Continuous subcritical reaction device for ethyl ester fish oil hydrolysis

A technology of ethyl ester fish oil and reaction device, which is applied in the direction of edible oil/fat, application, fatty acid esterification, etc., can solve the unfavorable industrial production, it is difficult to prepare high-content EPA+DHA glyceride fish oil products, and sampling analysis is not easy Convenience and other issues, achieve the effect of realizing waste utilization, improving production efficiency and conversion rate, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

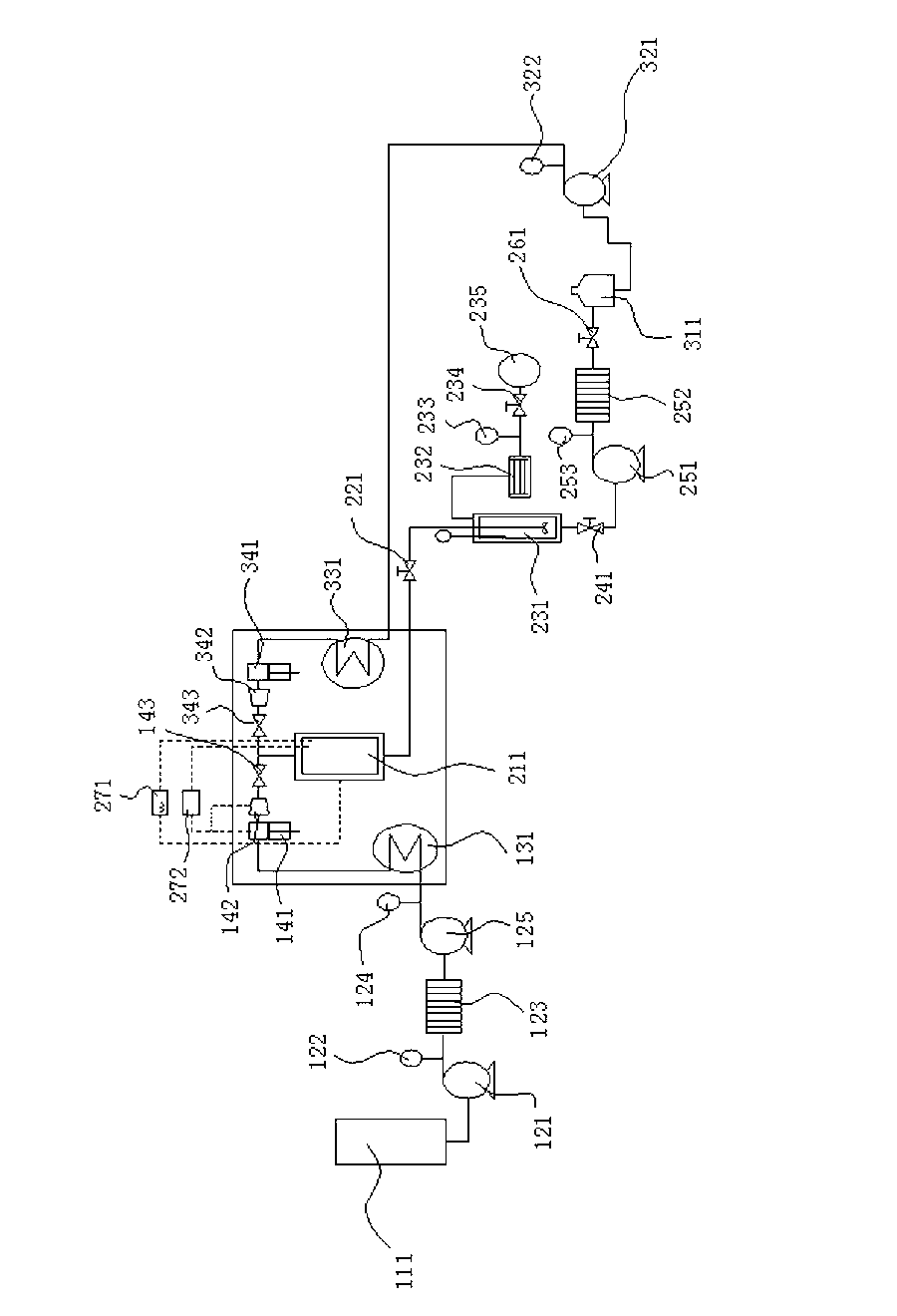

[0020] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0021] Such as figure 1 Shown, a kind of continuous type subcritical reaction device that is used for ethyl ester fish oil hydrolysis, comprises water storage tank 111, has the reaction chamber 211 of water inlet and water outlet and has the liquid storage tank 311 of liquid outlet, water storage tank 111 Between the water inlet of the reaction chamber 211, there are liquid filling pump one 121, preheater one 131, reciprocating booster pump one 141, supercharger one 142 and check valve one 143 connected sequentially through pipelines, and the liquid storage tank 311 and The water outlets of the reaction chamber 211 are connected with a screw valve 1 221 , a condensation evaporation tank 231 , a screw valve 2 241 , a fillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com