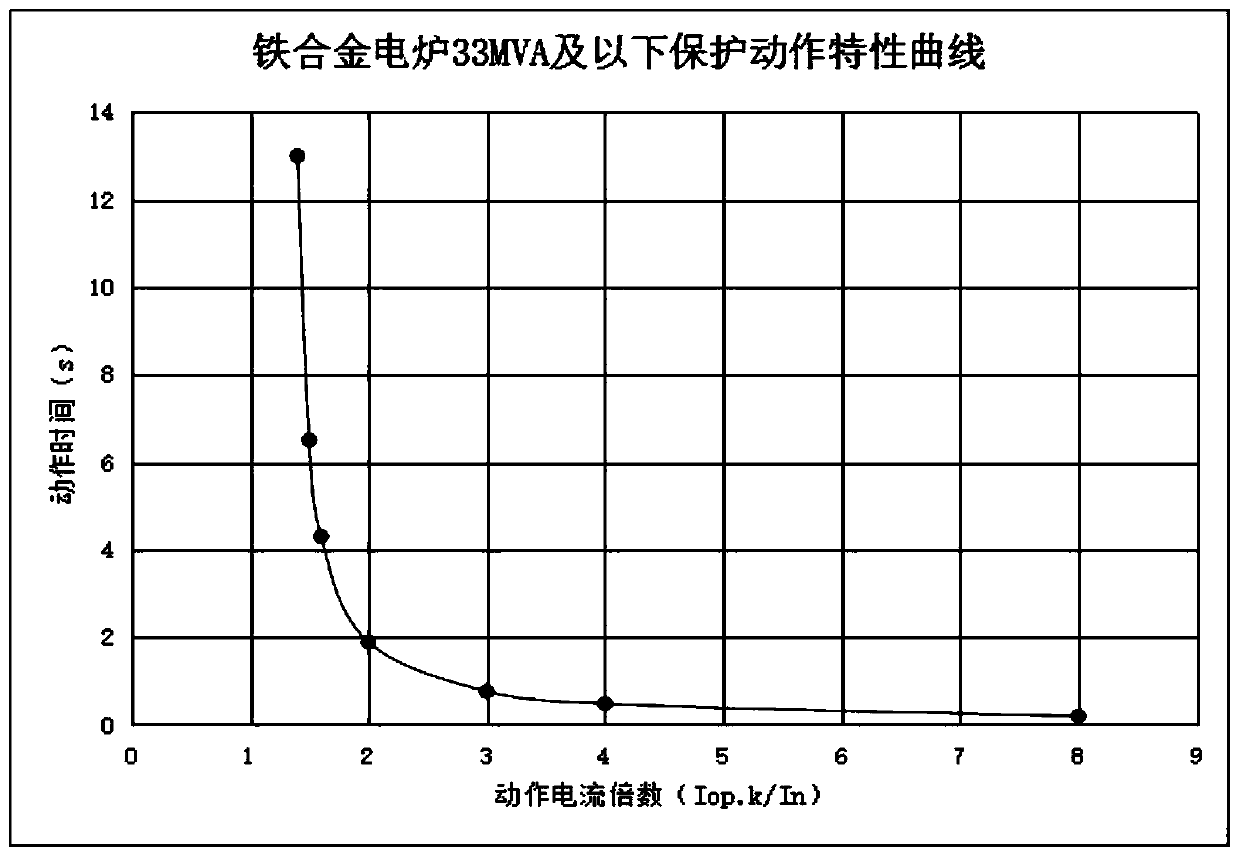

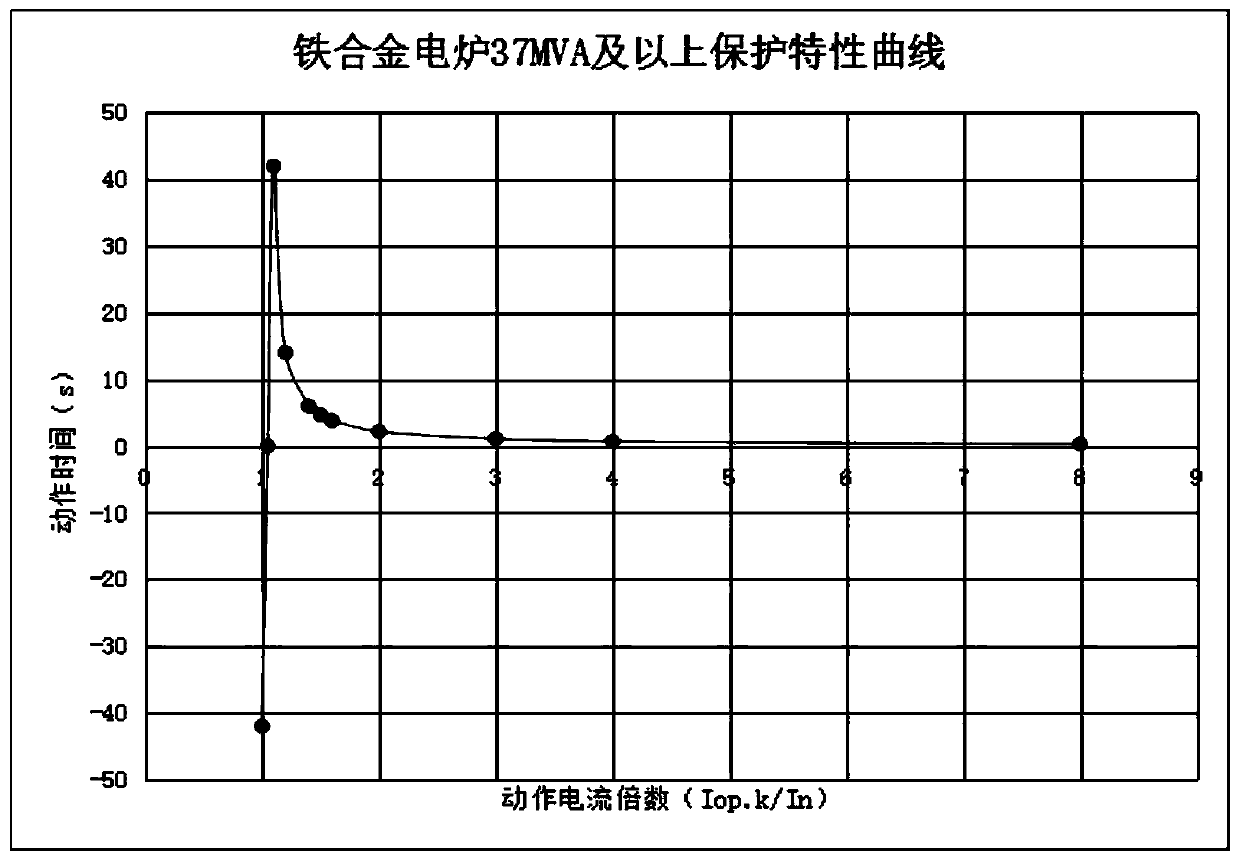

Relay protection configuration and setting method for high-voltage power distribution system of ferroalloy electric furnace

ActiveCN110556784AExtended service lifeMake up for the problem of dead zoneArrangements responsive to excess currentLow voltageTransformer

The invention discloses a relay protection configuration and setting method for a high-voltage power distribution system of a ferroalloy electric furnace. The method comprises overload protection, instantaneous current quick-break protection and low-voltage locking overcurrent protection, wherein the instantaneous current quick-break protection serves as main protection, and is set to be effectivewhen a short-circuit fault occurs in the transformer; the low-voltage locking overcurrent protection serves as backup protection of the instantaneous quick-break protection and is set to be effectivewhen a small-current grounding fault of the transformer occurs; and inverse time limit overload protection has an inverse time limit characteristic, is used as backup protection of the instantaneousquick-break protection and the low-voltage blocking overcurrent protection, is matched with an operation curve of the ferroalloy electric furnace transformer by utilizing an inverse proportion relation between time and current, and does not act during normal production. Each kind of protection can be used as backup protection of the next kind of protection, especially in an ungrounded system withthe high voltage side being a neutral point or places away from an electric power system. Although the fault current is small, the applied low-voltage locking overcurrent protection and the inverse time limit overload protection can be effective.

Owner:鞍钢集团工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com