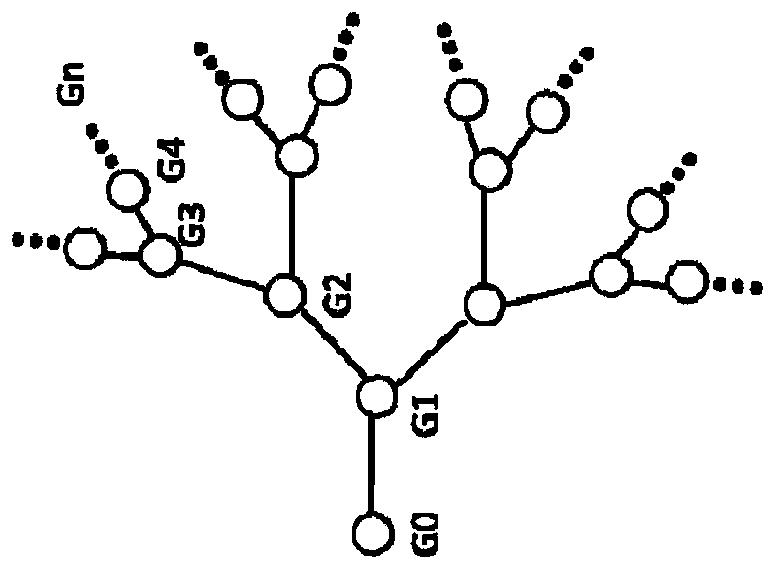

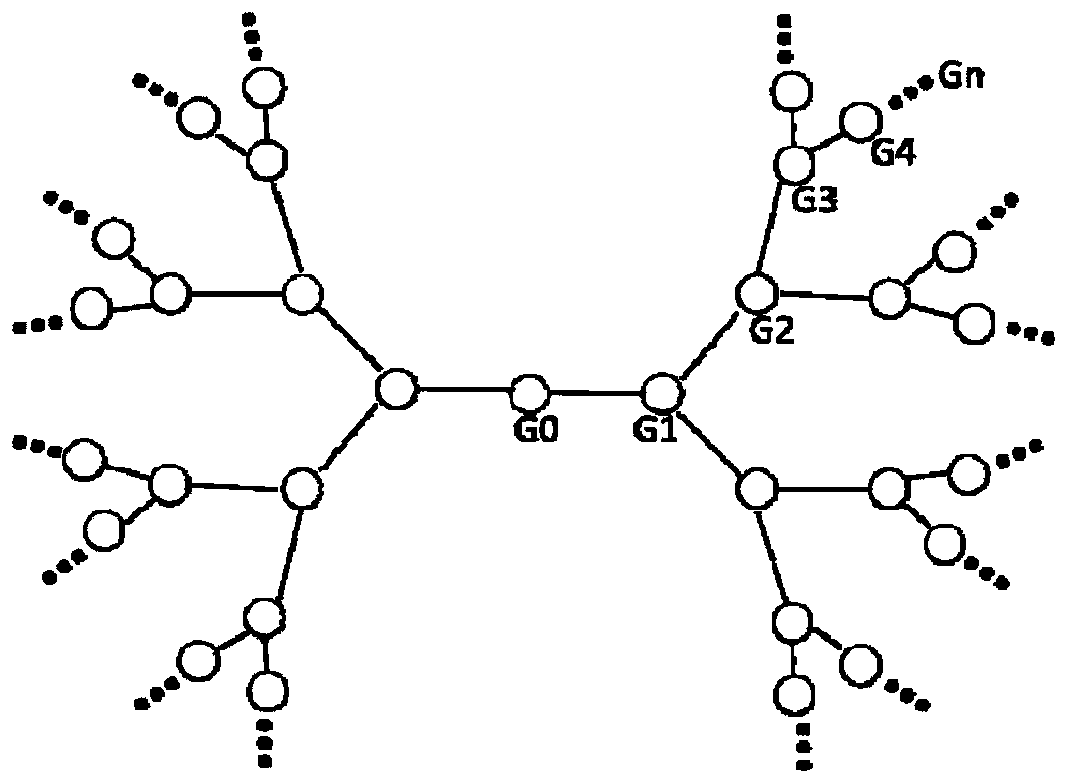

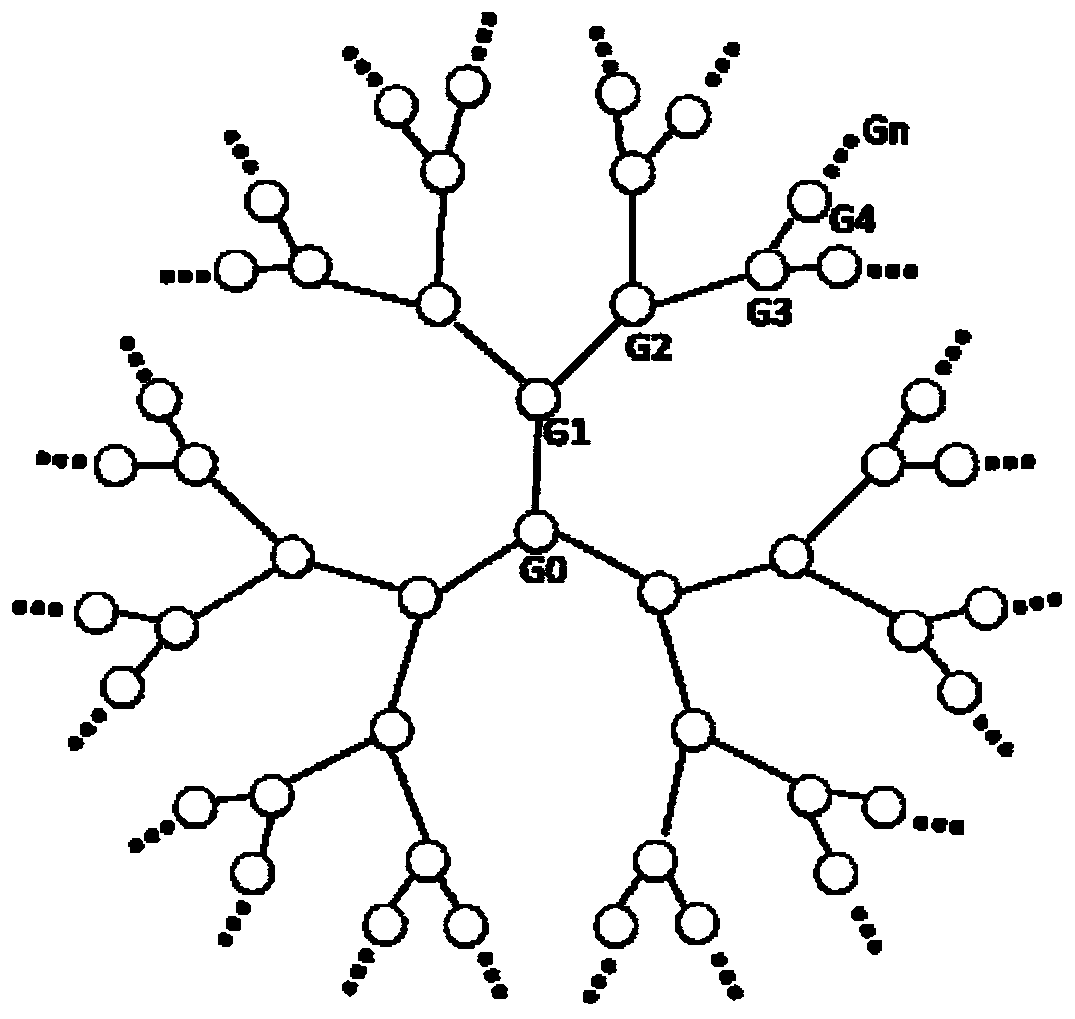

Dendritic branched molecular modified separation membrane and preparation method thereof, composite separation membrane and application of dendritic branched molecular modified separation membrane and composite separation membrane

A separation membrane and tree-like technology, applied in the field of fluid separation, can solve the problems of regulating separation membranes, which are rarely studied, and achieve the effect of maximizing balance, easy control, and increasing permeation flux.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] According to the second aspect of the present invention, the present invention provides a method for preparing a separation membrane modified by dendritic branched molecules, comprising the following steps: immersing the separation membrane in a solution of dendritic branched molecules, making the dendritic branched molecules A modified membrane is formed on the membrane surface of the separation membrane and / or the pore wall of the inner hole to obtain a dendritic branched molecule modified separation membrane.

[0061] In the present invention, the modified membrane formed on the membrane surface of the separation membrane and / or the hole wall of the inner hole includes the modified membrane formed on the membrane surface of the separation membrane, and the hole wall of the inner hole of the separation membrane. There are three situations in which a modified membrane is formed on the separation membrane and a modified membrane is formed on the membrane surface of the s...

Embodiment 1

[0106] This embodiment provides a polyamide dendrimer modified polyvinylidene fluoride (PVDF) microfiltration membrane, which is prepared according to the following method:

[0107] (1) Preparation of polyvinylidene fluoride casting solution, the formula is as follows, 15wt% PVDF, 1wt% (polyethylene glycol) PEG 400, 0.5wt% (polyvinylpyrrolidone) PVP solution, 83.5wt% (N-methylpyrrolidone ) NMP.

[0108] (2) After defoaming the polyvinylidene fluoride casting solution, it is phase transformed into a polyvinylidene fluoride microfiltration membrane in a coagulation bath, wherein the coagulation bath is composed of water at a temperature of 35°C.

[0109] (3) Immerse the polyvinylidene fluoride microfiltration membrane prepared above in the solution of polysulfonamide dendrimers for 1 hour, remove excess solution, and then immerse in FeCl 3 In the solution for 5min, remove excess solution. Place in deionized water for standby to obtain polysulfonamide dendrimer modified polyvin...

Embodiment 2

[0121] This embodiment provides a polyamide dendrimer modified polytetrafluoroethylene (PTFE) microfiltration membrane, which is prepared according to the following method:

[0122] (1) Configure the polytetrafluoroethylene casting film solution containing polyamide dendrimers, the formula is as follows, 15wt% (polytetrafluoroethylene) PTFE, 0.5wt% PEG400, 1wt% PVP solution, 2wt% polyamide dendrimers Molecule, 81.5 wt% NMP.

[0123] (2) The above-mentioned polytetrafluoroethylene casting film solution containing polyamide dendrimer is degassed, and then undergoes phase transformation into a polytetrafluoroethylene microfiltration membrane in a coagulation bath, wherein the coagulation bath is composed of water at a temperature of 25°C .

[0124] (3) Immerse the polytetrafluoroethylene multi-microfiltration membrane prepared above in the maleic anhydride ether solution for 10 minutes, remove the excess solution, and then place it in 40° C. deionized water for 5 minutes to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com