Relay protection configuration and setting method for high-voltage power distribution system of ferroalloy electric furnace

A technology of relay protection and high-voltage power distribution, applied in emergency protection circuit devices, protection against overcurrent, emergency protection devices with automatic disconnection, etc. Remove faults and other problems to achieve the effect of improving service life and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0064] The present invention provides a relay protection configuration scheme and a mathematical model of inverse time-limit overload relay protection. The relay protection scheme is shown in Table 2. A relay protection configuration and setting method for a ferroalloy electric furnace high-voltage power distribution system is organized as follows :

[0065] Table 2 Relay protection configuration and setting calculation of ferroalloy furnace transformer

[0066]

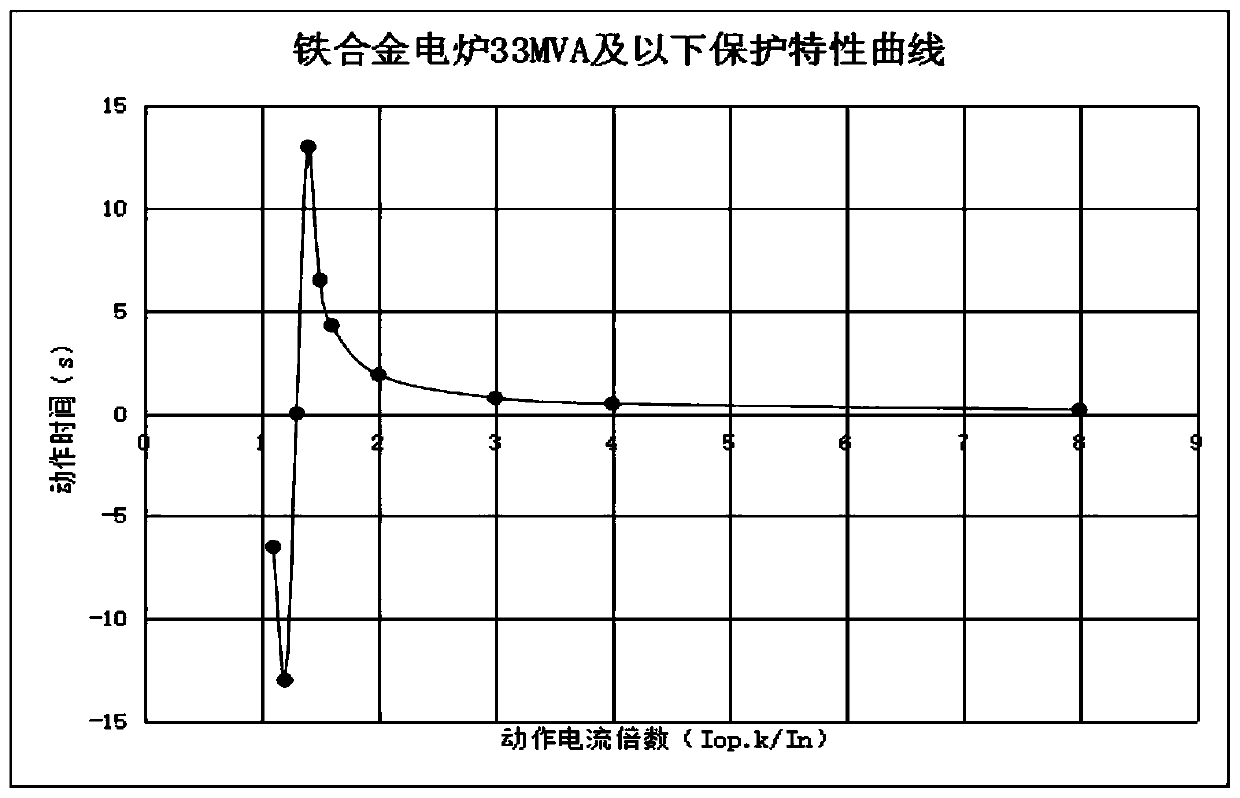

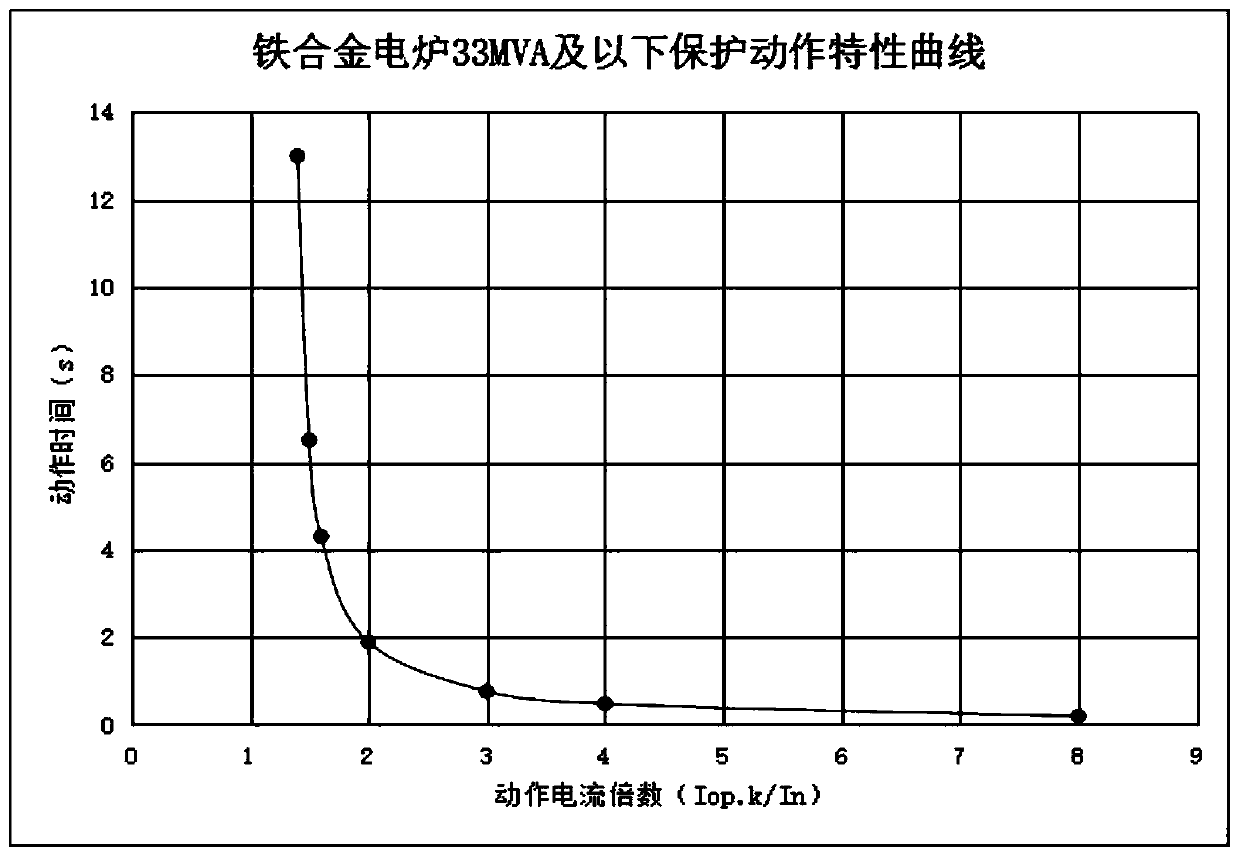

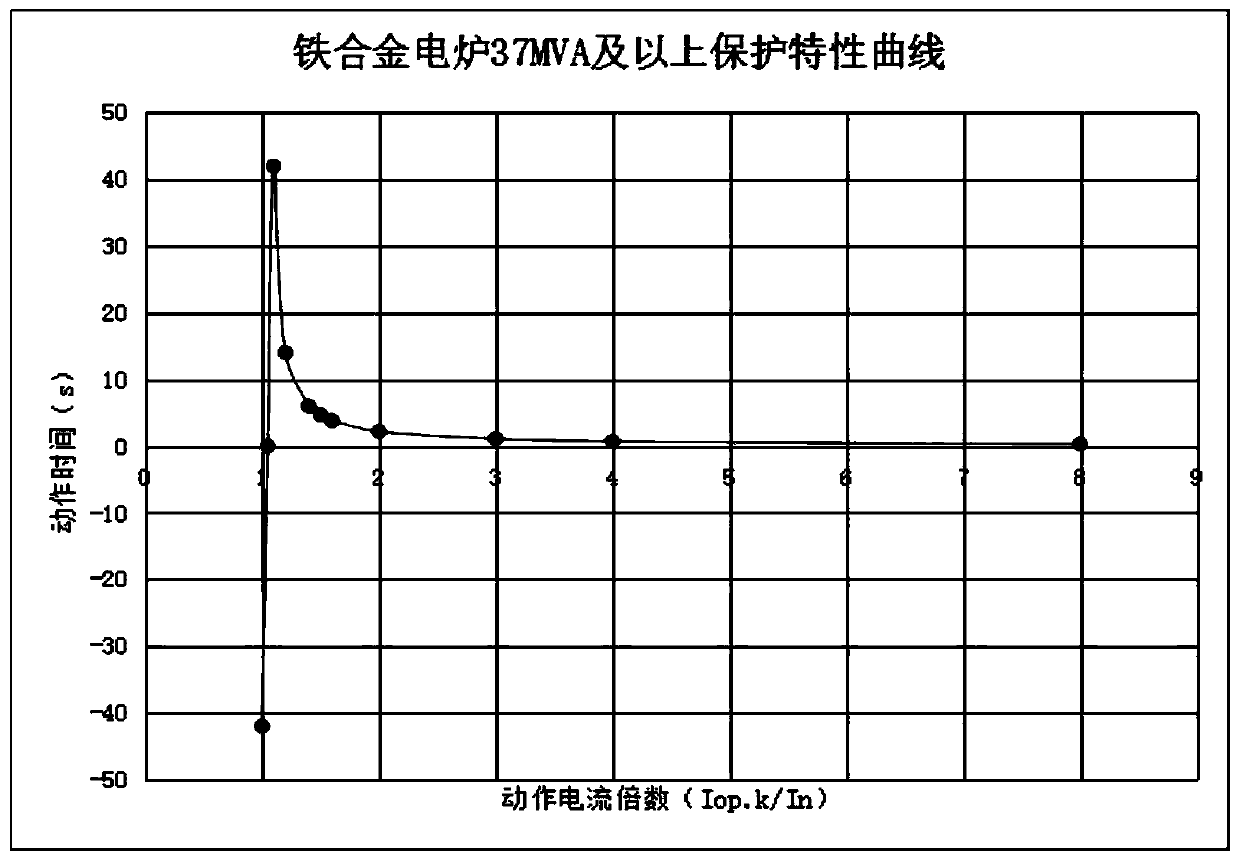

[0067] Such as Figure 5-7 Shown:

[0068] 1) The current quick-break protection is used as the main protection, which is mainly set for short-circuit faults inside the transformer. Due to the structural type of the ferroalloy furnace transformer, it is impossible for three-phase and two-phase short-circuit faults to occur inside the transformer (three single-phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com