Patents

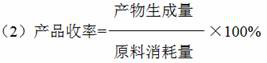

Literature

42results about How to "Realize continuous reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

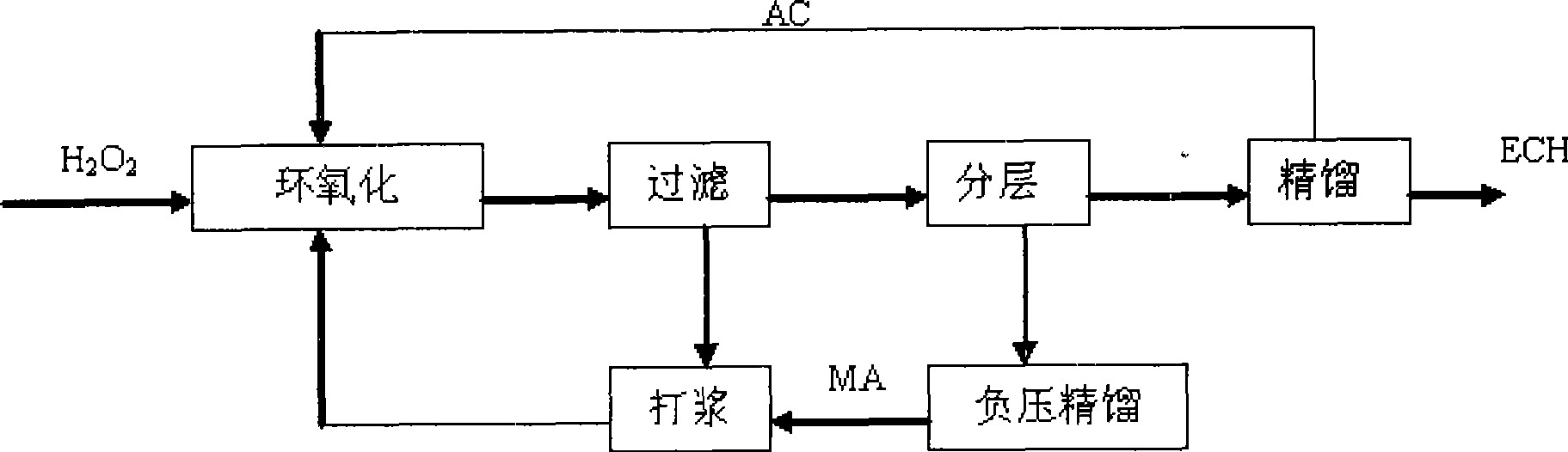

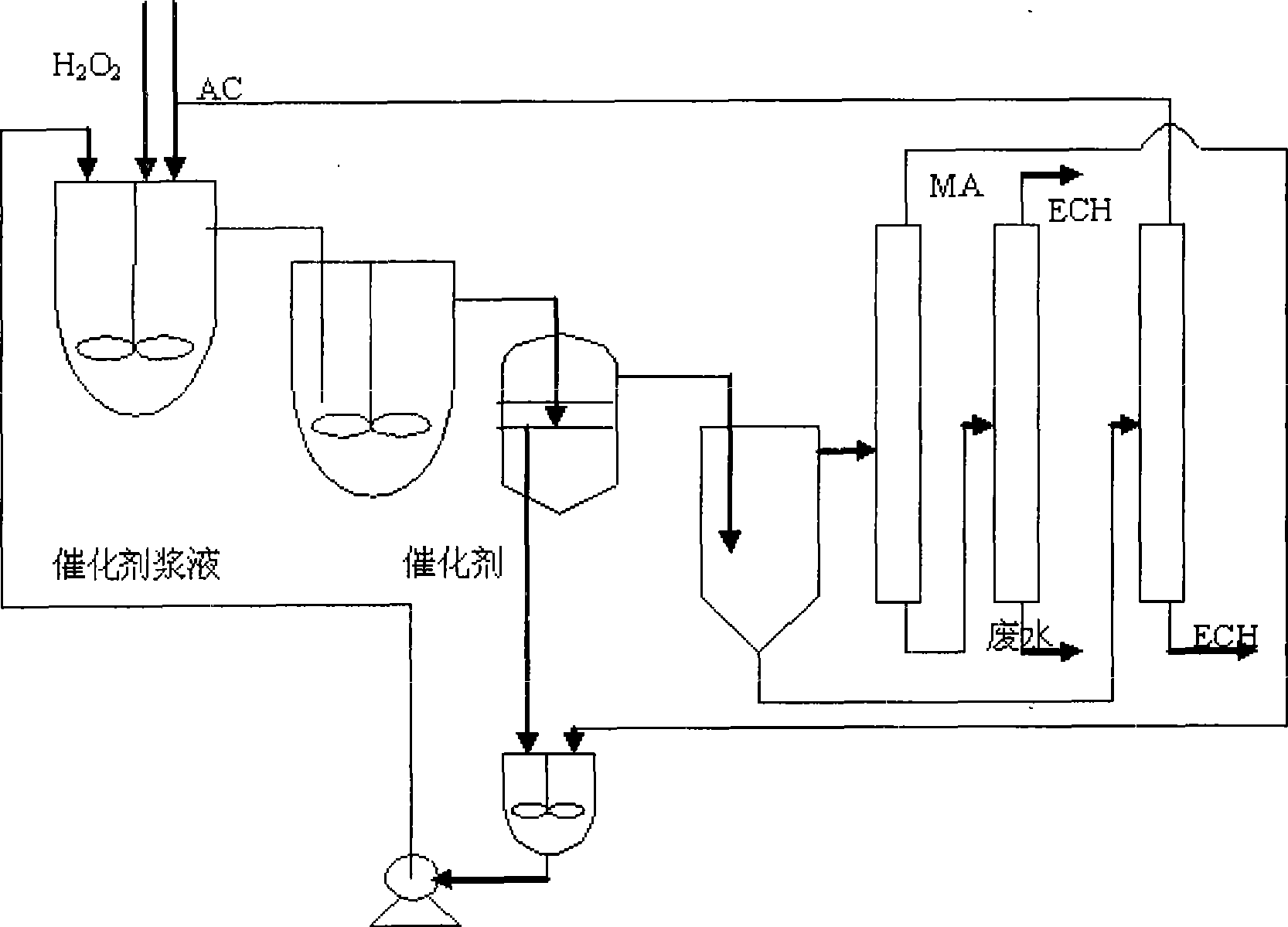

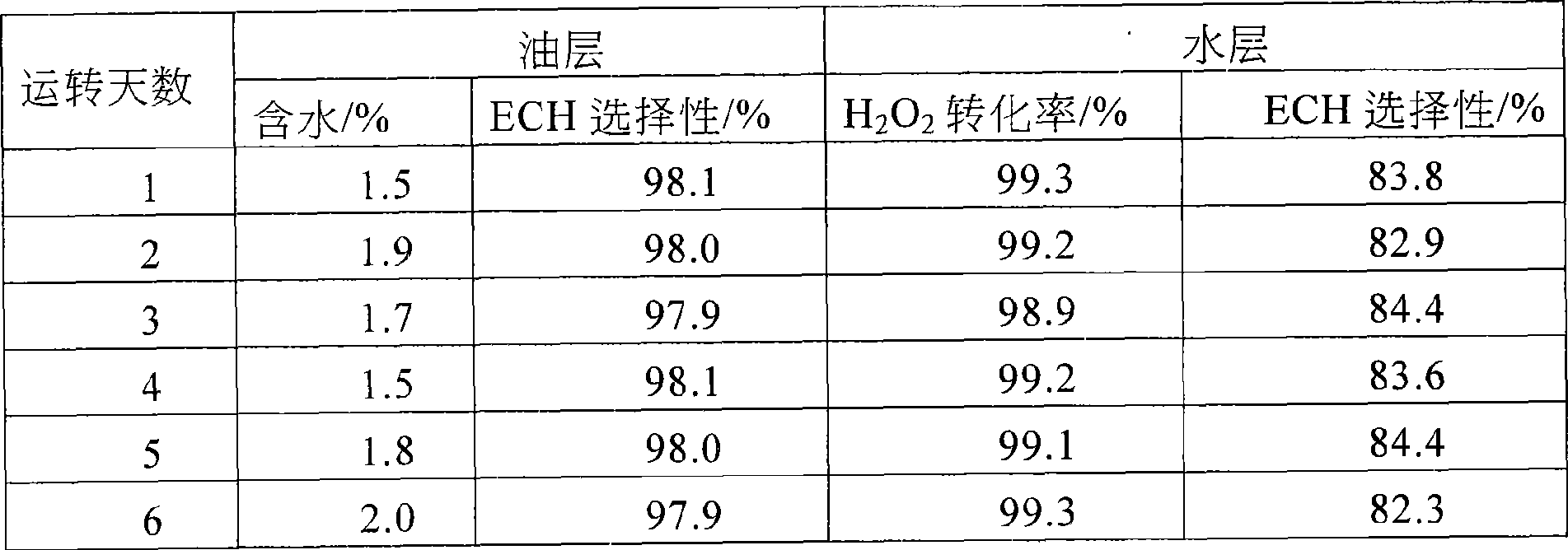

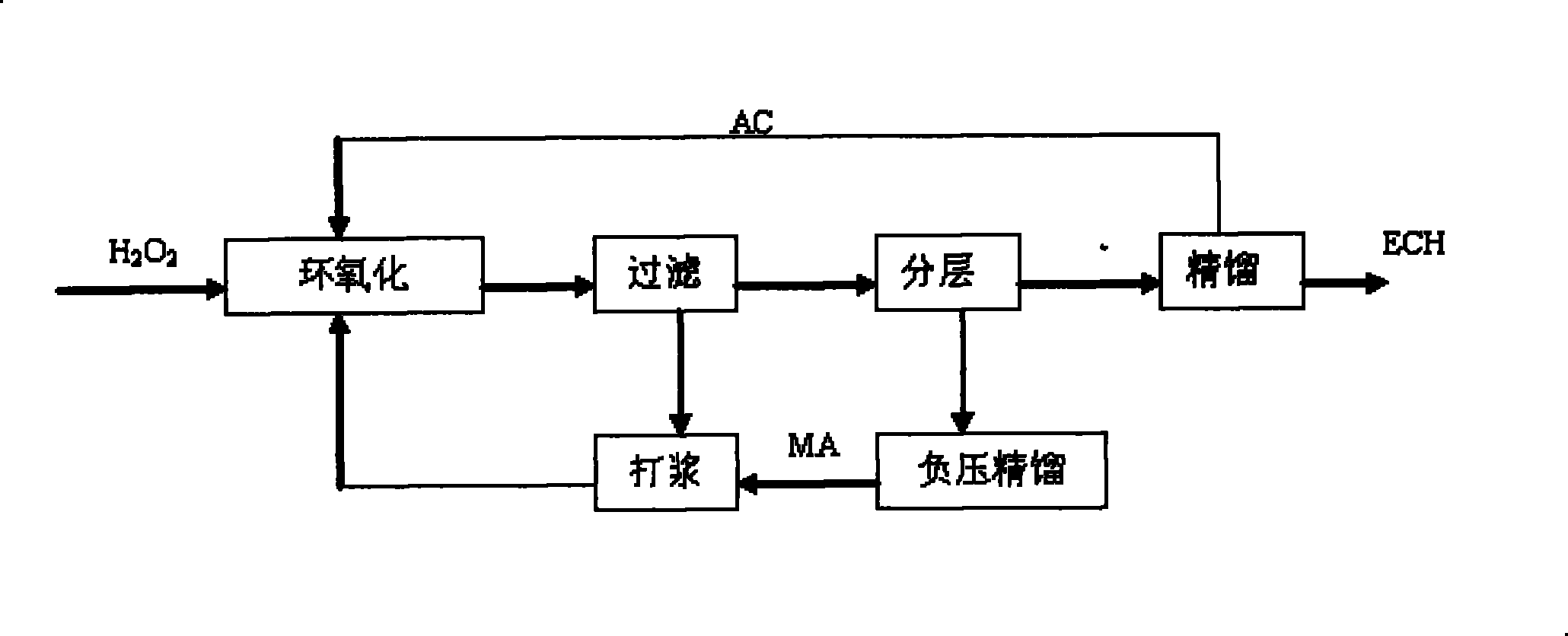

Continuous production method of epoxy chloropropane by hydrogen peroxide process

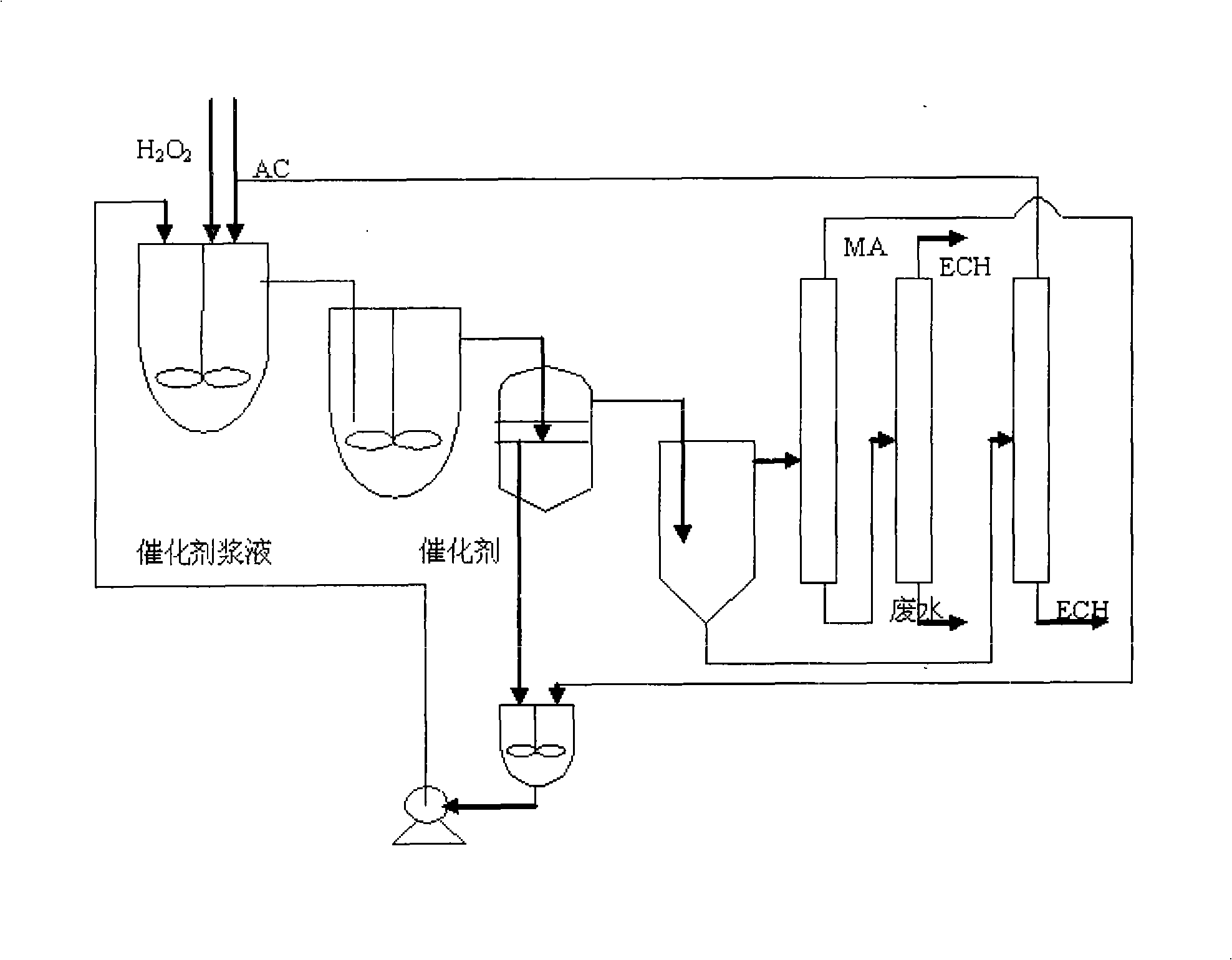

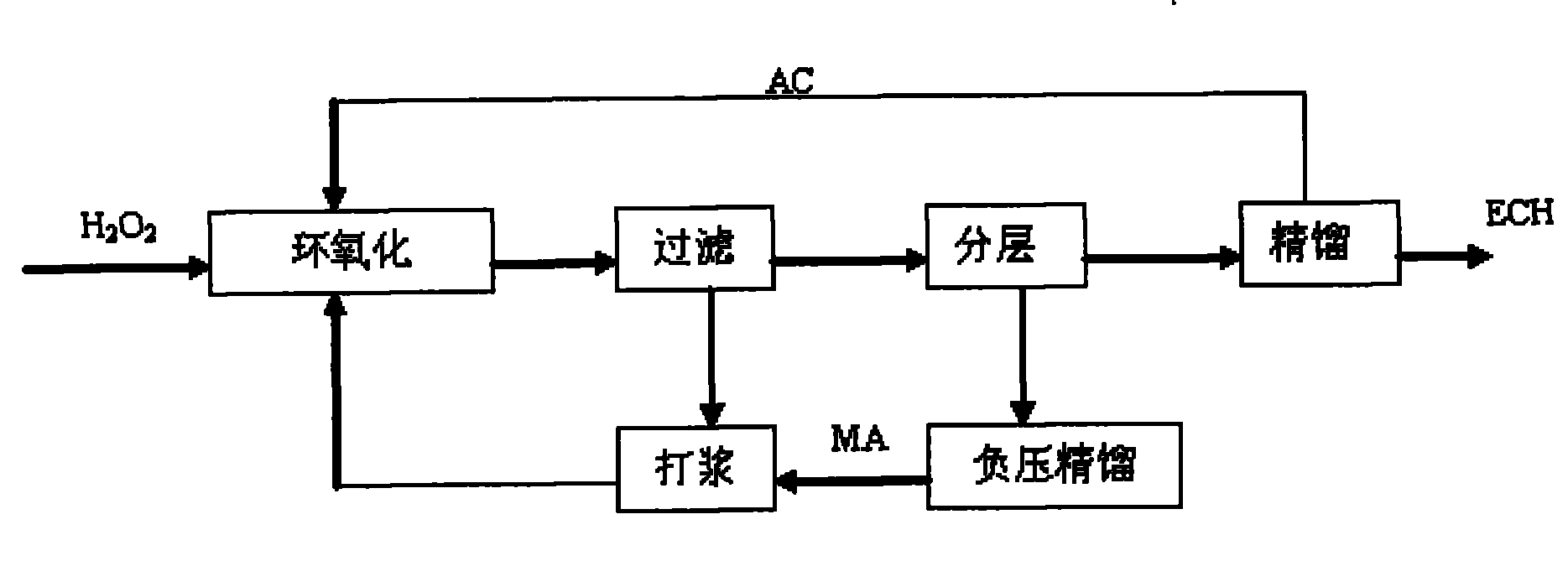

The invention provides a preparation method of chloroepoxy propane by chloropropene epoxidation. Chloropropene, a solvent and titanium silicalite molecular sieve catalyst fine particles are put in a reaction kettle for reaction at the temperature of 10-80 DEG C. The method is characterized in that the reaction kettle is a single kettle or multistage slurry bed reaction kettles with same or different volumes which are connected in series; the reaction solution needs not to be homogeneous phase, slurry particles of the chloropropene, the solvent and the titanium silicalite molecular sieve catalyst are added to a first stage reaction kettle by a metering pump, hydrogen peroxide is dropwise added to the first stage reaction kettle or each stage of the reaction kettles, the reaction occurs in a weakly acidic condition, materials are subject to oil-water delamination after the reaction to be divided into oil-phase slurry and water-phase slurry; the catalyst is suspended in the water phase, and the oil phase is sent to a rectification tower to separate the chloropropene, the epichlorohydrin and trace methanol; the water phase slurry is filtered, a catalyst filter cake or concentrated slurry is directly beaten by the solvent, and pumped to a first stage epoxidation reaction kettle, the water phase slurry contains the methanol, trace epichlorohydrin and the water which is generated by the reaction and the water which is taken by the hydrogen peroxide, the trace methanol and the epichlorohydrin are separated out by negative pressure rectification, and the recovered methanol is used for preparation of the catalyst slurry. The method has the advantages of simple process, little solvent consumption and high product separation yield, and is available for industrialized production.

Owner:JIANGSU YANGNONG CHEM GROUP +2

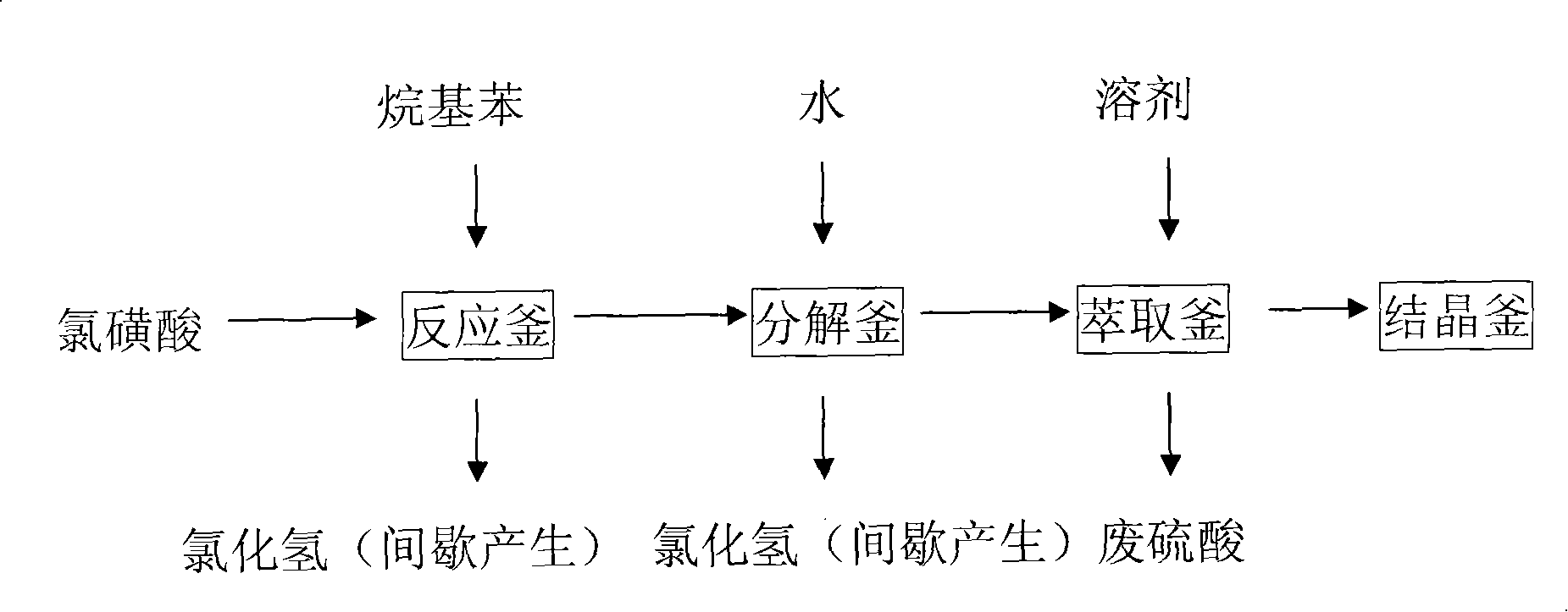

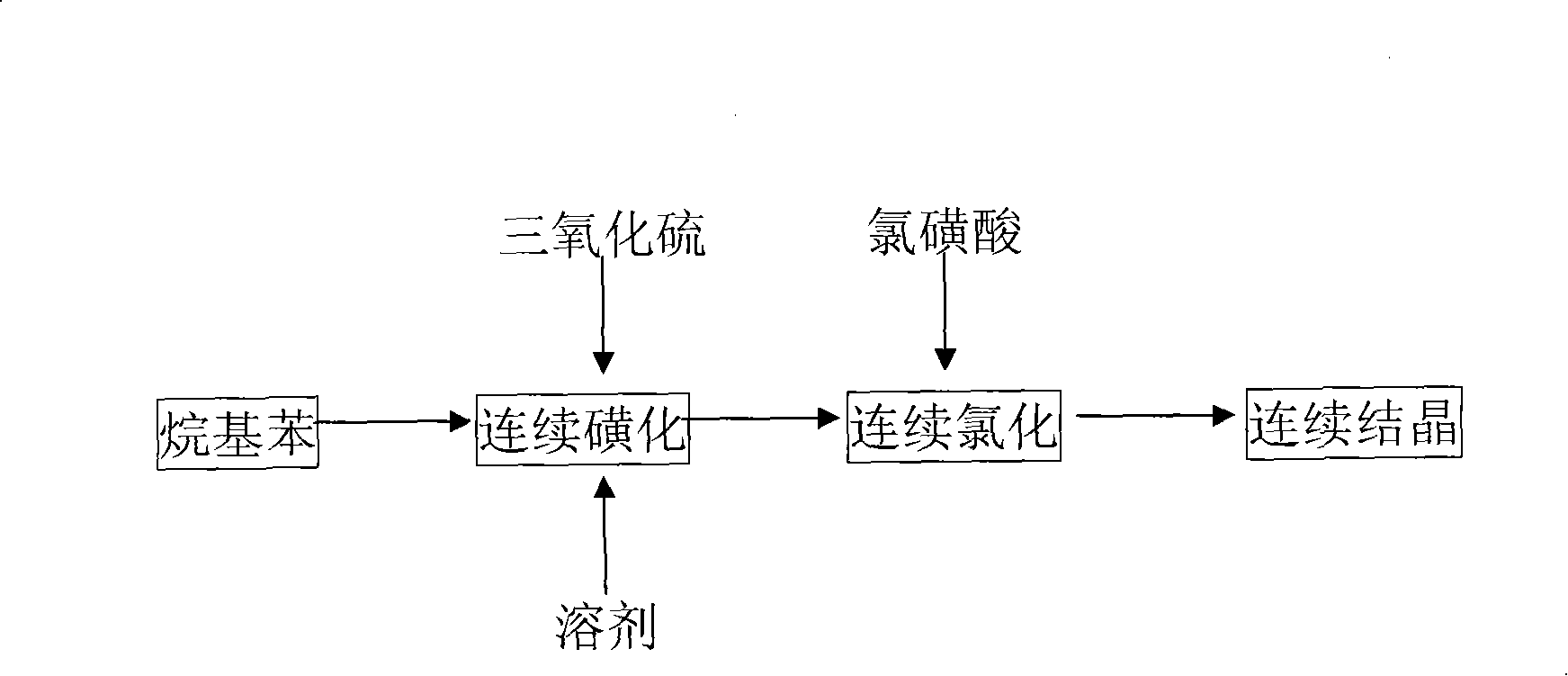

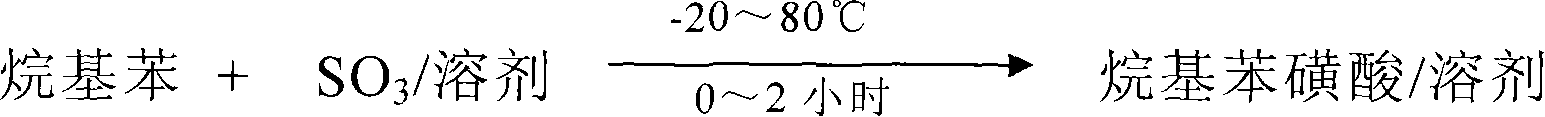

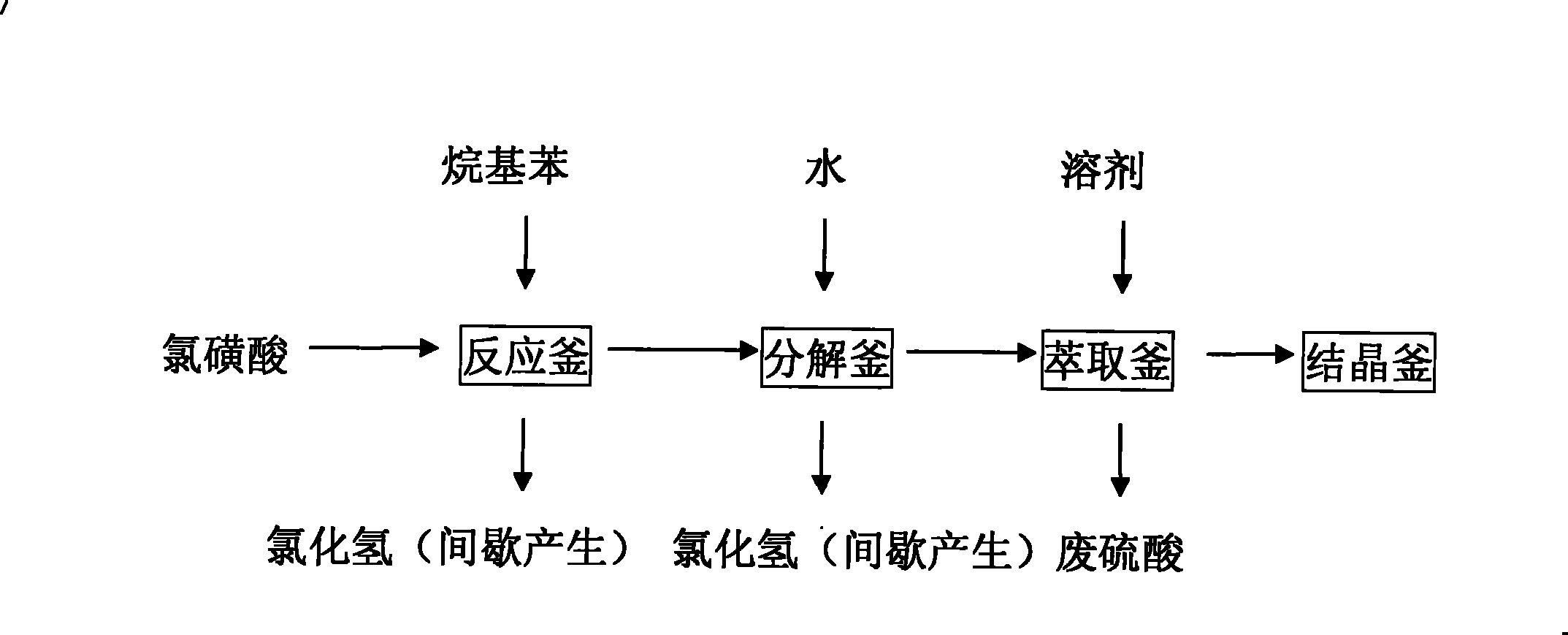

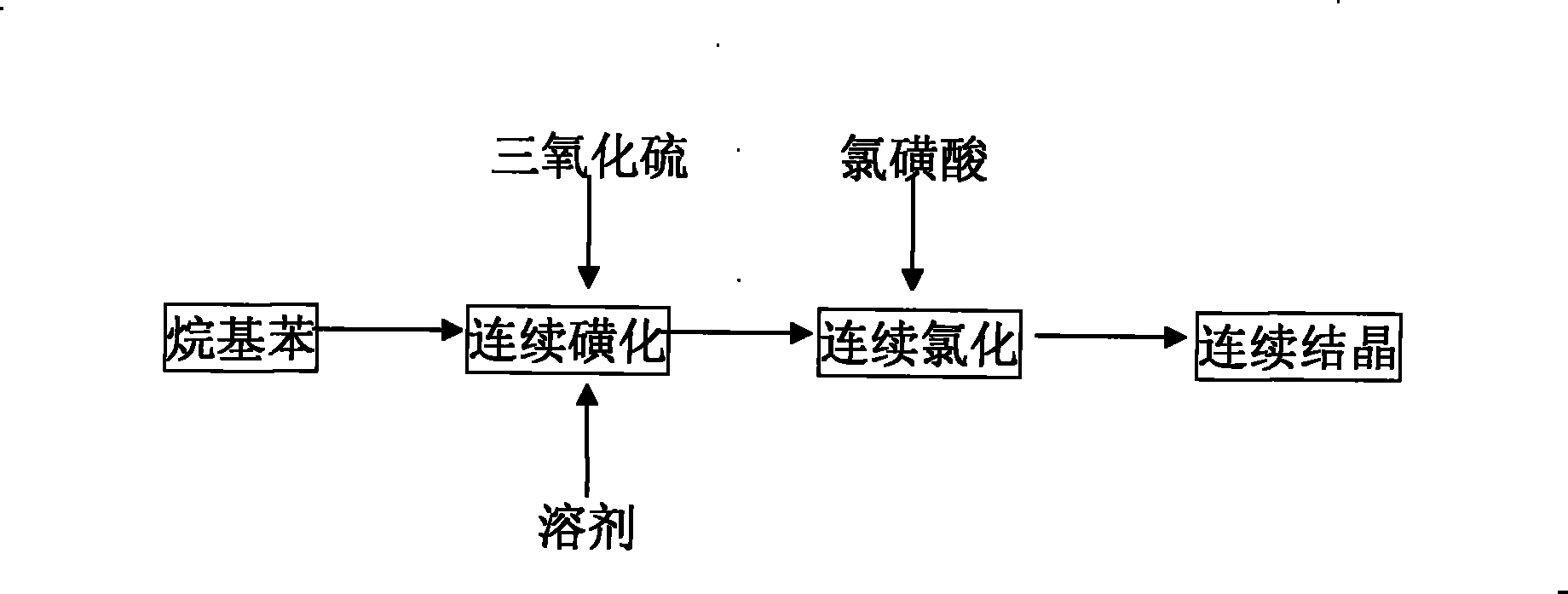

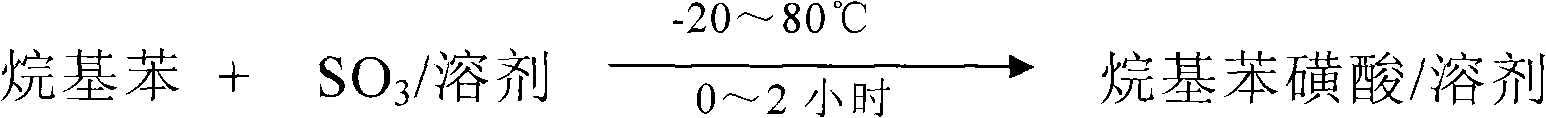

Industrial production method of alkylbenzene sulfonyl chloride

ActiveCN101195593ABy-product sulfuric acid reductionReduce energy consumptionSulfonic acid preparationWaxEconomic benefits

The invention relates to an industrialized production process of alkyl benzenesulfonyl chloridebenzene sulfonyl chloride, which uses tubular reactor to continuously or kettle-type intermittently sulfonate alkyl benzene and liquid sulfur trioxide in the solvent as liquid sulfur dioxide, liquid wax, ligarine, and halohydrocarbon of C1-C4, 90-120# solvent oil and alkane of C4-C8 or the like, directly treats the reaction product and chlorosulfonic acid with acyl chlorination via a tubular reactor continuously or a kettle intermittently, to generate alkyl benzenesulfonyl chloridebenzene sulfonyl chloride, washes alkyl benzenesulfonyl chloridebenzene sulfonyl chloride, removes acid, and desolventizes to generate product alkyl benzenesulfonyl chloridebenzene sulfonyl chloride. The invention avoids generating hydrochloride gas, to support tube continuous production, reduce dangerous chemical in production system, reduce equipment investment, and improve economic benefit, which replaces chlorosulfonic acid with sulfur trioxide to process sulphonation to realize clean production and reduce material cost.

Owner:浙江嘉福新材料科技有限公司

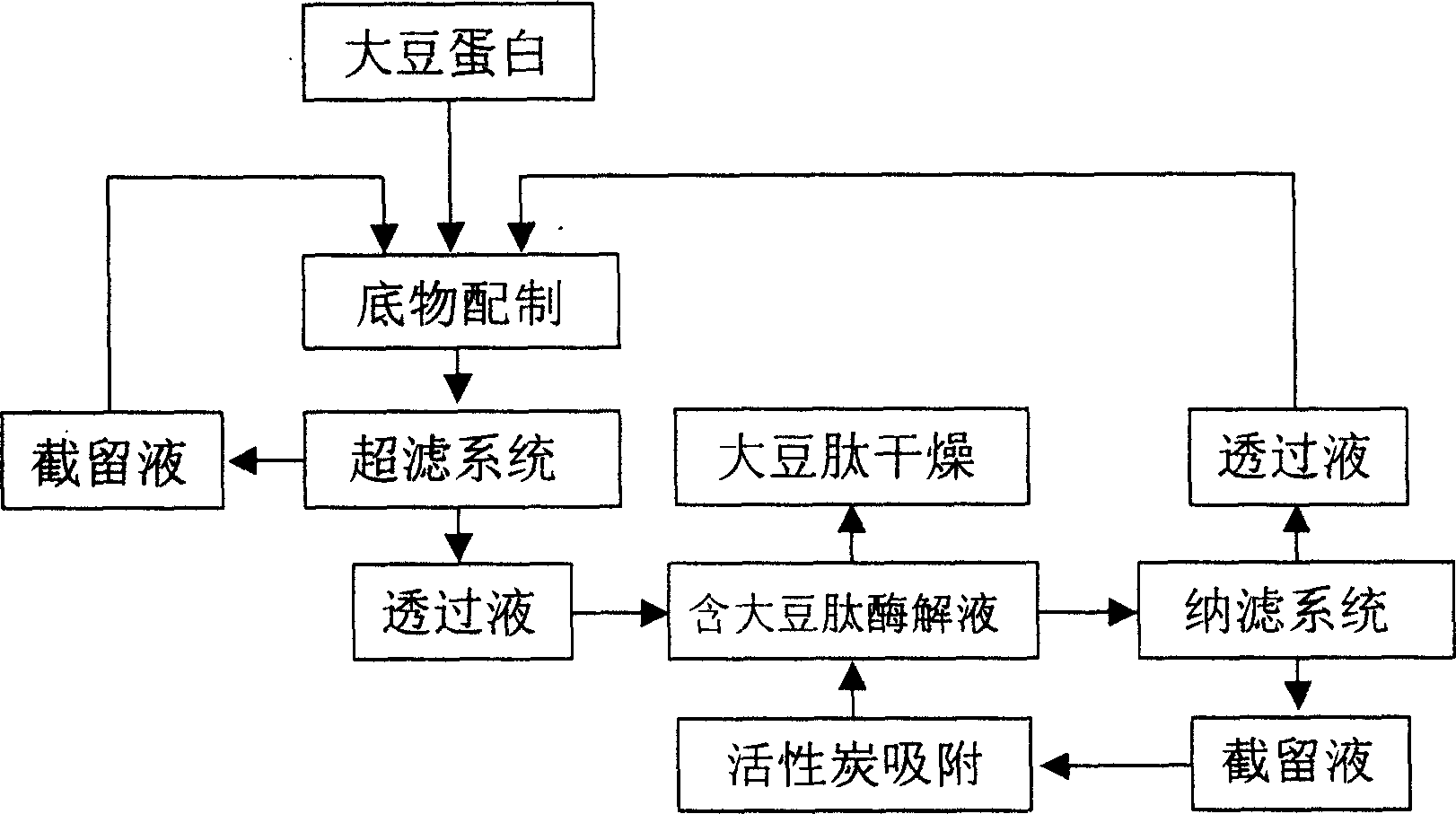

Method for preparing peptide of soybean through continuous enzyme membrane reaction of soyabean protein

InactiveCN1563405AComplete enzymatic hydrolysisStable concentrationFermentationActivated carbonUltrafiltration

A method for preparing soybean peptide by soybean protein continuous zyme film reactions is to carry out the bean protein zyme film reaction in super filtration and separation and to carry out activated carbon adsorption and bean peptide concentration. This invention can realize circulation use of zyme and mother liquid and bean peptide decolor, debitter and concentration at the same time.

Owner:GUANGXI UNIV

Continuous production method of epoxy chloropropane by hydrogen peroxide process

The invention provides a preparation method of chloroepoxy propane by chloropropene epoxidation. Chloropropene, a solvent and titanium silicalite molecular sieve catalyst fine particles are put in a reaction kettle for reaction at the temperature of 10-80 DEG C. The method is characterized in that the reaction kettle is a single kettle or multistage slurry bed reaction kettles with same or different volumes which are connected in series; the reaction solution needs not to be homogeneous phase, slurry particles of the chloropropene, the solvent and the titanium silicalite molecular sieve catalyst are added to a first stage reaction kettle by a metering pump, hydrogen peroxide is dropwise added to the first stage reaction kettle or each stage of the reaction kettles, the reaction occurs in a weakly acidic condition, materials are subject to oil-water delamination after the reaction to be divided into oil-phase slurry and water-phase slurry; the catalyst is suspended in the water phase, and the oil phase is sent to a rectification tower to separate the chloropropene, the epichlorohydrin and trace methanol; the water phase slurry is filtered, a catalyst filter cake or concentrated slurry is directly beaten by the solvent, and pumped to a first stage epoxidation reaction kettle, the water phase slurry contains the methanol, trace epichlorohydrin and the water which is generated by the reaction and the water which is taken by the hydrogen peroxide, the trace methanol and the epichlorohydrin are separated out by negative pressure rectification, and the recovered methanol is used for preparation of the catalyst slurry. The method has the advantages of simple process, little solvent consumption and high product separation yield, and is available for industrialized production.

Owner:JIANGSU YANGNONG CHEM GROUP +2

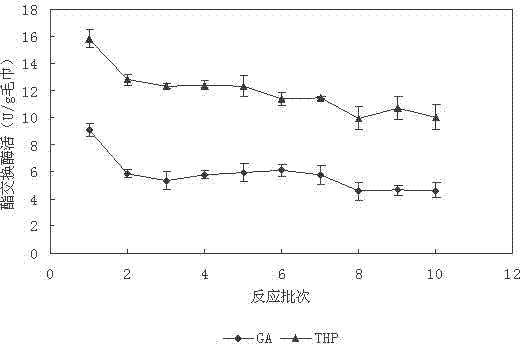

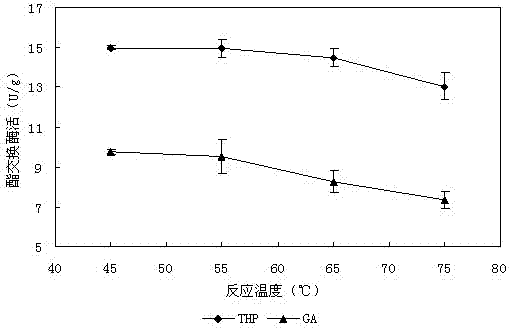

Preparation method of immobilized lipase with purified cotton towel as carrier

InactiveCN102206622AHas electrostatic attractionImmobilization process is simpleOn/in organic carrierCross-linkFiber

The invention provides a preparation method of an immobilized lipase with a purified cotton towel as a carrier. The method is an immobilization technique comprising the following steps of: adsorbing a polyethyleneimine aqueous solution with the purified cotton towel, adding a lipase solution after adsorption, vibrating with a constant-temperature shaking table, thus attaching the lipase to the purified cotton towel containing polyethyleneimine, removing the supernatant, and then cross-linking the purified cotton towel with the lipase and polyethyleneimine adsorbed by using a cross-linking agent. According to the invention, the towel carrier used by the preparation method has multiple gaps and long towel fibers, thus having a larger surface area, favoring the performing of immobilized-enzyme-catalyzed reaction, having very good mechanical strength, and the method can more easily separate the enzyme from the reaction system, compared with the granular carrier; the used cross-linking agent is tris(hydroxymethyl)phosphine which has a better cross-linking effect than glutaraldehyde; the used immobilization method has the advantages of mild conditions and multi-layer immobilization; and the obtained immobilized lipase has good temperature stability and high reaction activity, can shorten the reaction time and can be repeatedly used.

Owner:SOUTH CHINA UNIV OF TECH

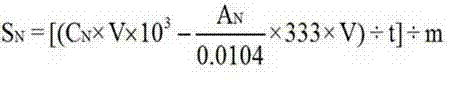

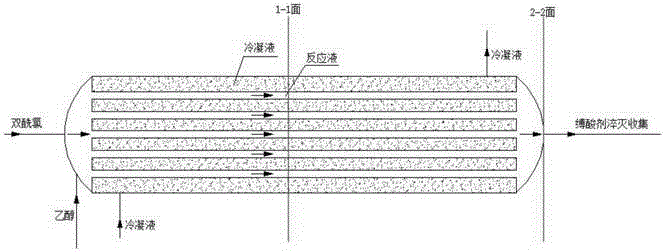

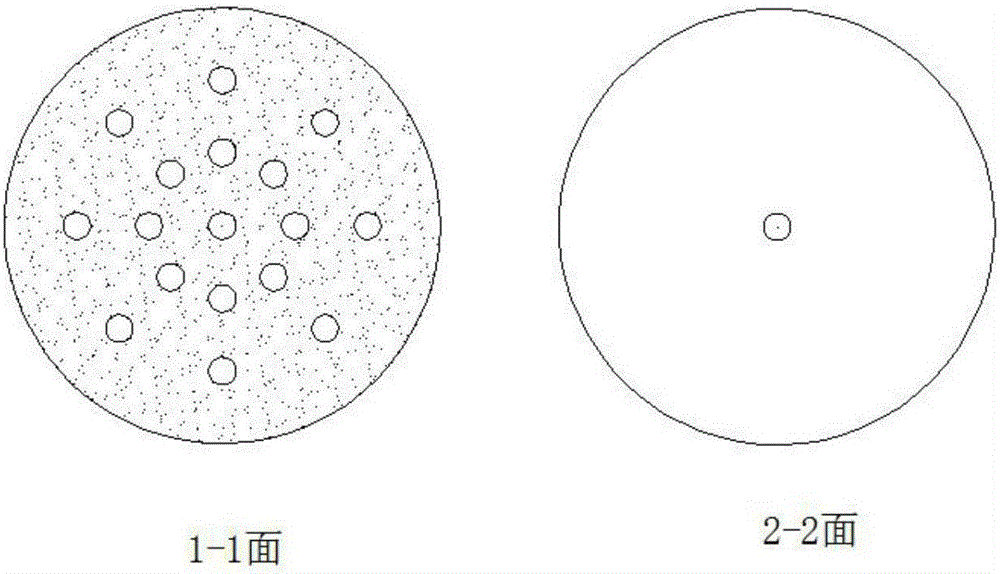

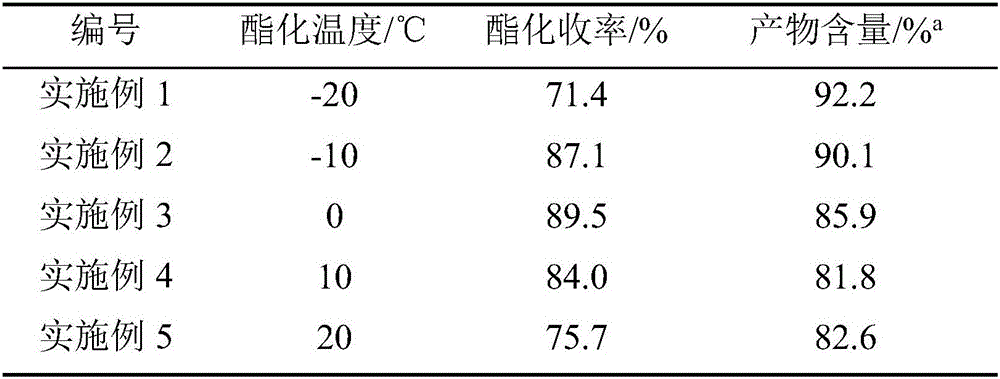

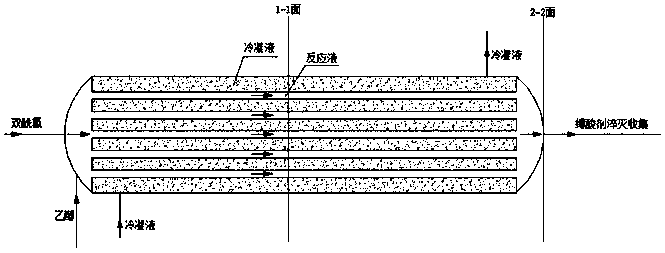

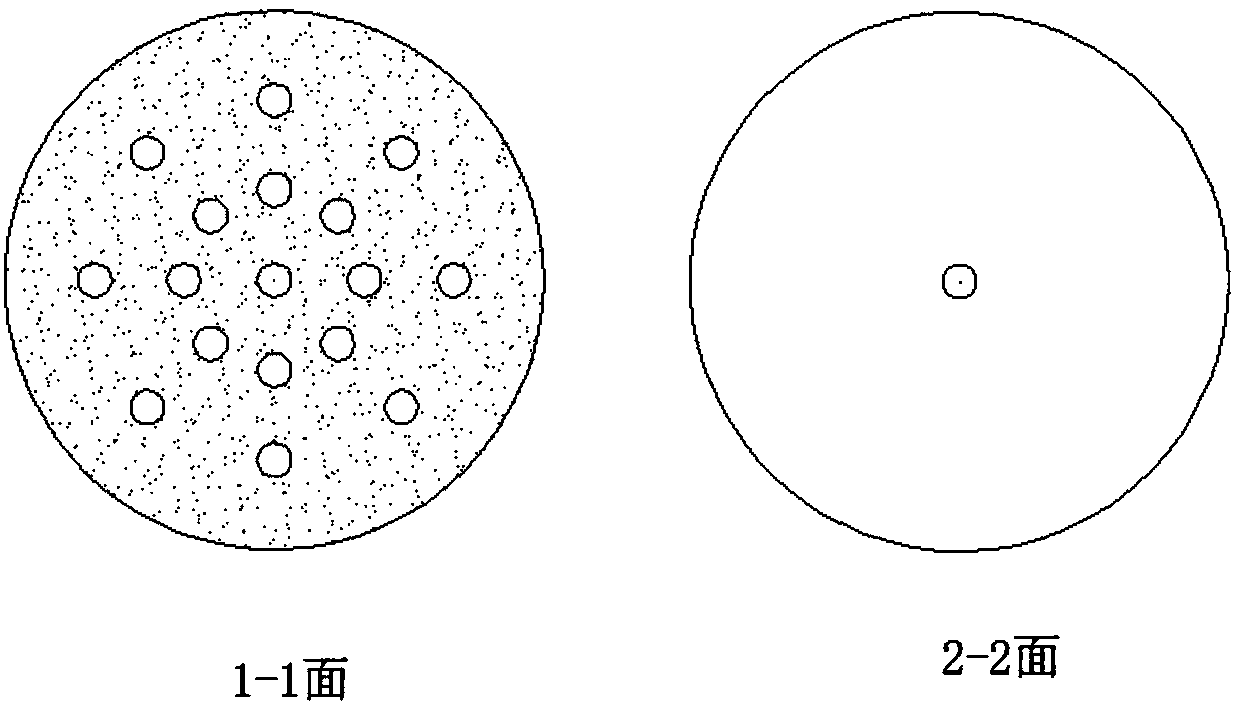

Novel synthesis method for 3-(alkoxy methyl phosphoryl)propionate

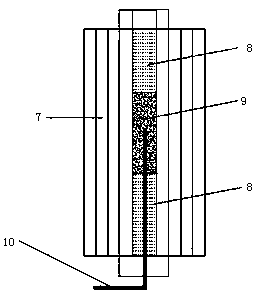

ActiveCN106565778AImprove heat exchange capacityEasy to operateGroup 5/15 element organic compoundsChemical/physical/physico-chemical processesSynthesis methodsReaction tube

The invention discloses a novel synthesis method for 3-(alkoxy methyl phosphoryl)propionate (short for "propionate") by carrying out esterification reaction on 3-(methyl phosphoryl chloride)propionyl chloride (short for "bis(acyl chloride) ") serving as a raw material. The method in which a novel array tubular reaction device is mainly adopted comprises the steps: feeding raw materials including bis(acyl chloride) and a hydroxyl compound from one side, then, releasing heat by reaction in glass tubes, enabling a condensed fluid to be in cross flow contact with the glass tube on the outer layer of a reaction tube, carrying out strong heat exchange, carrying out quenching treatment by using an acid binding agent after discharging as an esterification product, and then, collecting a product, so that continuous esterification synthesis reaction and sufficient heat exchange with a reaction solution can be realized, and an HCl gas serving as a byproduct has no corrosion to equipment. The method is simple in operation, high in heat exchange capability, precise in temperature control, environment-friendly and wide in large-scale application prospect.

Owner:ANHUI COSTAR BIOCHEM CO LTD

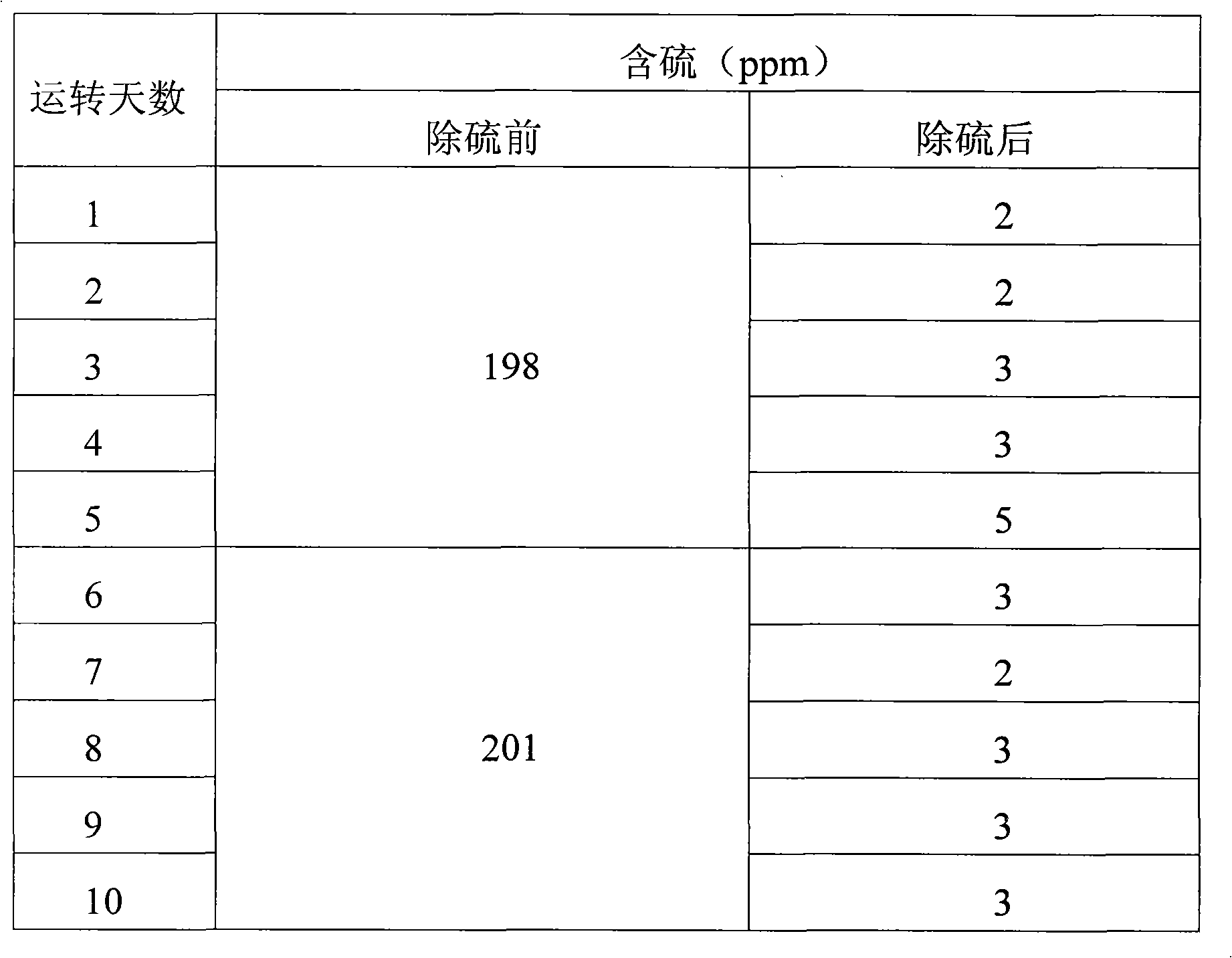

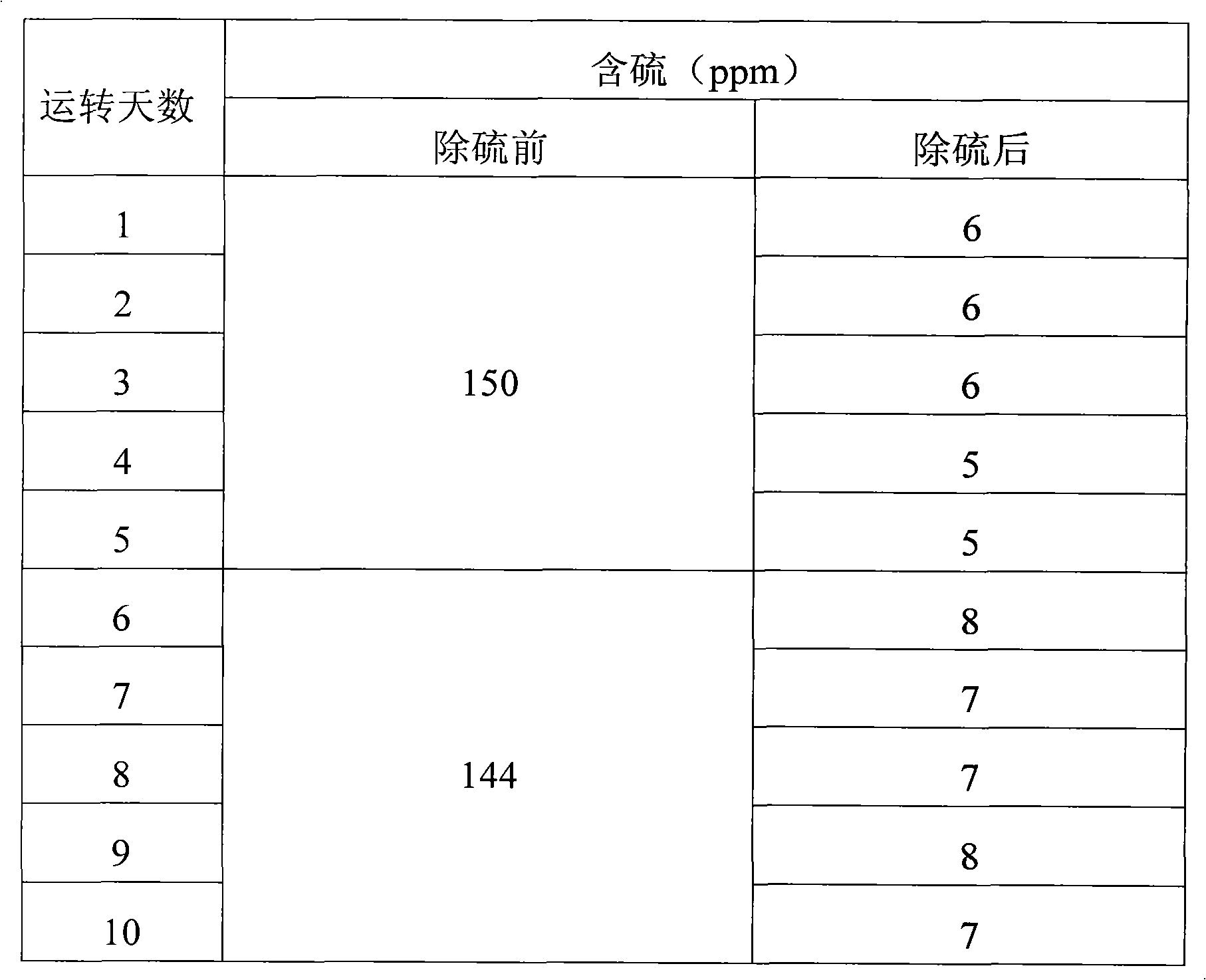

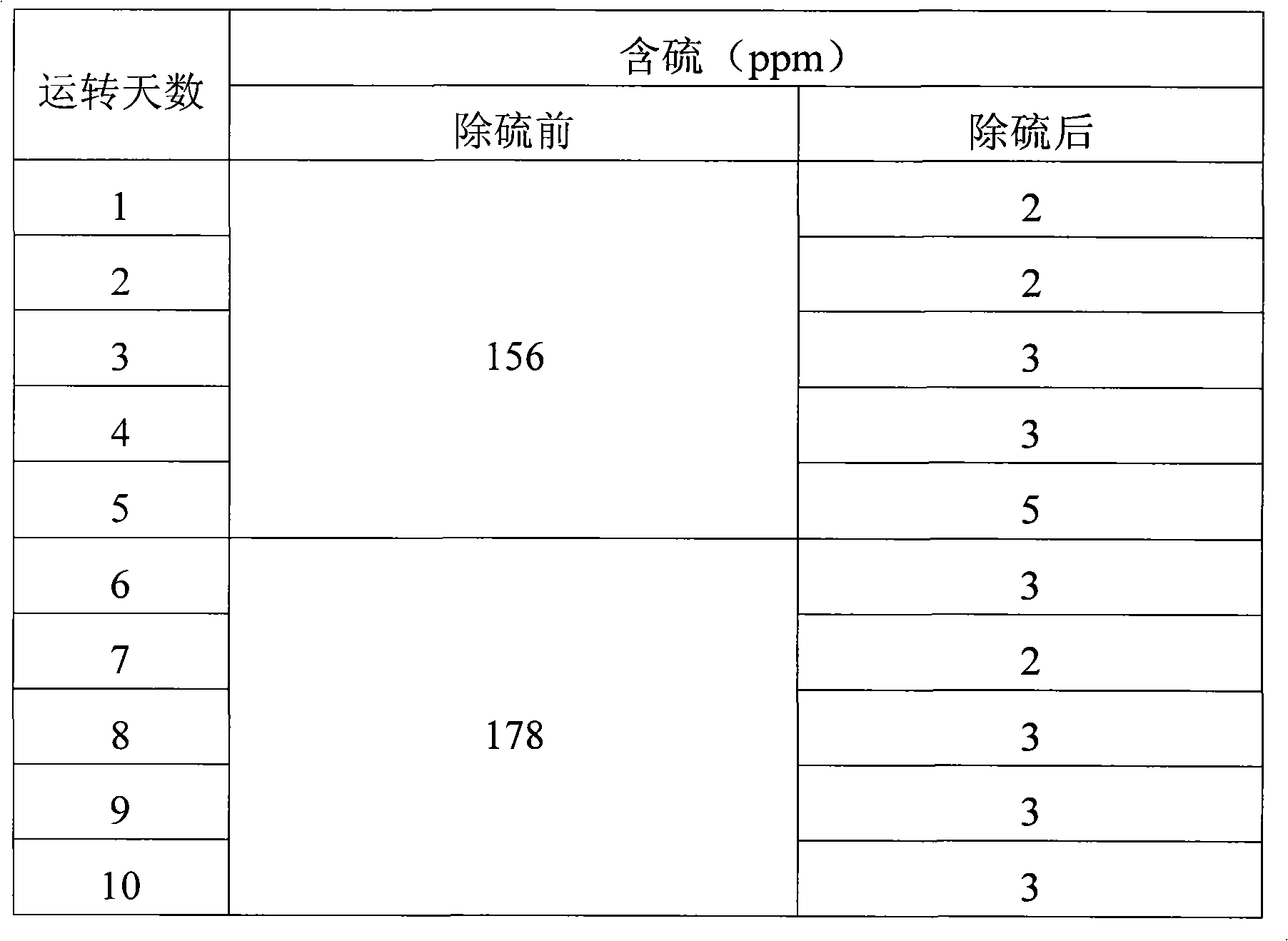

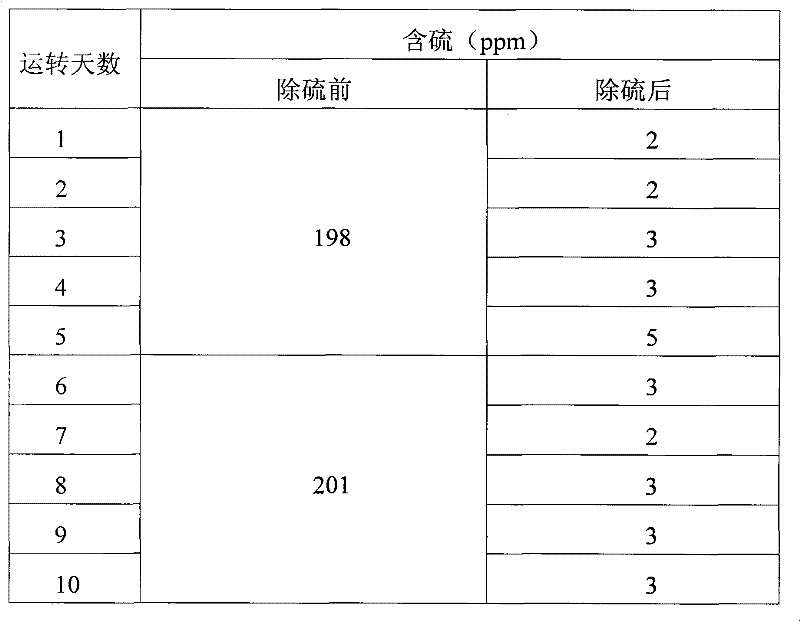

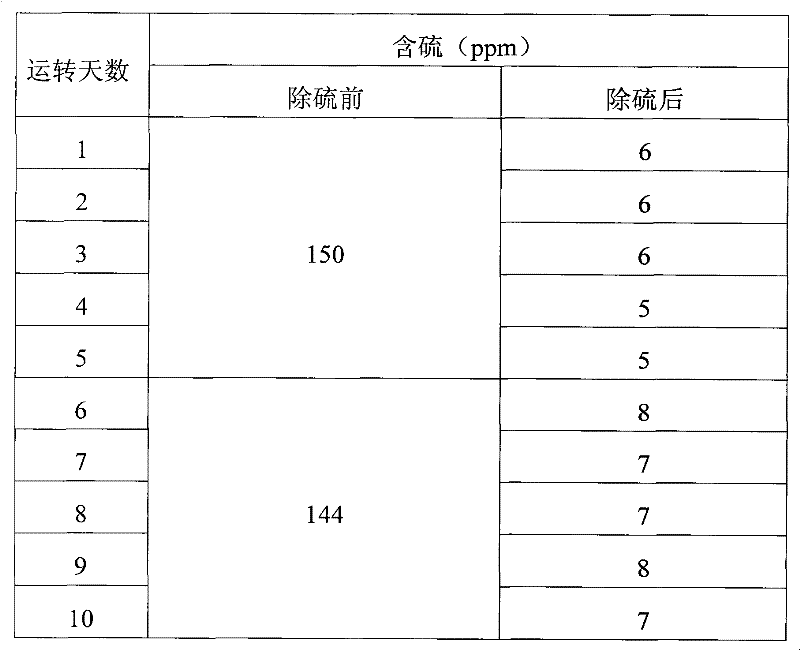

Method for removing sulphur from coking benzol

ActiveCN101602647AReduce consumptionLess "three wastes"Molecular sieve catalystsChemical modification purification/separationBenzeneMolecular sieve

The invention relates to a method for removing sulphur from coking benzol, belonging to the technical field of organic chemical engineering; and the invention in particular relates to continuous sulphur removal technology of coking benzol; the coking benzol, solvent, oxidant and titanium-silicon molecular sieve catalyst particles are added in a slurry bed reaction kettle and are reacted under the temperature of 10-90 DEG C, and the reacted products are divided into oil-phase slurry and water-phase slurry, alkaline washing and water-washing layering are carried out to the oil-phase slurry for obtaining sulphur-removal benzene, and the water-phase slurry is returned to the reaction kettle. After being treated, the coking benzol contained about 200ppm of sulphur contains 0-5ppm of sulphur; the method has simple flow, less three wastes and high yield coefficient and is easy to realize industrialization.

Owner:JIANGSU YANGNONG CHEM GROUP +1

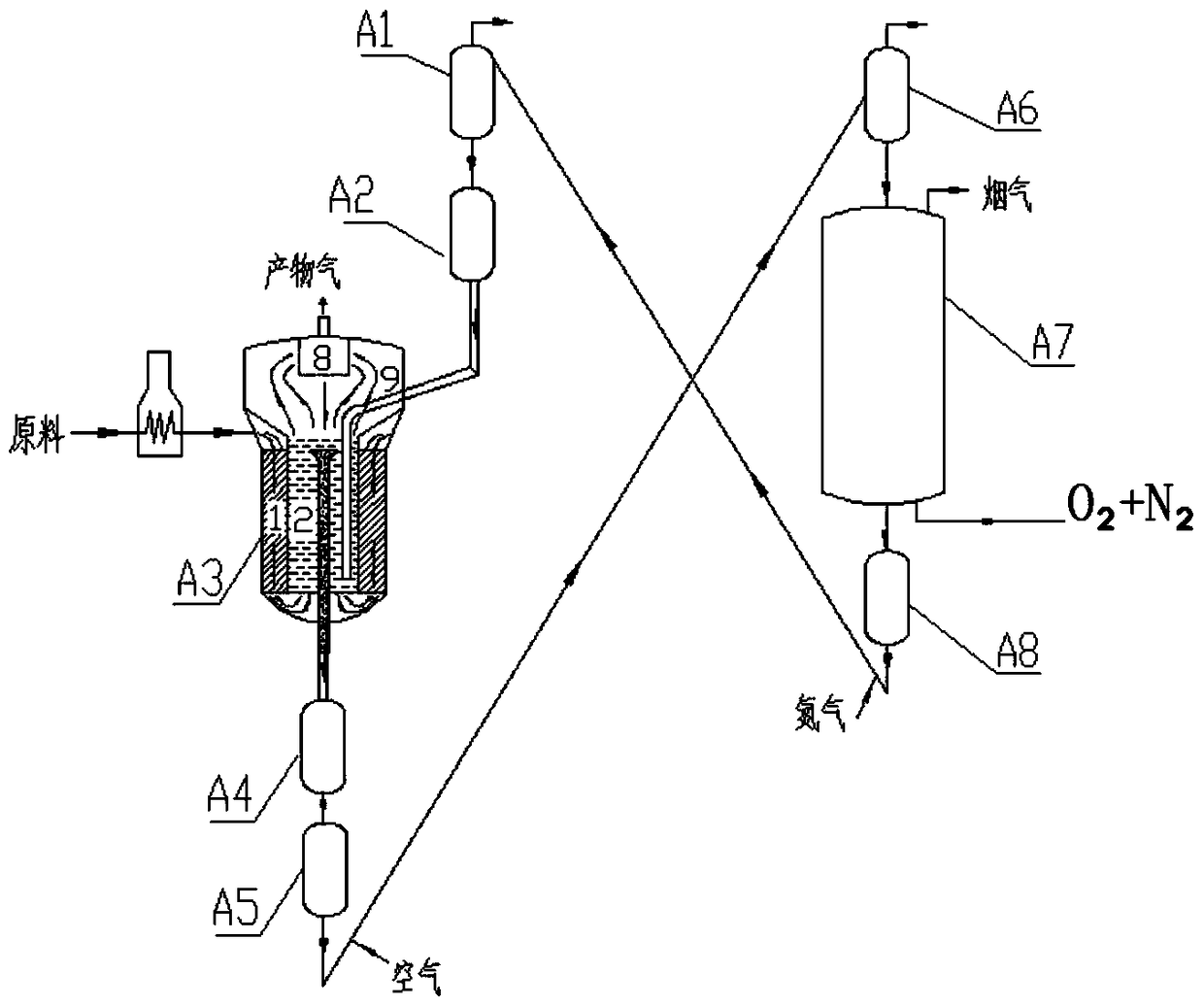

Methane-reforming and hydrogen-production method

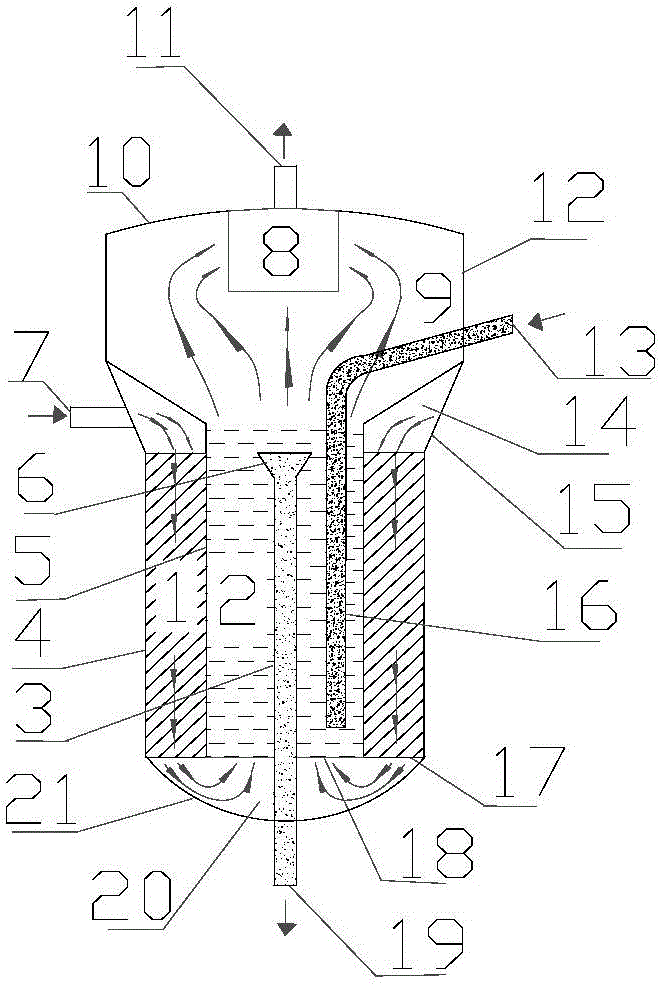

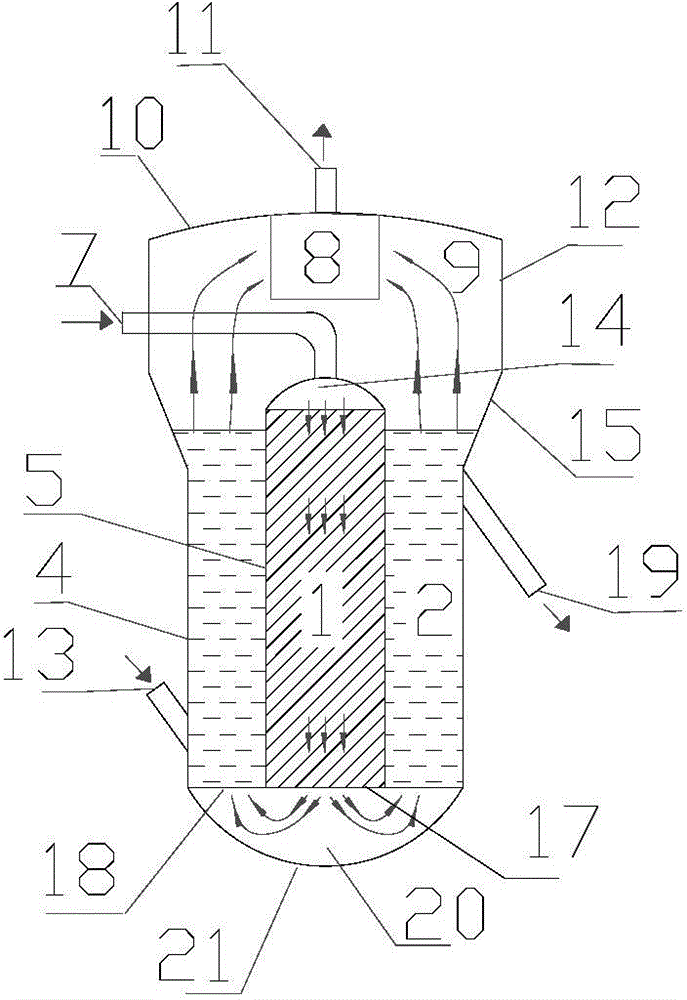

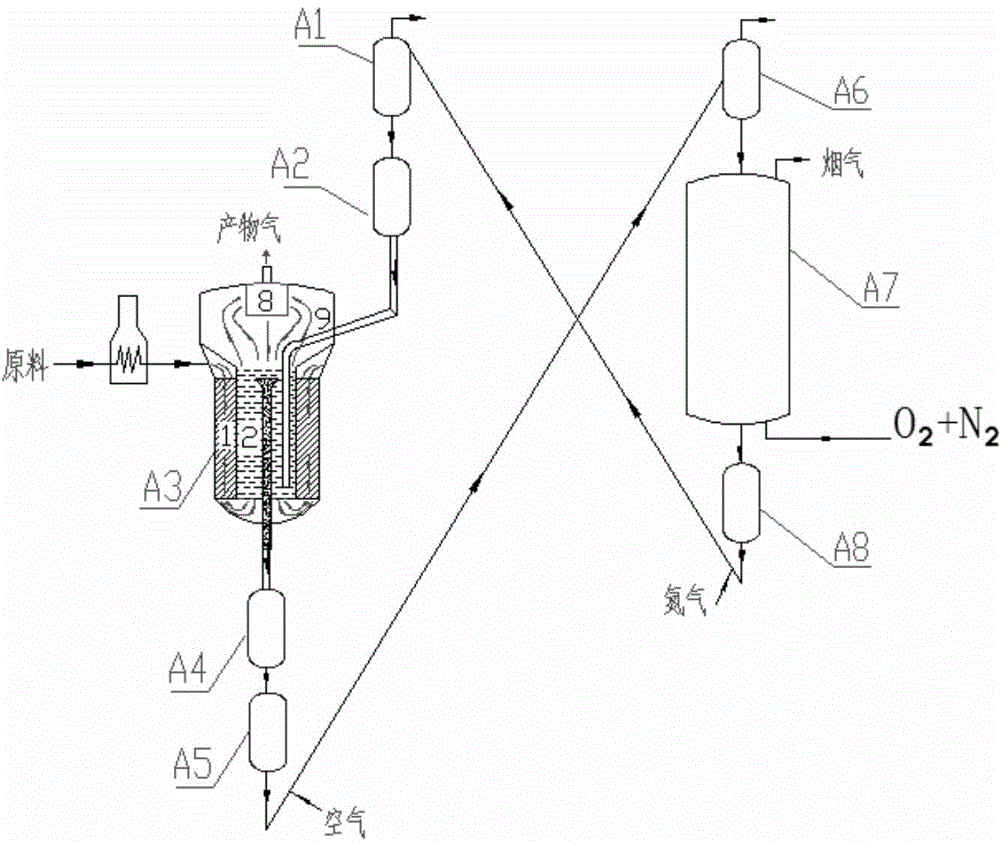

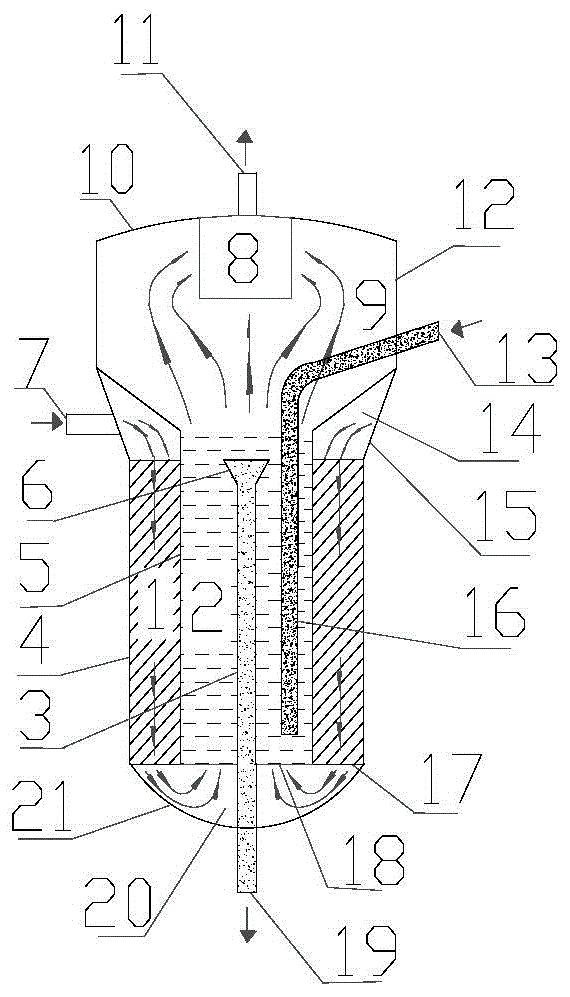

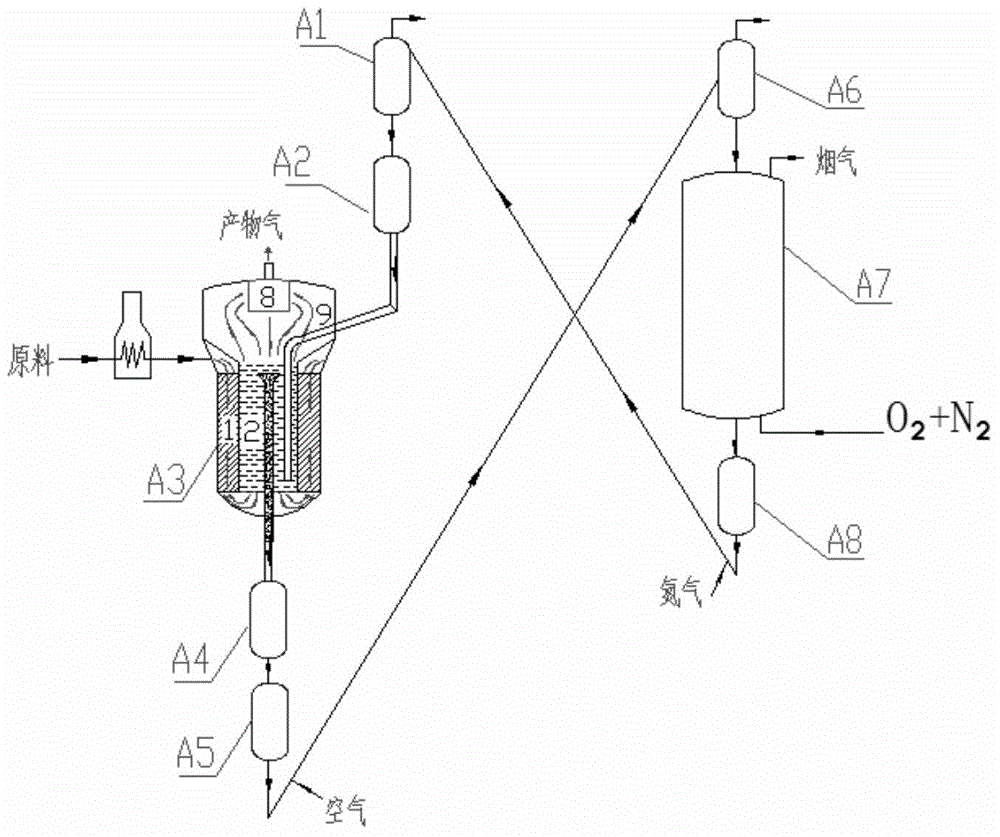

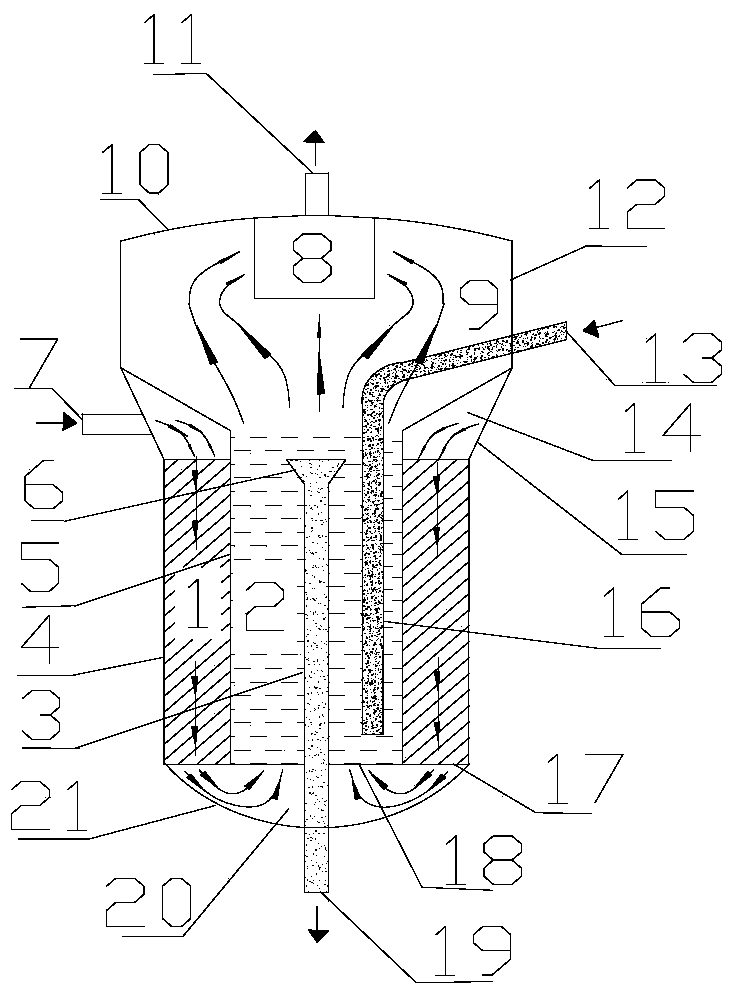

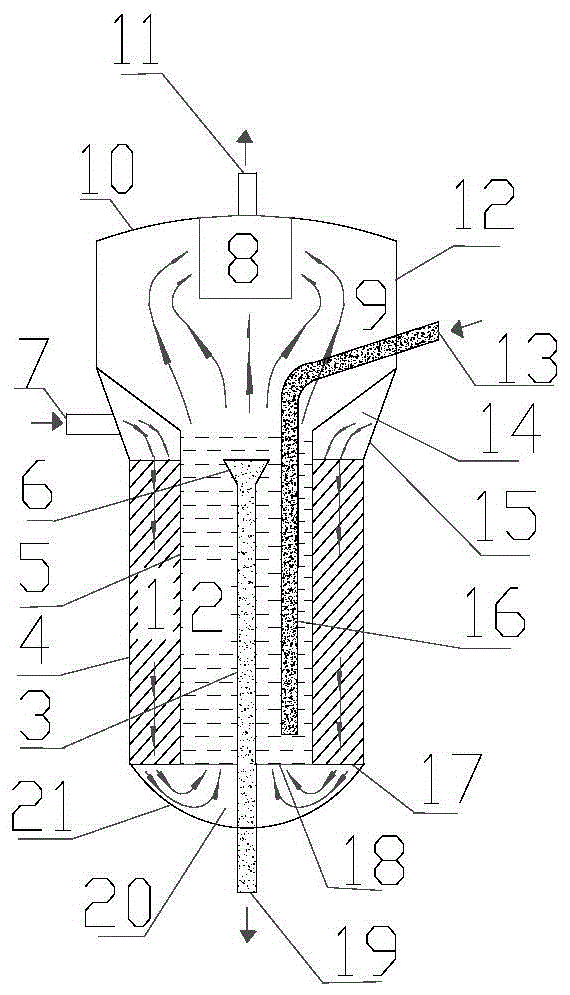

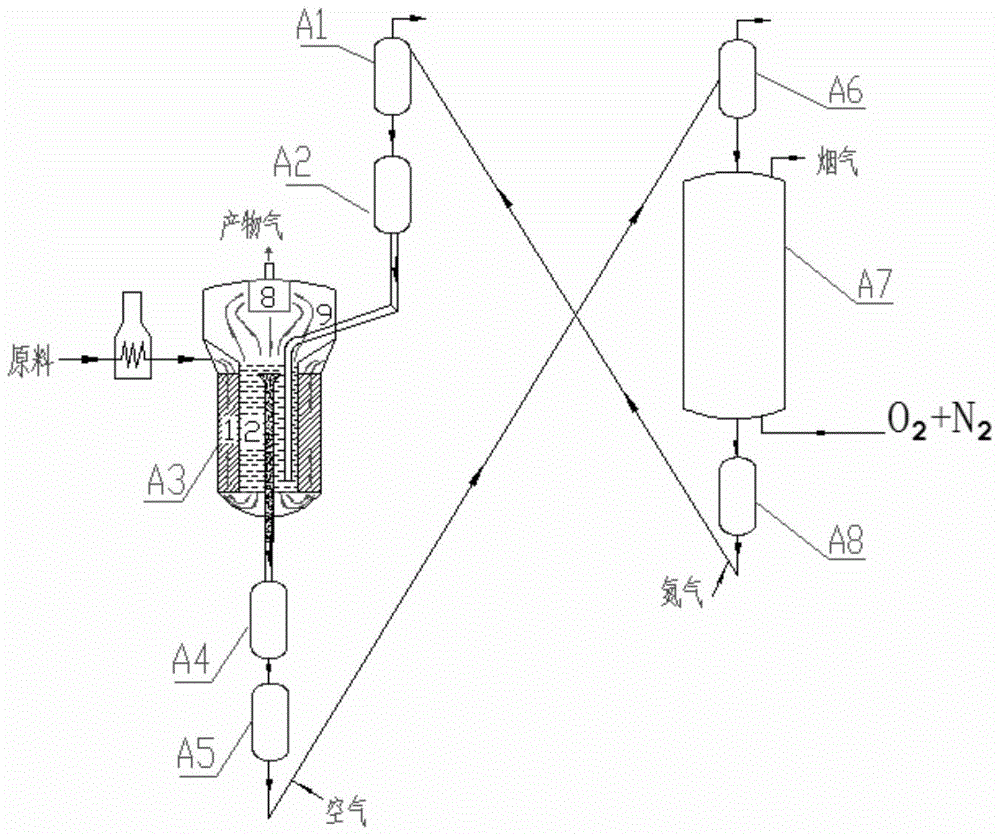

A methane-reforming and hydrogen-production method adopts a fixed bed-fluidized bed reactor which is divided into a particle settling zone, a reaction zone and a gas buffer zone from top to bottom; the reaction zone is divided into a fixed bed layer and a fluidized bed layer in the radial direction from outside to inside or from inside to outside; a separation plate which enables gas to pass through and enables catalyst particles not to pass through is arranged between the lower part of the fixed bed layer as well as the fluidized bed layer and the gas buffer zone; a space between the upper part of the fixed bed layer and the particle settling zone is closed; the upper part of the fluidized bed layer communicates with the particle settling zone; the upper part of the fixed bed layer is provided with a fluid feed inlet; the particle settling zone is internally provided with a gas-solid separator; a gas phase outlet of the gas-solid separator is a fluid discharge outlet of the reactor; the fluidized bed layer is also provided with a fluidized catalyst inlet and outlet. The methane-reforming and hydrogen-production method provided by the invention simplifies device construction and operation process, saves the energy consumption, and is beneficial for realizing continuous reaction and regeneration of production.

Owner:CHINA PETROLEUM & CHEM CORP +1

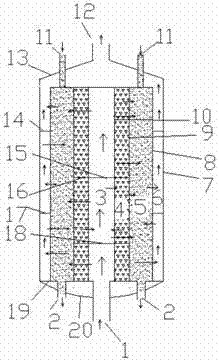

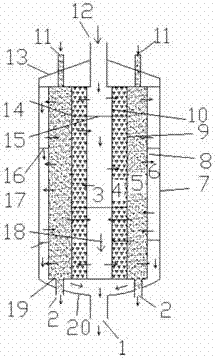

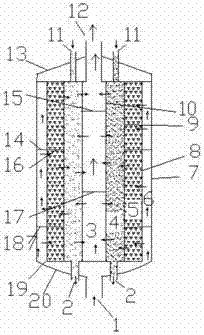

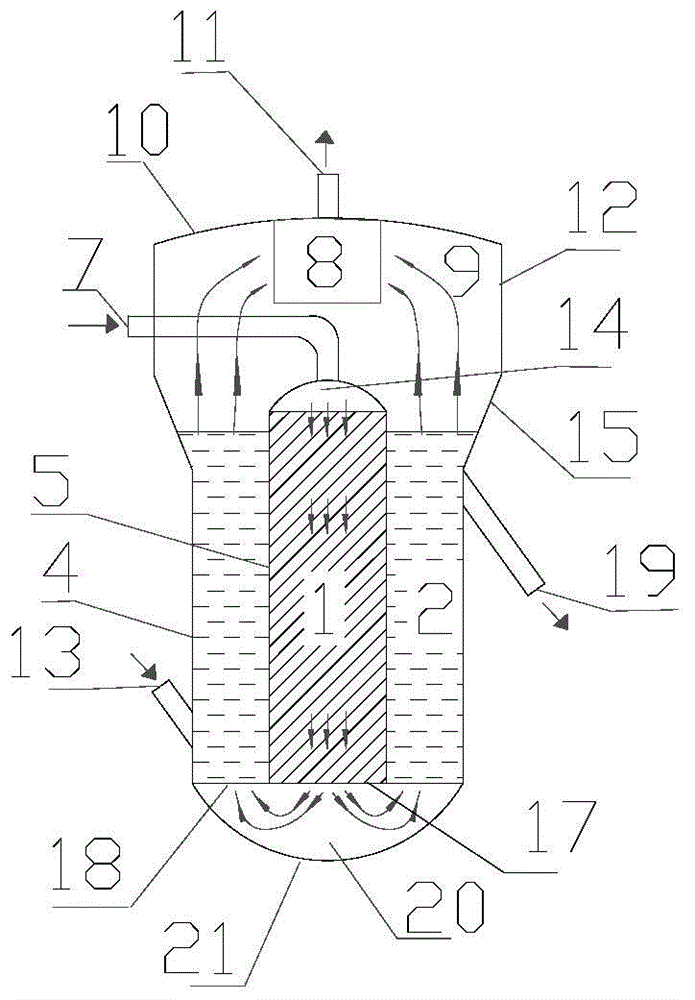

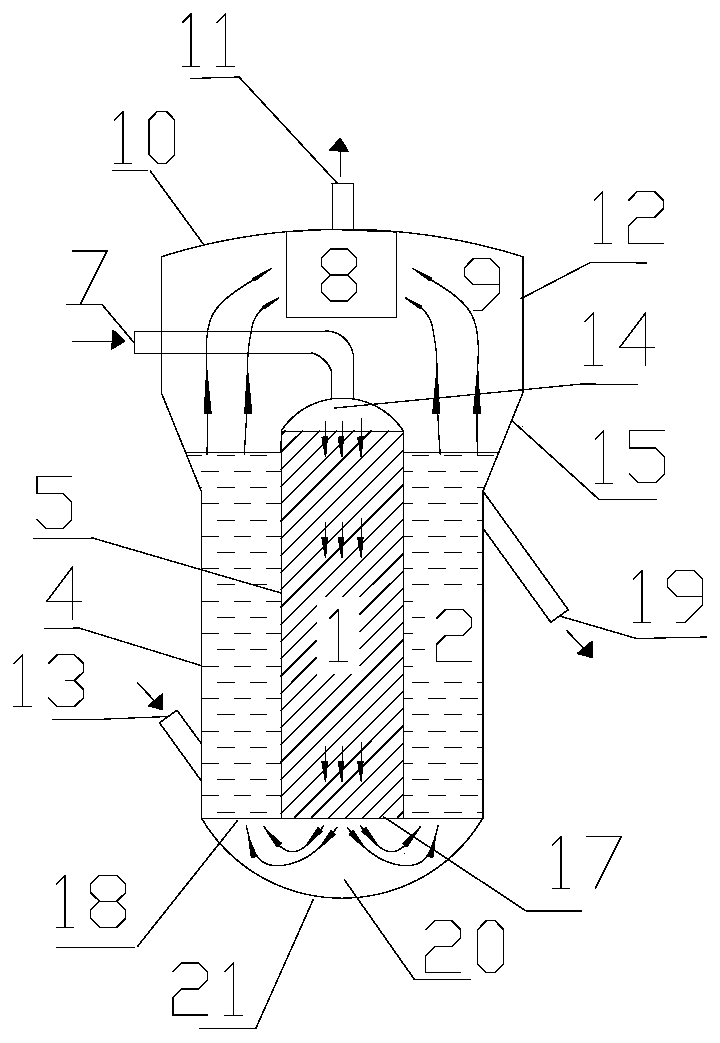

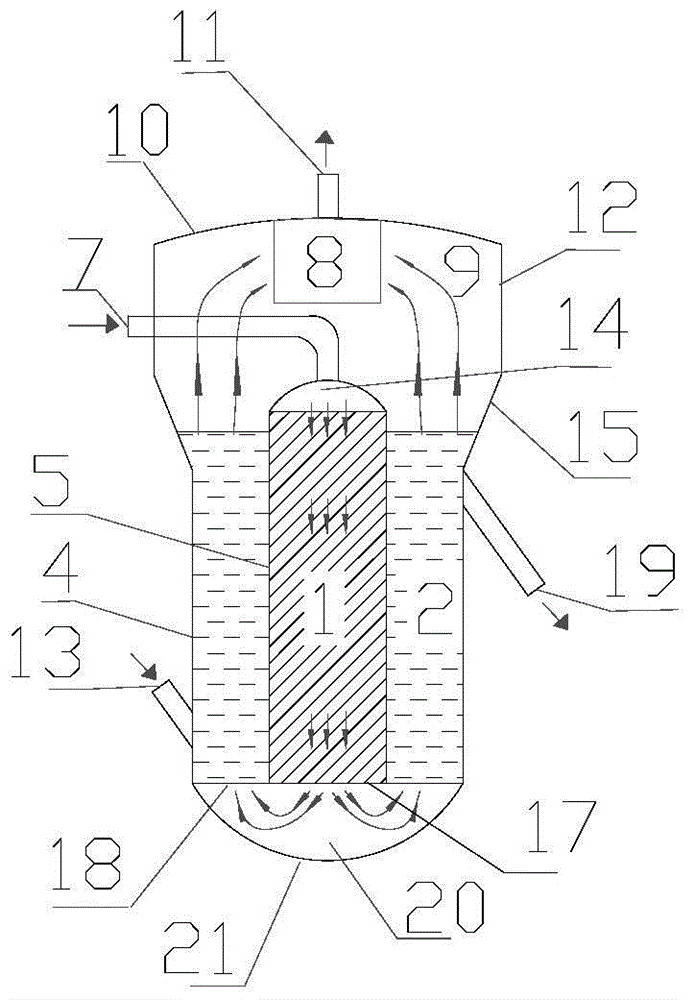

A method for adsorption and desulfurization of petroleum hydrocarbons

ActiveCN105623732BReduce wearSimple structureTreatment with hydrotreatment processesHydrogenHydrodesulfurization

A petroleum hydrocarbon adsorption desulfurization method adopts a moving bed radial flow reactor. The reactor is divided into a fluid feed channel, a catalyst fixed bed layer, a catalyst moving bed layer and a fluid discharge channel in the radial direction from outside to inside or from inside to outside; the top and the bottom of the reactor are respectively provided with a fluid feed inlet and a fluid discharge outlet; the top of the catalyst moving bed layer is provided with a moving bed catalyst inlet, and the bottom of the catalyst moving bed layer is provided with a moving bed catalyst outlet; the fluid feed channel, the catalyst fixed bed layer, the catalyst moving bed layer and the fluid discharge channel are separated by materials with pores. The wear of a catalyst can be reduced, a lot of hydrogen for reducing a hydrogenation desulfurization catalyst can be saved, device construction and operation process are simplified, energy consumption is saved, and the production continuous reaction and regeneration are facilitated. The method can be used for a deep desulfurization process of sulfur-containing C4 fractions and catalytically cracked gasoline. In addition, the reaction device provided by the invention has the advantages of simple structure and high production efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

Petroleum hydrocarbon adsorption desulfurization method

ActiveCN105623732AReduce wearSimple structureTreatment with hydrotreatment processesHydrogenHydrodesulfurization

A petroleum hydrocarbon adsorption desulfurization method adopts a moving bed radial flow reactor. The reactor is divided into a fluid feed channel, a catalyst fixed bed layer, a catalyst moving bed layer and a fluid discharge channel in the radial direction from outside to inside or from inside to outside; the top and the bottom of the reactor are respectively provided with a fluid feed inlet and a fluid discharge outlet; the top of the catalyst moving bed layer is provided with a moving bed catalyst inlet, and the bottom of the catalyst moving bed layer is provided with a moving bed catalyst outlet; the fluid feed channel, the catalyst fixed bed layer, the catalyst moving bed layer and the fluid discharge channel are separated by materials with pores. The wear of a catalyst can be reduced, a lot of hydrogen for reducing a hydrogenation desulfurization catalyst can be saved, device construction and operation process are simplified, energy consumption is saved, and the production continuous reaction and regeneration are facilitated. The method can be used for a deep desulfurization process of sulfur-containing C4 fractions and catalytically cracked gasoline. In addition, the reaction device provided by the invention has the advantages of simple structure and high production efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

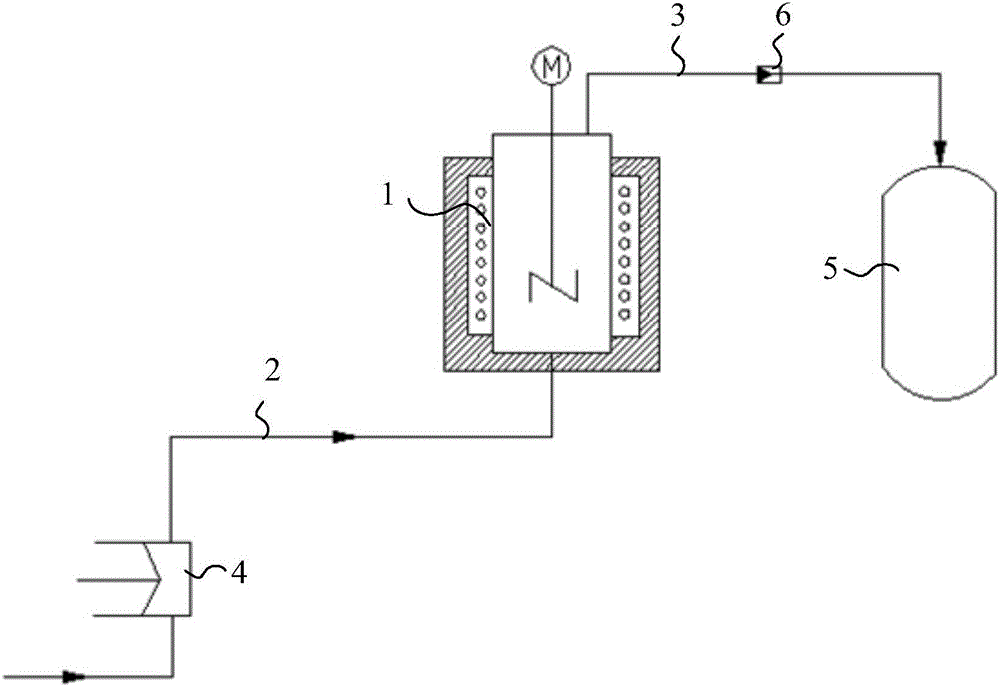

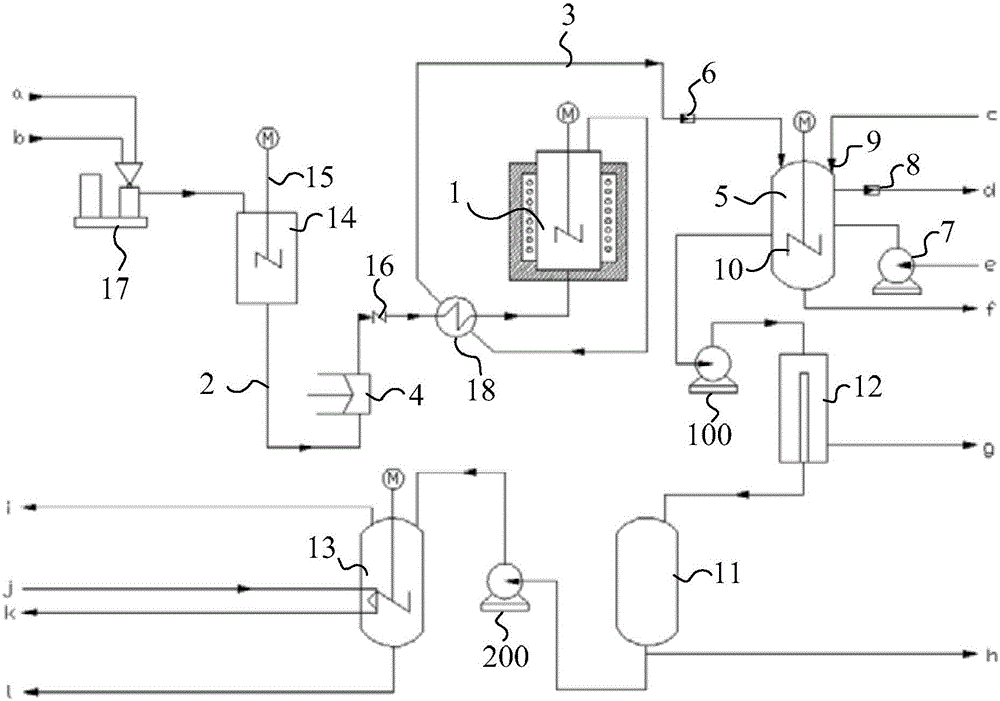

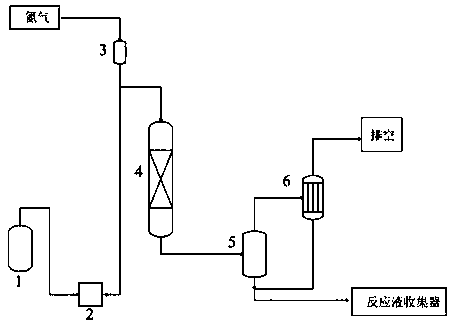

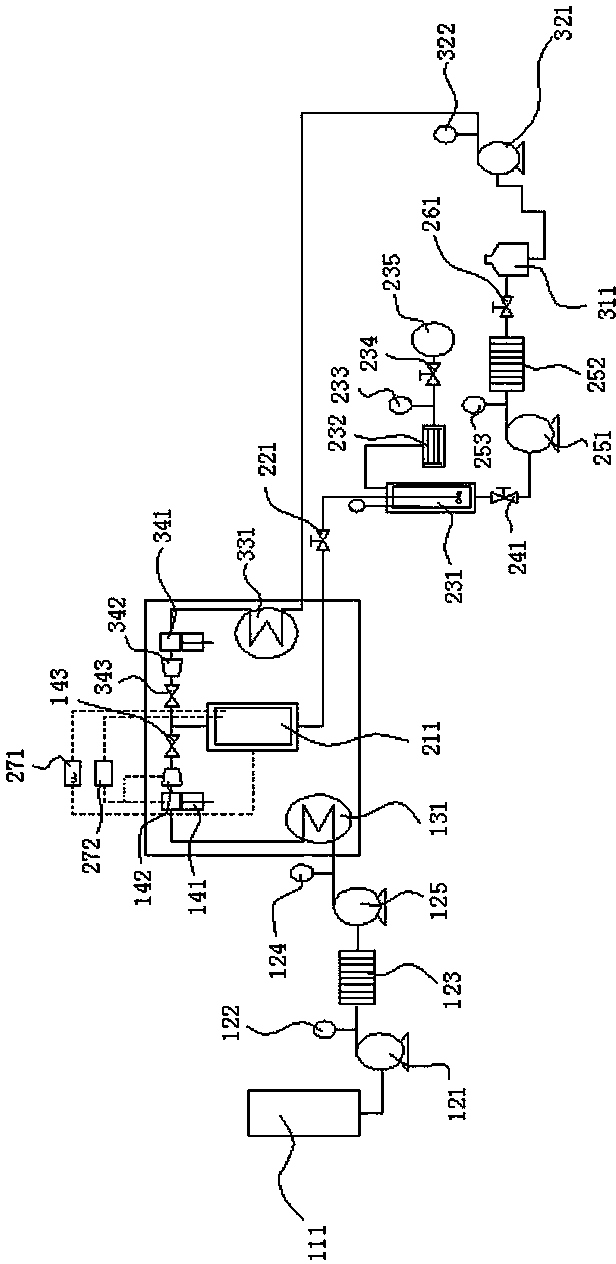

Hydrothermal liquidization system and hydrothermal liquidization method for biomass

ActiveCN106635112AEase of mass productionRealize continuous reactionLiquid hydrocarbon mixture productionHydrocarbon oils treatmentProcess engineeringContinuous reaction

The invention discloses a hydrothermal liquidization system and a hydrothermal liquidization method for biomass, relates to the technical field of biomass energy and aims to solve the problem that the hydrothermal liquidization system for the biomass in the prior art difficultly carries out continuous reaction of continuous feeding and continuous discharging. The hydrothermal liquidization system for the biomass provided by the invention comprises a reactor, a product collector and a flow control structure, wherein a feeding pipe and a product discharging pipe are connected to the reactor; a pressurizing device is serially connected onto the feeding pipe; the product collector is hermetically connected with the exhaust end of the product discharging pipe; the flow control structure is arranged between the product collector and the reactor and is used for controlling the flow, discharging to the product collector from the product discharging pipe, of the product, so that the discharging flow of the product discharging pipe is equal to the feeding flow of the feeding pipe. The hydrothermal liquidization system for the biomass, disclosed by the invention, is used for carrying out the continuous reaction of the continuous feeding and the continuous discharging.

Owner:ENN SCI & TECH DEV

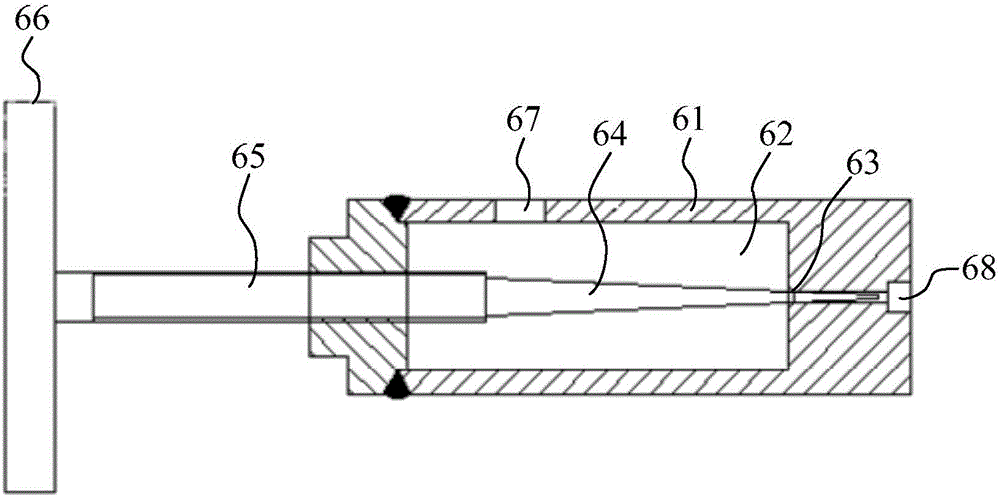

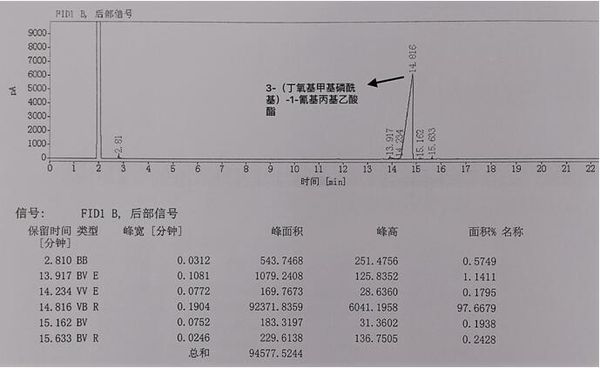

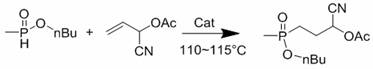

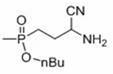

Method for synthesizing 3-(butoxy methyl phosphoryl)-1-cyanopropyl acetate based on micro-channel reactor

InactiveCN112110954AShort reaction cycleReduce security risksGroup 5/15 element organic compoundsChemical/physical/physico-chemical microreactorsAllyl acetateEngineering

The invention relates to the technical field of glufosinate-ammonium intermediate synthesis, and particularly discloses a method for synthesizing 3-(butoxy methyl phosphoryl)-1-cyanopropyl acetate based on a micro-channel reactor, and mainly aims to solve the problems of various production equipment types, high safety risk, difficulty in control, low production efficiency and the like of the method for synthesizing 3-(butoxy methyl phosphoryl)-1-cyanopropyl acetate in the existing glyphosate synthesis method. Methyl phosphinic acid monobutyl ester and 1-cyano-2-allyl acetate is taken as raw materials, continuous reaction is carried out under photocatalysis, the excellent mass and heat transfer characteristics of the micro-channel reactor are utilized, and under the condition that the yieldcan reach 96% or above, the reaction period is greatly shortened, the safety risk is reduced, and the production efficiency is improved.

Owner:SICHUAN FOURSTAR BIOTECH RANDD CORP

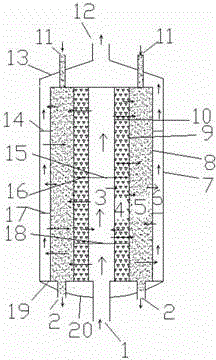

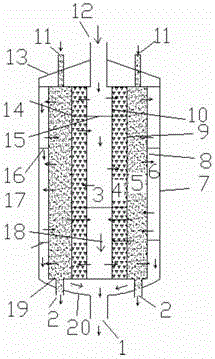

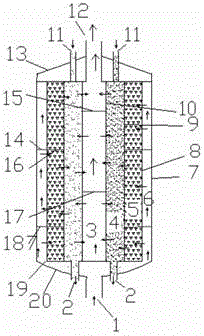

Petroleum hydrocarbon adsorption desulfurization method

ActiveCN105623733AReduce wearSimple structureTreatment with hydrotreatment processesFluidized bedGas phase

A petroleum hydrocarbon adsorption desulfurization method adopts a fixed bed-fluidized bed reactor which is divided into a particle settling zone, a reaction zone and a gas buffer zone from top to bottom; the reaction zone is divided into a fixed bed layer and a fluidized bed layer in the radial direction from outside to inside or from inside to outside; a separation plate which enables gas to pass through and enables catalyst particles not to pass through is arranged between the lower part of the fixed bed layer as well as the fluidized bed layer and the gas buffer zone; a space between the upper part of the fixed bed layer and the particle settling zone is closed; the upper part of the fluidized bed layer communicates with the particle settling zone; the upper part of the fixed bed layer is provided with a fluid feed inlet; the particle settling zone is internally provided with a gas-solid separator; a gas phase outlet of the gas-solid separator is a fluid discharge outlet of the reactor; the fluidized bed layer is also provided with a fluidized catalyst inlet and outlet. The petroleum hydrocarbon adsorption desulfurization method provided by the invention simplifies device construction and operation process, saves the energy consumption, and is beneficial for realizing continuous reaction and regeneration of production.

Owner:CHINA PETROLEUM & CHEM CORP +1

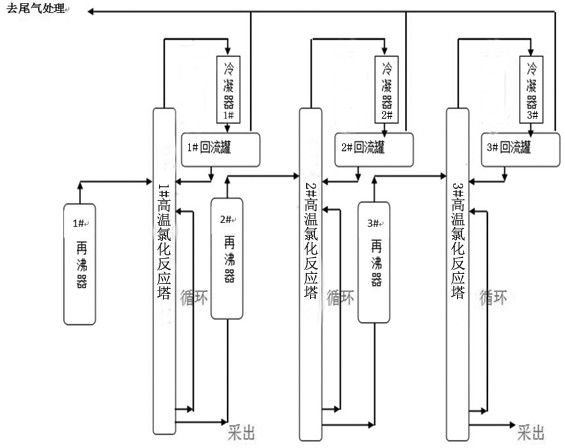

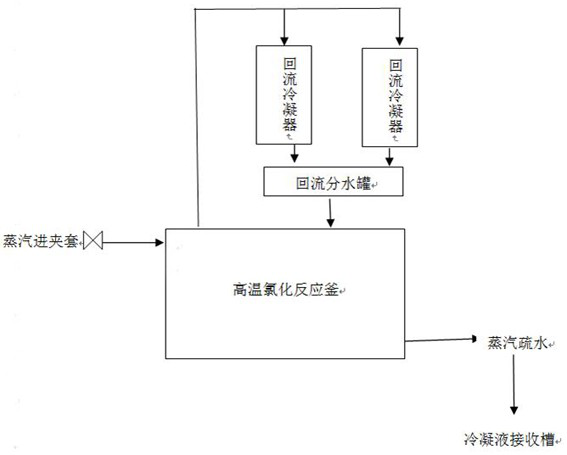

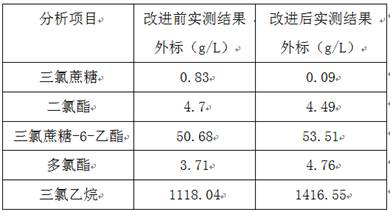

Sucralose continuous high-temperature reaction method and device thereof

PendingCN112574265ARealize continuous reactionSave the link of manual feedingSequential/parallel process reactionsSugar derivativesSucroseThermodynamics

The invention relates to a sucralose continuous high-temperature reaction method and a device thereof, which are characterized in that (1) low-temperature chlorination liquid is heated by a 1 # reboiler and then is fed into a 1 # high-temperature chlorination reaction tower, the temperature in the tower is controlled to be 68-71 DEG C, the pressure is -4-2Mpa, gas from the tower top returns to thetower after being condensed, and is circularly heated for 30min to obtain a solution A; (2) the solution A is heated by a 2 # reboiler and then enters a 2 # high-temperature chlorination reaction tower, the temperature in the tower is controlled to be 98-101 DEG C, the pressure in the tower is controlled to be -4-2 Mpa, gas coming out of the tower top is condensed and then returns to the tower, cyclic heating is conducted for 60 min, and a solution B is obtained; and (3) the solution B is heated by a 3 # reboiler and then enters a 3 # high-temperature chlorination reaction tower, the temperature in the tower is controlled to be 109-111 DEG C, the pressure in the tower is controlled to be -4-2 Mpa, gas coming out of the tower top is condensed and then returns to the tower, cyclic heating is conducted for 120 min, and a solution C is obtained. The device has the advantages that the three high-temperature chlorination reaction towers are connected in series, so that continuous reaction can be realized, the heating rate is increased, the pressure and the heating environment of a high-temperature chlorination system are optimized, the quality and the yield of a product are improved, and the tail gas emission amount is reduced.

Owner:ANHUI JINGHE IND

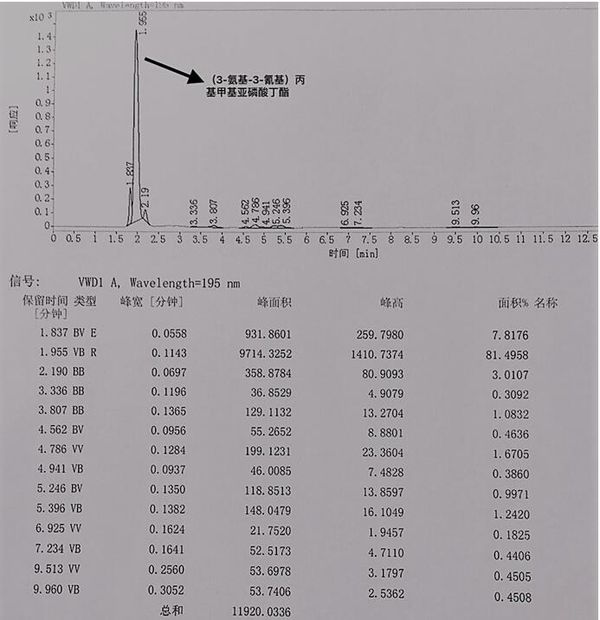

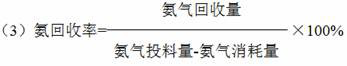

Method for synthesizing (3-amino-3-cyano) propyl methyl butyl phosphite based on micro-channel reactor

InactiveCN111995640AReduce typesReduce salt contentGroup 5/15 element organic compoundsChemical/physical/physico-chemical microreactorsPhosphorous acidAcyl group

The invention relates to the technical field of glufosinate-ammonium intermediate synthesis, and particularly discloses a method for synthesizing (3-amino-3-cyano) propyl methyl butyl phosphite basedon a micro-channel reactor. The invention mainly aims at solving the problems of the increase of the raw material consumption of a subsequent work section, wastewater and waste salt increase, huge production equipment, complex control and low production efficiency and the like of an existing (3-amino-3-cyano) propyl methyl butyl phosphite synthesis method. According to the method, 3-(butoxy methylphosphoryl)-1-cyanopropyl acetate, water and ammonia gas are adopted as raw materials; the micro-channel reactor is adopted, and flash evaporation degassing is used in combination to recover excess ammonia gas; the yield of the obtained (3-amino-3-cyano) propyl methyl butyl phosphite can reach 95% or above at most, the types of materials are reduced, the water amount of the system is reduced, continuous reaction is realized, the reaction period is greatly shortened, energy consumption is reduced, and the production cost is greatly reduced.

Owner:SICHUAN FOURSTAR BIOTECH RANDD CORP

Industrial production method of alkylbenzene sulfonyl chloride

ActiveCN101195593BSmall molecular weightReduced activitySulfonic acid preparationAlkaneSulfonyl chloride

The invention relates to an industrialized production process of alkyl benzenesulfonyl chloridebenzene sulfonyl chloride, which uses tubular reactor to continuously or kettle-type intermittently sulfonate alkyl benzene and liquid sulfur trioxide in the solvent as liquid sulfur dioxide, liquid wax, ligarine, and halohydrocarbon of C1-C4, 90-120# solvent oil and alkane of C4-C8 or the like, directly treats the reaction product and chlorosulfonic acid with acyl chlorination via a tubular reactor continuously or a kettle intermittently, to generate alkyl benzenesulfonyl chloridebenzene sulfonyl chloride, washes alkyl benzenesulfonyl chloridebenzene sulfonyl chloride, removes acid, and desolventizes to generate product alkyl benzenesulfonyl chloridebenzene sulfonyl chloride. The invention avoids generating hydrochloride gas, to support tube continuous production, reduce dangerous chemical in production system, reduce equipment investment, and improve economic benefit, which replaces chlorosulfonic acid with sulfur trioxide to process sulphonation to realize clean production and reduce material cost.

Owner:浙江嘉福新材料科技有限公司

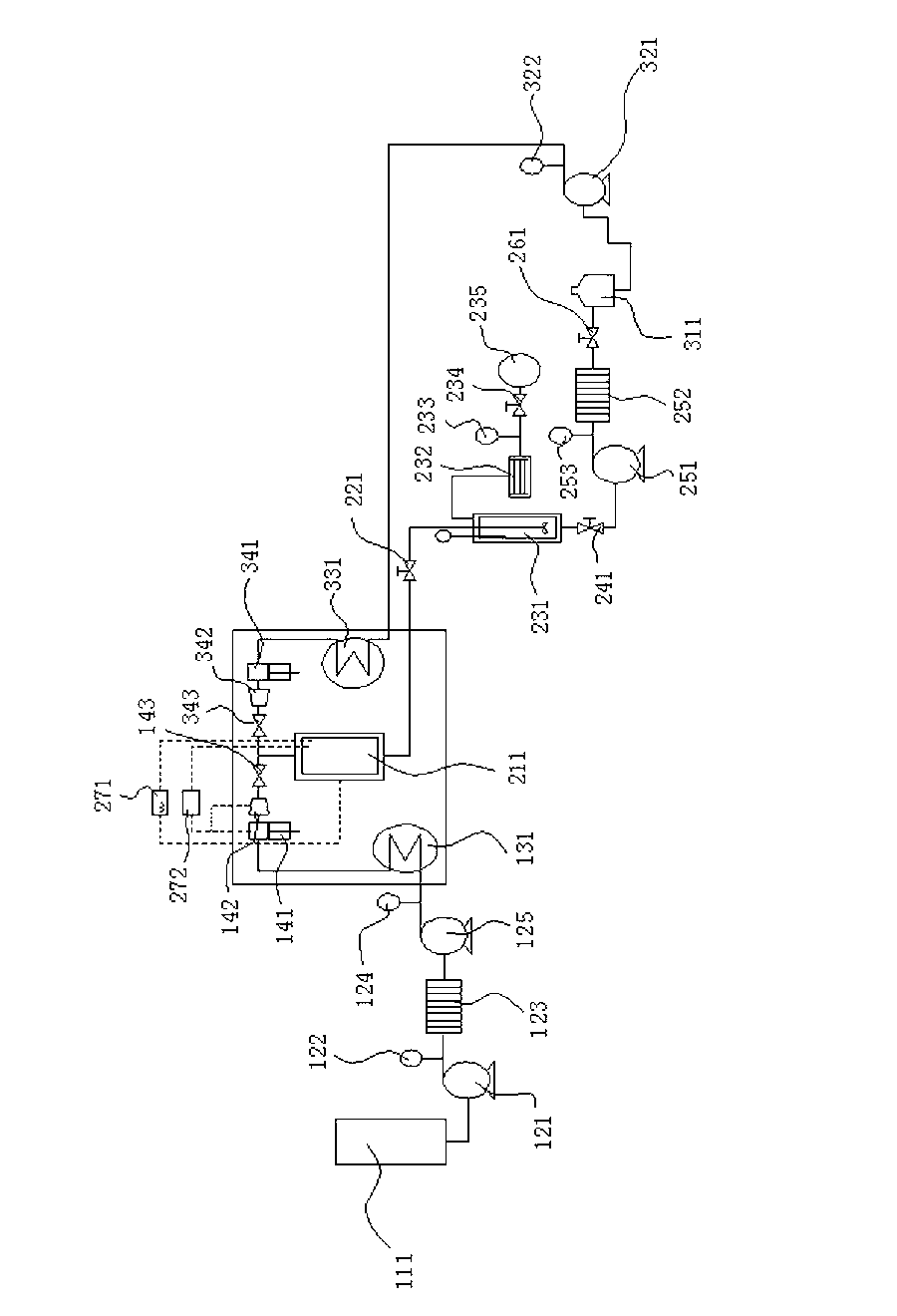

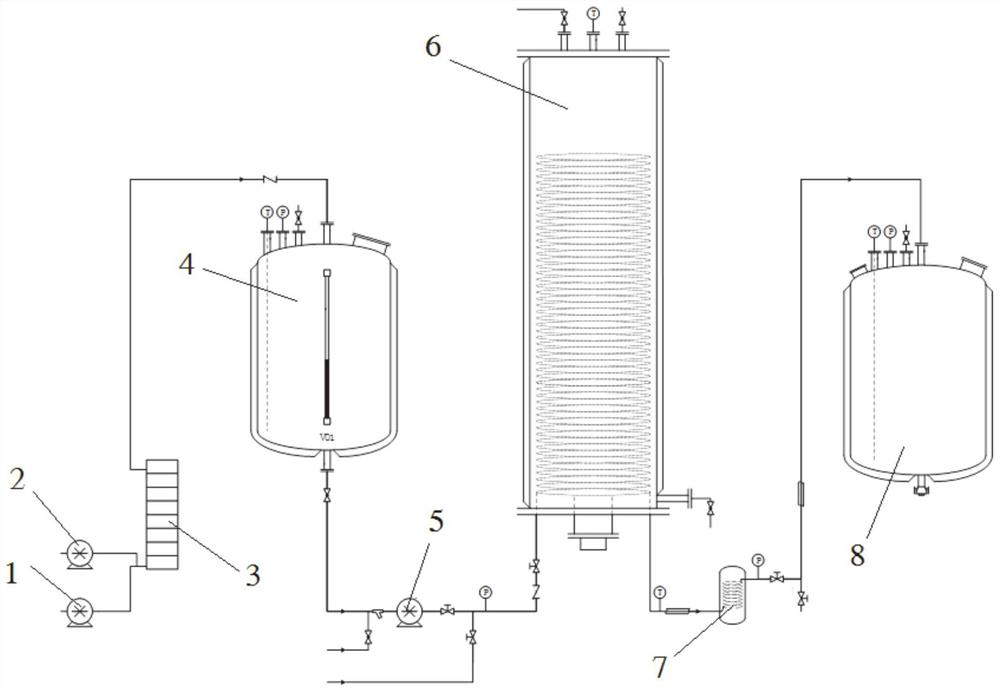

Continuous subcritical reaction device for ethyl ester fish oil hydrolysis

ActiveCN103013674AImprove productivity and conversionsRealize waste utilizationFatty acid esterificationFatty acids production/refiningEthyl esterWater storage tank

The invention provides a continuous subcritical reaction device for ethyl ester fish oil hydrolysis, and belongs to the technical field of foods. The continuous subcritical reaction device for ethyl ester fish oil hydrolysis comprises a water storage tank, a reaction chamber with a water inlet and a water outlet, and a liquid storage box with a liquid outlet, wherein a circulating structure capable of recovering water flowing from the liquid outlet to the reaction chamber and recycling the water is arranged between the liquid outlet of the liquid storage box and the water inlet of the reaction chamber, a control structure capable of controlling the pressure and the temperature in the reaction chamber is arranged on the reaction chamber, and a recycling structure capable of recycling ethanol separated from a condensing and evaporating pot is arranged on the condensing and evaporating pot. The continuous subcritical reaction device for ethyl ester fish oil hydrolysis can be used for solving the problems of inconvenience for sampling and analyzing, disadvantage to commercial process and the like of the traditional batch-type precritical reaction unit, and has the advantages of realizing the control of hydrolysis temperature and pressure, effectively increasing the working efficiency, and the like.

Owner:ZHEJIANG OCEAN UNIV

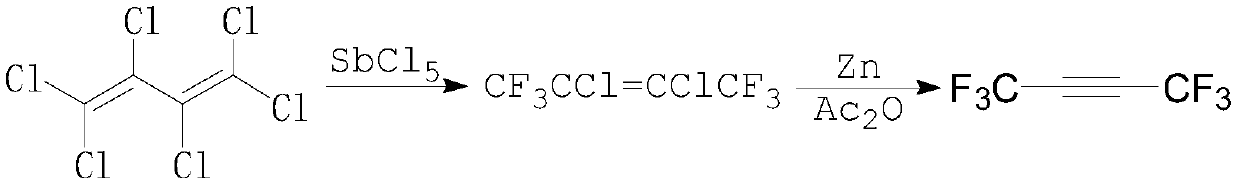

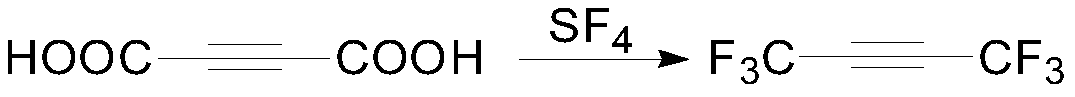

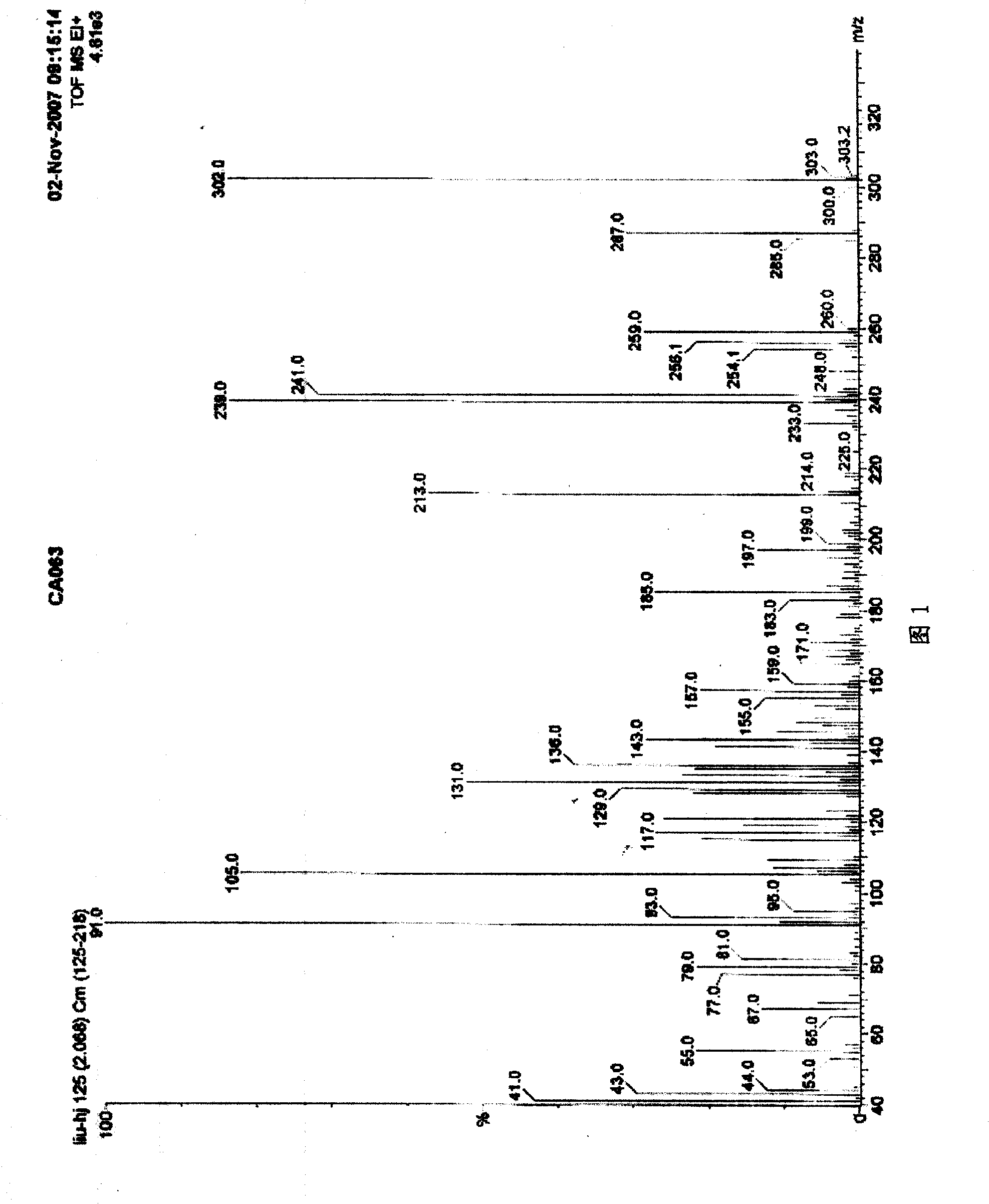

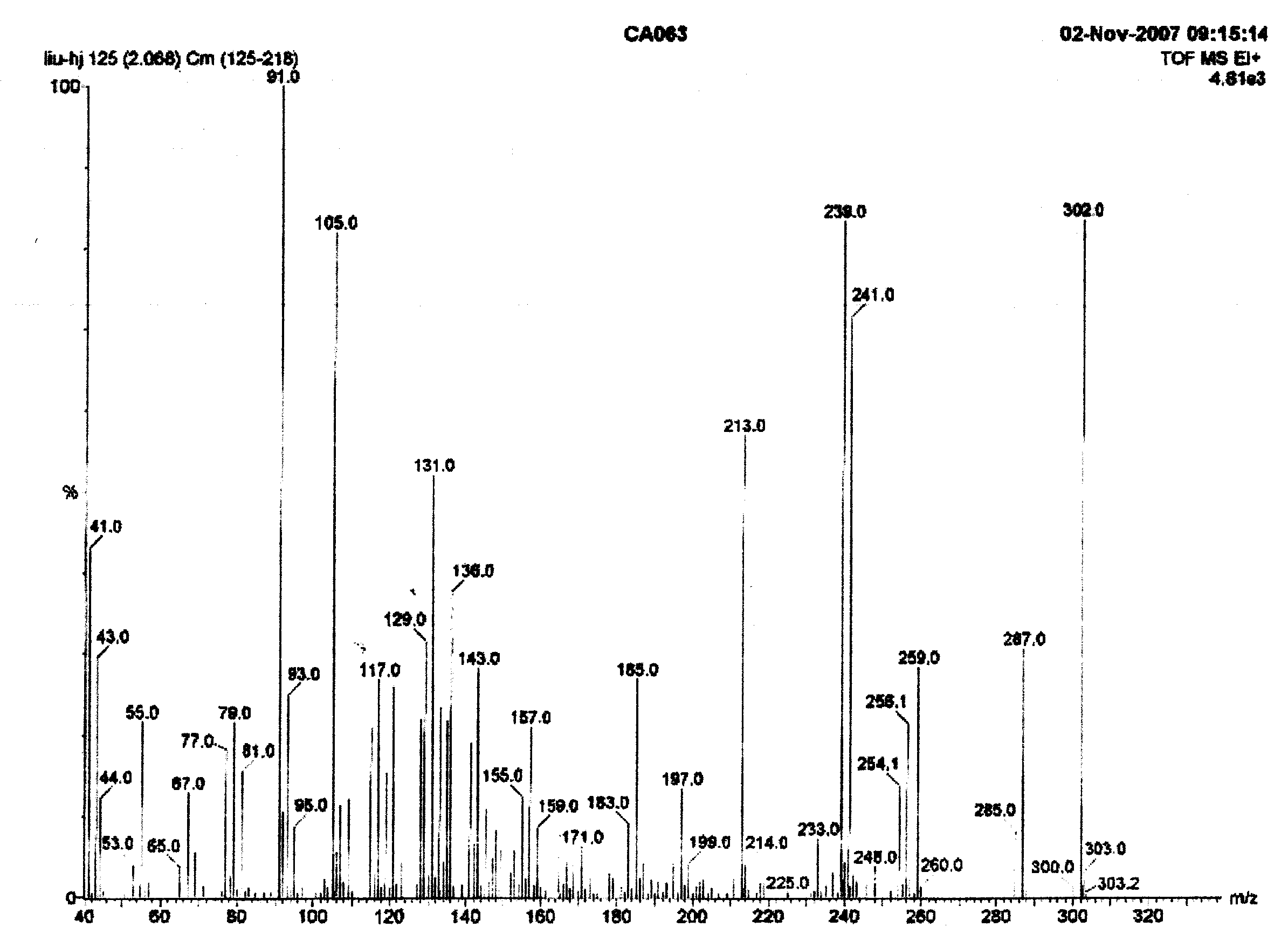

Method for preparing 1,1,1,4,4,4-hexafluoro-2-butyne through gas phase method

ActiveCN110950735ASimple processFew reaction stepsPreparation by dehalogenationChemical recyclingButenePtru catalyst

The invention discloses a method for preparing 1,1,1,4,4,4-hexafluoro-2-butyne through a gas phase method, wherein hexafluoro-2-chloro-2-butene as a raw material is subjected to a gas phase dehydrochlorination reaction under the catalytic action of a dechlorination catalyst to obtain 1,1,1,4,4,4-hexafluoro-2-butyne. The method has the advantages of simple process, economy, environmental protectionand easy industrialization.

Owner:JUHUA GROUP TECH CENT

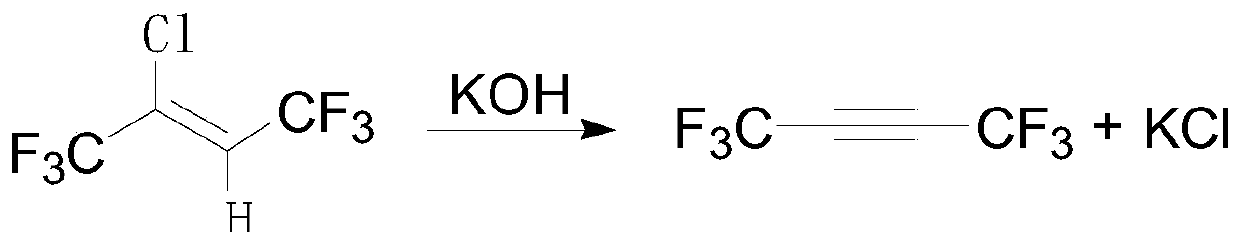

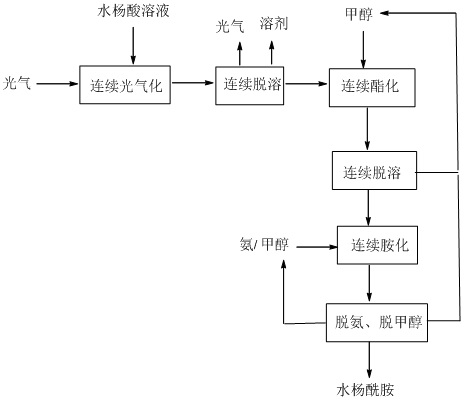

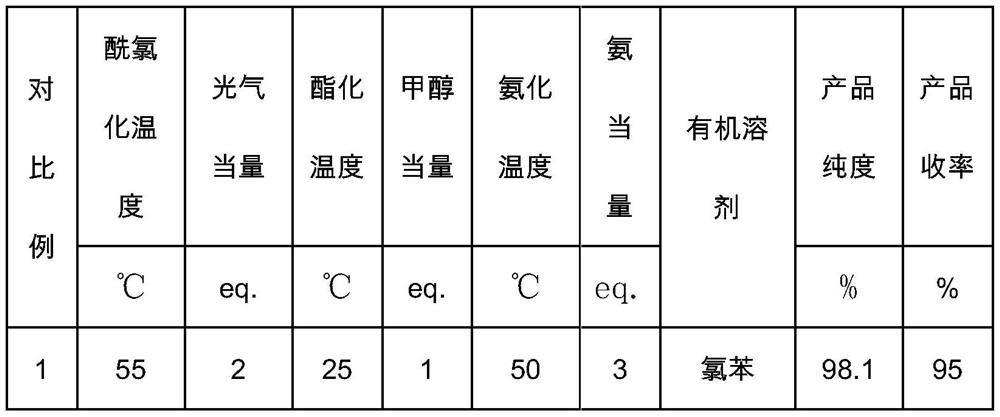

Method for synthesizing salicylamide by continuous method

ActiveCN113754553AHigh reaction yieldNo emissionsPreparation from carboxylic acid halidesOrganic compound preparationSalicylic acidMethyl salicylate

The invention discloses a method for synthesizing salicylamide by a continuous method, which comprises the steps of (1) carrying out acylating chlorination reaction on an acylating chlorination reagent phosgene and a salicylic acid solution in a continuous reactor to obtain salicyloyl chloride; (2) carrying out esterification reaction on salicyloyl chloride and methanol in the continuous reactor to obtain methyl salicylate; and (3) carrying out ammoniation reaction on the methyl salicylate and the methanol solution of ammonia in the continuous reactor to obtain salicylamide. The process has the beneficial effects that (1) the reaction yield of methyl salicylate is increased (98% or above), and no wastewater or waste acid is discharged; (2) the reaction yield of salicylamide is improved (98% or above), and no ammonia-nitrogen-containing wastewater is discharged; (3) the process realizes the continuous reaction of salicylamide, and saves the purification energy consumption and cost of the product; and (4) the product purity is high, and the operation is simple.

Owner:JIANGSU KUAIDA AGROCHEM

A fixed bed-fluidized bed reactor and its application

ActiveCN105617947BReduce wearSimple structureTreatment with hydrotreatment processesChemical/physical processesGas phaseFluidized bed

A fixed bed-fluidized bed reactor is divided into a particle settling zone, a reaction zone and a gas buffer zone from top to bottom; the reaction zone is divided into a fixed bed layer and a fluidized bed layer in the radial direction from outside to inside or from inside to outside; a separation plate which enables gas to pass through and enables catalyst particles not to pass through is arranged between the lower part of the fixed bed layer as well as the fluidized bed layer and the gas buffer zone; a space between the upper part of the fixed bed layer and the particle settling zone is closed; the upper part of the fluidized bed layer communicates with the particle settling zone; the upper part of the fixed bed layer is provided with a fluid feed port; the particle settling zone is internally provided with a gas-solid separator; a gas phase outlet of the gas-solid separator is a fluid discharge port of the reactor; the fluidized bed layer is also provided with a fluidized catalyst inlet and outlet. A petroleum hydrocarbon adsorption desulfurization method provided by the invention simplifies device construction and operation process, saves the energy consumption, and is beneficial for realizing continuous reaction and regeneration of production.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for adsorption and desulfurization of petroleum hydrocarbons

ActiveCN105623733BReduce wearSimple structureTreatment with hydrotreatment processesGas phaseFluidized bed

A petroleum hydrocarbon adsorption desulfurization method adopts a fixed bed-fluidized bed reactor which is divided into a particle settling zone, a reaction zone and a gas buffer zone from top to bottom; the reaction zone is divided into a fixed bed layer and a fluidized bed layer in the radial direction from outside to inside or from inside to outside; a separation plate which enables gas to pass through and enables catalyst particles not to pass through is arranged between the lower part of the fixed bed layer as well as the fluidized bed layer and the gas buffer zone; a space between the upper part of the fixed bed layer and the particle settling zone is closed; the upper part of the fluidized bed layer communicates with the particle settling zone; the upper part of the fixed bed layer is provided with a fluid feed inlet; the particle settling zone is internally provided with a gas-solid separator; a gas phase outlet of the gas-solid separator is a fluid discharge outlet of the reactor; the fluidized bed layer is also provided with a fluidized catalyst inlet and outlet. The petroleum hydrocarbon adsorption desulfurization method provided by the invention simplifies device construction and operation process, saves the energy consumption, and is beneficial for realizing continuous reaction and regeneration of production.

Owner:CHINA PETROLEUM & CHEM CORP +1

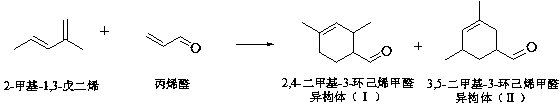

Method for continuous synthesis of ligustral in fixed bed reactor

InactiveCN109293485AInhibit aggregationIncrease profitOrganic compound preparationCarbonyl compound preparationAcroleinFixed bed

The invention provides a method for continuous synthesis of ligustral in a fixed bed reactor. The method is characterized by including raw material mixing and continuous reaction. The method providedby the invention adopts a modified Al2O3 catalyst to catalyze reaction, has low reaction temperature and pressure, effectively avoids the polymerization of acrolein in reaction raw materials, reducesenergy consumption, improves the utilization of raw materials, at the same time avoids the situation of severe reaction and difficult control of reaction temperature in one-pot process, and has high safety factor. The pure ligustral product prepared by the method provided by the invention has a content of 99.5%-99.7%, wherein the content of isomer I is 78.1-78.9%, the content of isomer II is 20.7-21.4%, the conversion rate of 2-methyl-1, 3-pentadiene in the process is 98.3-99.1%, and the product selectivity is 97.0-98.4%, and in terms of 2-methyl-1, 3-pentadiene, the yield of the reaction process is 95.4-97.0%.

Owner:SHANDONG NHU PHARMA

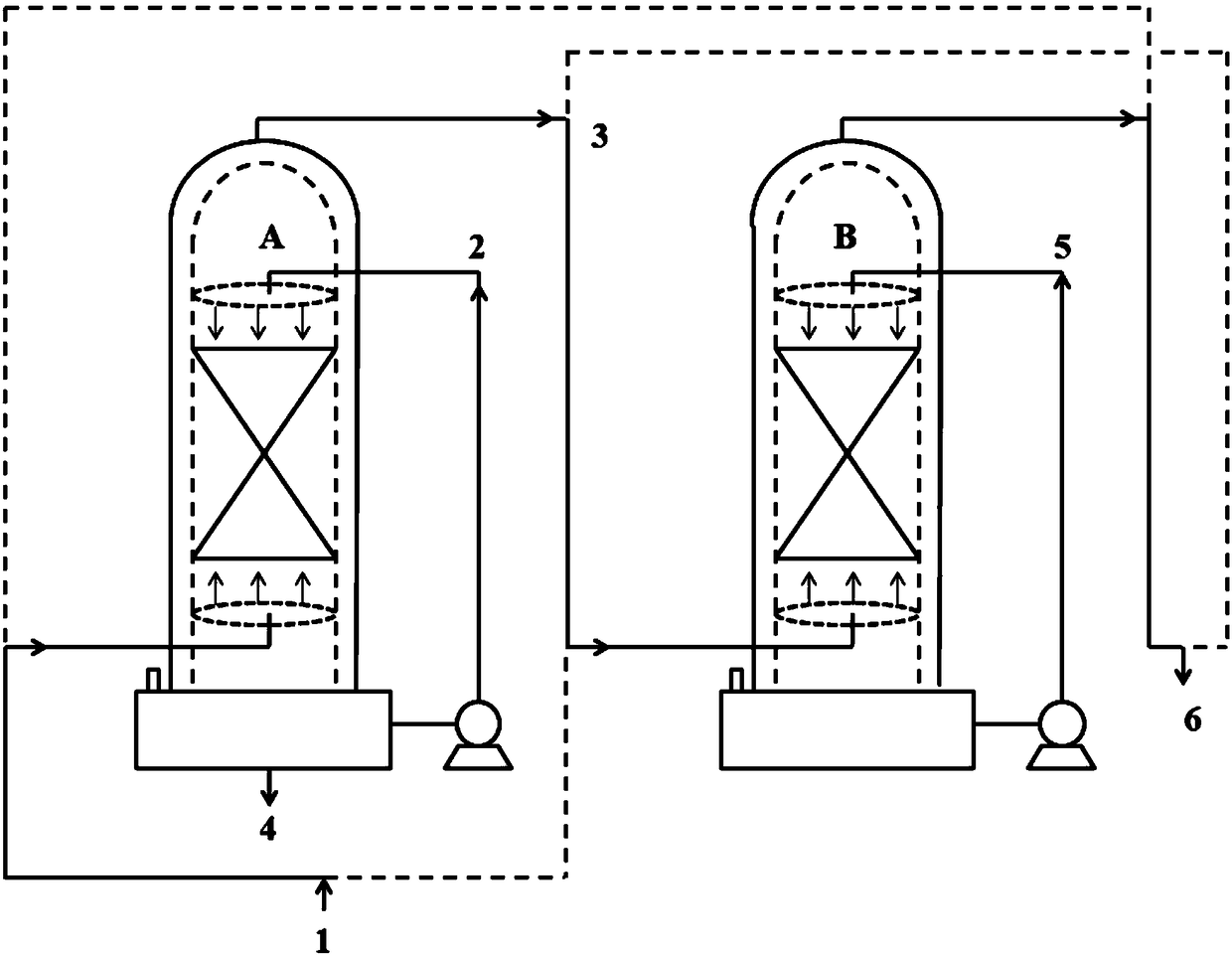

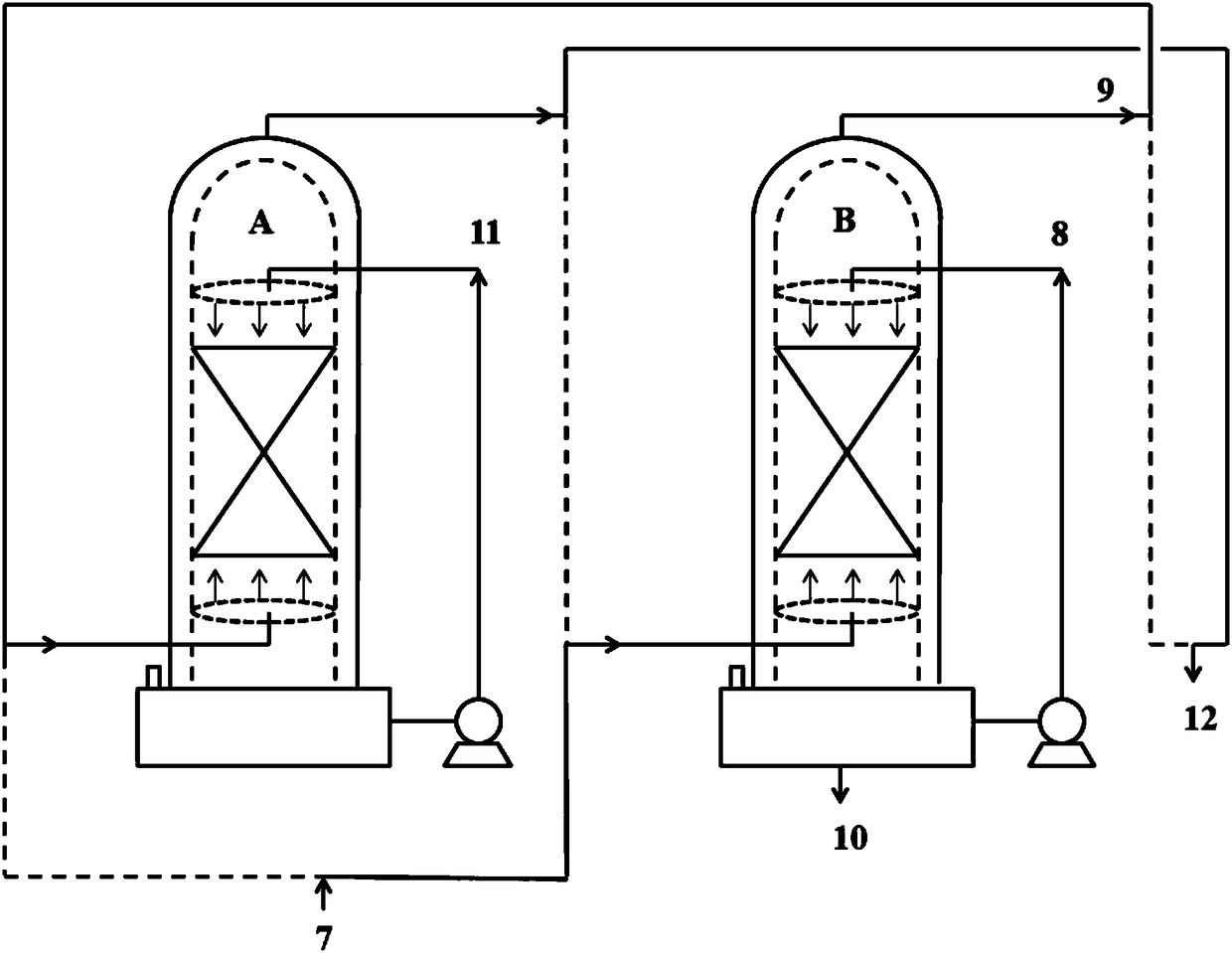

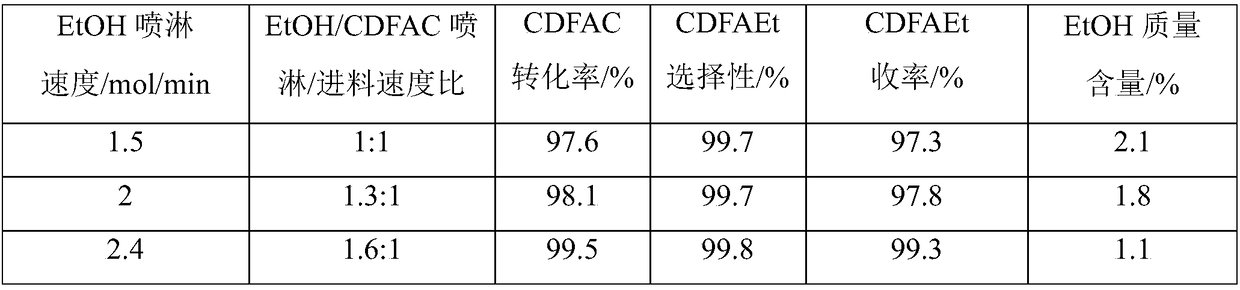

Method for preparing difluorochloroacetate and difluorochloroacetic acid through continuous non-catalytic reaction

ActiveCN109020812AReduce productionLow in alcohol or waterPreparation from carboxylic acid halidePreparation from carboxylic acid halidesAlcoholSpray tower

The invention provides a method for preparing difluorochloroacetate and difluorochloroacetic acid through a two-stage tandem continuous non-catalytic reaction, wherein a two-stage spraying tower tandem process is used during single-pass operation, and after the single-pass operation is completed, a first-stage absorption tower and a second-stage absorption tower are switched so as to continuouslycarry out a reaction. According to the present invention, the method has advantages of low alcohol or water content in the reaction product, easy separation and purification of the product, continuousreaction, high reaction efficiency, high yield, no requirement of catalysts and acid binding agents, less three-waste, and the like.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +2

Process for producing abietic acid

InactiveCN101219949BFriendly cleanWill not polluteCarboxylic compound separation/purificationOrganic acidOrganic solvent

The invention belongs to a method for separating and purifying every component of a colophony and discloses a method for preparing an abietic acid: step 1, adding ten mass fraction of colophony into 5 to 100 mass fraction of an organic acid solvent with 2 to 6 carbons, mixing uniformly and being heated to lead the colophony to be totally dissolved; step 2, adding the dissolved colophony liquid into a fixed bed reactor with a solid acid-cation exchange resin catalyst and the fixed bed reactor keeps a temperature between 30 DEG C and 90DEG C; the colophony liquid flows over the fixed bed reactor from top to bottom to acquire an abietic acid heterogeneous liquid; step 3, standing, crystallizing and filtering the abietic acid heterogeneous liquid under a room temperature to acquire a crude crystallizing product of the abietic acid; step 4, dissolving the crude crystallizing product of the abietic acid by an organic solvent and then recrystallizing, and then obtaining a pure abietic acid after drying the recrystallized abietic acid crystal by vacuum. The method uses solid acid-strong acid cation exchange resin catalyst as a reaction catalyst of hete over more than 85 percent.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Method for removing sulphur from coking benzol

ActiveCN101602647BReduce dosageImprove desulfurization effectMolecular sieve catalystsChemical modification purification/separationMolecular sieveBenzene

The invention relates to a method for removing sulphur from coking benzol, belonging to the technical field of organic chemical engineering; and the invention in particular relates to continuous sulphur removal technology of coking benzol; the coking benzol, solvent, oxidant and titanium-silicon molecular sieve catalyst particles are added in a slurry bed reaction kettle and are reacted under thetemperature of 10-90 DEG C, and the reacted products are divided into oil-phase slurry and water-phase slurry, alkaline washing and water-washing layering are carried out to the oil-phase slurry for obtaining sulphur-removal benzene, and the water-phase slurry is returned to the reaction kettle. After being treated, the coking benzol contained about 200ppm of sulphur contains 0-5ppm of sulphur; the method has simple flow, less three wastes and high yield coefficient and is easy to realize industrialization.

Owner:JIANGSU YANGNONG CHEM GROUP +1

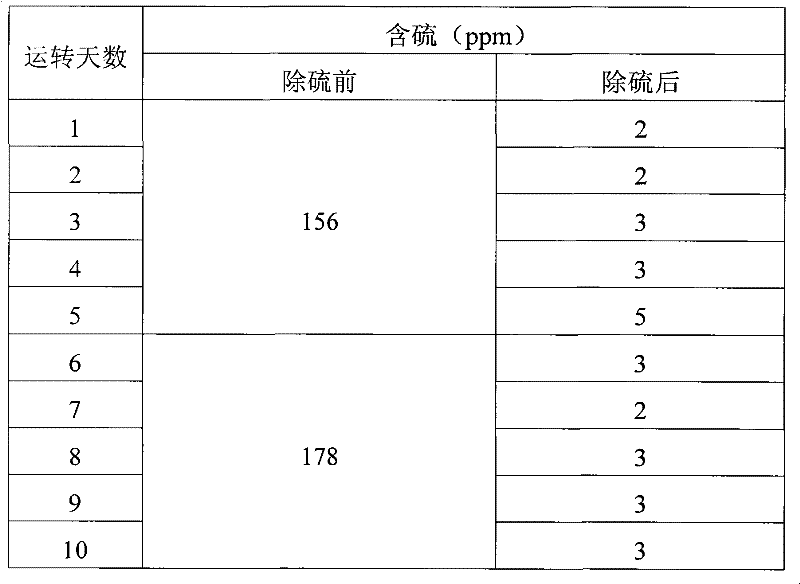

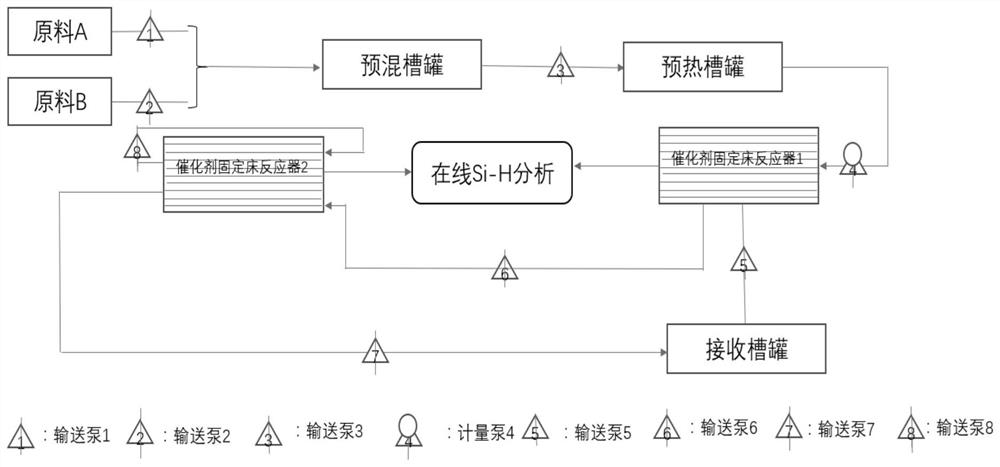

Continuous reaction process and continuous reaction equipment of ammonium sulfamate

InactiveCN113428846AReduce energy consumptionShort reaction timeAmidosulfonic acidTemperature controlLiquid state

The invention discloses a continuous reaction process and continuous reaction equipment of ammonium sulfamate. The continuous reaction process comprises the steps of (1) taking 20-25% of ammonia water and sulfamic acid as raw materials, and adding the raw materials into a reactor, wherein the reactor is formed by connecting one or more solid-liquid mixers in series through a pipeline; (2) arranging temperature control equipment on both the solid-liquid mixers and the pipeline, and in the reaction process, carrying out compensation type heating on the solid-liquid mixers and the pipeline so as to enable the temperature required by the saturation solubility of the ammonium sulfamate in a direct reaction liquid state to be reached through the heat release of the reaction and the compensation heating of the reactor; and (3) after the reaction is finished, directly filtering, cooling and crystallizing without concentrating to obtain an ammonium sulfamate crystal product. According to the method, the ammonium sulfamate can be continuously and automatically produced, no carbon dioxide is generated, the method has great environmental protection significance, the reaction time is reduced from the hour level to the second level, no concentration process exists, and the energy consumption is greatly reduced.

Owner:山东青维企业管理咨询有限公司

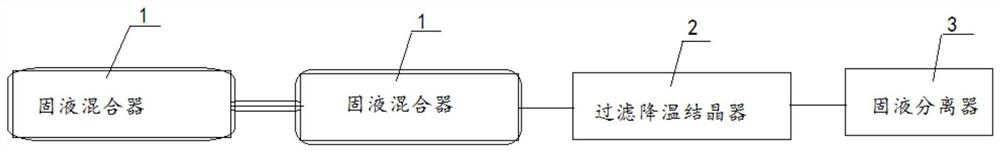

Method for carrying out hydrosilylation reaction by using activated carbon fiber immobilized noble metal catalyst

ActiveCN113801328AUniform pore size distributionImprove adsorption capacityMetal/metal-oxides/metal-hydroxide catalystsFiberActivated carbon

The invention relates to a method for applying an activated carbon fiber immobilized rare precious metal catalyst to a hydrosilylation reaction. A heterogeneous catalyst is prepared by immobilizing a homogeneous noble metal catalyst for hydrosilylation on the surface of activated carbon fiber (ACF). The heterogeneous catalyst is fixed in a polytetrafluoroethylene pipeline to serve as a fixed bed reactor for hydrosilylation, and the effect of efficiently catalyzing the hydrosilylation can be achieved. A large number of micropores of the activated carbon fiber (ACF) are directly formed in the surface, no internal diffusion stage exists, and the catalyst has the advantages of being high in immobilization efficiency, good in catalytic selectivity, improved in catalytic activity and the like. In the post-treatment stage, the activated carbon fiber immobilized noble metal catalyst can be conveniently separated from a reaction system and recycled, so that the problem of noble metal loss in the industrial production process is effectively solved, and meanwhile, the quality of an organic silicon product is improved.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

Continuous subcritical reaction device for ethyl ester fish oil hydrolysis

ActiveCN103013674BTemperature controlControl pressureFatty acid esterificationFatty acids production/refiningWater storage tankFish oil

The invention provides a continuous subcritical reaction device for ethyl ester fish oil hydrolysis, and belongs to the technical field of foods. The continuous subcritical reaction device for ethyl ester fish oil hydrolysis comprises a water storage tank, a reaction chamber with a water inlet and a water outlet, and a liquid storage box with a liquid outlet, wherein a circulating structure capable of recovering water flowing from the liquid outlet to the reaction chamber and recycling the water is arranged between the liquid outlet of the liquid storage box and the water inlet of the reaction chamber, a control structure capable of controlling the pressure and the temperature in the reaction chamber is arranged on the reaction chamber, and a recycling structure capable of recycling ethanol separated from a condensing and evaporating pot is arranged on the condensing and evaporating pot. The continuous subcritical reaction device for ethyl ester fish oil hydrolysis can be used for solving the problems of inconvenience for sampling and analyzing, disadvantage to commercial process and the like of the traditional batch-type precritical reaction unit, and has the advantages of realizing the control of hydrolysis temperature and pressure, effectively increasing the working efficiency, and the like.

Owner:ZHEJIANG OCEAN UNIV

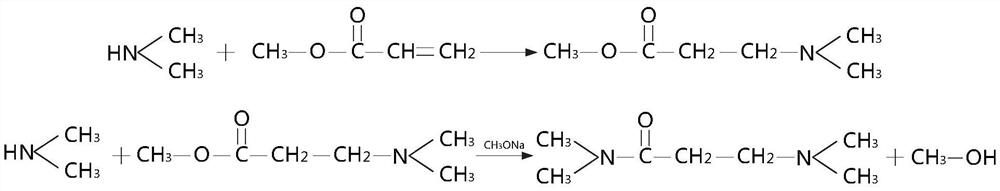

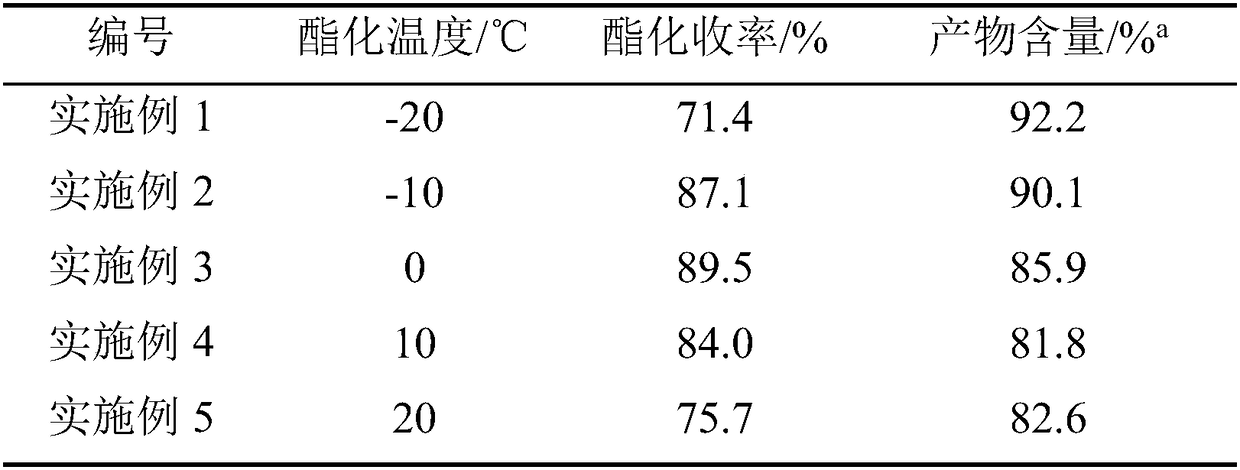

System and process for continuous synthesis of 3-(n,n-dimethylamino)-n,n-dimethylpropionamide without catalyst

ActiveCN112266332BIncrease reaction rateReduce side effectsOrganic compound preparationCarboxylic acid amides preparationProcess engineeringDimethylamines

The invention discloses a system and a process for catalyst-free continuous synthesis of 3-(N,N-dimethylamino)-N,N-dimethylpropionamide. The system comprises a plate heat exchanger, a buffer storage tank, a Pump and pipeline reactor; the material inlet of the plate heat exchanger is connected to the material main line, and the material main line is used to connect the methyl acrylate source and the dimethylamine source. The process is as follows: methyl acrylate and dimethylamine enter the plate heat exchanger and heat to 10-50 °C for reaction, then enter the buffer storage tank for buffering, and enter the pipeline reactor through the material pump for continuous reaction. The temperature and pressure were adjusted to 180 to 260° C. and 5.5 to 15 MPa, respectively. The process of the invention does not need a catalyst to avoid the generation of salt solid waste, and realizes the continuous production and can shorten the reaction time.

Owner:山东瑞博龙化工科技股份有限公司

A kind of 3-(alkoxymethylphosphoryl) propionate synthetic method

ActiveCN106565778BRealize continuous reactionEasy to operateGroup 5/15 element organic compoundsChemical/physical/physico-chemical processesSynthesis methodsPhotochemistry

The invention discloses a novel synthesis method for 3-(alkoxy methyl phosphoryl)propionate (short for "propionate") by carrying out esterification reaction on 3-(methyl phosphoryl chloride)propionyl chloride (short for "bis(acyl chloride) ") serving as a raw material. The method in which a novel array tubular reaction device is mainly adopted comprises the steps: feeding raw materials including bis(acyl chloride) and a hydroxyl compound from one side, then, releasing heat by reaction in glass tubes, enabling a condensed fluid to be in cross flow contact with the glass tube on the outer layer of a reaction tube, carrying out strong heat exchange, carrying out quenching treatment by using an acid binding agent after discharging as an esterification product, and then, collecting a product, so that continuous esterification synthesis reaction and sufficient heat exchange with a reaction solution can be realized, and an HCl gas serving as a byproduct has no corrosion to equipment. The method is simple in operation, high in heat exchange capability, precise in temperature control, environment-friendly and wide in large-scale application prospect.

Owner:ANHUI COSTAR BIOCHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com